Garmin GMA 340 User manual

GMA

340

AUDIO PANEL

JUIAINTENANCE MANUAL

Garmin International

1200

E.

151"

Street

Olathe,

KS

66062

USA

1

90-00

1

49-02

(Rev

B)

June

2001

3

The document reference is online, please check the correspondence between the online documentation and the printed version.

0

Copyright

1998-2001

GAMIN

Corporation

All

Rights Reserved

REVISION

REVISION

DATE

A 1/4/99

B

61710

1

Except

as

expressly provided herein, no part ofthis manual may be reproduced, copied, transmitted, disseminated, downloaded or

stored in any storage medium, for any purpose without the express prior written consent of GARMIN Corporation. GARMIN

Corporation hereby grants permission to download a single copy of this manual and of any revision to this manual onto

a

hard

drive or other electronic storage medium to be viewed and to print one copy of this manual or of any revision hereto, provided that

such electronic or printed copy of this manual or revision must contain the complete text of this copyright notice and provided

hrtherthat any unauthorized commercial distribution ofthis manual or any revision hereto is strictly prohibited.

DESCRIPTION

ECO

#

-

Initial

Release

Add 340 Dual

ADF

and field

replacement

of

main

board.

15949

GARMIN

International,

Inc.

1200

E.

15lStStreet

Olathe,

KS

66062

USA

Telephone: 913-397-8200,Dealer

Line:

1-800-800-1420

Web SiteAddress:

www.mrmin.com

INFORMATION

SUBJECT

TO

EXPORT

CONTROL

LAWS

This document may contain information which is subject to the Export Administration Regulations ("EAR") issued by the United

States Department of Commerce

(1

5

CFR, Chapter VII, Subchapter C) and which may not be exported, released, or disclosedto

foreign nationals inside or outside of the United States without first obtaining an export license. A violation of the EAR may be

subject to

a

penalty of up to

10

years imprisonment and

a

fine ofup to

$1,000,000

under Section

2410

of the Export

Administration Act of

1979.

Include this notice with any reproduced portion ofthis document.

190-00

149-02Rev

B

The document reference is online, please check the correspondence between the online documentation and the printed version.

TABLE

OF

CONTENTS

SECTION

1

DESCFUPTIONAND OPERATION

PARAGRAPH PAGE

1.1 INTRODUCTION

.............................................................................................................................

1-1

1.2 GENERAL DESCRIPTION

..............................................................................................................

1-1

1.3 THEORY

OF

OPERATION

.............................................................................................................

1-2

SECTION

2

SPECIAL TESTEQUIPMENT

2.1 INTRODUCTION

.............................................................................................................................

2-1

2.2 GMA 340 REAR CONNECTORS

....................................................................................................

2-1

2.3 GMA 340 TEST PANEL

..................................................................................................................

2-1

2.4 TEST HARNESS.

J

1

AND 52 PIN ASSIGNMENTS

......................................................................

2-4

SECTION

3

TROUBLESHOOTING

3.1 TROUBLESHOOTING

....................................................................................................................

3-1

3.2 TROUBLESHOOTING PROCEDURES

..........................................................................................

3-1

3.3 POWER ON CHECK

........................................................................................................................

3-5

3.4 28

V

LIGHTING

...............................................................................................................................

3-5

3.5 14

V

LIGHTING

...............................................................................................................................

3-5

3.6 PTT ANNUCIATOR CHECK

..........................................................................................................

3-5

SECTION

4

DISASSEMBLY AND REASSEMBLY

4.1 INTRODUCTION

.............................................................................................................................

4-1

4.2 TOOLS REQUIRED

.........................................................................................................................

4-1

4.3 DISASSEMBLING THE UNIT

........................................................................................................

4-1

4.4 REASSEMBLY

.................................................................................................................................

4-3

190-00

149-02

Rev

B

I

The document reference is online, please check the correspondence between the online documentation and the printed version.

SECTION

5

TESTING

5.1 GENERAL

.........................................................................................................................................

5-1

5.2 ADJUSTMENT/MEASUREMENT ACCURACY

..........................................................................

5-1

5.3

5.4

5.5

5.6 TEST PANEL

....................................................................................................................................

5-2

5.7 BENCH TESTING

............................................................................................................................

5-2

5.8 TEST EQUIPMENT SETUP

............................................................................................................

5-2

5.9 STANDARD TEST SIGNALS

.........................................................................................................

5-5

5.10 POWER OFF CHECK

......................................................................................................................

5-6

5.1

1

POWER ON CHECK

........................................................................................................................

5-6

5.12 LOADED MICROPHONE VOLTAGE INPUTS

.............................................................................

5-7

5.13 PILOT PTT TESTS

...........................................................................................................................

5-7

5.14 FUNCTIONAL TEST

.......................................................................................................................

5-8

TEST EQUIPMENT PRECAUTIONS

.............................................................................................

5-1

REQUIRED TEST EQUIPMENT

....................................................................................................

5-2

REAR CONNECTORS PRECAUTION

...........................................................................................

5-1

SECTION

6

REPLACEABLEASSEMBLIES

6.1 LIST

OF

REPLACEABLE PARTS

..................................................................................................

6-1

SECTION

7

ASSEMBLY DRAWINGS

7.1 ASSEMBLY DRAWINGS

...............................................................................................................

7-1

11

190-001

49-02

Rev

B

The document reference is online, please check the correspondence between the online documentation and the printed version.

LIST OF FIGURES

FIGURE PAGE

2-1 GMA 340 Rear Connectors (Viewed from the Rear)

........................................................................

2-1

2-2 Typical Test Panel Layout

.................................................................................................................

2-3

2-3 Test Panel Schematic Diagram

..........................................................................................................

2-6

2-4 Coax Cable Assembly

.....................................................................................................................

2-10

3-1 Front Panel Connector Detail

............................................................................................................

3-2

3-2

3-3

5-1

GMA 340 Test Connections

..............................................................................................................

5-3

7-1 GMA 340 Front Panel Assembly

......................................................................................................

7-1

7-2 Marker Lamp Rack Assembly. Front and Rear Detail

......................................................................

7-1

7-3 GMA 340 Final Assembly

.................................................................................................................

7-2

Main Board Component Location. Partial Layout

............................................................................

3-3

Power Input Board

.............................................................................................................................

3-4

LIST

OF

TABLES

Table PAGE

2.1

.

Test Panel Parts List

..........................................................................................................................

2-2

2.2

.

J1

and 52 Pin Assignments

................................................................................................................

