Garnet SeeLeveL II 709 Series Troubleshooting guide

Page 1SeeLeveL II 709 Series Display Manual

HOLDING TANK MONITORS

CANADA

Garnet Instruments

286 Kaska Road

Sherwood Park, AB T8A 4G7

USA

Garnet US Inc.

5360 Old Granbury Road

Granbury, TX 76049

Through decades of experience and development the SeeLeveL tank

monitor series has established itself as the gold standard in level

measurement technology for the Recreational Vehicle industry.

The SeeLeveL II™ has a combination of features, accuracy, reliability, and

diagnostic capability that provide the best possible user experience.

Depending on the model, the SeeLeveL II monitors battery voltage, and

displays percentage of full readouts for FRESH, GREY, GALLEY, and BLACK

tank levels. In addition, the system can display the operating characteristics

of each of the tank sending units, giving it unsurpassed diagnostic

capability.

INTRODUCTION

709 Series Manual_v1.0 - 21-Oct-2022

DISPLAY INSTALLATION GUIDE

& USER MANUAL FOR 709 SERIES

709-2P |709 |709-P3 |709-P3W |709-HP3W

709-BTP3 | 709-RVC |709-RVC PM |709-RVC NLP

709-N2K NLP | 709-4 |709-4P |709-4LP

Document the following information for future reference. See page 4 for

more information.

Model Number: ___________________________________________________________

Serial Number: ____________________________________________________________

Date of purchase: _________________________________________________________

Page 2SeeLeveL II 709 Series Display Manual

SAFETY INFORMATION

WCAUTION: explains safety information that could cause damage to

the product, including data loss.

WWARNING: explains dangers that might result in personal injury or

death.

WNOTE: expands on information for any procedures.

Safety Symbols

Read these instructions carefully and look at the equipment to become

familiar with the device before trying to install, operate, service, or maintain

it. The following special messages may appear throughout this manual

or on the equipment to warn of potential hazards or to call attention to

information that claries or simplies a procedure. “Notes”, “Cautions”,

and “Warnings” have been used to bring special matters to the immediate

attention of the reader.

WWARNING: All power circuits must be fused. If a fuse is not provided with the system

then it is the installer’s responsibility to install a fuse with the maximum rating your model

requires. A relay may be required for models with a pump or heater switch. For

information about the requirements for your model please refer to the Specications

document located on our website.

For more detailed information please refer to the chapter entitled

TROUBLESHOOTING GUIDE”, section “How to avoid damaging the display or pump

switch due to excessive current”.

2022 Garnet Instruments. All rights reserved. No part of this publication may be reproduced,

Transmitted, transcribed, stored in a retrieval system or translated into any language in any

form by any means without the prior written consent of Garnet Instruments. Information in this

manual is subject to change without notice and does not represent a commitment on the part

of GARNET.

TABLE OF CONTENTS

INTRODUCTION........................................................................................................................1

SAFETY INFORMATION .......................................................................................................... 2

ABOUT THE SYSTEM............................................................................................................... 3

Series Model Features Table..................................................................................................... 4

Model and Serial Number Info................................................................................................ 4

INSTALLATION INFORMATION ............................................................................................ 4

Installation Documentation Downloads .............................................................................. 4

Tools and Equipment to Install Display................................................................................ 4

DISPLAY INSTALLATION......................................................................................................... 5

Display Panel Mounting Template ......................................................................................... 5

Connect Wiring to the Display ................................................................................................ 5

OPERATION GUIDE.................................................................................................................. 6

To Read a Water or Sewer Tank Level ................................................................................... 6

To Read the Battery Voltage ..................................................................................................... 6

To Read the LPG Tank Level (if equipped)........................................................................... 6

RV-C Bus Communication (if equipped).............................................................................. 7

NMEA 2000 Network (if equipped) ....................................................................................... 7

CONFIGURATION GUIDE ....................................................................................................... 8

Set the LED Brightness................................................................................................................ 8

Program the Number of Senders........................................................................................... 8

Calibrate the LPG Sender (if equipped) ............................................................................... 9

Set tank capacity (709-N2K NLP only).................................................................................. 9

Calibrate the Battery Voltage................................................................................................... 9

CONFIGURATION GUIDE (Bluetooth Model Only).........................................................10

Program Alarm Set Points for Each Tank...........................................................................10

Trip Polarity....................................................................................................................................10

Inclusion in the Common Alarm Output ...........................................................................10

Failure Polarity (if equipped with LPG) ...............................................................................10

Program the Display as Primary or Secondary................................................................11

Check the Primary/Secondary Mode ..................................................................................11

Enable/Disable the LPG Sender (if equipped with LPG) ..............................................11

Check Hardware/Software Revision ....................................................................................11

TROUBLESHOOTING GUIDE.................................................................................................12

Error Codes....................................................................................................................................12

Sender Diagnostics ....................................................................................................................12

RV-C Diagnostics (if equipped).............................................................................................13

Wiring Diagnostics .....................................................................................................................14

Troubleshooting & Installation Tips ....................................................................................16

WARRANTY & SERVICE INFORMATION............................................................................18

Select from contents list below to go to that page.

Pump and Heater Switch Safety Precaution

Changes or modications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

Page 3SeeLeveL II 709 Series Display Manual

ABOUT THE SYSTEM

The Senders

Each sender panel is a exible self-adhesive printed circuit board which is

adhered to the side of the holding tank. The sender panel can be cut to length

to match the height of the tank, and it auto calibrates itself so that it can read

from Empty to Full regardless of the height of the tank.

In addition to the level, the sender also transmits diagnostic information about

its operation. This information can be used to determine if there is buildup of

sludge on the inside of the tank, or to determine if the sender is damaged or

delaminating from the side of the tank. If sludge buildup in the tank becomes

extreme the gauge will cease to operate properly, so by monitoring the signal

power the tank can be cleaned before the buildup gets excessive.

Multiple senders are available with the ability to double stack the senders to

provide accurate level measurement for tank heights ranging from 4” to 25”.

(See Sender Installation guide for available sender options-link on page 4)

