Garmin Force User manual

FORCE®KRAKEN TROLLING MOTOR LIVESCOPE™BRACKET

INSTALLATION INSTRUCTIONS

Important Safety Information

WARNING

See the Important Safety and Product Information guide in the product box for product warnings and other

important information.

Always disconnect the trolling motor from the battery before performing any service.

You are responsible for the safe and prudent operation of your vessel. Sonar is a tool that enhances your

awareness of the water beneath your boat. It does not relieve you of the responsibility of observing the water

around your boat as you navigate.

CAUTION

Failure to install and maintain this equipment in accordance with these instructions could result in injury,

damage to the product and/or vessel, or poor product performance.

Read all installation instructions before proceeding with the installation. If you experience difficulty during the

installation, go to support.garmin.com for more information.

Tools Needed

• #2 Phillips screwdriver

• 2.5 mm allen wrench (included)

• 5 mm allen wrench (included)

• 6 mm allen wrench (included)

• Diagonal pliers

• Electrical tape

• Zip ties

• Grommet wrench (included)

• Marine grease (included)

• Torque wrench

GUID-9EAA0430-70F9-4795-82EB-AB34895E5623 v1September 2023

Mounting Considerations

NOTICE

To avoid possible damage to the trolling motor and transducer, and to ensure proper functionality, you must use

only the hardware included in this kit. The included bolts may not be the same as bolts that came with your

LiveScope transducer, and using the incorrect bolts may result in product damage and failure.

• You should mount the LiveScope transducer where it will not interfere while stowing the trolling motor.

• You may mount your LiveScope transducer on either the starboard side or the port side of your trolling motor

shaft.

• Once the LiveScope transducer is mounted, the motor can only stow in one direction. Choose which side you

want the propeller to face when stowed, because it cannot be changed after installation.

NOTE: You may need to adjust the trolling motor stow side. See the Force Kraken Trolling Motor Owner's

Manual for instructions.

• After installation, you can set the LiveScope transducer to the preferred viewing mode.

• Firmly tighten all LiveScope transducer bracket adjustment knobs before each use.

Refer to the LiveScope transducer instructions for more information about connecting, mounting and securing

the LiveScope transducer cable after installation.

