10 11

Getting Started 3

Before putting the machine

into operation

Correctly using the device

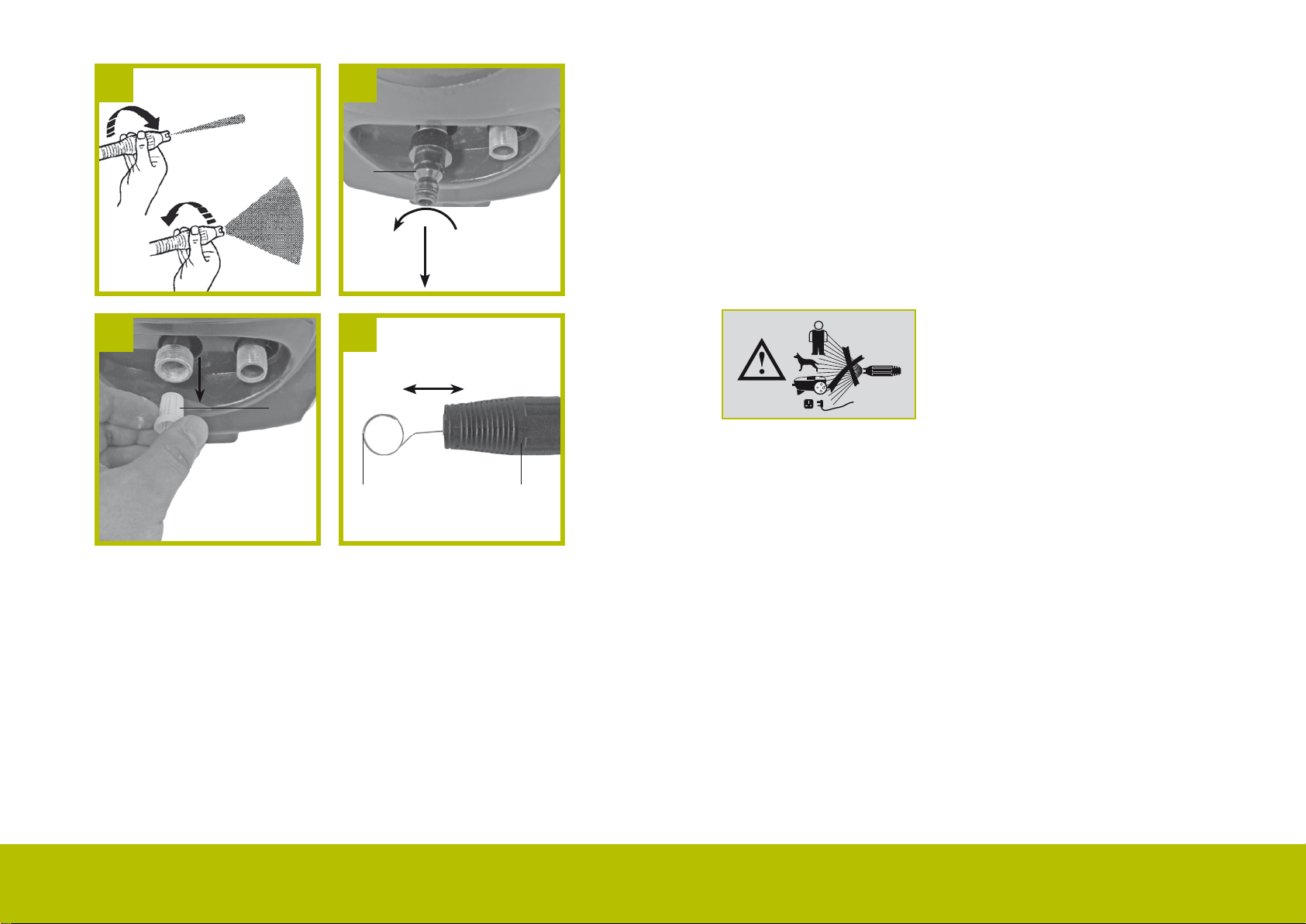

• Thehigh-pressurecleanermustbesetonalevel,stablesurface.

• Itisrecommendedthatyoumaintainthecorrectoperating

position every time you use the machine by placing one hand

on the pistol and the other on the lance.

• Neverdirectthewaterjettowardelectricallinesorthe

machine itself.

• Itisnormalforthepumptoleakalittle;thisisnecessary

to avoid damage to the pump when it is at a standstill.

• Neverusetheequipmentinpotentiallyexplosiveareasunder

any circumstances!

• Theoperatingtemperaturemustbebetween+5and+60°C.

• Donotcoverormodifythelanceorthespraynozzlesinanyway.

• Thehigh-pressurecleanerisdesignedtobeusedwithcold

orlukewarmwater(max.60°C);highertemperaturescan

damage the pump.

• Donotusewaterthatisdirty,grittyorcontainsanychemical

products, as these could impair operation and shorten the life

of the equipment.

• Whenusingthepressurewasher,werecommendyouwear

safety goggles to guard your eyes from flying debris/water spray.

Operation

The equipment consists of an assembly with a pump, which is

encased in a shock absorbing housing. The equipment comes with

a lance and a non-slip gun (for an optimal working position), whose

shape and configuration comply with the applicable regulations.

Using for the first time

Once you have completely assembled the high-pressure cleaner

and connected all connections, proceed as follows:

Turn on the water inlet supply. Press safety pin “a” (Fig. 2) on the

spray gun and pull back trigger lever “b” (Fig. 2) in order to bleed

the trapped air out of the device.

Turn on the device by switching the ON/OFF switch (Fig. 1/12) to “I”.

To temporarily turn o, release the trigger lever (b), at which point

the device goes to standby. As soon as you press the trigger lever

again (b), the high-pressure cleaner restarts.

To completely turn o the high-pressure cleaner, switch the ON/OFF

switch (Fig. 1/12) to “0”.

Using cleaning agent (Fig. 2;7)

Unscrew and remove the foam nozzle (7) from the cleaning agent

tank (15) (Fig. 7). Fill a suitable cleaning agent into the cleaning

agent tank (15) and replace the foam nozzle (7). Fit the foam nozzle

(7) to the pistol (14) as shown in Fig. 2. The cleaning agent will be

added automatically.

Holder for the gun/accessories (Fig. 1;8)

The gun and accessories can be kept in the provided holder

(10) (Fig. 8) in order to save space when not in use.

Instructions 4

Helpline No. UK/Northern Ireland 0151 649 1500 Rep. Ireland 1890 946244

Web Support www.einhell-uk.co.uk

Model Number: 7944

Helpline No. UK/Northern Ireland 0151 649 1500 Rep. Ireland 1890 946244

Web Support www.einhell-uk.co.uk

Model Number: 7944