2-5

3.1. Front Panel Connector Detail

............................................................................................................

3-2

3-2 Main Board Connector Detail

...........................................................................................................

3-3

3.3. Power Input Board Connector Detail

................................................................................................

3-4

Field Replaceable Parts List

..............................................................................................................

6-1

6-1

...

190-00149-02

Rev

B

111

The document reference is online, please check the correspondence between the online documentation and the printed version.

This page intentionally left blank.

iv

190-001

49-02

Rev

B

The document reference is online, please check the correspondence between the online documentation and the printed version.

SECTION

1

DESCRIPTION AND OPERATION

1.1

INTRODUCTION

This manual provides functional testing and assembly-levelrepair information for the GARMIN GMA 340,

GMA 340H and GMA 340 Dual ADF Audio Panels. Reference to GMA 340 throughout this manual refers to all

versions of the unit. Information pertaining to the installation and operating instructions can be found in the

GMA 340 Audio Panel Installation Manual, 190-00149-0

1.

This manual is designed to aid the bench technician

in isolating failures

co

the assembly level only. If necessary, the GMA 340 can be returned to GARMIN for all

service work, including maintenance and repair. Contact GARMIN at the following address for more details:

GARMIN

1200

E.

151st

Street

Olathe,

KS

66062

1-913-397-8200 or 1-800-800-1020

1.2

GENERALDESCRIPTION

The GARMIN GMA 340

is

a

panel mounted TSO’d audio panel that provides control of the aircraft audio

system. The GMA 340 provides flexibility in switching up to three microphone and audio transceiver

communication inputs. Audio selection ofNAV 1,NAV 2, ADF, DME and marker audio is available on the

GMA 340 and GMA 340H. In addition, selection of ADF 1and ADF 2 is provided on the GMA 340 Dual ADF.

The GMA 340 includes a voice activated (VOX) intercom system and a three-lamp marker beacon receiver and

display. One or two stereo entertainment inputs are also provided. (One on the GMA 340 Dual ADF, two on the

other units.)

The VOX intercom uses rotary knobs for volume and squelch adjustment while selection of

all

other functions is

accomplished with the use of pushbuttons.

Marker HI and LO and button annunciation is accomplished with LED devices. Front panel backlightingof

button function, squelch and volume control knobs is provided by LED’Scontrolled by the aircraft lightingbus.

On the GMA 340 and GMA 340H the split com function allows the pilot and copilot to talk on Com

1

and Com

2

simultaneously.

The unit is constructed from high quality materials and uses surfacemount components extensively. Specialized

equipment and procedures are required to repair circuit boards having surface-mounted components. GARMIN

does not authorize the repair of GMA 340 circuit boards. If necessary, circuit boards and assemblies for the

GMA 340 can be economically replaced through the GARMIN board exchange program.

The following assemblies and printed circuit boards can be field replaced:

0

Front Panel Assembly-Contains the front panel bezel, button key cap assembly, marker beacon lamp

assembly and front panel board assembly.

0

Marker Beacon Lamp Rack Assembly-Contains marker beacon incandescent lamps and lamp rack.

Fits onto the front panel assembly.

0

Flexible Circuit Cables-Connects the frontpanel to the main circuit board assembly.

190-00149-02

Rev

B

1-1

The document reference is online, please check the correspondence between the online documentation and the printed version.

Power Input Board Subassembly-Contains filtering components for the aircraft power line, panel

lighting bus and speaker ground line. Fits onto the main board assembly.

0

Main Board Subassembly-Contains the main operating circuits for the unit. Fits onto the chassisframe.

Installation Screw Shaft-Secures the unit chassis into the mounting rack.

0

1.3

THEORY

OF

OPERATION

Internallythe GMA 340 is divided into three printed circuit boards: Main Board, Front Panel Board and Power

Input Board.

1.3.1 Power Input Board Assembly

The Power Input Board Assembly accepts three power-signal inputs; aircraft power, panel lightingbus line and

the speaker ground line from the main board. The main power input, the panel lighting lines and speaker ground

line are filtered before returning to the main board.

1.3.2 Main Board Assembly

The Main Board Assembly contains the main operating circuits for the audio panel. It accepts audio inputs from

the various pilot and passenger microphones and directs them to the appropriate output. It also accepts audio

from the aircraft avionics receivers and conditions the signals for use among the various phone and speaker

outputs.

The Main Board Assembly also contains the Marker Beacon Receiver. The marker receiver accepts the

75

MHz

signal from the Marker Beacon Antenna. The receiver attenuates the signal to the desired level for either high or

low sensitivity.

The marker beacon circuit detects the 400

Hz,

1300

Hz,

and 3000 Hz marker tones. By means of audio filters,

the circuit lights the appropriate marker lamp as the signal is received.

The detected audio tones are also passed to the audio output. When marker audio

is

present, the tones are heard

on the speaker or phones.

A mute circuit quiets the audiotone when the MKWMUTE button is pressed and automatically rearms the audio

circuit for the next received marker.

1.3.3 Front Panel Board Assembly

The Front Panel Board Assembly contains the panel lighting, button annunciator

LED’S,

front panel button

switches and the marker beacon lamps.

1-2

190-00149-02

Rev

B

The document reference is online, please check the correspondence between the online documentation and the printed version.

SECTION

2

SPECIALTEST EQUIPMENT

2.1 INTRODUCTION

This section describes special test equipment required for testing the GMA 340 Audio Panel. The Test Panel and

associated cables identified in this section may be fabricated locally accordingto the diagrams and parts

information given. Standard test equipment is listed in Section

5,

TESTING. For any questions regardingthe

operation of the special test equipment listed in this section, contact the GARMIN Product Support Department

at the address or telephone number given in Section

1.

