Rotary Pellet Stove Cleaning System

Operating Instructions

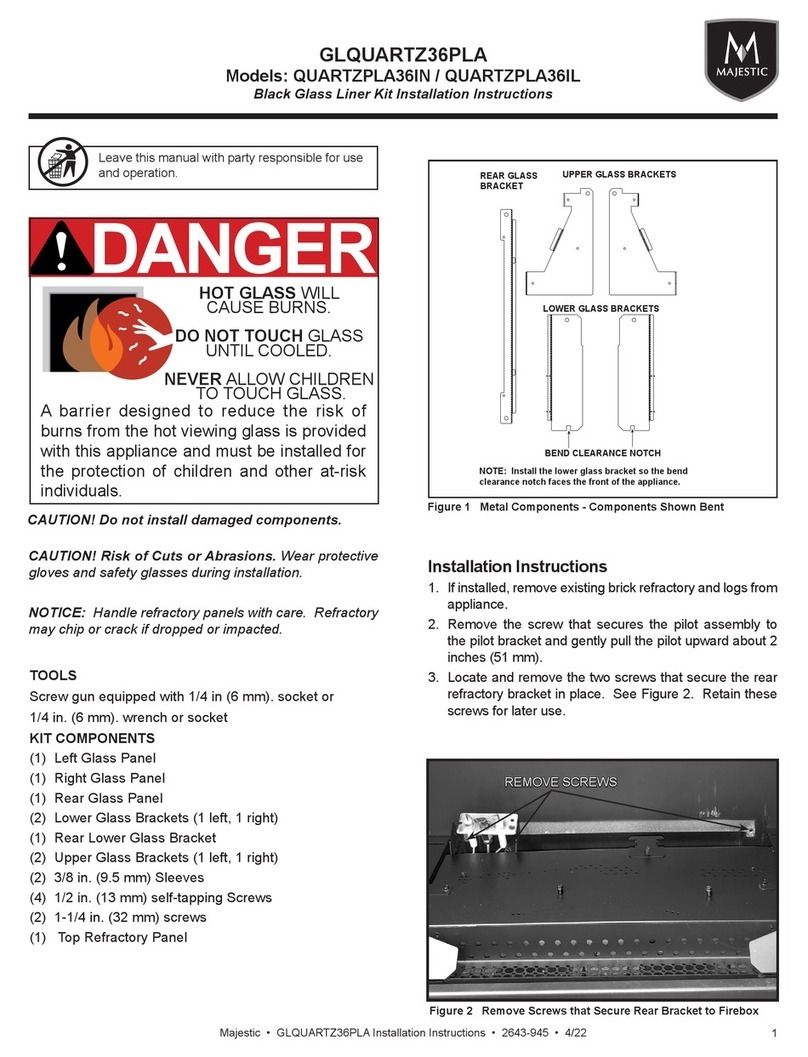

Recommended Drill:

Any cordless drill with a 3/8” or

1/2” chuck with an adjustable

clutch will work.

Setting the Clutch on your

cordless drill:

a. Adjust clutch to a setting in

the middle of the range or

slightly lower.

b. You should be able to hold

the properly adjusted

chuck with your hand &

prevent it from spinning yet

there should be a fair

amount of torque.