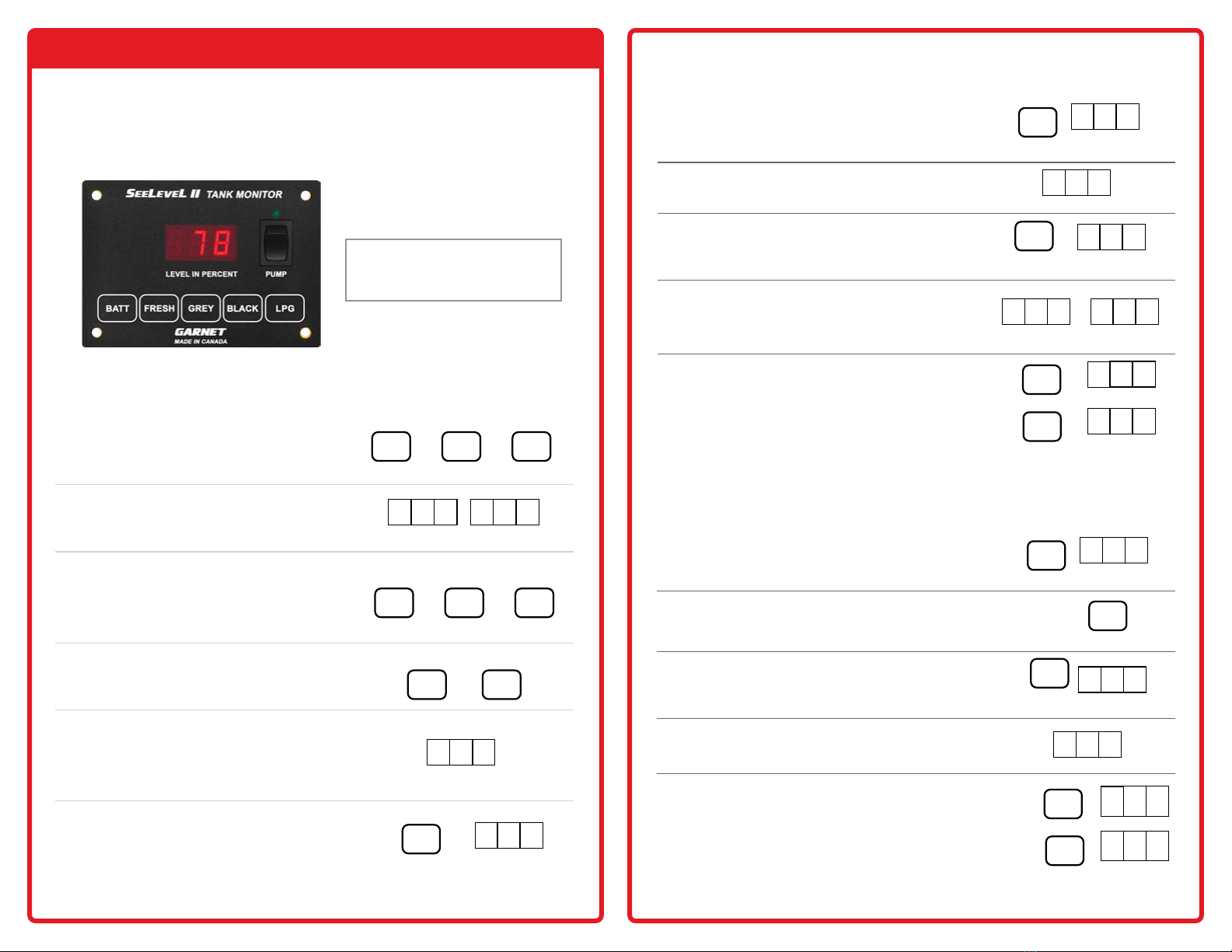

The Display

The display receives the information from sender panels via a single 2 conductor

wire and shows the level information in percent of full on a 3-digit LED display,

from 0% to 100%. When the button for a particular tank is pressed, the display

shows the level for that tank.

Battery Voltage

The system also shows the RV battery voltage by measuring the voltage which

powers the display. The voltage is shown with a resolution of 0.1 volt.

Diagnostics

If a sender is operating properly and connected to the display with good wiring,

then the display will show the level normally. If the wiring is disconnected,

shorted, cut, or if the sender panel is defective, then the display will indicate

an error code. The various error codes are shown in the section entitled

“TROUBLESHOOTING GUIDE”.

With these diagnostic features and the digital nature of the tank level sensing

technology, it is almost impossible for the system to indicate an incorrect water

level, and in the very unlikely event it does occur, servicing is greatly aided with

the diagnostic information.

LPG (if equipped)

The display can use an existing LPG electrical sender to show the LPG level. It

can be automatically calibrated to any sender and shows the level information

in percent of full on a 3-digit LED display, from 0% to 100%.

Bluetooth® (if equipped)

The display has Bluetooth® wireless technology, which allows you to check

your tank levels, battery voltage, and LPG tank levels on any compatible

smartphone or tablet device with a free downloadable app available on both

iTunes and Google Play. This model include one alarm output which can be

used to signal a high or low water or sewer level as required.

(See separate manual for app installation and operation-link on page 4)

RV-C (if equipped)

Models equipped with RV-C are compatible with RV’s that have an RV-C

network system. These models include one alarm output which can be used to

signal a high or low water or sewer level as required.

Dierent Display Types (If equipped)

Displays with RV-C, Bluetooth, or Alarms operate dierently from displays

without these features. In order to keep the tank level and alarm information

current, these displays regularly scan the senders every 10 to 15 seconds. When

a tank button is pressed, the information displayed is recalled from the most

recent scan. A tank on hold is scanned more frequently. Systems with two

displays are congured so that the primary display initiates the scanning and

the secondary display passively listens to the sender information, this way both

displays stay updated without interfering with each other.

Alarm Output (If equipped)

The single common alarm output can be programmed to indicate a high or low

sewage level, a high or low water level, or a high or low LPG level. More than

one alarm can be assigned to the alarm output. This output can be connected

to an indicator light and used to show a high sewer level and/or a low water

level, alerting the user that attention is required. Another example is the alarm

could be used on the black tank to prevent toilet use when the tank is full.

NMEA 2000 Network (If equipped)

Model 709-N2K NLP is NMEA 2000 Network compatible, the tank levels and

capacity are available on the NMEA Bus.

Page 4SeeLeveL II 709 Series Display Manual

Tools and Equipment to Install Display

□screwdriver or power driver

□wire cutters/stripper

□wire crimper

□electrical tape

□butt connectors

□saw to cut a hole for display (if required)

Optional items available to purchase if required. Go to our website for

more information:

□Filler Panel to t previous display hole that is too large.

□Gasket to prevent the display monitor from shorting if mounting to a

metal surface.

INSTALLATION INFORMATION

The installation for the complete system consists of mounting the display

inside the RV, programming, cutting, and mounting the senders to the

sides of the tanks, connecting the wiring, and programming the display.

This manual provides information for all 709 series models. It is important

to read carefully for specic instructions about your model. See Series

Model Feature table to nd out the features on each model.

Installation Documentation Downloads

Other documentation will be required to complete installation for your

specic model. Get them from our website Resource Library either by

selecting the link below or scan the QR code and search for your model.

garnetinstruments.com/holding-tanks-resource-library/

• Sender Installation Manual

• Wiring diagrams

• 709-BTP3 Bluetooth App manual (if equipped)

• Specications - download link at RVgauge.com

Model and Serial Number Info

Before installing your system, look for the model and serial number on the

back of the display, as shown below. Write these numbers on the inside

cover of this handbook for future reference.

No.

Tanks

Pump

Switch

7.5 amp

Pump

Switch

10 amp

Heater

Switch

10 amp LPG BATT RV-C Bluetooth

709-2P 2 . .

709 3 . .

709-P3 3 . .

709-P3W 3 . . .

709-HP3W 3 . . . .

709-BTP3 3 . . . .

709-RVC 3 . . .

709-RVC PM 3 . . . .

709-RVC NLP 3 . . .

709-N2K NLP .

709-4 4 .

709-4P 4 . .

709-4LP 4 . . .

Series Model Features Table

WCAUTION: If a pump or heater requires more amperage than the

switch allows, a relay is required.

