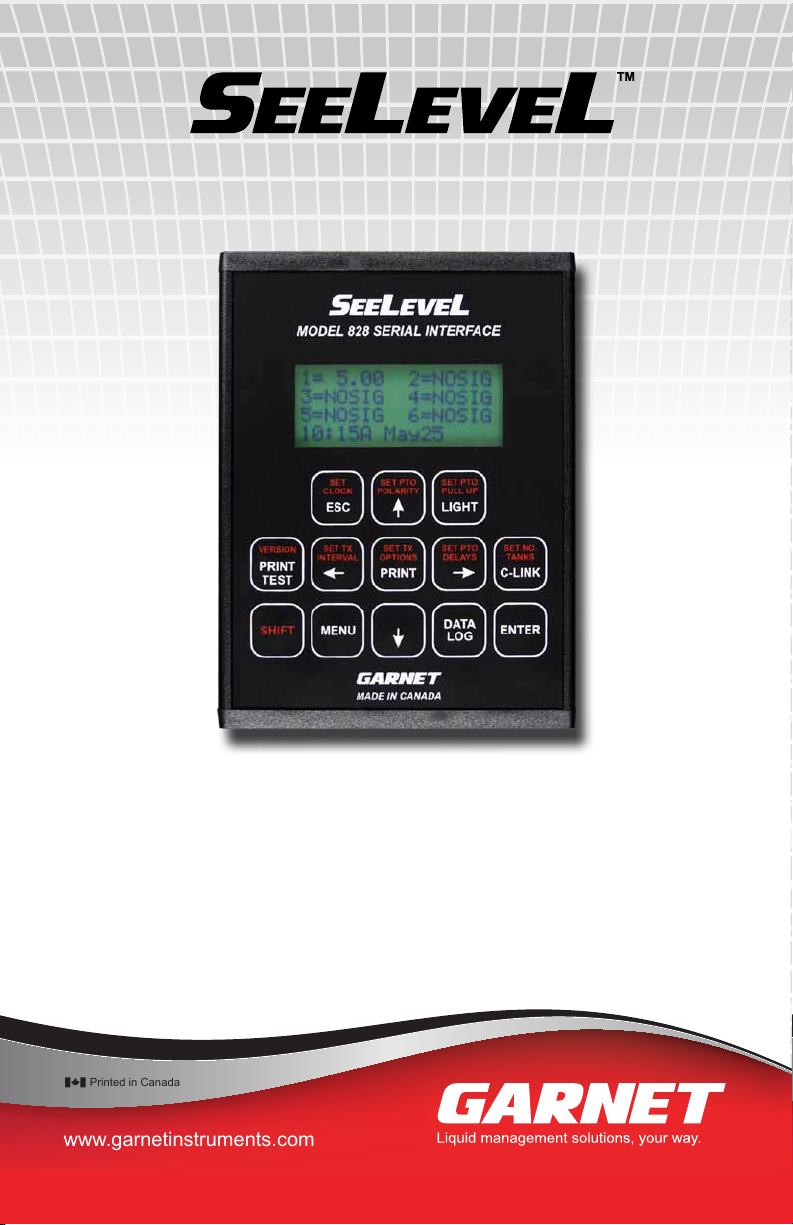

Garnet SEELEVEL 828 User manual

Printed in Canada

www.garnetinstruments.com

MODEL 828 MANUAL

Serial Interface

Page 2 828 Manual

Table of Contents

CHAPTER 1 - OVERVIEW.............................................................................................3

CHAPTER 2 - DESCRIPTION.......................................................................................4

CHAPTER 3 - INSTALLATION GUIDE.......................................................................7

CHAPTER 4 - SERIAL COMMANDS.........................................................................8

CHAPTER 5 - TROUBLESHOOTING GUIDE......................................................... 19

CHAPTER 6 - SERVICE AND WARRANTY INFORMATION............................ 20

MAIL IN WARRANTY ................................................................................................. 21

GARNET

SEELEVELTM

Serial Interface

MODEL 828

828 Manual_v7.2 - 04-Sep-2018

Page 3

828 Manual

CHAPTER 1 - OVERVIEW

Congratulations on purchasing the Garnet Instruments Model

828 SEELEVEL™ Serial Interface. The Model 828 is designed to

interface up to six 808P2/810PS2 displays or one 806B display to

a standard RS232 serial connection for data acquisition. This can

be connected to a remote computer, PLC or cellular modem and

an external printer can be attached to a second serial port to print

receipts for historical PTO events. There is a Power Take Off (PTO)

sense line to determine when transmitted data is required. This

prevents false readings from being transmitted while the truck is

moving.