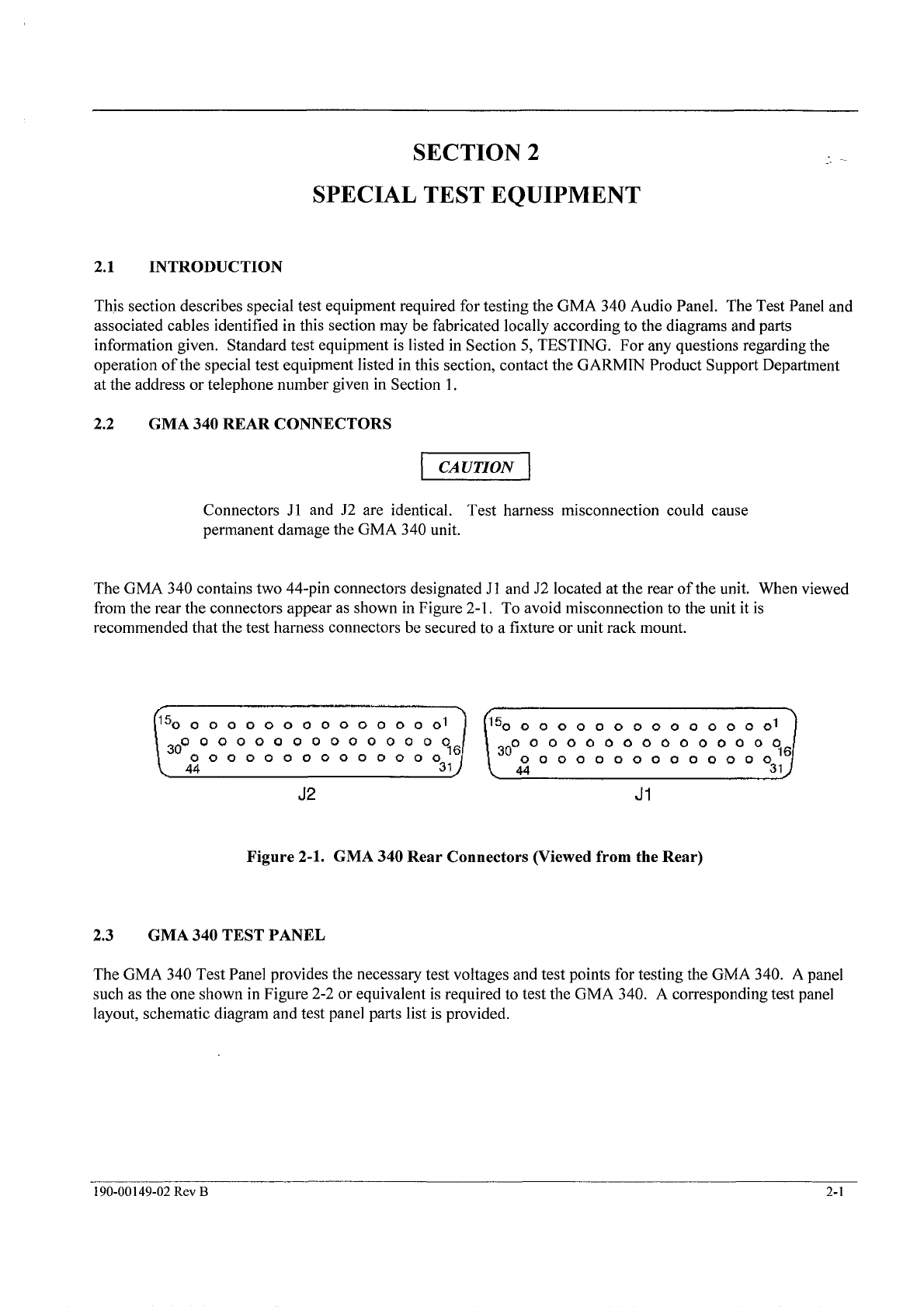

2.2 GMA340 REAR CONNECTORS

Connectors J1 and 52 are identical. Test harness misconnection could cause

permanent damage the GMA 340 unit.

The GMA 340 contains two 44-pin connectors designated J1 and 52 located at the rear of the unit. When viewed

from the rear the connectors appear as shown in Figure 2-1.

To

avoid misconnection to the unit it is

recommended that the test harness connectors be secured to a fixture or unit rack mount.

000000000000000

OOOOOOOOOOOOOO

44

44

J2

J1

Figure 2-1. GMA 340 Rear Connectors (Viewed from the Rear)