Installing the Transducer on a Trolling Motor

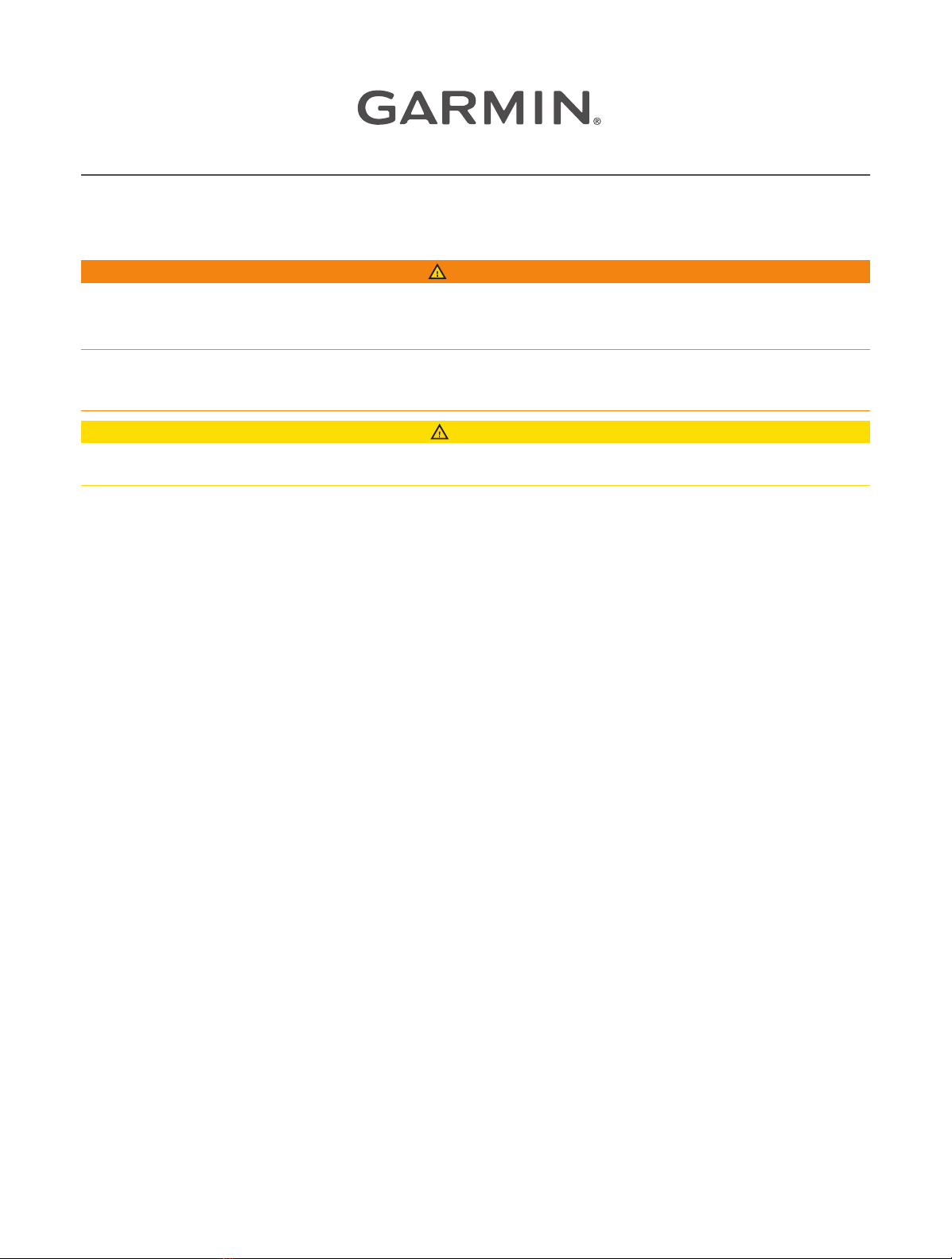

Opening the Shaft Cap

WARNING

Before you open the shaft cap, you must disconnect the motor from the power source. Failure to disconnect the

power source can lead to electrical shock or damage to the motor.

1Using a #2 Phillips screwdriver, remove the four screws that secure the lid of the shaft cap.

You should place these screws in a safe place, because you must use them to close the shaft cap.

2Carefully lift up the lid of the shaft cap to access the cable connectors inside.

NOTICE

There are two cables connected to the top of the shaft cap. Take care when opening the shaft cap to avoid

damaging the cables or connectors.