Page 4 828 Manual

CHAPTER 2 - DESCRIPTION

The 828 has a 4x16 LCD display to congure the setup options,

verify connections, help with troubleshooting, and to display

the levels of the SEELEVEL™ gauges. The number of levels displayed

corresponds to the number of compartments congured.

Historical PTO events are saved to memory. These events log the

time and volume when a PTO is turned on and when the PTO is

turned off. The PTO events can be retrieved from memory through

the serial connection, or time stamped receipts can be printed

using a portable printer.

Many of the 828 keypad buttons require a ve digit numeric

password authentication before they can be used. The default

password is “11111”. Entering the last three characters ‘111’

correctly provides Level 1 Access which enables the CLOCK button.

Entering all ve digits correctly provides Level 2 Access allowing all

functions. The PRINT, LIGHT, VERSION, and DATALOG buttons are

always available. Access to Level 1 and 2 expires after 10 minutes.

The password can be changed using the Set Password Key serial

command. If in Geotab New (mode 2) the password “99991”

will provide access to the MENU button functionality to change

the mode back to ASCII (mode 0) so the Set Password Key serial

command could be used to reset the password.

Description of Keypad Buttons:

ENTER button: This button is used to store setup changes into

programmer memory.

ESC button: This is used to exit various menus.

button: This button is used to navigate through setup menus.

button: This button is used to navigate through setup menus.

button: This button is used to navigate through setup menus.

button: This button is used to navigate through setup menus.

PRINT button: Select a tank and historical PTO event to print and

send its level out the printer serial port .

LIGHT button: This turns the display backlight on and off.

SHIFT button: This button is used to select the button functions

printed in red. SHIFT must be held down while pressing the other

button.

Page 5

828 Manual

SET CLOCK+SHIFT button: Set the on board real time clock.

Use the up and down buttons to change the highlighted time/

date, and the sideways buttons to select which item to set. Use

the ENTER button to save the time and date shown, and exit the

menu. To exit the menu without saving, use the ESC button.

SET PTO POLARITY+SHIFT button: Select whether the PTO is

active when high or low polarity is present on the PTO wire. Use

the up and down buttons to change the selection. Use the ENTER

button to save the value shown, and exit the menu. To exit the

menu without saving, use the ESC button.

SET PTO PULLUP+SHIFT button: Select whether the PTO pull-up

is on or off. Use the up and down buttons to change the selection.

Use the ENTER button to save the value shown, and exit the menu.

To exit the menu without saving, use the ESC button.

SET PTO DELAY+SHIFT button: Sets the delay after the PTO is

engaged or disengaged before a serial data transmit is done. Use

the up and down buttons to change the value shown. Use the

sideways buttons to select the engage or disengage delay. Use

the ENTER button to save the value shown, “st” will be shown for a

couple of seconds to verify that the value has been stored. Once

the new values have been stored, use the ESC button to exit the

menu. Any changes made after pressing the ENTER button will

not be stored.

VERSION+SHIFT button: Shows the hardware and software

version of the 828.

SET NO. TANKS+SHIFT button: Set the number of compartments

to be monitored and displayed on the LCD screen for updates. This

should match the number of SEELEVEL™ gauges. Use the up and

down buttons to change the value shown. Use the ENTER button

to save the value shown, and exit the menu. To exit the menu

without saving, use the ESC button. Currently, 806 gauges can

only monitor compartment one. The 806 gauge must be viewing

compartment one to work.

SET TX INTERVAL+SHIFT button: Sets the interval between

automatic serial data transmissions of the levels shown on the

display. This can be from 1 to 99,999 seconds. Use the up and

down buttons to change the highlighted digit. Use the sideways

buttons to select a different digit. Use the ENTER button to save

the value shown, and exit the menu. To exit the menu without

saving, use the ESC button.

Page 6 828 Manual

SET TX IN OPTIONS+SHIFT button: Sets the transmit interval

options. The 828 can be congured to send or not send interval

updates during the time that the PTO is disengaged. Updates are

always sent during the time that the PTO is engaged. Use the up

and down buttons to change the selection. Use the ENTER button

to save the value shown, and exit the menu. To exit the menu

without saving, use the ESC button.