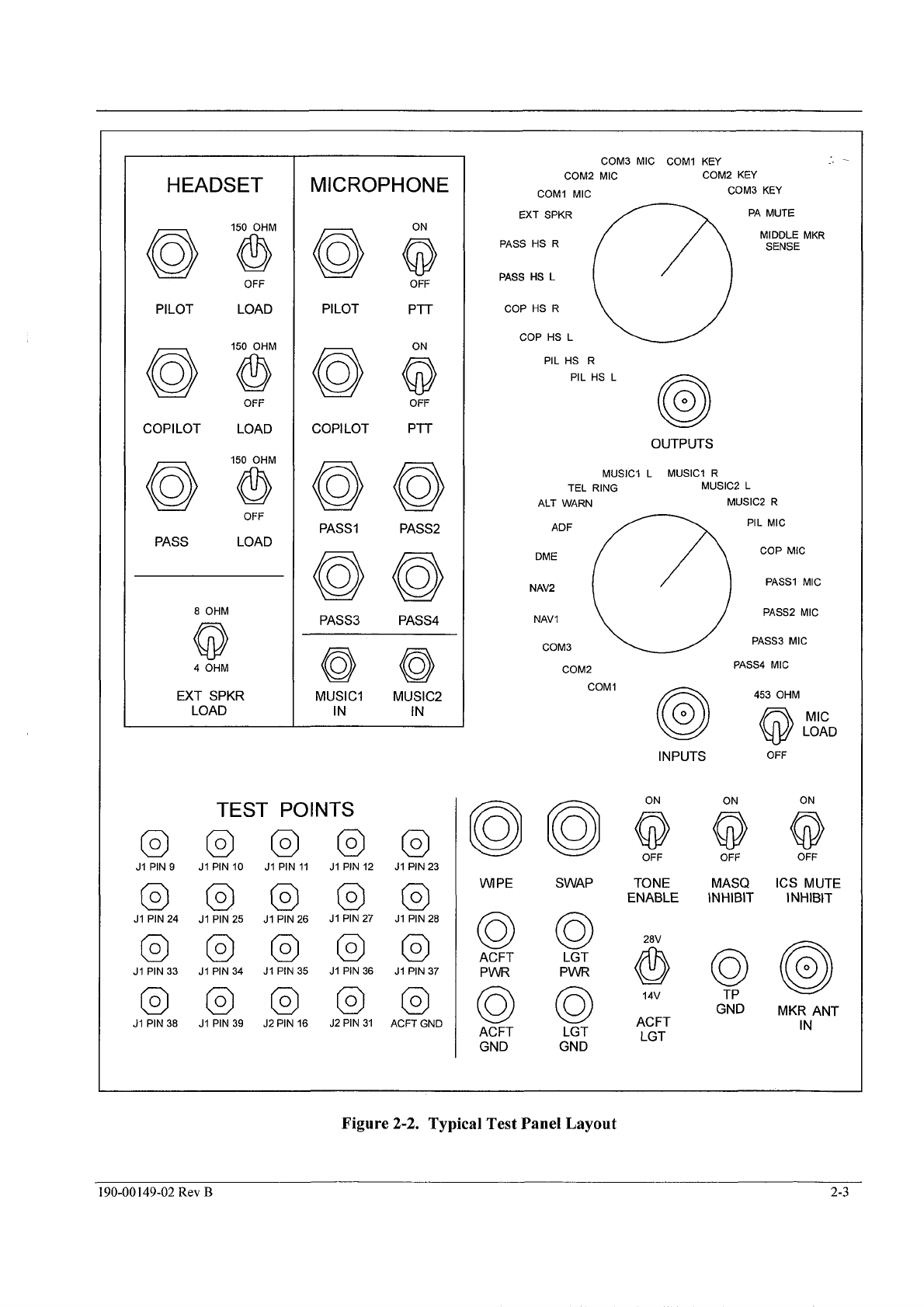

2.3 GMA340 TEST PANEL

The GMA 340 Test Panel provides the necessary test voltages and test points for testing the GMA 340. A panel

such as the one shown

in

Figure

2-2

or equivalent is required to test the GMA 340. A correspondingtest panel

layout, schematic diagram and test panel parts list is provided.

190-00149-02

Rev B

2-1

The document reference is online, please check the correspondence between the online documentation and the printed version.

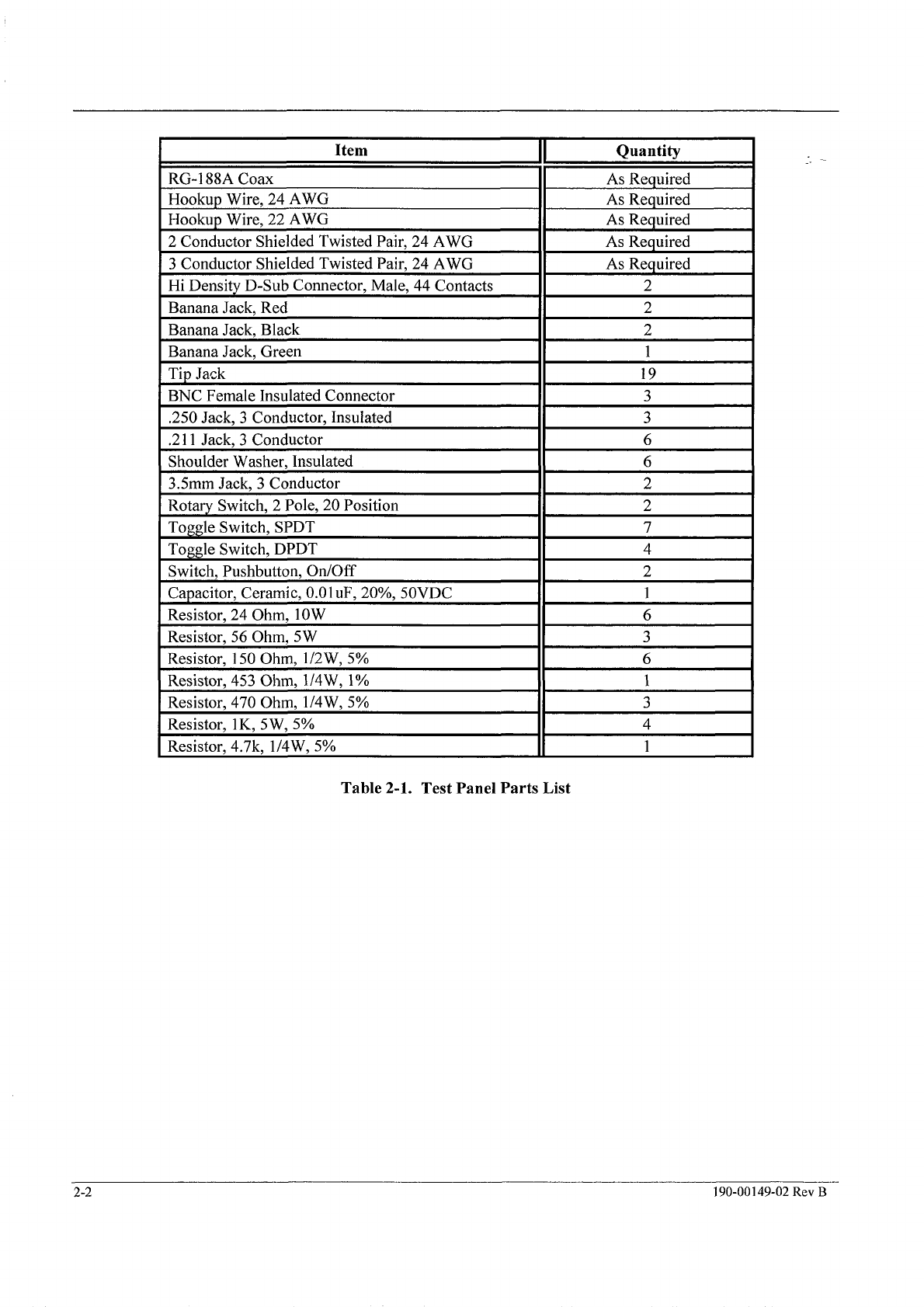

Item

RG-188A Coax

Hookup Wire, 24 AWG

Hookup Wire, 22 AWG

2 Conductor Shielded Twisted Pair, 24 AWG

3 Conductor Shielded Twisted Pair, 24 AWG

Banana Jack. Red

Hi Density D-Sub Connector, Male, 44 Contacts

Quantity

As Required

As Required

As Required

As Required

As Required

2

2

Rotary Switch,

2

Pole, 20 Position

Toggle Switch, SPDT

Toggle Switch. DPDT

Banana Jack, Black

Banana Jack, Green

Tip Jack

BNC Female Insulated Connector

.250 Jack,

3

Conductor, Insulated

.2

11

Jack, 3 Conductor

Shoulder Washer, Insulated

3.5mm Jack. 3 Conductor

Switch, Pushbutton, On/Off

Capacitor, Ceramic, 0.01uF, 20%, SOVDC

2

1

19

3

3

6

6

2

I

Resistor. 24 Ohm. 1OW

II

6

I

Resistor, 470 Ohm, 1/4W,

5%

Resistor,

1K,

5W, 5%

Resistor, 4.7k, 1/4W, 5%

Resistor, 56 Ohm, 5W

Resistor, 150Ohm, 1/2W,5%

Resistor. 453 Ohm. 1/4W.