RESOURCE

LIBRARY

Page 5SeeLeveL II 709 Series Display Manual

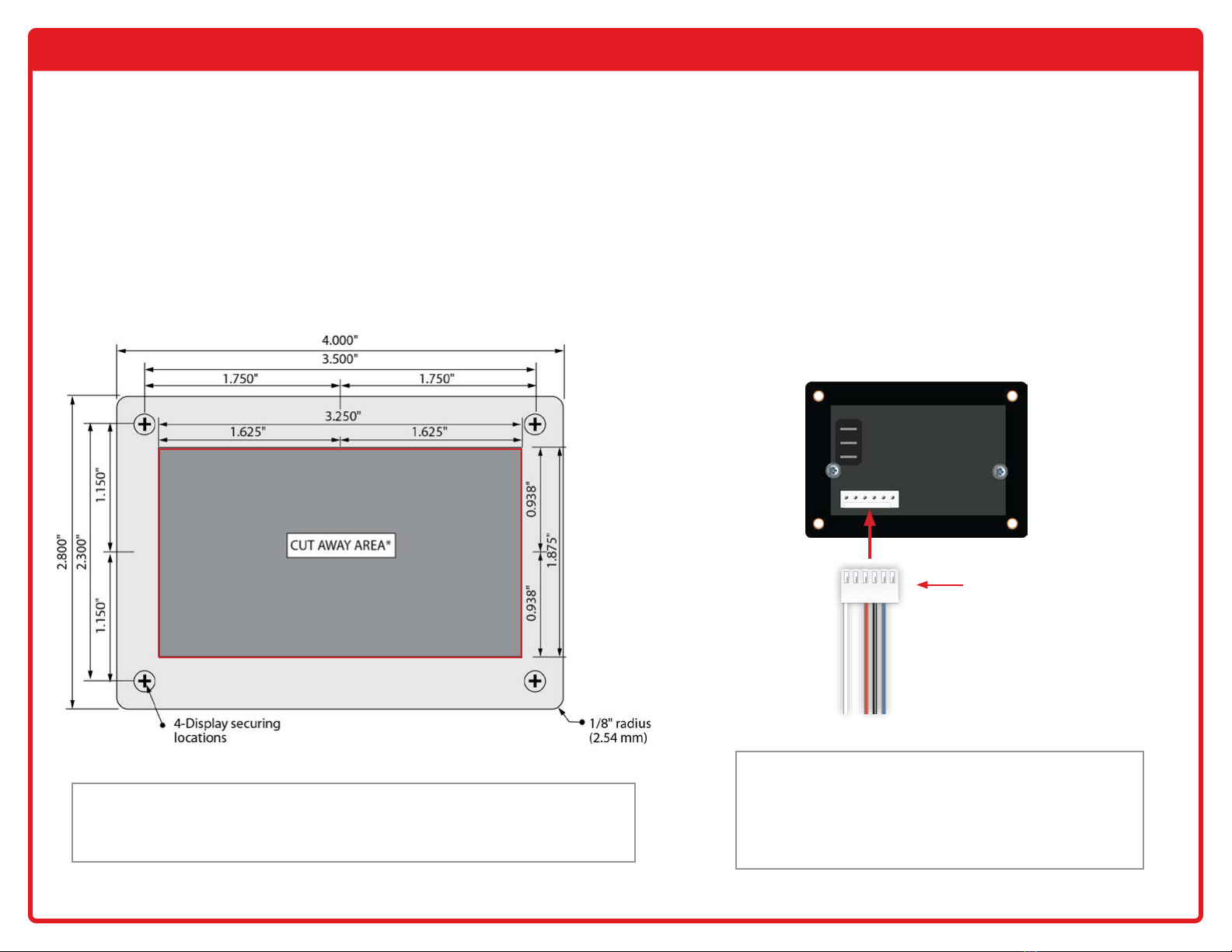

Connect Wiring to the Display

It is easier to connect the wiring to the display connector rst, and

then plug the connector into the display panel. Refer to the wiring

diagram for your model from our Resource Library using the link

or QR code on page 4.

The senders need to be grounded to a single ground wire from the

display. Make sure that the system ground is connected to the

breaker panel ground.

WWARNING: All power circuits must be fused. If a fuse is not

provided with the system then it is the installer’s responsibility to install

a fuse with the maximum rating your model requires.

A relay may be required for models with a pump or heater switch.

For information about the requirements for your model please

refer to the specications page and wiring diagram.

DISPLAY INSTALLATION

The installation consists of mounting the display inside the RV, programming, cutting and fastening the senders to the sides of the holding tanks, connecting the

wiring, and programming the display. When wiring DO NOT use spade connectors to join wires, only use crimp-on butt connectors or solder the wires together.

WCAUTION: If mounting the display in a metal panel or wall there is a risk the display can short

circuit causing permanent damage. Non-conductive mounting spacers are available to purchase to

help prevent damaging the display. Contact Garnet or go to our website for further details. More

installation tips are available in the “Troubleshooting and Installation Tips” section.

Display

connector

Display Panel Mounting Template

Mount the display by cutting a hole in the wall with the given dimensions plus

four screw holes. The thickness of the RV wall needs to be thick enough to retain

the screws. The panel will be mounted onto the wall using the four included

#4 screws, or dierent screws as required. The cutout diagram below is actual

size and can be used as a template. The depth of each model varies 1” - 1 3/8”

(25 - 35 mm), model dependent.

Page 6SeeLeveL II 709 Series Display Manual

OPERATION GUIDE

The display is the only system component that is accessed by the user. All

user input to the display is done using the buttons along the bottom of the

display. Operation of the display is as follows:

1. Press and release button for the

corresponding tank.

2. LED display shows the level in percent.

Display shuts o after about 5 seconds.

3. To read another tank level, battery voltage

or LPG level press that corresponding

button before the 5 seconds is up. The 5

second time-out is restarted every time a

button is pressed.

4. To continuously display reading, press and

release the desired button twice.

5. Continuous display mode is indicated by a

decimal point on the right hand side. The

level is updated once per second. User

can watch the level change while the tank

is being lled or drained.

6. Continuous display mode shuts o after

5 minutes. To end the hold mode sooner,

press any tank button and display will shut

o.

or

or or

FRESH GREY BLACK

BATT LPG

FRESH +FRESH

To Read a Water or Sewer Tank Level

or

FRESH

GREY

BLACK

LEVEL IN PERCENT

7 8

LEVEL IN PERCENT

1. Press and release the BATT button to display

the battery voltage. LED display shows the

battery level in volts.

2. The display shuts o after about 5 seconds.

3. Hold the BATT button and the display will

continuously re-check voltage and show

updated value.

4. The reading may icker back and forth

between two values, for example, 12.6 and

12.7 volts. This is normal behavior for a

digital voltage display.

5. To read a tank level press the corresponding

button before the 5 seconds is up. The 5

second time-out is restarted every time a

button is pressed.

To Read the Battery Voltage

Hold

or

+

BATT

BATT

GREY

LPG

LEVEL IN PERCENT

2 3

LEVEL IN PERCENT

5 6

LEVEL IN PERCENT

12. 6

LEVEL IN PERCENT

12. 7

LEVEL IN PERCENT

12. 6

LEVEL IN PERCENT

12. 0

LEVEL IN PERCENT

=

+FRESH

LEVEL IN PERCENT

78.

LEVEL IN PERCENT

1. Press and release the LPG button. Display

shuts o after about 5 seconds.

2. Press and release the LPG again, to display

a new reading. The 5 second timer will be

restarted.

3. Hold the LPG button and reading will remain

displayed.

4. The display will shut o 5 seconds after the

button is released.

5. To read another tank level or battery voltage

press that corresponding button before the 5

second time is up for the LPG. The 5 second

time-out is restarted every time a button is

pressed.

To Read the LPG Tank Level (if equipped)

+

or

+

Hold

LPG

LPG

LPG

GREY

BAT T

LEVEL IN PERCENT

7 8

LEVEL IN PERCENT

12. 0

LEVEL IN PERCENT

5 6

LEVEL IN PERCENT

5 6

LEVEL IN PERCENT

WNOTE: The model shown is a

709-P3W. Some models may have

dierent button and switch options.

Page 7SeeLeveL II 709 Series Display Manual

RV-C is a communications protocol based on CAN that is used for control,

coordination, and diagnostics. CAN bus interface allows continuous

communication with RV-C compatible systems.

The senders use a default source address of 72 and SPN-ISB instances are

0 for fresh, 1 for black, 2 for grey and 18 for galley (depending how the

display is equipped). The LPG sensor uses a default source address of 73

and a SPN-ISB instance of 3.

1. By disabling the LPG or changing the FRESH/GREY/BLACK to zero

senders, you are disabling that sender’s updates over the RV-C bus as

well.

2. The RV-C has a 4-pin connector as shown in the yellow box in the

image below. The connector pins conform to the RV-C standard.

3. All RV-C displays will have a wired connection for the RV-C Bus in

addition to the 4-pin connector as shown in the green box in the image

below. Refer to the wiring diagrams for each specic model for pin out

details.

RV-C Bus Communication (if equipped)

WNOTE: Anyone that intends on connecting to the RV-C bus should have a knowledge of

the RV-C specication. For more information on RV-C protocol go to: www.rv-c.com

NMEA 2000 is a marine communications protocol that is used for control,

coordination, and diagnostics. The 709-N2K is NMEA 2000 network

compatible, the tank levels and capacity are available on the NMEA bus for

the fresh, grey, and black tanks.

The 709-N2K reports as NMEA device class 75 (sensor communication

interface) with an NMEA function code of 150 (uid level). Garnet

Instrument’s manufacturer code is 873, and the 709-N2K product code

is 15197. The 709-N2K adheres to NMEA database version 2.200. By

changing the FRESH/GREY/BLACK to zero senders, you are disabling that

sender’s updates over the NMEA bus as well.

The display has a 4-pin connector as shown in the yellow box in the image

below. Refer to the wiring diagram for pin out details.

The pin closest to the tab on the connector is pin 1.

You can purchase the connector required to connect to our display on the

Digi-Key website. Digikey part #3M155844-ND.

NMEA 2000 Network (if equipped)

W NOTE: Anyone that intends to connect to the NMEA 2000 bus should have

a knowledge of the NMEA 2000 specication. For more information on NMEA

2000 protocol go to: www.nmea.org.

NMEA Connector Pinout

Pin Signal Description

1 +Voltage

2 CAN-Hi

3 CAN-Lo

4 -Voltage

RV-C Connector

Pin Signal Description

1 Open

2 CAN-Hi

3 CAN-Lo

4 Ground

Page 8SeeLeveL II 709 Series Display Manual

CONFIGURATION GUIDE

Set the LED Brightness

The LED brightness can be adjusted to suit the user and the operational

circumstances. If it is to be used in the service bay area where sunlight can reach

it, the LED brightness should be high.