MENU button: Sets the 828 Mode and Gauge type. Use the up

button to set the 828 to 806 gauge viewing compartment one.

Use the down button to set the 828 to use 808 and 810 gauges.

Use the right and left buttons to select ASCII (mode 0), Geotab Old

(mode 1), or Geotab New (mode 2) serial transmit modes. Use ESC

button to exit.

In mode 0, which is the default, ASCII characters are sent out when

PTO changes occur, interval updates are sent, and compartment

data has been scanned.

In mode 1, Geotab’s RS232 Extended Data Message Format GO2/

GO3/GO4 is used when PTO changes occur and interval updates

are sent.

In mode 2, Geotab’s Third Party Data (Message Type 0x80) protocol

is used when PTO changes occur and interval updates are sent.

DATA LOG button: Send all the historical PTO events out the

serial port.

DATA LOG+ SHIFT button: Clear all historical PTO events from

memory.

Note that if one of the set menus is entered and there has been

no button pressed for one minute, the menu will automatically exit

without saving. This way the system cannot be accidentally left in

one of the set menus where it will not respond to serial data.

Page 7

828 Manual

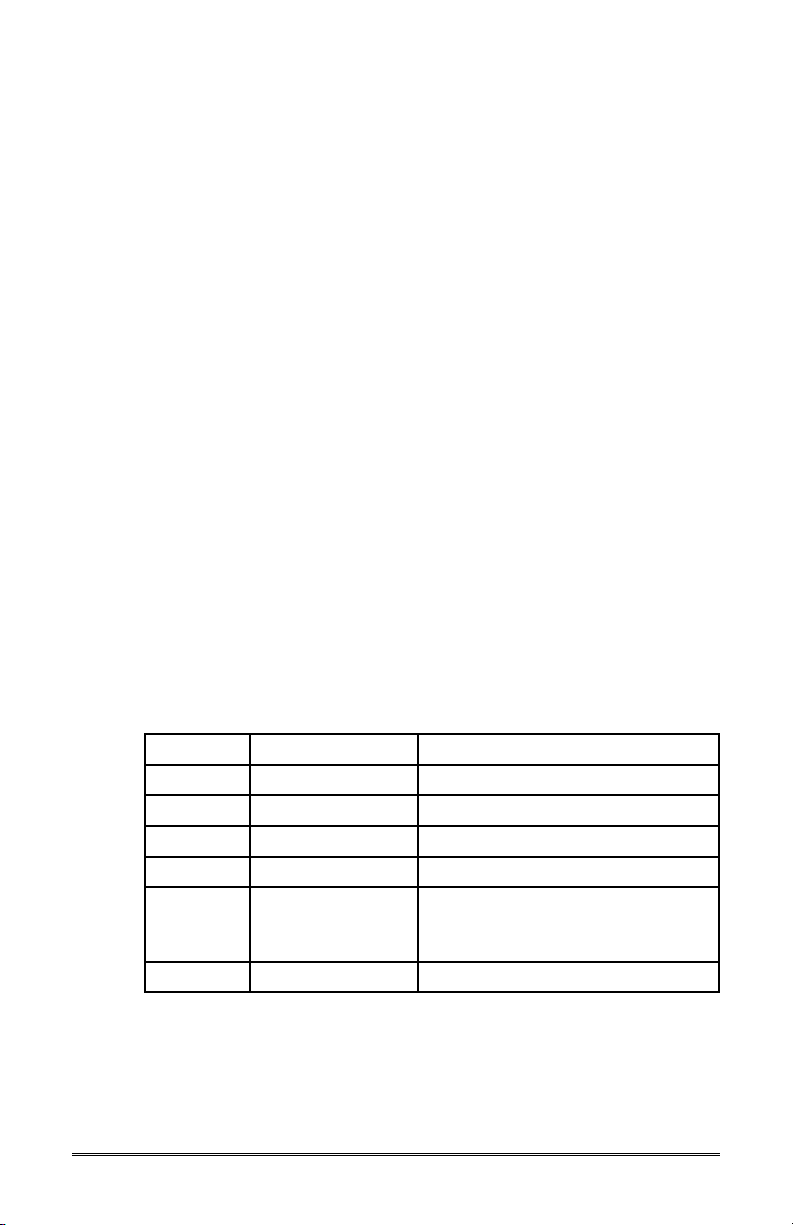

CHAPTER 3 - INSTALLATION GUIDE

1. The 828 is not weatherproof. The connectors on the ends of

the 828 need to be clear of obstructions. Ensure that the unit

is mounted in an appropriate location.