1%

3

4

1

~

Table

2-1.

Test Panel Parts List

2-2

190-00149-02

Rev

B

The document reference is online, please check the correspondence between the online documentation and the printed version.

HEADSET

PILOT

@

@

COPILOT

PASS

150

OHM

@

@

69

OFF

LOAD

150

OHM

OFF

LOAD

150

OHM

OFF

LOAD

8 OHM

EXT SPKR

LOAD

J1

PIN

9

6)

(3

@

J1

PIN24

J1

PIN33

J1

PIN38

MICROPHONE

@

PILOT

COP1LOT

PASS1

PASS3

ON

@

OFF

@

OFF

@

@

PTT

ON

PTT

PASS2

PASS4

@@

MUSlCl MUSIC2

IN IN

TEST

POINTS

@@@

J1

PIN

10

J1

PIN

11

J1

PIN

12

J1

PIN

25

J1

PIN

26

J1

PIN27

J1 PIN 34

J1

PIN

35

J1

PIN 36

@@a

J1

PIN 39

J2

PIN

16

J2

PIN

31

J1

PIN23

@

@

(3

J1

PIN

28

J1

PIN37

ACFT GND

COM3 MIC COMI KEY

COMI MIC COM3 KEY

COM2 KEY

COM2 MIC

PA MUTE

MIDDLE MKR

SENSE

EXT SPKR

PASS HS R

PASS

HS

L

COP HS R

COP HS L

PIL

HS

R

HS

@

OUTPUTS

MUSlCl L MUSlCl R

TEL RING MUSIC2 L

ALT WARN MUSIC2 R

PIL MIC

COP MIC

PASS1 MIC

NAV2

PASS2 MIC

NAV’

PASS3 MIC

COM3 PASS4 MIC

COM2

COMI

(@

‘5

LOADMIC

WIPE

0

0

ACFT

PWR

ACFT

GND

INPUTS

ON ON

OFF OFF

SWAP TONE MASQ

ENABLE INHIBIT

PWR

0

LGT

GND

28V

14V

TP

GND

ACFT

LGT

OFF

ON

@

OFF

ICS MUTE

INHIBIT

MKR ANT

IN

Figure

2-2.

Typical Test Panel

Layout

190-00149-02

Rev

B

2-3

The document reference is online, please check the correspondence between the online documentation and the printed version.

1.

Proper insulation and grounding ofjacks, plugs, switches, and shielded wires is required to avoidaudio

signal ground loops.

2.

To

ensure proper shieldingand grounding, the test panel should be housed in a conductive metal enclosure.

It is critical that all hardware be electrically isolated from the test panel chassis to avoid audio ground loops.

3. Unless otherwise noted, all wires used in the test panel are 24 AWG.

4. Aircraft power leads should be as short as possible and routed near the test panel faceplate. Use 22 AWG

wire for the connections from 52 pins

8

through 11to the test panel ACFT PWR and ACFT GND banana

jacks.

5.

Use

a

minimal length of RG-188A coax cable or equivalent from the test panel MKR

IN

connector to 51

pins 1and 2.

6.

All two and three conductor shieldedwires must have shields terminated at one end only. The other end

must be left floating from ground.

7.

Shielded wires for the harness from the test panel to the unit under test should be terminated

to

the

respective

J1

and 52 connector backshells.

8.

Use Belden wire #83318and #83333 or equivalent for two and three conductor shielded pairs respectively.

9.

Both rotary switches have a dedicated BNC connector for convenient connection to the test equipment.

Deck “A” common of each rotary switch is wired to the appropriate BNC center conductor. Deck

“B”

common of each rotary switch is wired to the appropriate BNC outer conductor.

10. The TP GNDjack is the single point ground connection between the test panel and the power supply.

Shielded wires within the test panel may terminate to any point on the test panel chassis.

1

1.

The wiring harness from the test panel to the unit under test should be as short as possible for convenient

testing of the GMA 340.

12. Test panel labeling may be altered to accommodate the GMA 340 Dual ADF. Regardless of labeling, all

functions will be tested on all versions of the unit.