1. To program the LED brightness, the

display needs to enter the brightness

programming mode. To do this, press and

hold down the BATT button, the display

will show the battery voltage.

2. Continue to hold down the BATT button,

press and hold the GREY button (use

the BLACK button for 709-2P). Continue

to hold down both buttons for about

5 seconds until the display shows

bri indicating brightness programming

mode. Then release both buttons.

3. The current brightness level is displayed.

b-1 is the minimum brightness and b-4 is

the maximum brightness.

4. Press the GREY tank button (use the

BLACK button for 709-2P) to increase

brightness, or the FRESH tank button to

decrease brightness.

5. When the display shows the correct

brightness, press the BATT button to exit

the programming mode.

Hold

+

Hold

BATT

GREY

LEVEL IN PERCENT

b- 2

LEVEL IN PERCENT

b- 3

LEVEL IN PERCENT

b- 4

LEVEL IN PERCENT

b- 1

FRESH

GREY

BATT

LEVEL IN PERCENT

12. 6

LEVEL IN PERCENT

br i

Hold

BATT

Program the Number of Senders

To program the number of senders for each tank, the display needs to enter

the sender programming mode. By default each tank is set for single sender

application. This should only be done at the time of installation; there is no

reason to change the number of senders afterward. Make sure that the number

of senders programmed into the display matches with the number of senders

connected; otherwise the display will show an error.

1. Press and hold down the button for the tank

to be programmed, the display may show a

level or an error message for that tank.

2. Continue to hold down the button for the

tank, and hold down the BATT button. The

display will show dIA (diagnostics). Continue

to hold down both buttons until the display

enters the programming mode, this should

take about 5 seconds (RV-C, BTP3, and N2K

models take about 10 seconds).

3. When the programming mode is entered, the

display will show FrS if entering the number

of senders for the fresh tank, GrS if entering

the Grey tank, or bLS if entering the black

tank. When this occurs release both buttons.

4. The display will show 1SE (one sender) or

2SE (two senders). This is what is currently

programmed into the display. These are the

only two options; the display will not work

with more than two senders per tank.

Note: For classic versions, 1 or 2 senders

are the only options, but for RV-C and BTP3

the options are 0, 1, or 2 senders. 0 senders

removes that tank from the RVC or bluetooth

data.

5. To change the number of senders, press the

tank button, each time the button is pressed

the display will toggle between 1SE and 2SE.

6. When the display shows the correct number

of senders, press the BATT button to save

any changes to exit the programming

mode. Each tank will need to be calibrated

individually using this procedure.

Hold

+

1 Sender 2 Senders

or or

Hold Hold

FRESH GREY

BATT

BATT

LEVEL IN PERCENT

15 E

LEVEL IN PERCENT

25 E

Hold

BLACK

LEVEL IN PERCENT

D1 A

or or

FRESH GREY BLACK

WCAUTION: For displays that have a GALLEY button the GREY and

GALLEY tanks can only have one sender per tank and cannot be stacked.

Fresh Grey Black

LEVEL IN PERCENT

fr S

LEVEL IN PERCENT

bL S

LEVEL IN PERCENT

Gr S

Page 9SeeLeveL II 709 Series Display Manual

The LPG tank must be full when the sender is calibrated, otherwise

the calibration will be invalid. Fill the LPG tank by using an alternate

measurement method, such as weight, a spit valve, or a mechanical gauge

on the tank.

1. To calibrate, press and hold the LPG

button, the display will show some LPG

level.

2. Continue to hold down the LPG button,

press and hold down the BATT button.

Continue to hold down both buttons for

about 5 seconds until the display shows

LPG.

3. When LPG displays release both buttons,

the display will show CAL for a second

and then shut o, completing the

calibration procedure.

4. The LPG can be re-calibrated as many times as desired, although recalibration

should not be needed unless the LPG tank sender or the display has been

replaced.

Calibrate the LPG Sender (if equipped)

Hold

Hold

+

BATT

LPG

LEVEL IN PERCENT

5 6

LEVEL IN PERCENT

LP G

LEVEL IN PERCENT

CA L

Calibrate the Battery Voltage

In order to properly recalibrate the battery voltage, supply 13.0 Vdc to the display.

The display will recalibrate to 13.0 volts, supplying voltage greater or less than

13.0 volts will cause the displayed voltage to be inaccurate.

1. Remove power from the display.

2. Press and hold the BATT button.

Continue to hold the BATT button for the

remainder of the steps.

3. Apply 13.0 Vdc to the display.

4. Continue to hold the BATT button until

the voltage appears. When this occurs

release the BATT button.

Hold

BATT

LEVEL IN PERCENT

13. 0

Hold

BATT

Hold

BATT

LEVEL IN PERCENT

13. 0

WWARNING: This should not normally ever need to be done, it is a factory calibration. In

the unlikely event that the battery voltage is very inaccurate, this procedure can be tried to

correct the error.

1. Press and hold down the tank button to

be programmed, then press and hold the

BATT button. After 15 seconds, the tank

capacity edit mode is displayed.

2. The display will show either FcA if

entering the tank capacity for the fresh

tank, GcA for the Grey tank, or bcA for the

black tank.

3. The unit will display the tank capacity in

US gallons. Press the GREY tank button

to increase, or the FRESH tank button to

decrease.

4. When the display shows the correct tank

capacity, press the BATT button to save

changes and exit programming mode.

Set tank capacity (709-N2K NLP only)

or or

Hold Hold

FRESH GREY

Hold

BLACK

Fresh Grey Black

FRESH

GREY

BATT

LEVEL IN PERCENT

fc A

LEVEL IN PERCENT

bc A

LEVEL IN PERCENT

Gc A

Hold

+BATT

Page 10SeeLeveL II 709 Series Display Manual

Trip Polarity

Inclusion in the Common Alarm Output

Failure Polarity (if equipped with LPG)

1. While the BLACK button is held down, the display

shows “Hi” on the left for a high level alarm or

“Lo” for a low level alarm.

2. After the button is released, the left digit shows

“H” for a high level alarm which means the alarm

turns on (closes) when the uid level is equal to

or higher than the set point, and the alarm is o

(open) when the uid level is below the set point.

3. An “L” shows a low level alarm which means the

alarm turns on (closes) when the uid level is

below the set point, and the alarm is o (open)

when the uid level is equal to or above the set

point.

While the BLACK button is held down, the display

shows an “i” on the right if the alarm is included and

an “n” if not included. After the button is released

the decimal on the right indicates that the alarm is

included in the common alarm output. If any of the

included alarms are on, then the common alarm is

on. All of the included alarms must be o for the

common alarm to be o.

While the LPG button is held down the display shows

“FtF” for fail to full, or “FtE” for fail to empty. After

the button is released, the left decimal on shows fail to

full which means that if the sender fails the alarm acts

as though the tank is full. The left decimal o shows

fail to empty which means that if the sender fails the

alarm acts as though the tank is empty. or

Hold

BLACK

Hold

Hold

BLACK LEVEL IN PERCENT

Hi

LEVEL IN PERCENT

Lo

LEVEL IN PERCENT

Ft F

LEVEL IN PERCENT

FT E

LEVEL IN PERCENT

H

LEVEL IN PERCENT

L

LEVEL IN PERCENT

i

Program Alarm Set Points for Each Tank

To program the alarm point for each tank, the display needs to enter the alarm

programming mode.

1. To enter the alarm programming mode, press

and hold down the button for the tank to be

programmed, the display may show a level or

an error message for that tank.

2. While continuing to hold down the button

for the tank, press and hold down the BATT

button. The display will immediately show

”dIA” (diagnostics), continue to hold down

both buttons until the display enters the alarm

test menu, this should take about 5 seconds.

The LPG tank does not show “dIA”.

3. When the alarm test menu is entered, the

display will show “ALr” for about 5 seconds.

Release the buttons.

4. Depending on which tank is selected and

the status of the alarm, the display will show

a simulated low uid level below the alarm

set point (FLo, GLo, bLo, LLo) or a high

level above the alarm point (FHi, GHi, bHi,

LHi). The alarm test menu allows the alarms

to be manually activated to test. The same

tank button toggles the simulated uid level

between low and high.