2

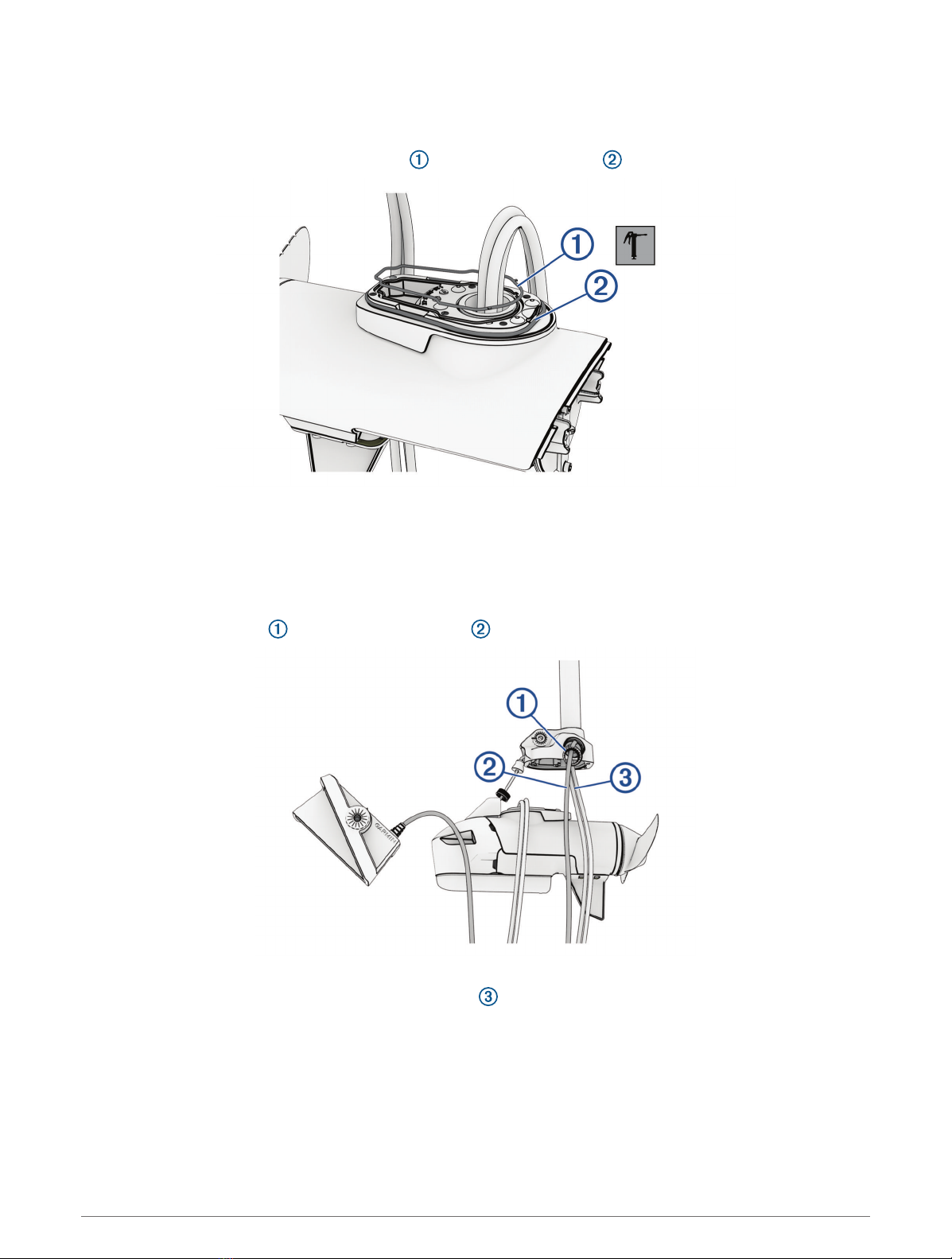

Disconnecting the Cables in the Shaft Cap

Before you can disconnect the cables in the shaft cap, you must open the shaft cap (Opening the Shaft Cap,

page2).

1Unscrew and disconnect the USB connector .

Ensure the o-ring remains in place inside the connector.

2Release the latch and pull the connectors apart to disconnect the data cable.

3If present, unscrew and disconnect the transducer cable , and cut off the locking ring.

4Cut the zip ties .

5Slide down the protective coverings on the power cables.

6Using a 2.5 mm allen wrench, remove the four set screws on the two power cables.

7Disconnect the power cables.

8Remove the protective coverings from the power cables.

3

Removing the Propeller Drive Motor

1Using a 5mm hex bit or wrench, remove the six screws that secure the shaft base to the propeller drive

motor.

You should dispose of these six screws. New screws, washers, and O-rings are provided in the kit.

2If your trolling motor has a transducer installed, using the tool included in the kit, remove the recessed nut

that secures the transducer cable to the shaft.

4

3Straighten the cables at the top of the shaft, and slowly pull the propeller drive motor away from the shaft

base until you can see the power and data cables connected to the propeller drive motor.

4Holding the cables only, slowly pull them through the shaft, taking care that the connectors do not get caught

on the top of the shaft.