2. The 828 needs to be supplied with +12VDC from the truck

through a 1 amp fuse along with a good chassis ground.

3. One signal wire needs to be fed from the truck’s PTO to the

PTO INPUT on the 828. This wire needs to either have an active

high or active low signal.

4. The six remote inputs allow a single 828 to communicate with

up to six different SEELEVEL gauges. Connect the remote outputs

from the SEELEVEL 806B, 806Bi, 808P2 or 810PS2 systems to

the REMOTE wire inputs on the 828. NOTE: The ground used

for the 828 has to be the same ground connection used for

the 806B, 808P2 or 810PS2.

5. Connect the serial data port to the serial device using a

standard 9 pin serial cable.

6. The serial port settings for both serial ports are 9600 baud, no

parity, 8 data bits, 1 stop bit ASCII communications.

Printer Tx

RS232Rx

RS232Tx

+12 VDC

Ground

PTO

Remote 1

Remote 2

Remote 3

Remote 4

Remote 5

Remote 6

Printer

Serial Port Serial Data

Port

Page 8 828 Manual

CHAPTER 4 - SERIAL COMMANDS

The following section describes the dened 828 serial commands.

The serial data requests are ASCII data strings. Throughout

this section <CR> represents a single carriage return character

(hexadecimal 0x0D). In this section Red text represents serial

data being received by the 828. Blue text represents serial data

being transmitted from the 828. Either uppercase or lowercase

characters can be used, the response will be in the case that is

used to make the request.

Set Password Key

‘k=11111’ sets the ve digit numeric password key.

k=11111<CR>

k,11111<CR>

Request Password Key

‘k’ requests the the ve digit numeric password key.

k<CR>

k,11111<CR>

Set Gauge Type (808/810 or 806)

Set the type of gauge connected to the 828. ‘g=0’ for 808 or 810,

‘g=1’ for 806.

808 or 810 806

g=0<CR> g=1<CR>

g,0<CR> g,1<CR>

Request Gauge Type (808/810 or 806)

‘g’ requests the type of gauge connected to the 828.

808 or 810 806

g<CR> g<CR>

g,0<CR> g,1<CR>

Currently, 806 gauges can only monitor compartment one. The

806 gauge must be viewing compartment one to work.

Page 9

828 Manual

Mode conguration

The 828 can be set up to operate in three modes of operation.

‘m=0’ sets mode 0, ‘m=1’ sets mode 1, and ‘m=2’ sets mode 2.

IMPORTANT NOTE: The 828 only accepts serial commands when

in mode 0 or 1. If the 828 is set to mode 2 via a serial command,

it can only be set back to mode 0 or 1 via the front keypad MENU

button.

m=0<CR> m=1<CR> m=2<CR>

m,0<CR> m,1<CR> m,2<CR>

In mode 0, which is the default, ASCII characters are sent out when

PTO changes occur, interval updates are sent, and compartment

data has been scanned.

In mode 1, Geotab’s RS232 Extended Data Message Format GO2/

GO3/GO4 is used when PTO changes occur and interval updates

are sent.

In mode 2, Geotab’s Third Party Data (Message Type 0x80) protocol

is used when PTO changes occur and interval updates are sent.

Request Mode

‘m’ requests the mode from the 828.

Mode 0 Mode 1

m<CR> m<CR>

m,0<CR> m,1<CR>

Page 10 828 Manual

PTO change (Mode 0)

During normal operations, a change of PTO status causes the 828

to send out a comma separated list of values corresponding to the

PTO status followed by the number of channels being monitored.

The transmit is done after a programmable delay.

p,E,11.16,79.00, 0.00, 0.00, 0.00, 0.00<CR>

The next example shows the PTO disengaged and only two

channels being monitored.

p,D,11.16,79.00<CR>

The next example shows the PTO engaged and all six compartments

having invalid data.

p,E,NOSIG,NOSIG,NOSIG,NOSIG,NOSIG,NOSIG<CR>

The level reading will always be ve characters including the

decimal place. If no decimal place is present a space character will

pad the least signicant byte. NOSIG shows no valid level data.

ERROR shows level data error.