5. To set the alarm point, press and hold the

same tank button, after about 3 more seconds,

the display will show “FAS” (Fresh Alarm Set),

“GAS”, or “bAS”, “LAS”, depending on which

tank is selected. Release the button.

or or

Hold Hold Hold

Hold

+

Q

E

8

FRESH GREY BLACK

BAT T

LEVEL IN PERCENT

GL o

LEVEL IN PERCENT

bL o

LEVEL IN PERCENT

lL o

LEVEL IN PERCENT

FL o

LEVEL IN PERCENT

GH i

LEVEL IN PERCENT

bH i

LEVEL IN PERCENT

lH i

LEVEL IN PERCENT

FH i

LEVEL IN PERCENT

GA 5

LEVEL IN PERCENT

bA 5

LEVEL IN PERCENT

lA 5

LEVEL IN PERCENT

FA 5

BATT

LPG

FRESH

GREY

BLACK

GREY

or

To set the alarm point, the GREY button increases the

value.

The FRESH button decreases the value.

If the FRESH or GREY buttons are held down, after 1

second the numbers will change quickly. The alarm point

can be from 0% to 99%.

The BLACK button cycles through the trip polarity and

the inclusion in the common alarm output.

The LPG button toggles the failure polarity.

The BATT button saves and returns to the previous menu.

6.

FRESH

LEVEL IN PERCENT

di A

LEVEL IN PERCENT

AL r

CONFIGURATION GUIDE (BLUETOOTH MODEL ONLY)

LEVEL IN PERCENT

H90.

LPG

LEVEL IN PERCENT

L2 0

LEVEL IN PERCENT

H90.

.

LEVEL IN PERCENT

n

(Low level alarm at 20%, not included in

the common alarm and fail to empty.)

(Hi level alarm at 90%, included in

the common alarm and fail to full.)

(Alarm included in common output)

Page 11SeeLeveL II 709 Series Display Manual

Program the Display as Primary or Secondary

Check the Primary/Secondary Mode

This setting should normally only need to be done when installing the

gauge. An optional second display can be added to the system. This

allows for a display in the service bay and one inside the coach. To avoid

reading errors when using dual displays, one display needs to be set to

secondary mode. A display in secondary mode monitors the primary

displays sender requests and will only scan the tank levels at a much

slower rate if the primary display is disconnected. The alarms are inactive

on the secondary display. All RVC displays are primary by default.

To program a display to be either primary or secondary display:

1. With power removed, press and hold the

BATT and FRESH buttons and then power

the display.

2. The display will show “Scn” for 5 seconds,

then change to “SEC” or “Pri” depending on

current programming.

3. The FRESH button sets the mode to PRIMARY

the GREY button to SECONDARY

the BATT button saves and exits.

+

1. Press and hold down the BATT button, the

display will show the battery voltage.

2. While continuing to hold down the BATT

button, press and hold down the BLACK

button.

3. Continue to hold down both buttons for

about 5 seconds until the display shows

“Pri” for primary mode or “SEC” for

secondary mode. When viewing is complete,

release both buttons to return to normal

operation.

or

LEVEL IN PERCENT

Sc n

LEVEL IN PERCENT

SE C

LEVEL IN PERCENT

Pr i

LEVEL IN PERCENT

SE C

LEVEL IN PERCENT

Pr i

LEVEL IN PERCENT

12. 0

Check Hardware/Software Revision

Hardware and software updates may be periodically released to add

features. To check the hardware and software version of the display, use

the following procedure.

1. Press and hold down the BATT button, the

display will show the battery voltage.

2. While continuing to hold down the BATT

button, press and hold down the FRESH

button.

3. Continue to hold down both buttons for

about 5 seconds until the display shows a

number such as “4.10”, the rst number is the

hardware version and the last two numbers

are the software version. When viewing is

complete, release both buttons to return to

normal operation.

+

LEVEL IN PERCENT

12. 0

LEVEL IN PERCENT

4. 1 0

Enable/Disable the LPG Sender (if equipped with LPG)

The LPG sender can only be disabled from the primary display of

RVC and Bluetooth models. If these steps are used on the secondary

display, no change will result.

1. Press and hold down the LPG button.

2. While continuing to hold down the LPG

button, press and hold down the BATT

button. Continue to hold down both buttons

for about 10 seconds until the display shows

“AbL”.

3. When this occurs release both buttons, the

display will show “En” for enabled or “diS”

for disabled.

4. Press the LPG button to switch between

enabled and disabled.

5. Press the BATT button to save and exit the

menu.

Hold

or

Hold

+LPG

BATT

BATT

+

LEVEL IN PERCENT

E n

LEVEL IN PERCENT

di 5

LEVEL IN PERCENT

Ab L

LEVEL IN PERCENT

LP G

BAT T FRESH

FRESH GREY

BAT T

Hold

BATT

Hold

BLACK

+

Hold

BATT

FRESH

Page 12SeeLeveL II 709 Series Display Manual

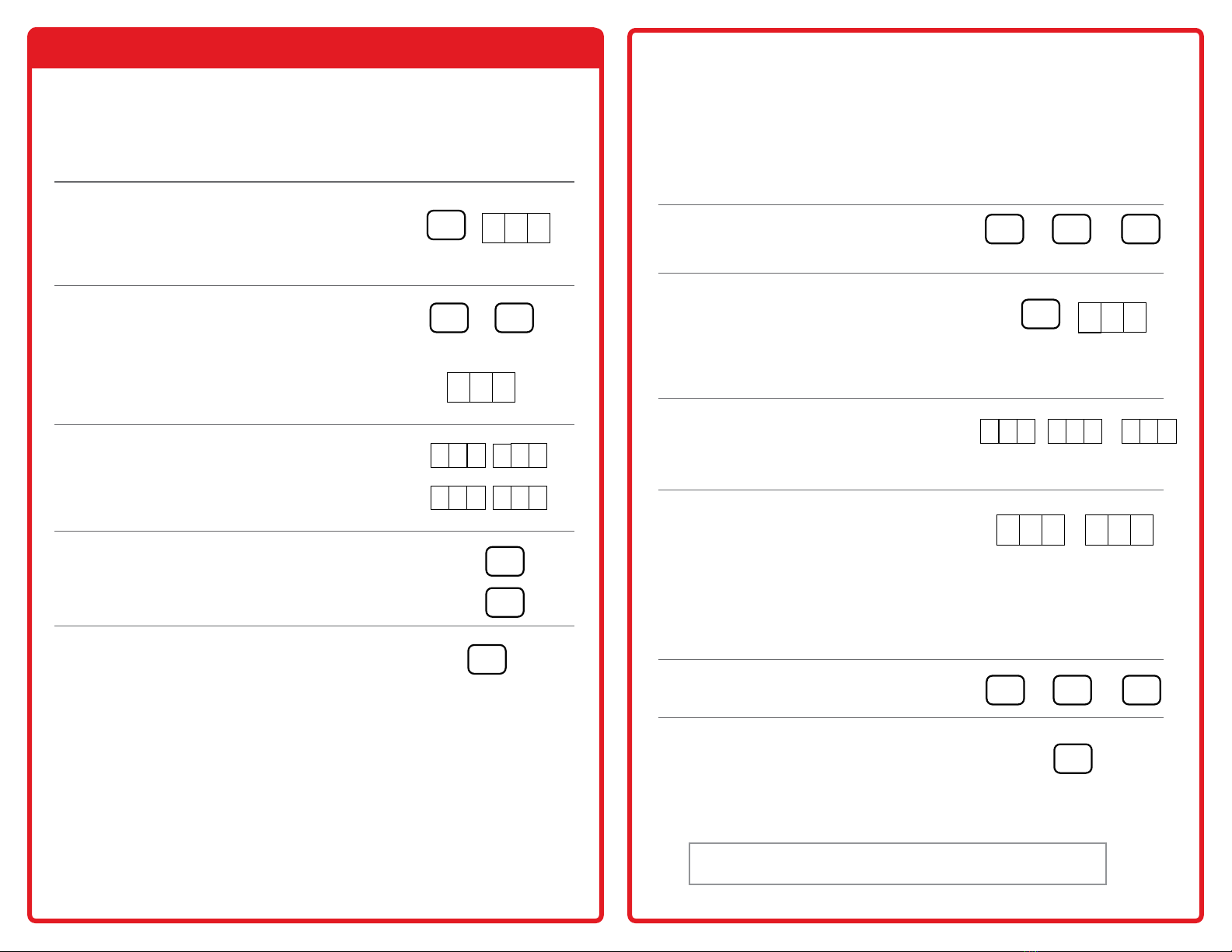

TROUBLESHOOTING GUIDE

DISPLAY CODE POSSIBLE CAUSE SOLUTION

Open circuit 1. If a sender is unresponsive.