NOTICE

When removing the propeller drive motor from the shaft, you must pull the cables themselves, and not the

motor. Pulling on the propeller drive motor may damage the cable connections inside the motor. The motor

should not be supported by the cables alone. Supporting the motor only with the cables may damage the motor.

The power cables and transducer cable (if present) should pull through the shaft completely.

Removing the Cable Grommets

1Using the tool included in the kit, remove the recessed grommet nuts from both sides.

2Push out the grommets from the inside of the downshaft adapter.

5

Replacing the Motor Gaskets

Before you can replace the motor gaskets, you must remove the propellor drive motor and pull all cables

completely through the shaft.

1Remove and discard the blue motor gasket and black motor gasket .

2Using the grease packet included in the kit, apply grease to the new blue and black motor gaskets included in

the kit and install them in place of the gaskets you removed.

Feeding the Cables Through the Shaft

1Using diagonal pliers, carefully cut off the locking ring from the connector at the end of the LiveScope

transducer cable.

2Place the grommet nut over the LiveScope cable with the threaded side facing the downshaft adapter.

3Feed the LiveScope cable a few feet into the shaft through the side hole of the downshaft adapter.

4Bundle the power and any existing transducer cables , and feed them completely through the shaft with

the LiveScope cable.

NOTE: You should leave approximately 15 to 20 cm (6 to 8in.) of LiveScope cable between the downshaft

adapter and transducer to allow for repositioning and changing modes after installation.

6

Installing the LiveScope Cable Grommet

1Apply a thin film of the included marine grease to the LiveScope cable grommet and along the section of

the LiveScope cable that feeds through the grommet.

2Place the grommet over the LiveScope cable and slide it into the downshaft adapter .

3Using the included grommet nut wrench, tighten the grommet nut .

Installing the Propeller Drive Motor

Before you can install the propeller drive motor in the shaft, you must route the LiveScope transducer cable

through the shaft (Feeding the Cables Through the Shaft, page6).

1Using canned compressed air or an air compressor, blow out any dirt or debris in the six threaded holes on

the top of the propeller drive motor.

2Gently pull the ends of the power cables as you feed them the rest of the way through the shaft.

NOTICE

When feeding the cables, you must pull on the cable and not on the cable connectors.

3Prepare the six bolts in the kit by placing a washer and a 4.75mm (3/16in.) O-ring on each one.

NOTE: There are three different bolt lengths. Make sure the bolts are in the positions shown in the illustration

before tightening.

4Using the grease packet included in the kit, apply grease to the 4.75mm (3/16in.) O-ring on each bolt.

Avoid getting grease on the bolt threads.

7

5Apply a medium-strength thread-locking compound (not included) such as LOCTITE® 243™ to the threads in

the six threaded holes on the top of the propeller drive motor.

NOTICE

You must apply thread-locking compound in these holes to maintain a tight connection between the shaft base

and the propeller drive motor. Failure to use thread-locking compound can lead to water ingress and damage to

the motor.

6Using a 5mm hex bit or wrench, thread all six of the prepared bolts approximately halfway to make sure that

the shaft base and the propeller drive motor are properly aligned and the gasket is in place.

7With the shaft base and the propeller drive motor properly aligned, lightly tighten all six bolts by hand.

8Using a torque wrench, tighten all six bolts to 4N-m (35lbf-in).

Installing the Grommets

1Using the grease packet included in the kit, apply a thin film grease to the grommets and the section of the

transducer cable that feeds through the cable grommet .

2Place the cable grommet over the transducer cable and slide it into the downshaft adapter .

3Slide the solid grommet into the downshaft adapter.

4Using the included grommet nut wrench , tighten the grommet nuts .

8

Adapter Kit Overview

Item Name Description

Transducer bracket Holds the LVS32, LVS34, or LVS62 transducer (sold separately) on the

trolling motor

Mounting puck Provides a mounting location for the transducer bracket.