PTO change (Mode 1)

During normal operations, a change of PTO status causes the 828

to send out a message compatible with Geotab’s “RS232 External

Data Message Format GO2/GO3/GO4”.

Byte Value Description

0STX 0x02

1 Message Type 1 0x01

2 Body Length (x) 1-27

3 to 2+x Data x byes of data, max of 30 bytes

3+x to

4+x

Checksum 2 byte checksum (big endian) of

bytes 0 to 2+x with 0x01 added

to each byte before summing

5+x ETX 0x03

Page 11

828 Manual

When the Geotab device receives the message the Geotab device

will send an acknowledge back on the serial port.

Byte Value Description

0STX 0x02

1ACK 0x06

2ETX 0x03

According to the Geotab’s “R232 External Data Message Format

GO2/GO3/GO4” documentation:

[When the Geotab device receives the 828 data], a log record

of type 38 will be saved to the [Geotab] ash containing the

last GPS date time. A log record type 39 will follow with the

same date/time as the type 38 log record providing additional

data.

To ensure compatibility with Geotab devices, only four channels

should be congured in the 828 when using Mode 1, since the

Body Length is limited to 27 characters.

The Data part of the message contains a comma separated list of

values corresponding to the PTO status followed by the number

of channels being monitored. The transmit is done after a

programmable delay.

E,11.16,79.00, 0.00, 0.00

The next example shows the Data part of the message with the

PTO disengaged and only two channels being monitored.

D,11.16,79.00

The next example shows the Data part of the message with the

PTO engaged and all four compartments having invalid data.

E,NOSIG,NOSIG,NOSIG,NOSIG

The level reading will always be ve characters including the

decimal place. If no decimal place is present a space character will

pad the least signicant byte. NOSIG shows no valid level data.

ERROR shows level data error.

Page 12 828 Manual

Set PTO conguration

There are four items to congure:

1. Resistor pullup on or off.

2. PTO engagement polarity high or low.

3. Transmit delay upon PTO disengagement.

4. Transmit delay upon PTO engagement.

‘u=1’ turns the PTO pullup on, ‘u=0” turns the PTO pullup off.

u=1<CR> u=0<CR>

u,1<CR> u,0<CR>

‘e=1’ means the PTO is engaged when the signal is high (+12V),

‘e=0’ means the PTO is engaged when the signal is low (ground).

e=1<CR> e=0<CR>

e,1<CR> e,0<CR>

‘w=0’ to ‘w=99’ sets the delay in seconds after the PTO has

disengaged before the level is read and transmitted. Numbers

larger than 99 will be ignored. This gives time for the liquid

agitation due to loading to settle. During this delay new gauge

values will be continue to be read. Once the delay expires, new

gauge values will be ignored.

w=0<CR> w=60<CR>

w,0<CR> w,60<CR>

‘x=0’ to ‘x=99’ sets the delay in seconds after the PTO has engaged

before the level is read and transmitted. Numbers larger than

99 will be ignored. This gives time for the liquid agitation due

to the trucking moving to settle. If the delay is set to 0, then

the stored values obtained when the PTO was disengaged will be

transmitted, since there will not have been any time to read the

new values from the gauges.

x=0<CR> x=60<CR>

x,0<CR> x,60<CR>

Page 13

828 Manual

Request PTO conguration

‘u’ requests the PTO conguration for the pullup.

Pullup turned on Pullup turned off

u<CR> u<CR>

u,1<CR> u,0<CR>

‘e’ requests the PTO conguration for the engagement polarity.

Engaged when high Engaged when low

e<CR> e<CR>

e,1<CR> e,0<CR>

‘w’ requests the delay in seconds after the PTO has disengaged

before the level is read and transmitted.

w<CR> w<CR>

w,0<CR> w,60<CR>

‘x’ requests the delay in seconds after the PTO has engaged before

the level is read and transmitted.

x<CR> x<CR>

x,0<CR> x,10<CR>

PTO status request

‘p’ requests the PTO status from the 828 where ‘E’ is PTO engaged

and ‘D’ is PTO disengaged.