2. There is an open circuit in the

wiring so the sender is not

connected. See Wiring Diagnostics

owchart on page 14.

Short circuit Blue communication wire from

senders to display is shorted to

ground.

Error Indicates signal corruption

between the sender and display

due to bad wiring, bad senders,

or multiple senders programmed

the same.

Check all the senders

to make sure they are

programmed correctly.

If they are, replace the

sender that is creating

the error.

Stacked senders

The display has been

programmed for a single sender

where double-stacked senders

have been connected. The display

has not been set to look for two

senders

Change the senders or

reprogram the display as

required.

The display has been

programmed for double-stacked

senders and one of these error

codes are showing:

• ntP - only the bottom sender is

reporting

• nbo - only the top sender is

reporting

Correct the programming

on the sender.

The memory used to store

programming for battery voltage

calibration value and tank sender

signal values has failed.

Replace the display.

The only LPG diagnostic code is

the open circuit. If the wiring to

the LPG sender is shorted then the

LPG will always show “0”.

Error Codes

If a sender or its wiring is not operating properly, the following codes are

shown on the display:

LEVEL IN PERCENT

OP n

LEVEL IN PERCENT

sh t

LEVEL IN PERCENT

Er r

LEVEL IN PERCENT

St A

LEVEL IN PERCENT

nt P

No top sender

LEVEL IN PERCENT

nb o

No bottom sender

LEVEL IN PERCENT

CA L

Calibration failure

LEVEL IN PERCENT

OP n

For LPG only

W NOTE: There are no diagnostics for battery voltage.

Reviewing Sender Diagnostics

The sender diagnostics can be reviewed periodically to check for any

degradation of the tank senders. If a sender appears to be malfunctioning,

reviewing the diagnostics should be the rst step in the troubleshooting

process. There are two diagnostics for the senders:

Sender signal power is an indication of how much signal is being

transmitted through the tank wall and picked up by the receive part of the

sender. Sender height is the number of receive segments present in the

sender.

SIGNAL POWER PROBLEM POSSIBLE CAUSE RESULT

If the signal power is too low.

It can indicate a sender

which is detached from

the tank, excessive

buildup on the inside of

the tank, bad wiring to

the sender, low battery

voltage, or a defective

sender.

Typical signal power

should be 50% to

60%.

The minimum signal

power for proper

operation is 20%.

P00 is 100%

SENDER HEIGHT PROBLEM RESULT

The number of segments reporting is

less than the amount of segments on the

sender.

One or more segments are not

reporting. Either cut sender to a

shorter length or replace the sender.

The senders always auto calibrate to the length that they are cut, so this diagnostic

allows the user to conrm the length and to make sure that the auto calibration is

working properly.

Sender Diagnostics

These diagnostics can be used to check the senders:

Page 13SeeLeveL II 709 Series Display Manual

1. Press and hold the button for the tank to be

checked, the display will show the level for that

tank.

2. While continuing to hold down the button for

the tank, press the BATT button.

3. When the display shows ”dIA”, release the

buttons, the display will then change to showing

the signal power diagnostic.

4. This is indicated by a “P” showing on the left

digit, for example ”P26” indicates a 26% signal

power. “P00” is 100%.

5. The signal power will show for 5 seconds. The

display will then change to showing the sender

height.

This is indicated by a small “h”showing on the

left digit, for example “h 6” indicates that the

sender has 6 receive segments.

6. After 5 seconds of showing the height, the

display will shut o.

Check Signal Power Diagnostics

+ +

LEVEL IN PERCENT

h6

LEVEL IN PERCENT

7 8

LEVEL IN PERCENT

di A

LEVEL IN PERCENT

P2 6

LEVEL IN PERCENT

FMI (Failure Mode Identier) Table

1Datum value before normal range DIS or OFF

2Datum value erratic or invalid ERR, BOT, TOP, NTP, NBP,

or SIN

5Open circuit, or output current below normal OPN

6Grounded circuit, or output current above

normal SHT

RV-C Diagnostics (if equipped)

Here is a list of the messages broadcast over the RV-C bus:

Hold

FRESH

Hold

FRESH BAT T

Page 14SeeLeveL II 709 Series Display Manual

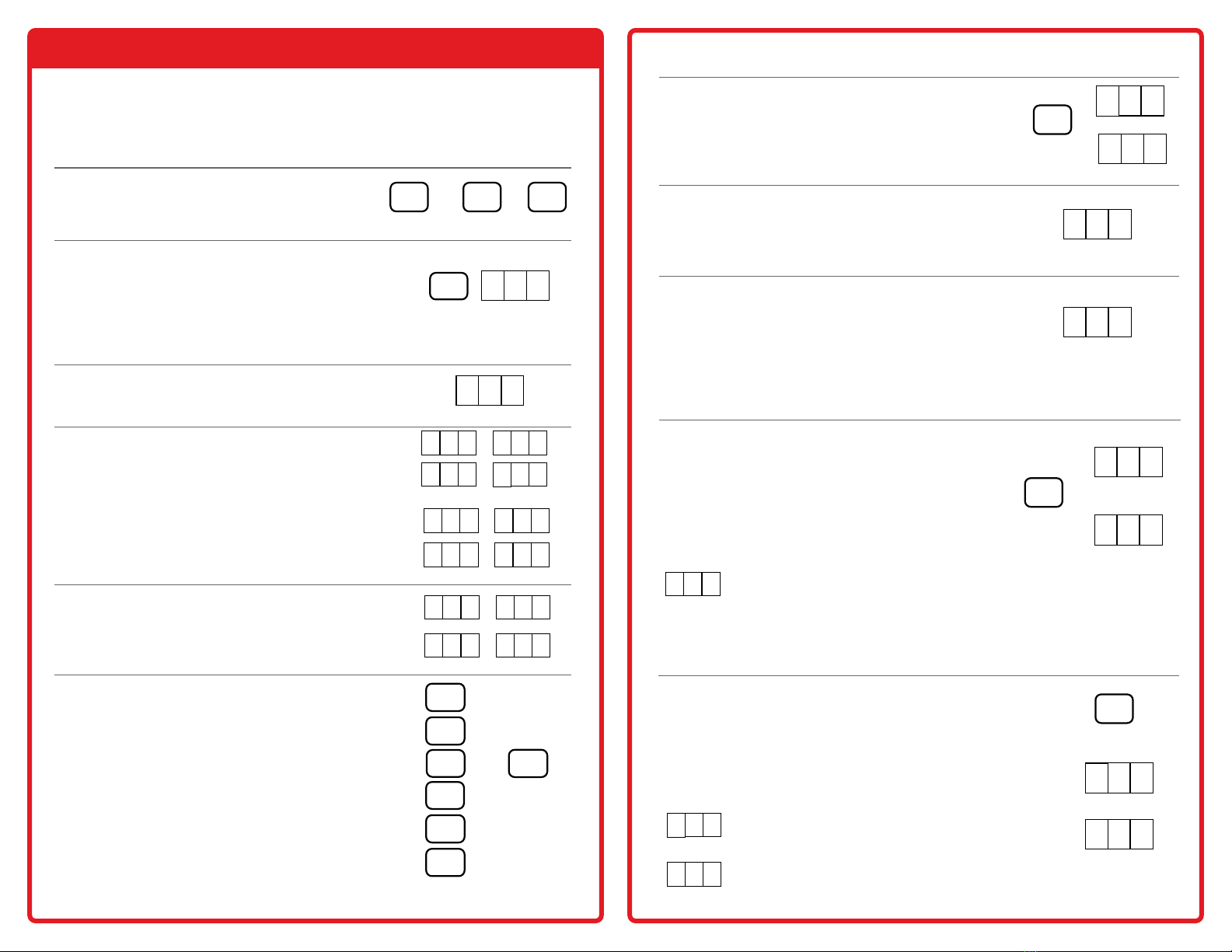

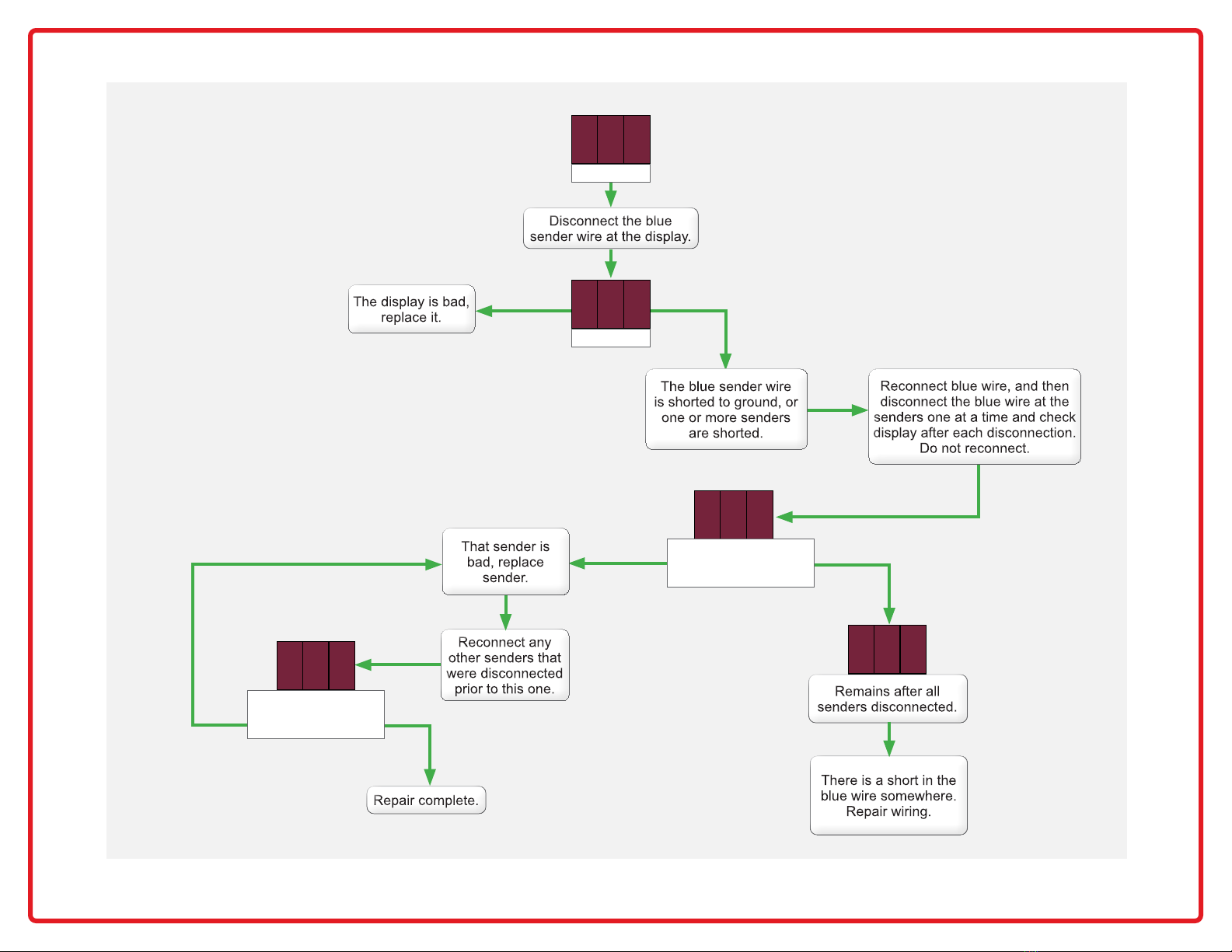

Wiring Diagnostics

OPEN CIRCUIT O P n

S h t

Shows?

S h t

Shows?

S h t

Shows?

ALL SINGLE

NO YES

NOYES

NO YES

Shows?

Page 15SeeLeveL II 709 Series Display Manual

SHORT CIRCUIT S h t

Shows?

S h t

Remains?

S h t S h t

YES NO

YES NO

NOYES

S h t

Comes back on

when sender

reconnected?

Disappears

when a sender is

disconnected?

Page 16SeeLeveL II 709 Series Display Manual

Troubleshooting & Installation Tips

What to do if the system freezes or is unresponsive

If the display is unresponsive, it may be “hung” due to a static discharge or electrical

noise. Try rebooting it by shutting o the 12V power to it for a few seconds, then

turning it back on.

What to do if operation becomes erratic or stops completely

Make sure all wiring connections are solid. Do not use spade connectors to join

wiring as they will degrade over time. Use insulated crimp-on butt connectors or

solder and insulate the wire connections.

What to do in dual console systems if the two displays do not read the same

For dual display console applications, if the consoles disagree the most likely

reason is a bad console ground. Both console grounds, and the sender grounds,

must be connected together with ground wiring. Do not depend on metal chassis

components. See item 2 in the following section for further details.

What to do if readings jump or are inaccurate

1. We have had a few instances where 120VAC interference has caused the

readings to stall and create a gap; readings would skip from 50% to 70% and

then begin to function again. The cause was wiring between consoles and

senders being tied too close to entrance boxes for shore power or bundled with

other high AC voltage lines or junction boxes.

2. Always ground the senders and the console to the same ground circuit. This is

very important; RV’s can have several ground circuits with resistance between

them. We have had instances where two consoles are installed with a dierent

ground for the service bay console and interior console. If you see dierent

levels from each console on the same tank, then the ground circuit is not

common. Connect both consoles to the same ground back to the breaker

panel ground point.

What to do if the system indicates a residual or non-zero water level even

though the tank is drained completely

1. This can be due to a convex tank bottom or a sloped tank bottom. In the case

of the convex bottom tank a ring of water may remain after draining. In the

case of the sloped bottom (to the drain valve side) a very small amount of

water left in the tank will result in a non-zero level indication. In both of these

cases, temporary installation of the sender using duct tape or masking tape will

allow the installer to check the tank level before committing to a nal sender

position. After cutting the sender to length and connecting the wires, be

sure to tape down both sides of the sender to eliminate air gaps between the

sender and tank surface which can cause low signal strength and unpredictable

performance. The ends of the sender must be at least ¼” to ½” away from the

tank bottom and top to allow for wall thickness. The exterior bottom & top

of the tank are not the same as the interior bottom & top; depending on the

tank wall thickness the inside height is ½” to 1” shorter than the outside height.

Knowing the wall thickness of your tank will allow you to nd the optimal

sender position; placing the sender where it can “see” the water will ensure

proper level calculation and sender operation.

2. The signal strength should be in the 50% range for best performance. If the

signal strength is in the 20% range it is indicative of a high resistance in a

connector, a bad ground, or improper bonding of the sender to the tank (a

possible air gap on one or both sides of the sender).

3. With the console installed you can check the level on each tank, if you get an

indicated level of 10% to 20% and you know this is too high, reposition the

sensor board as follows:

4. The close proximity of metal to the sender can be misinterpreted as water,

since they have similar electrical characteristics. Any metal such as steel,

aluminum, copper, or brass can aect the sender reading if it is closer than

about 2” from the face of the sender. If there are metal frame pieces, brackets,

straps, pipes, ducts, etc. close to the sender you may have to move the sender

away from them. Again, trial positioning using tape is necessary until the

problem disappears. Flexible pieces of metal can be held away from the sender

with rubber wedged between the sender and the metal. If the metal is o

to the side of the sender, or just butting to the edge then it is usually not a

problem, particularly on the right hand side of the sender.

5. Make sure that metal doors or covers are far enough away from the sender as

well, once everything is closed up the positioning may change. The symptoms

of exposure to large metal components are usually a non-zero reading when

the tank is empty, or the level appearing to jump suddenly as the tank is

drained or lled.

6. On fresh tanks there is sometimes a potential to not be able to use all the

water in the tank, we suggest you elevate the fresh sender 1” o the tank

bottom and position the top of the sender to allow for vent position (if the vent

is on the side of the tank). This way you should see ‘0’ before the pump starts

to suck air. Some tanks have a sump style draw system, in this case there is no

concern with unusable water, just allow for the wall thickness when positioning

the sender board (usually ½” to 1” margin from the outer shell). If the sender is

positioned above the vent then the maximum reading may be less than 100%.

7. There may be a buildup on the inside walls of black and grey tanks. We get

calls occasionally about older coaches that have not been in service for a few

years in which the black tank will now indicate a level even though it is empty.