Turn to adjust clutch

Set on middle setting or lower

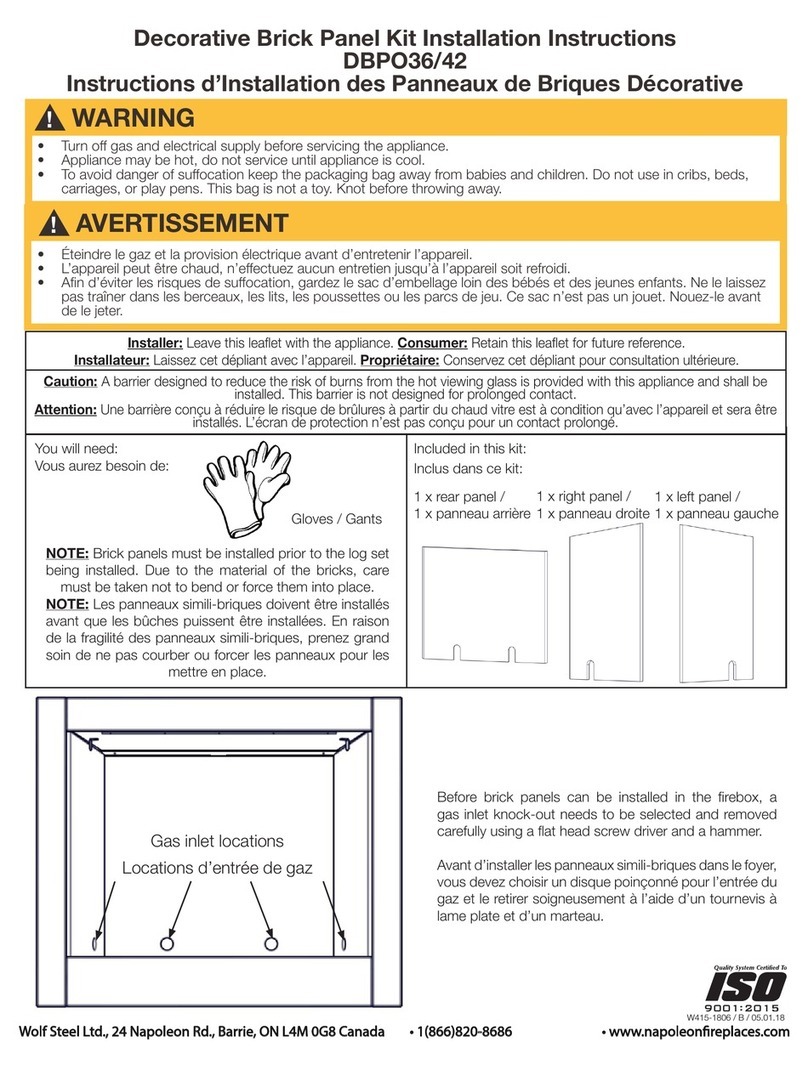

Connecting the rods

1.) To connect the rods, simply

screw them together and

tighten with two pairs of

pliers.

Use a small piece of duct tape

around the joint of the fittings

after tightening.

This will reduce the risk of

the rods unscrewing if you

accidentally reverse the drill.

Important Note: Always spin the

drill in the Clockwise

Direction as the rods may

come apart even if tightened

with pliers.

Operating Instructions

4

Recommended Drill:

Any cordless drill with a 3/8” or

1/2” chuck with an adjustable

clutch will work.

Setting the Clutch on your

cordless drill:

a. Adjust clutch to a setting in

the middle of the range or

slightly lower.

b. You should be able to hold

the properly adjusted

chuck with your hand &

prevent it from spinning yet

there should be a fair

amount of torque.

Turn to adjust clutch

Set on middle setting or lower

Connecting the rods

1.) To connect the rods, simply

screw them together and

tighten with two pairs of

pliers.

Use a small piece of duct tape

around the joint of the fittings

after tightening.

This will reduce the risk of

the rods unscrewing if you

accidentally reverse the drill.

Important Note: Always spin the

drill in the Clockwise

Direction as the rods may

come apart even if tightened

with pliers.