Engaged Disengaged

p<CR> p<CR>

p,E<CR> p,D<CR>

Page 14 828 Manual

Scan all compartments (Mode 0)

‘s’ request a scan of all congured compartments. The 828 sends

out a comma separated list of values corresponding to the PTO

status followed by the number of channels being monitored.

s<CR>

s,D,11.16,79.00, 0.00, 0.00, 0.00, 0.00<CR>

s<CR>

s,E,11.16,79.00<CR>

Scan a specic compartment (Mode 0)

‘s1’ to ‘s6’ request a scan of a specic compartment. The 828 sends

out a value corresponding to the requested compartment.

s1<CR> s2<CR> s3<CR>

s1,11.16<CR> s2,79.00<CR> s3, 0.00<CR>

s4<CR> s5<CR> s6<CR>

s4, 0.00<CR> s5, 0.00<CR> s6, 0.00<CR>

Set Number of Compartments

‘c=1’ to ‘c=6’ sets the number of compartments to be monitored

and displayed on the LCD screen. This normally corresponds to

the number of SEELEVEL™ gauges connected. This value must be

from 1 to 6, any other number will be ignored. Any digits after

the rst one will be ignored. However, if some compartments are

not being used and the fastest possible update rate is desired, the

number of compartments can be set lower. Note, however, that as

the number of compartments is reduced, it is always the highest

numbered ones that are removed.

c=1<CR> c=6<CR>

c,1<CR> c,6<CR>

Currently, 806 gauges can only monitor compartment one. The

806 gauge must be viewing compartment one to work.

Request Number of Compartments

‘c’ reads the number of compartments being monitored and

displayed on the LCD screen. This normally corresponds to the

number of SEELEVEL™ gauges connected (see above).

c<CR> c<CR>

c,1<CR> c,6<CR>

Page 15

828 Manual

Set Update Interval (0=no automatic updates)

The 828 can be congured to automatically send updates on a

timed interval. The update interval is specied in seconds, the value

must be between 0 and 99,999 seconds. Values larger than 99,999

will be ignored. Within approximately one second of setting the

interval, the rst interval transmission will be done.

I=60<CR> I=7200<CR>

I,60<CR> I,7200<CR>

By setting the update interval to 0, automatic updates are turned

off.

I=0<CR>

I,0<CR>

Set Transmit Interval Options

The 828 can be congured to send or not send interval updates

during the time that the PTO is disengaged. Updates are always

sent during the time that the PTO is engaged.

Do send Do not send

o=1<CR> o=0<CR>

o,1<CR> o,0<CR>

Request Transmit Interval Options

Do send Do not send

o<CR> o<CR>

o,1<CR> o,0<CR>

Interval Update (Mode 0)

In Mode 0, when an auto update interval has been dened, the 828

sends out a comma separated list of values corresponding to the

PTO status followed by the number of channels being monitored

on the dened interval, followed by the time and date. The interval

is specied in seconds.

i,E,11.16,79.00, 0.00, 0.00, 0.00, 0.00,12:48:16AM Mar 23

2008<CR>

Interval Update (Mode 1)

In Mode 1, when an auto update interval has been dened, the 828

sends the same message previously dened in the PTO Change

(Mode 1) section of this document. The interval is specied in

seconds.

Page 16 828 Manual

Request Read PTO historical events

‘r’ requests a read of the PTO historical events. This includes the

volumes when the PTO was enabled ‘E’, disabled ‘D’, and the total

‘T’ product change based on the difference.

r<CR>

R,007,E, 4.00, 3:49:53PM Jan 14 2016<CR>

R,007,D,33.00, 3:50:07PM Jan 14 2016<CR>

T,007,+29.00, 3:50:07PM Jan 14 2016<CR>

R,006,E, 2.66, 5:46:04PM Jan 04 2016<CR>

R,006,D, 2.66, 9:37:51AM Jan 07 2016<CR>

T,006,+00.00, 9:37:51AM Jan 07 2016<CR>

R,005,E, 49.0, 5:40:24PM Dec 16 2015<CR>

R,005,D, 55.7, 5:11:09PM Jan 04 2016<CR>

T,005,+006.7, 5:11:09PM Jan 04 2016<CR>

R,004,E, 39.0, 6:23:58PM Dec 15 2015<CR>

R,004,D, 39.2, 6:24:10PM Dec 15 2015<CR>

T,004,+000.2, 6:24:10PM Dec 15 2015<CR>

R,003,E, 35.7, 6:22:33PM Dec 15 2015<CR>

R,003,D, 34.5, 6:21:55PM Dec 15 2015<CR>

T,003,-001.2, 6:21:55PM Dec 15 2015<CR>

R,002,E, 22.7, 6:21:11PM Dec 15 2015<CR>

R,002,D, 25.2, 6:21:21PM Dec 15 2015<CR>

T,002,+002.5, 6:21:21PM Dec 15 2015<CR>

R,001,E, 20.7, 6:20:46PM Dec 15 2015<CR>

R,001,D, 20.7, 6:20:52PM Dec 15 2015<CR>

T,001,+000.0, 6:20:52PM Dec 15 2015<CR>

Request Read PTO historical events with only the Totals

‘R’ requests a read of the PTO historical events, but only sends out

the total ‘T’ the product changed based on the diffence between

when the PTO was enabled and then the PTO was disabled.