The likely cause is that the tank has a signicant build-up, probably exceeding

¼” to ½” thick! Redex is not an acceptable chemical to promote clean tank

walls; it is far too slow to get the breakdown action started. Use an RV type

of liquid chemical, we suggest Tissue Digester, Sensor Cleaner, or the latest

we have used called Happy Campers Holding Tank Extreme Cleaner available

at www.happycampersworld.com. The next time you take a trip, leave with

WNOTE: In the case of a convex tank bottom, usually found on large at tanks,

raising the sender is the best solution to accomplish a zero reading when the

tank is empty. This may result in having to shorten the sender by an additional

segment.

On sloped tanks, which are used to promote complete draining, one alternative

is to measure the end of the tank opposite from the drain valve. It may be

necessary to extend the wire harness to be able to measure on the optimal side.

On the drain valve side, the best choice is to elevate the sender to avoid reading

a puddle at the drain valve.

Page 17SeeLeveL II 709 Series Display Manual

a high concentration of the chemical in the tank and approximately 30% full

of fresh water. Hopefully you can drive for 2-3 days allowing the tank levels

to rise through normal use. We recommend that you exceed the level that

you see the system report when the tank is empty. After the sloshing and the

soaking hopefully the build-up will be ushed away when the tank is drained

and ushed. If you still have symptoms the treatment may required a few more

times. The waste did not build up on the tank wall in one day, so it may not

dissolve in one treatment! The build-up looks like water to the system since it

holds a signicant volume of water in the build-up area. It takes much more

than a lm or piece of tissue to cause the error.

What to do if the system reads a zero water level at all times, or does not reach

100%

1. This may be due to excessive tank wall thickness. We have tested the sender

on an actual tank with 3/8“ wall thickness to ensure proper operation. If you

encounter an excessively thick tank wall the symptom will be a zero reading

regardless of the actual tank level. The cross check would be to test the sender

on another tank by taping it in place temporarily, if it now works the tank wall

thickness is well over 3/8”. You can also use a 1 gallon jug or a 5 gallon pail as

a test tank to crosscheck operation of the sender.

2. A symptom we have seen is the sender will not indicate 100% when the tank is

full. If the sender is positioned too high on the tank, then water cannot reach

high enough on the sender for it to read 100%. The top of the sender must be

at least ¼” to ½” away from the top of the tank to allow for wall thickness.

3. Another possibility is a tank wall thickness issue that may occur at the corners

or edges of the tank. This has not been a common issue, and the only

correction you can make is to move the board slightly lower, away from the

thick area.

What to do if sender delamination occurs

1. We have had reports of the senders literally falling o the tanks or showing

serious delamination. This is likely caused by a lack of tank surface preparation.

Surface prep is very simple, wipe the area to be adhered to with products like

Pro Bond, alcohol, or acetone. Do not use thinners because they leave residues

which attack the adhesive. Ambient temperatures of less than 60°F or 15°C

prevent the bonding agents in the adhesive from working properly; use a heat

gun to warm the tank surface if necessary. Also be sure the surface is dry, again

a heat gun is the best way to dry the bonding area. Finally, the surface of the

tank must be smooth. The adhesive works much better on smooth surfaces,

if necessary use an orbital sander with ne grit paper (220 grit) to quickly

accomplish the desired smoothness.

2. Another possibility is the wiring harness pulling on the sender. Make sure the

wiring to the tank sender is well supported so that it does not put a load on

the sender. Be sure to support all connecting harnesses; do not let the board

support the harness, this will in time cause delamination of the board from

the tank. One simple way to do this is to use Gorilla tape across the top of the

sender at a 90 degree angle to the sender orientation, with the wiring held in

place by the tape. The wires from the sender must be routed straight up or to

the right for reliable operation.

How to protect the sender from road spray and debris

3. On installations where the holding tank is exposed to under chassis road spray

and ying rocks etc. we recommend the use of an auto body undercoat, which

is easily purchased in auto parts stores. This tar based material clings well to

the senders and protects from water and debris.

4. One material in particular is 3M Professional Grade Rubberized Undercoating,

product code 03584. Another product that works well is a Dominion Sure Seal

rubberized undercoating such as Gravel Guard Rocker Guard Coating.

5. After the system is completed and tested apply the undercoat over the

complete board using two coats. Do not use lacquer, enamel paint, or plastic

paint for auto bumpers as these contain chemicals that will dissolve the

conformal coating on the board and cause malfunctions.

How to avoid damaging the display when mounting

1. If mounting the display in a metal panel or wall there is a risk of permanent

damage due to a jagged opening or too small of an opening. The metal panel

can short-circuit the display rendering it inoperable and requiring the installer

to replace it. Ensure that the edges of the cutout are smooth and that no

material is bent outward where it can dig into the display. Make sure that the

cutout is large enough so that the display can be easily inserted without having

to angle it. There is a ½” border all around the display to cover the edge of the

hole, so if the hole is a bit larger than the minimum requirement it will still be

covered by the display.

2. When fastening the display to the panel, make sure that it is centered in the

hole and not resting on one edge.

3. Non-conductive mounting spacers are available to help prevent damaging the

display. Contact Garnet for further details.

How to avoid damaging the display or pump switch due to excessive current

1. Please be aware that the water pump switch circuit has a limitation on current

draw of 7.5 amps, some large pumps can draw over 10 amps. These high drain

pumps must use a relay or the display console printed circuit will overheat and

damage the display permanently.

2. If the 12V supply line from the electrical panel does not have a 7.5 amp

fuse rating, please be sure to install the supplied fuse holder with a 7.5 amp

automotive style fuse inline on the +12V red wire.

Page 18SeeLeveL II 709 Series Display Manual

WARRANTY & SERVICE INFORMATION

Find warranty claim process information refer to our support page on our

website:

DISCLAIMER OF WARRANTY ON HARDWARE

Garnet Instruments warrants equipment manufactured by Garnet to be free from defects in

material and workmanship under normal use and service for a period of one year from the date

of sale from Garnet or an Authorized Dealer. The warranty period will start from the date of

purchase or installation as indicated on the warranty card. Under these warranties, Garnet shall

be responsible only for actual loss or damage su ered and then only to the extent of Garnet’s

invoiced price of the product. Garnet shall not be liable in any case for labor charges for indirect,

special, or consequential damages. Garnet shall not be liable in any case for the removal and/or

reinstallation of defective Garnet equipment. These warranties shall not apply to any defects or

other damages to any Garnet equipment that has been altered or tampered with by anyone other

than Garnet factory representatives. In all cases, Garnet will warrant only Garnet products which

are being used for applications acceptable to Garnet and within the technical speci cations of the

particular product. In addition, Garnet will warrant only those products which have been installed

and maintained according to Garnet factory speci cations.

LIMITATION ON WARRANTIES

These warranties are the only warranties, expressed or implied, upon which products are sold by

Garnet and Garnet makes no warranty of merchantability or tness for any particular purpose in

respect to the products sold. Garnet products or parts thereof assumed to be defective by the

purchaser within the stipulated warranty period should be returned to the seller, local distributor,

or directly to Garnet for evaluation and service. Whenever direct factory evaluation, service or

replacement is necessary, the customer must rst, by either letter or phone, obtain a Returned

Material Authorization (RMA) from Garnet Instruments directly. No material may be returned

to Garnet without an RMA number assigned to it or without proper factory authorization. Any

returns must be returned freight prepaid to: Garnet Instruments, 286 Kaska Road, Sherwood Park,

Alberta, T8A 4G7. Returned warranted items will be repaired or replaced at the discretion of Garnet

Instruments. Any Garnet items under the Garnet Warranty Policy that are deemed irreparable by

Garnet Instruments will be replaced at no charge or a credit will be issued for that item subject to

the customer’s request.

If you do have a warranty claim or if the equipment needs to be serviced, contact the installation

dealer. If you do need to contact Garnet, we can be reached as follows:

CANADA UNITED STATES

Garnet Instruments Garnet US Inc.

286 Kaska Road 5360 Granbury Road

Sherwood Park, AB T8A 4G7 Granbury, TX 76049

CANADA USA

www.garnetinstruments.com/support/

NOTES:

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

_______________________________________________________________________________

This manual suits for next models

13

Table of contents

Popular Tank Equipment manuals by other brands

TransTank

TransTank TransLoc Product handbook

Morrison

Morrison 915 Series Installation, operation and maintenance instructions

Trane

Trane RSDT1000F0 Installation, operation and maintenance

Alfalaval

Alfalaval GJ 10 instruction manual

Alfalaval

Alfalaval Toftejorg SaniJet 20 instruction manual

Graf

Graf Carat series Installation and maintenance instructions