Operating Instructions

4

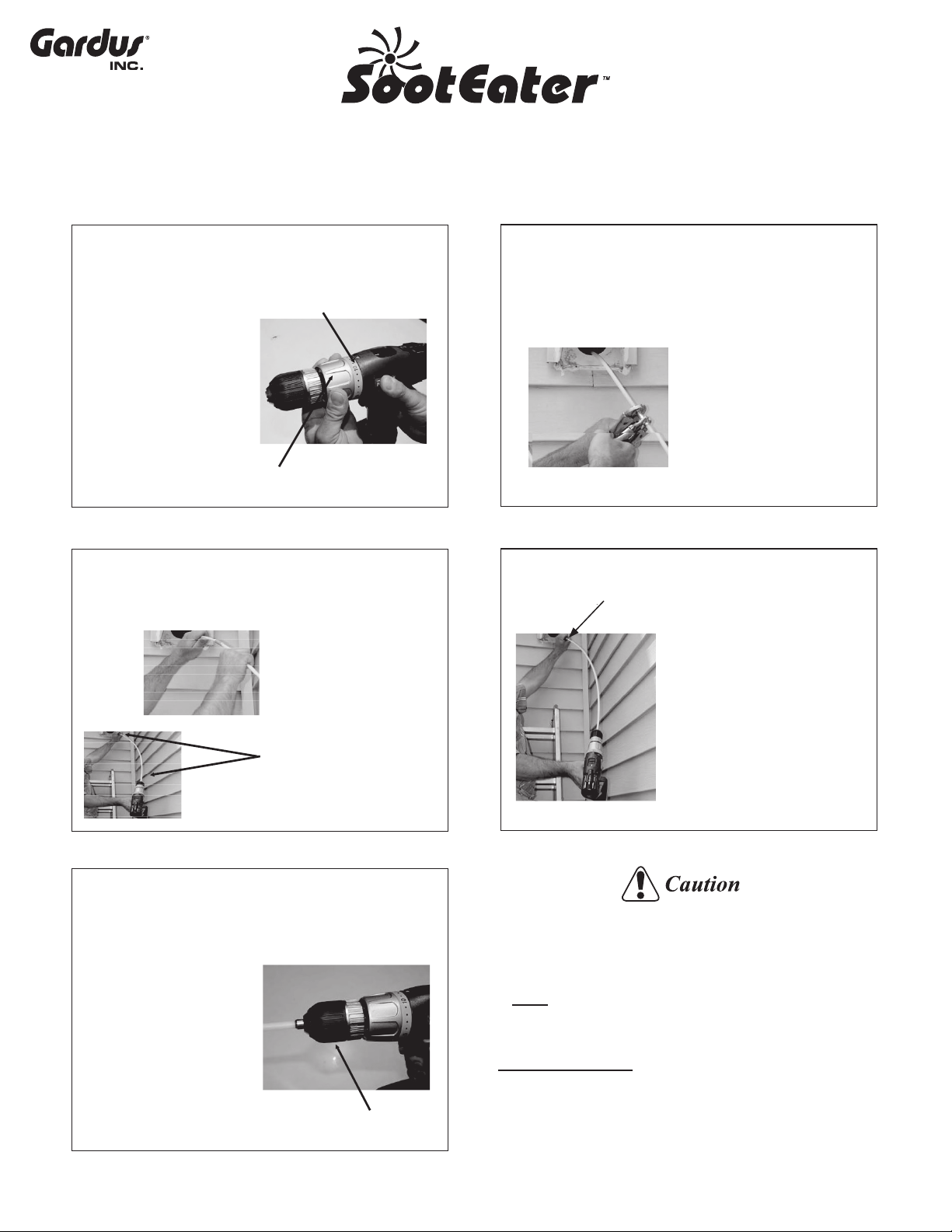

Optional method for connecting rods

2.) This method requires a

great deal of caution but

will speed up the

cleaning process.

a. Start the threads by

hand to insure that they

are not cross-threaded.

b. Insert the other end of

the rod into the drill

chuck.

c. Spin the rods clockwise

while holding the rod

you are connecting to.

Methods for disconnecting the rods

1) Use two pairs of pliers to

loosen & then unscrew

the rods by hand.

2) You can disconnect each

rod using the drill as well.

a. Hold the end of the rod,

which is inside the vent,

very tightly.

b. Reverse the drill while

holding the rod end to

unscrew the rod which is

connected to the drill.

Important Note: be sure that

the rods that are still in the

vent do not spin as this will

cause them to disconnect

inside the vent.

Hold end of rod very tightly by

hand or with pliers

5

Optional method for connecting rods

2.) This method requires a

great deal of caution but

will speed up the

cleaning process.

a. Start the threads by

hand to insure that they

are not cross-threaded.

b. Insert the other end of

the rod into the drill

chuck.

c. Spin the rods clockwise

while holding the rod

you are connecting to.

Methods for disconnecting the rods

1) Use two pairs of pliers to

loosen & then unscrew

the rods by hand.

2) You can disconnect each

rod using the drill as well.

a. Hold the end of the rod,

which is inside the vent,

very tightly.

b. Reverse the drill while

holding the rod end to

unscrew the rod which is

connected to the drill.

Important Note: be sure that

the rods that are still in the

vent do not spin as this will

cause them to disconnect

inside the vent.