R<CR>

T,007,+29.00, 3:50:07PM Jan 14 2016<CR>

T,006,+00.00, 9:37:51AM Jan 07 2016<CR>

T,005,+006.7, 5:11:09PM Jan 04 2016<CR>

T,004,+000.2, 6:24:10PM Dec 15 2015<CR>

T,003,-001.2, 6:21:55PM Dec 15 2015<CR>

T,002,+002.5, 6:21:21PM Dec 15 2015<CR>

T,001,+000.0, 6:20:52PM Dec 15 2015<CR>

Page 17

828 Manual

Conguration commands for printer

‘L1=’ sets line 1 text on printout; maximum length is 32 characters

‘L2=’ sets line 2 text on printout; maximum length is 32 characters

‘L3=’ sets line 3 text on printout; maximum length is 32 characters

‘L4=’ sets line 4 text on printout; maximum length is 32 characters

‘N1=’ sets compartment 1 name; maximum length is 16 characters

‘N2=’ sets compartment 2 name; maximum length is 16 characters

‘N3=’ sets compartment 3 name; maximum length is 16 characters

‘N4=’ sets compartment 4 name; maximum length is 16 characters

‘N5=’ sets compartment 5 name; maximum length is 16 characters

‘N6=’ sets compartment 6 name; maximum length is 16 characters

‘Q=’ sets the units to be printed; maximum length is 16 characters

‘-=’ sets the text to print when delivered; maximum length is 16

characters

‘+=’ sets the text to show when loaded; maximum length is 16

characters

‘L5=’ sets line 5 text on printout; maximum length is 32 characters

‘L6=’ sets last line of text on printout; maximum length is 32

characters

Sets the units on printout to “gallons”

Q=gallons<CR>

Q,gallons<CR>

Sets the rst compartment name to “Compartment A”

N1=Compartment A<CR>

N1,Compartment A<CR>

Request Time

‘t’ requests the current time and date.

t<CR>

t,12:48:16AM Mar 23 2008<CR>

Page 18 828 Manual

Set Time

‘T=’ set the time. The format is hour, minute, second, AM or

PM, each represented by 2 digits and separated by a colon. The

hour may or may not have the leading zero, but the minutes and

seconds must have the leading zero.

T=04:46:09PM<CR> T=4:46:09PM<CR>

t, 4:46:09AM Mar 04 2008<CR> t, 4:46:09AM Mar 04 2008<CR>

Set Date

‘D=’ set the date. The format is month, date, year, each represented

by 2 digits and separated by a colon. The month may or may not

have the leading zero, but the date and year must have the leading

zero.

D=03:04:08<CR> D=3:04:08<CR>

t,12:48:16AM Mar 4 2008<CR> t,12:48:16AM Mar 4 2008<CR>

Version Request

‘v’ requests the current 828 software version.

v<CR>

v,SeeLeveL 828,HW F,SW 6.15<CR>

Page 19

828 Manual

CHAPTER 5 - TROUBLESHOOTING GUIDE

To aid in troubleshooting, the 828 uses the LCD display to

verify proper operation. When the 828 has power and ground

connections, the LCD will be turned on. The PTO input is shown,

when active, on the bottom right corner beside the time and date.

Diagnostic information is shown for all six remote inputs. Only the

congured number of compartments are displayed.

If the values on the display show ‘ERROR’ verify that the correct

Gauge type has been congured using the MENU button. An

806 gauge system must use the 806 conguration, and an

808P2/810PS2 gauge system must use the 808/810 conguration.

If serial commands are not working correctly verify that the correct

Mode has been congured using the MENU button. The default

ASCII mode should normally be used unless you are connecting

to a Geotab system.