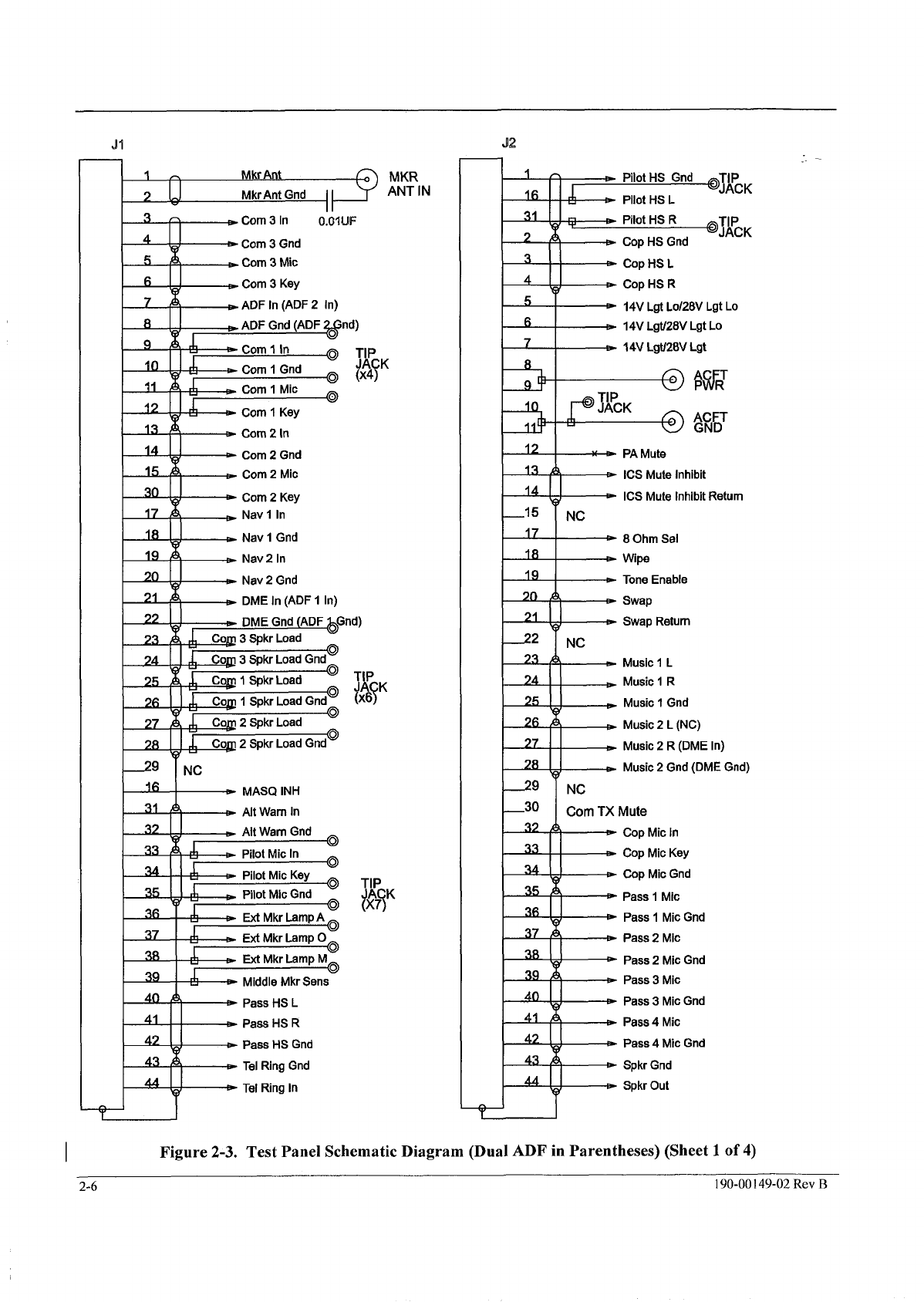

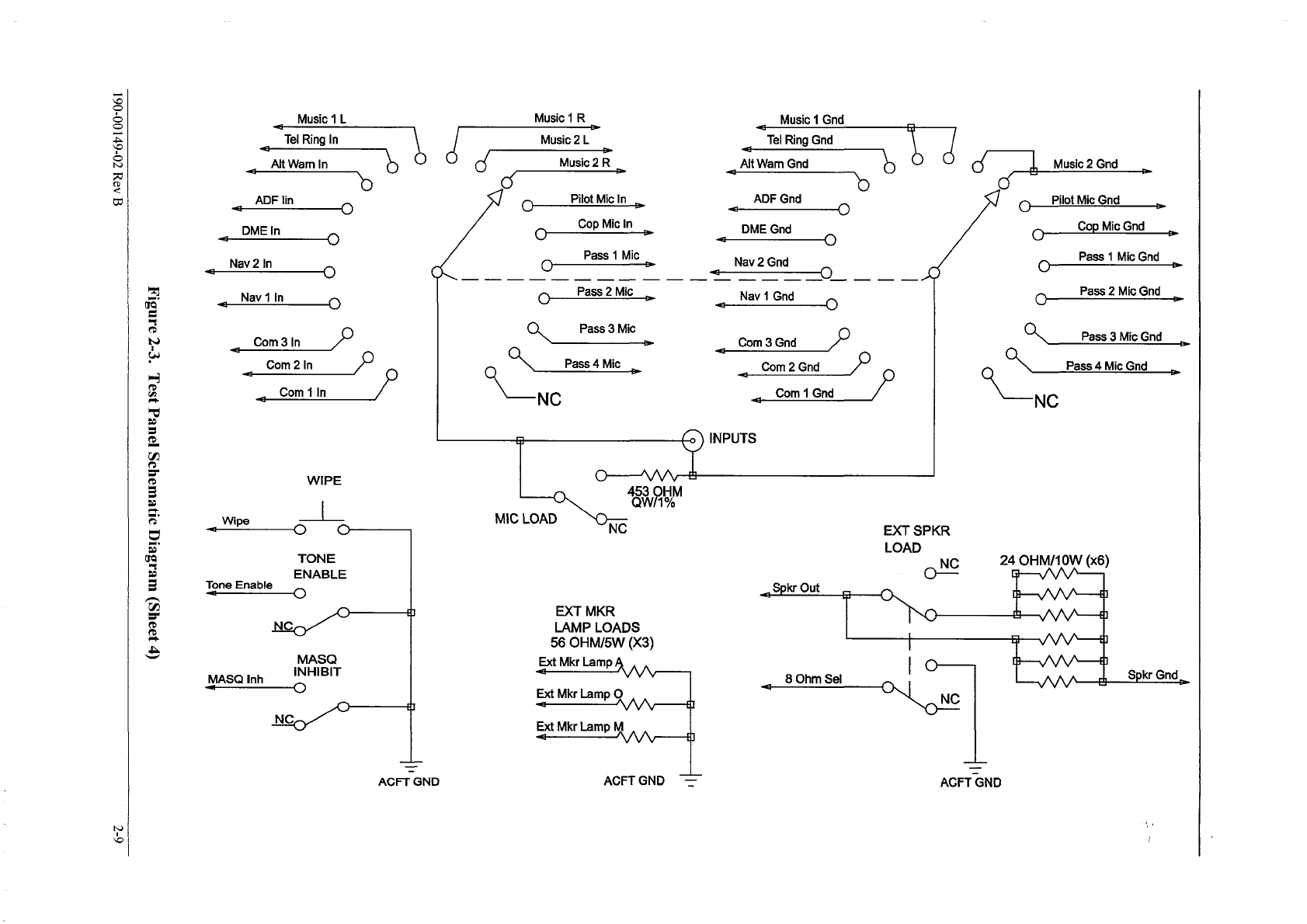

2.4

TEST HARNESS,

J1

AND

52

PIN ASSIGNMENTS

The following table provides pin assignment information for connectors

J

1and 52 test harness construction. The

test harness, an integral part of the test panel, is similar to connections in an aircraft.

2-4

190-00

149-02

Rev

B

The document reference is online, please check the correspondence between the online documentation and the printed version.