M8 socket head cap screw

and washer Secures the mounting puck to the motor

LVS34/LVS62 adapter disc Smaller disc profile with wider ridged section

LVS32 adapter disc Thicker disc profile with narrow ridged section

Bracket attachment knob Large knob with short threaded section that secures the transducer

bracket to the mounting puck

LVS32 attachment knob Small knob with short threaded section that secures an LVS32 trans

ducer to the transducer bracket

LVS34 attachment knob Medium knob with medium threaded section that secures an LVS34

transducer to the transducer bracket

LVS 62 attachment knob Large knob with long threaded section that secures an LVS62 trans

ducer to the transducer bracket

9

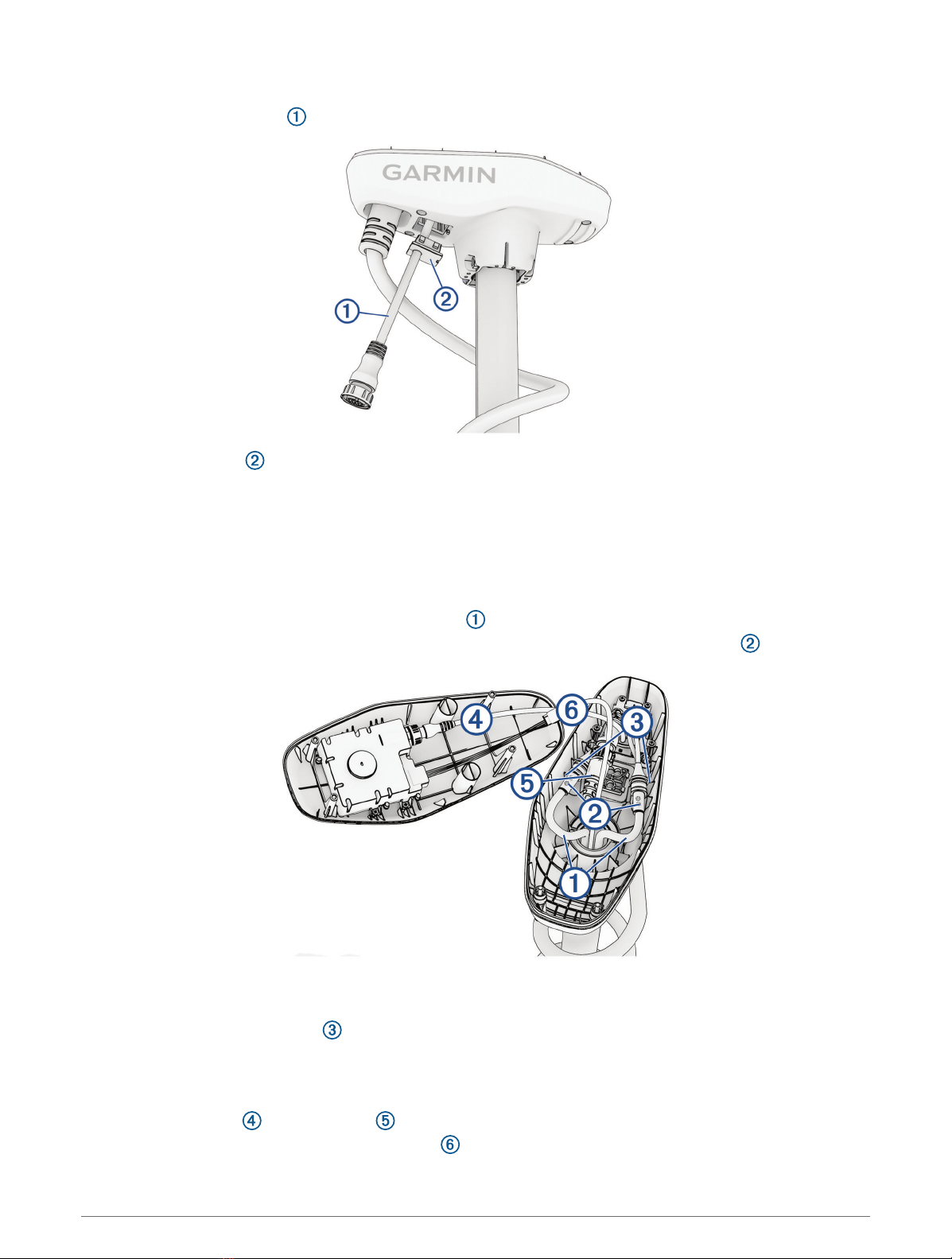

Attaching the LiveScope Mounting Puck

1Align the prominent tooth on the mounting puck with the recess on the downshaft adapter .