Page 20 828 Manual

CHAPTER 6 - SERVICE AND WARRANTY INFORMATION

T

he warranty will only apply only if the warranty card that is shipped with the equipment

has been returned to Garnet Instruments Ltd.

DISCLAIMER OF WARRANTY ON HARDWARE

Garnet Instruments Ltd. warrants equipment manufactured by Garnet to be free from defects in

material and workmanship under normal use and service for a period of one year from the date

of sale from Garnet or an Authorized Dealer. The warranty period will start from the date of

purchase or installation as indicated on the warranty card. Under these warranties, Garnet shall

be responsible only for actual loss or damage suffered and then only to the extent of Garnet’s

invoiced price of the product. Garnet shall not be liable in any case for labor charges for indirect,

special, or consequential damages. Garnet shall not be liable in any case for the removal and/or

reinstallation of defective Garnet equipment. These warranties shall not apply to any defects or

other damages to any Garnet equipment that has been altered or tampered with by anyone other

than Garnet factory representatives. In all cases, Garnet will warrant only Garnet products which

are being used for applications acceptable to Garnet and within the technical speci cations of the

particular product. In addition, Garnet will warrant only those products which have been installed

and maintained according to Garnet factory speci cations.

LIMITATION ON WARRANTIES

These warranties are the only warranties, expressed or implied, upon which products are sold by

Garnet and Garnet makes no warranty of merchantability or tness for any particular purpose in

respect to the products sold. Garnet products or parts thereof assumed to be defective by the

purchaser within the stipulated warranty period should be returned to the seller, local distributor,

or directly to Garnet for evaluation and service. Whenever direct factory evaluation, service or

replacement is necessary, the customer must rst, by either letter or phone, obtain a Returned

Material Authorization (RMA) from Garnet Instruments directly. No material may be returned to

Garnet without an RMA number assigned to it or without proper factory authorization. Any returns

must be returned freight prepaid to: Garnet Instruments Ltd, 286 Kaska Road, Sherwood Park,

Alberta, T8A 4G7. Returned warranted items will be repaired or replaced at the discretion of Garnet

Instruments. Any Garnet items under the Garnet Warranty Policy that are deemed irreparable by

Garnet Instruments will be replaced at no charge or a credit will be issued for that item subject to

the customer’s request.

If you do have a warranty claim or if the equipment needs to be serviced, contact the installation

dealer. If you do need to contact Garnet, we can be reached as follows:

CANADA UNITED STATES

Garnet Instruments Ltd. Garnet US Inc.

286 Kaska Road 5360 Granbury Road

Sherwood Park, AB T8A 4G7 Granbury, TX 76049

CANADA USA

MODEL NO. SERIAL NO.

DATE PURCHASED DATE INSTALLED

YR/MO/DAY YR/MO/DAY

COMPANY NAME

PRINCIPAL CONTACT

ADDRESS

TELEPHONE FAX

IN CANADA RETURN TO:

Garnet Instruments Ltd.

286 Kaska Road

Sherwood Park, AB T8A 4G7

CANADA

SENDER BAR SERIAL NO. (if applicable)

IMPORTANT: WITHOUT THE SERIAL NUMBER OF EACH UNIT IT IS

DIFFICULT TO DETERMINE WARRANTY VALIDITY

DEALERS NAME

WARRANTY CONTACT

ADDRESS

TELEPHONE FAX

IN UNITED STATES RETURN TO:

Garnet US Inc.

5360 Old Granbury Road

Granbury, TX 76049

USA

IMPORTANT: RETURNING THIS CARD WILL ENABLE US TO NOTIFY YOU IN THE EVENT OF A PRODUCT RECALL OR TO SUPPLY YOU WITH REQUIRED PRODUCT SAFETY INFORMATION.

TO MAXIMIZE YOUR WARRANTY PLEASE REGISTER ONLINE AT www.garne nstruments.com OR MAIL THIS FORM IN TO GARNET.

LIMITED WARRANTY REGISTRATION

Table of contents

Popular Recording Equipment manuals by other brands

Sonance

Sonance Impedance-Multiplying Volume Control VC30RIM instruction manual

Akai

Akai MPK mini MK3 quick start guide

Patching Panda

Patching Panda PUNCH MG user manual

Ekssperimental Sounds

Ekssperimental Sounds INDSTRLZR manual

Focusrite

Focusrite Clarett 2Pre USB user guide

Glensound

Glensound EXPRESS MKII Product details