Hold end of rod very tightly by

hand or with pliers

5

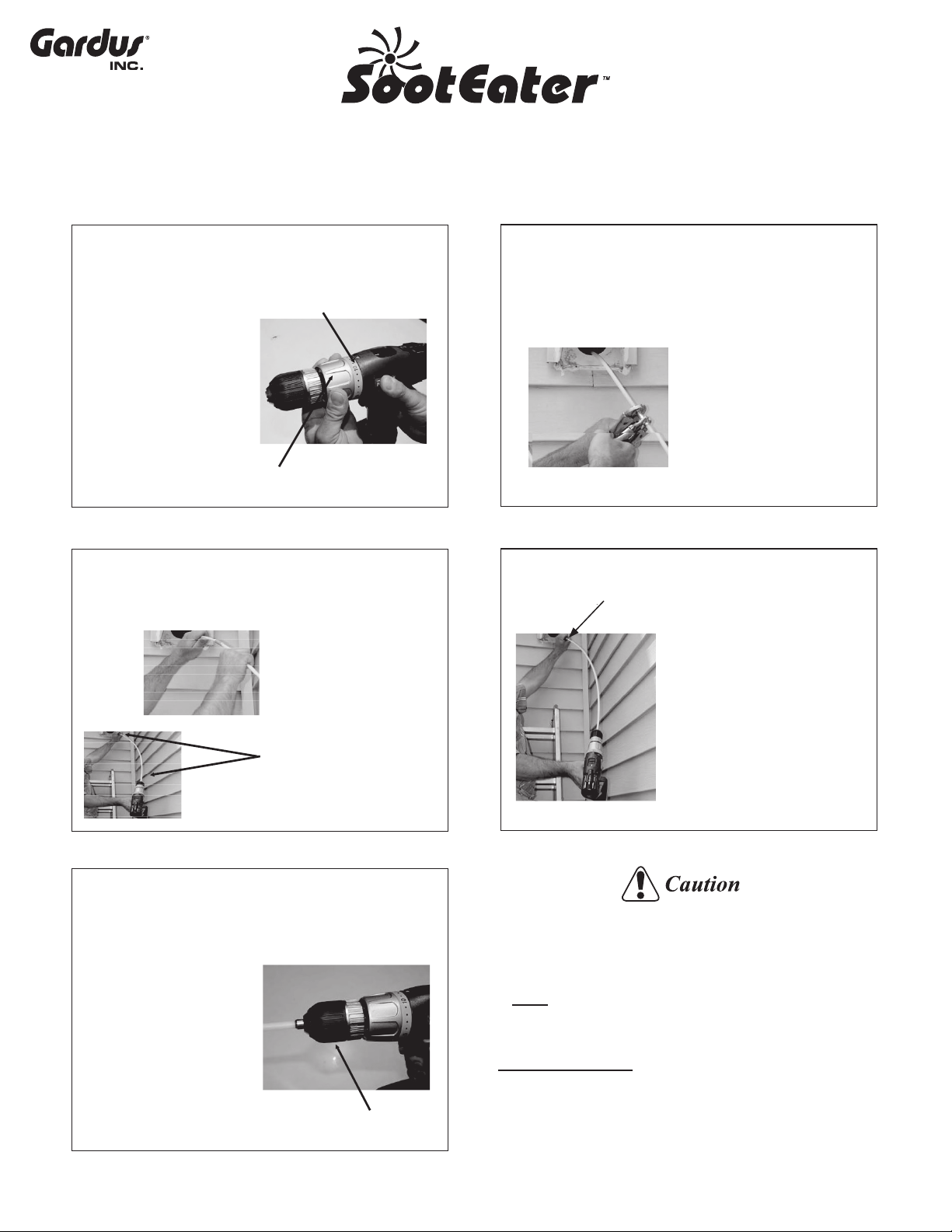

Inserting the rod into

the drill chuck:

a. The fittings on the

rods are designed to

fit into any type of

drill without an

adapter.

b. Simply insert the

steel rod fitting into

the chuck of the drill

and tighten by hand. Twist chuck to tighten

Attaching the Lint Trap

Brush to the FlexRod:

Screw the Lint Trap Brush

onto the rod by hand then

tighten with two pairs of

pliers.

Important Notes:

Only use this brush by hand.

“Do Not Use the Drill to Spin.”

While cleaning with the brush by

hand, rotate the rod clockwise

to ensure that the brush does

not loosen.

6

• Always rotate the rods in the clockwise direction when spin-

ning the rods into the vent & coming back out of the vent.

• Failure to do so will cause the rods to un-screw and disconnect.

• Never force the rods or over-torque the rods with the drill.

Doing this may result in property damage, rod breakage or

personal injury.

To avoid rod breakage

1. Only use a drill with an adjustable clutch. (a cordless drill is

recommended)

2. Keep clutch setting on drill at halfway or lower when rotating

the rods.