2Fasten the mounting puck to the downshaft adapter using the included hex head screw and washer .

3Using a torque wrench, tighten the hex head screw to 7 N-m (62 lbf-in).

10

Assembling the LiveScope Mounting Bracket and Transducer

1Using the large knob with a short threaded section , attach the short side of the bracket to the

LiveScope mounting puck .

2Select an action:

• For LVS34 and LVS62 transducers, peel the backing off of the smaller transducer disc , align the pins

with the pinholes on the mounting bracket, and press the sticky side on the outside of the mounting

bracket.

• For an LVS32 transducer, peel the backing off of the thicker transducer disc , align the pins with the

pinholes on the mounting bracket, and press the sticky side on the outside of the mounting bracket.

3Select an action:

• For an LVS32 transducer, use the small knob to attach the transducer to the bracket.

• For an LVS34 transducer, use the medium knob with a medium threaded section to attach the

transducer to the bracket.

• For an LVS62 transducer, use the large knob with a long threaded section to attach the transducer

to the bracket.

11

Installing the LiveScope Cable in the Shaft Cap

1Feed the LiveScope cable completely through the square hole in the shaft cap.

2Install the grommet on the LiveScope cable.

The grommet is split on one side to make it easy to install on the cable.

3Push from the outside to secure the square grommet in the shaft cap.

4Route the LiveScope cable alongside the coil cable, using electrical tape to hold the cables together.

5Route the LiveScope cable to the chartplotter and connect it.

Connecting the Cables in the Shaft Cap

1Place the protective coverings on the power cables .

2Reconnect the power cables and, using a 2.5 mm hex bit or wrench, tighten the set screws .

3Slide the protective coverings over the power cable connections.

4Secure the power cables to the shaft cap using zip ties at the locations you removed them when

disconnecting the power wires .

5Install the included split collar on the LiveScope transducer cable (Installing Locking Rings on the Cables,

page13).

6If present, install the included split collar on the GT56 transducer cable.

7Reconnect the USB and transducer cable (if present), and tighten the collars.

8Align both sections of the data cable connector and press together to connect them.

12

Installing Locking Rings on the Cables

Before you install locking rings on the cables, you must route the cables through the shaft and into the shaft

cap.

To make the cable-routing process possible, you removed the locking rings from the transducer cables

previously during the LiveScope transducer bracket installation process. Replacement locking rings are provided

for the LiveScope transducer cable and the GT56 transducer cable (if equipped).

1Separate the two halves of the locking ring .

2Align the two halves of the locking ring over the cable and snap them together.

3Insert the o-ring into the end of the connector.

Closing the Shaft Cap

Before you can close the shaft cap, you must connect the cables inside the shaft cap (Connecting the Cables in

the Shaft Cap, page12).

1Place the lid on the shaft cap.

2Using a #2 Phillips screwdriver, install the four screws to secure the lid of the shaft cap.

© 2023 Garmin Ltd. or its subsidiaries

Garmin®, the Garmin logo, Force®, and LiveScope™ are trademarks of Garmin Ltd. or its subsidiaries, registered in the USA and other countries. These trademarks may not

be used without the express permission of Garmin.

LOCTITE® is a trademark of Henkel Corporation in the U.S. and elsewhere.

13

© 2023 Garmin Ltd. or its subsidiaries support.garmin.com

Other manuals for Force

7

Table of contents

Other Garmin Outboard Motor manuals