Pin

#

11

Connector J1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

Mkr Ant

Mkr Ant Gnd

Corn

3

In

Corn

3

Gnd

Corn

3

Mic

Corn

3

Key

ADF In (ADF

2

In)

ADF Gnd (ADF

2

Gnd)

Corn

1

In

Corn

1

Gnd

Corn

1

Mic

Corn

1

Key

Corn

2

In

Corn

2

Gnd

Corn

2

Mic

MASQ Inh

Nav

1

In

Nav

1

Gnd

Nav

2

In

Nav

2

Gnd

DME In (ADF

1

In)

DME Gnd(ADF

1

Gnd)

Corn

3

Spkr Load

Corn

3

Spkr Load Gnd

Corn

1

SpkrLoad

Corn

1

Spkr Load Gnd

Corn

2

Spkr Load

Corn

2

Spkr Load Gnd

NC

Corn

2

Key

Pilot Headset R

Alt Wrn Gnd

Pilot Mic In

Pilot Mic Key

Pilot Mic Gnd

Ext White Lamp; A

Ext Blue Lamp;

0

Ext Amber Lamp; M

Middle Mkr Sens

Pass Headset L

Pass Headset R

Pass Headset Gnd

Tel Ringer Gnd

Tel Ringer In

Connector52

Pilot Headset Gnd

CO-PilotHeadset Gnd

CO-PilotHeadset L

CO-Pilot Headset R

14V

Lgt

LoI28V

Lgt Lo

14VLgtl28V

Lgt Lo

14VLgtf28V

Lgt

Aircraft Power

Aircraft Power

Aircraft Ground

Aircraft Ground

PA Mute

ICS Mute Inhibit

ICS Mute Inhibit Return

NC

Pilot Headset L

8

Ohm Select

Reserved

Tone Enable

Swap

Swap Return

NC

Music

1

L In

Music

1

RIn

Music

1

Gnd

Music

2

L In (NC)

Music

2

R In (DME In)

Music

2

Gnd (DME Gnd)

NC

Corn

TX

Mute

Pilot Headset

R

CO-PilotMic In

CO-PilotMic Key

CO-PilotMic Gnd

Pass

1

Mic

Pass

1

Mic Gnd

Pass

2

Mic

Pass

2

Mic Gnd

Pass

3

Mic

Pass

3

Mic Gnd

Pass

4

Mic

Pass

4

Mic Gnd

SpkrGnd

Spkr Out

Table 2-2. J1 and 52 Pin Assignments (Dual ADF in Parentheses)

190-00149-02

Rev

B

2-5

The document reference is online, please check the correspondence between the online documentation and the printed version.

311

1

MKR

ANT IN

ADF

In

(ADF 2

In)

w

,I

DME

In

(ADF 1

In)

TIP

@jK

JZ

1

14VLgt L0/2BV Lgt Lo

14VLgff28VLgt Lo

ACFT

PWR

ACFT

GND

ICS Mute Inhibit

ICS Mute InhibitReturn

Music2

R

(DME

In)

Music

2

Gnd

(DME

Gnd)

Pass

1

Mic

Gnd

Pass2

Mic

Gnd

Pass

3

Mic

Gnd

Pass4

Mic

Gnd

Figure

2-3.

Test Panel Schematic Diagram (Dual ADF

in

Parentheses) (Sheet

1

of

4)

2-6

190-00

149-02

Rev

B

The document reference is online, please check the correspondence between the online documentation and the printed version.

HEADSET

LOADSWITCHES

U

/\

A

E-

Pilot

HS

R

I-

f*{

-

Pass

bund

I

PassHS

L

E-

Pass

HS

R

UA

Pass

1

Mic

PASS

1

MIC

Pass

3

Mic

Gnd

Pass

3

Mic

PASS

3

MIC

PILOT

PlT

Iv

PilotMlc

Gnd

PilotMic

In

Pilot Mic

Kev

PIL

T

MI8

COPILOT PTT

I----

lb_

Cop Mic

Gnd

Cop Mic

In

Cop Mic

Key

COPILOT

MIC

ACFT LGT

SELECT

14VLgt LoI28V LgtLo

d-\

14VLgtl28VLgtLo

14v

14VLgtl28V Lgt LGT

Music2 Gnd

s

Music2

L

Music2

R

MUSIC

2

IN

Pass2 Mic

g$gs

2

Pass4 Mic

Gnd

Music1

Gnd

A

Pass4 Mic

A

Music1R

PASS

4

MUSIC

1

MIC

IN

Figure

2-3.

Test Panel Schematic Diagram (Sheet

2)

190-00149-02

Rev

B

2-1

The document reference is online, please check the correspondence between the online documentation and the printed version.

,Corn

3

Mic

,Corn

2

Mic

,Corn

1

Mic

I

1-

Middle MkfSens@

flu&

Spkr

Gnd

0

A

0-NC

0-NC

-NC

ACFT

GND

TP

GND

SWAP

Swap

oio

SwapReturg

ICS

MUTE

INHIBIT

0

ICSMute Inhibit

ICS

Mute Inhibit Return

NOTE:

All

loadsare

QW/5%

unlessotherwisenoted.

-

ACFT-GND

TP

CHASSIS

The document reference is online, please check the correspondence between the online documentation and the printed version.

Music

1

L

Tel Ring

In

Pb

ADF lin

<

0

DME In

0

0

Nav

2

In

NavlIn

0

n

h

Corn

3

In

7,

Corn

2

In

Corn

1

In

/

WIPE

*

o---

Wipe

TONE

ENABLE

Tone

Enable

MASQ

INHIBIT

0

MASQ

Inh

b

I

-I

-

-

ACFT

GND

Music 1R Music

1

Gnd

-

l-9

L"

I

Music

2

L

-

e

Music

2

R

Tel RingGnd

At

Wam Gnd

b

PilotMic

In

ADF Gnd

DME Gnd

Nav

2

Gnd

Cop Mic In

-

Pass

1

Mic

Pass

4

Mic

MICLOAD

EXT

MKR

LAMP

LOADS

56

OHM/5W

(X3)

Ext

Mkr Lamp

1

ACFTGND

PilotMicGnd

Cop

MicGnd

Pass

1

MicGnd

0

Pass

2

MicGnd

Pass

3

MicGnd

Pass4MicGnd

'NC

EXT

SPKR

LOAD

24

OHMllOW

(x6)

KzzL

I

I

I

-

U

Spkr Gnd

9"

8

Ohm

Sel

-

ACFTGND

The document reference is online, please check the correspondence between the online documentation and the printed version.

(

'-.

C

(7AX CALiLE

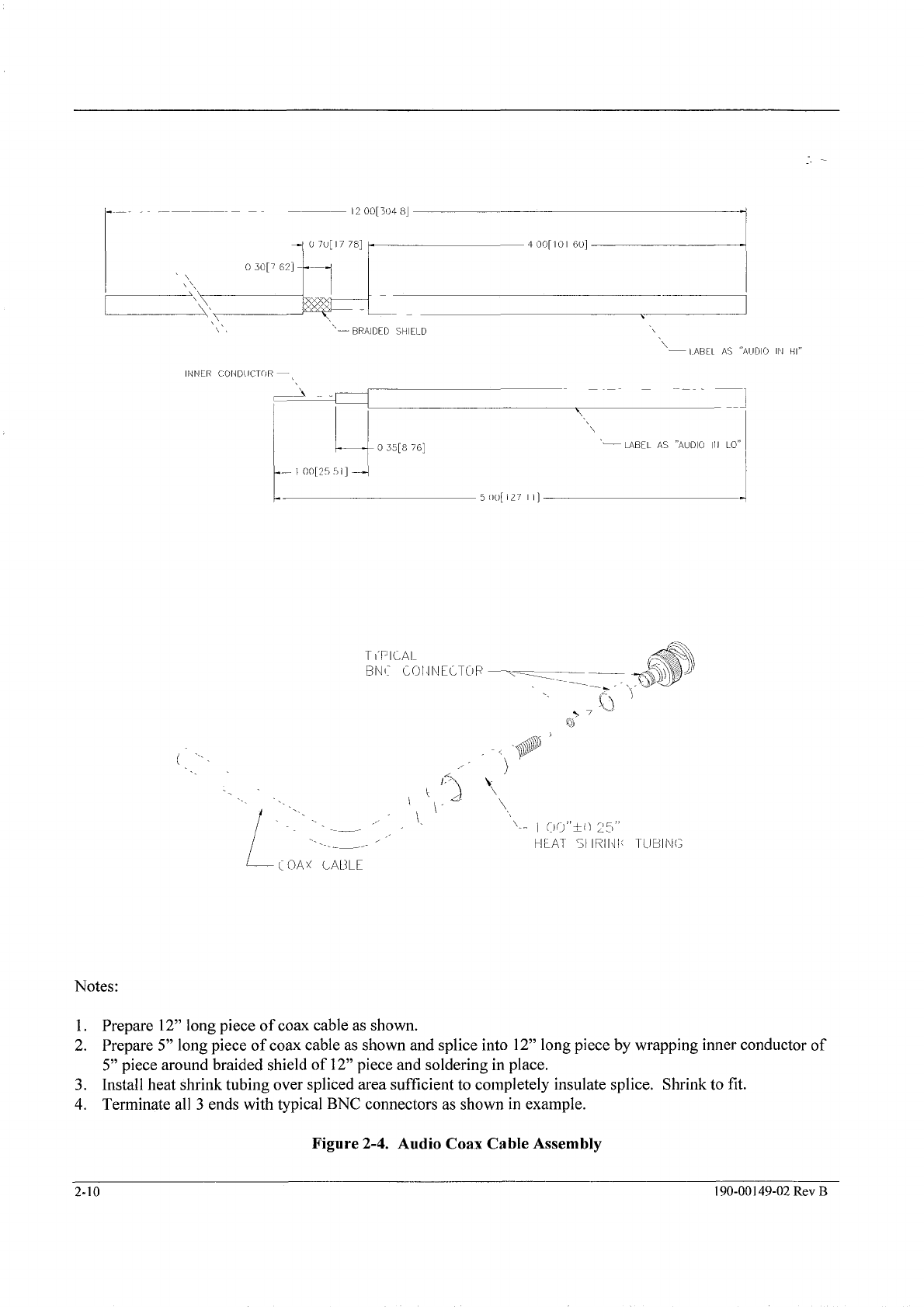

Notes:

1.

Prepare

12"

long piece of coax cable as shown.

2.

Prepare

5"

long piece of coax cable as shown and splice into

12"

long piece by wrapping inner conductor

of

5"

piece around braided shield of

12"

piece and soldering in place.

3.

Install heat shrink tubing over spliced area sufficient to completely insulate splice. Shrinkto fit.

4.

Terminate all

3

ends with typical BNC connectors as shown in example.

Figure

2-4.

Audio

Coax

Cable Assembly

2-10

190-00149-02

Rev

B

The document reference is online, please check the correspondence between the online documentation and the printed version.

SECTION

3

TROUBLESHOOTING

Individual components and assemblies in the GMA 340 Audio Panel can be

damaged by ESD (Electrostatic Discharge). Observe proper ESD procedures

when troubleshooting the unit.

3.1

TROUBLESHOOTING

This section contains information to aid in troubleshooting the GMA 340 to the replaceable assembly level. In

general, entry into the troubleshooting section occurs after

a

failure in the testing section. The type

of

failure

found in the test procedure determines the correct troubleshooting procedure. After the faulty module

is

isolated

and repair is made, the unit should be retested using the functional test procedure in Section

5,

TESTING of this

manual to ensure that the repaired area is operating correctly and that other areas have not been damaged during

the repair procedure.

3.2

TROUBLESHOOTING PROCEDURES

This troubleshooting guide

is

designed to allow isolation of malfunctions to the power input board or the front

panel subassembly. These checks reference specific tests in Section

5,

TESTING

of

this document. Referring to

the disassembly section, remove the top and bottom covers to perform the checks in the following paragraphs.

For tests not covered in this section, the entire unit must be returned to the factory for repair and return to service.

Figures 3.1, 3.2 and 3.3 are provided for connector location, pin numbering orientation and pin function.

190-00

149-02

Rev

B

3-

I

The document reference is online, please check the correspondence between the online documentation and the printed version.

no

0

0

0

=:O

0

000

00

ono

00

000

=:

00

0000

Figure 3.1. Front Panel Rear View, Connector J1 and 52 Location

Front Panel

Pin

1=:-1

I

Pilot

II

J1

Pin

22

I

I

CREW

II

J1

Pin

23

I

I

TEST

II

J1

Pin

18

I

Table 3.1. Front Panel Connector Detail (Dual ADF in Parentheses)

3-2 190-00149-02

Rev

B

The document reference is online, please check the correspondence between the online documentation and the printed version.

Other manuals for GMA 340

4

This manual suits for next models

3

Table of contents

Other Garmin Stereo System manuals

Garmin

Garmin FUSION MS-RA210 User manual

Garmin

Garmin Meteor 300 User manual

Garmin

Garmin GMA 342 User manual

Garmin

Garmin Fusion Apollo RA770 User manual

Garmin

Garmin Fusion Apollo MS-RA770 User manual

Garmin

Garmin FUSION User manual

Garmin

Garmin GMA 340 Owner's manual

Garmin

Garmin FUSION Apollo MS-WB670 User manual

Garmin

Garmin Fusion APOLLO RV-RA770 User manual

Garmin

Garmin Fusion MS-BB100 User manual