Garrecht Avionik VT-01 User manual

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 1

VT-01

Secondary Surveillance Radar

Transponder Mode-S

Installation Manual

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 2

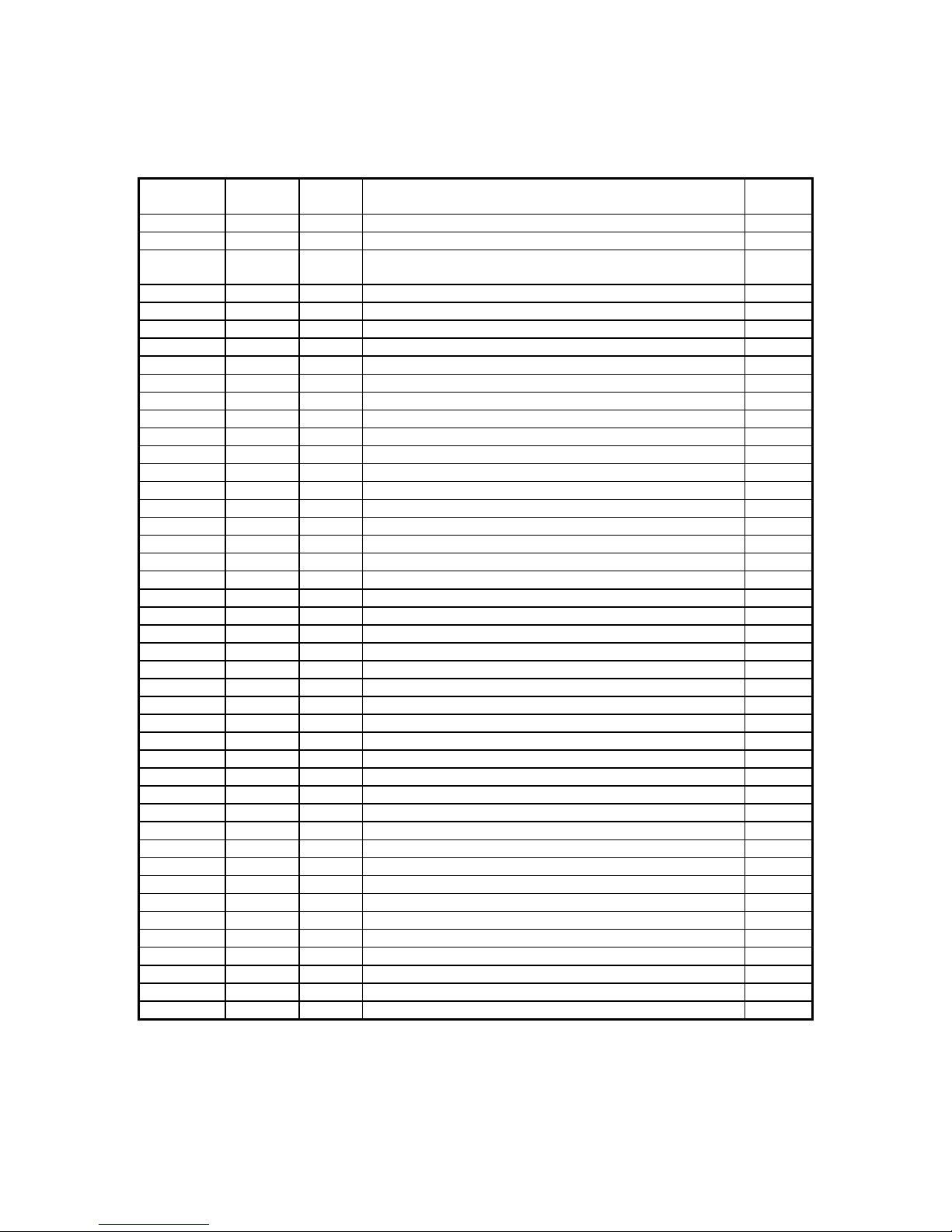

Record of Revisions

Always keep this page in front of this document.

Date Revision

Page(s)

Description of Change Inserted

by

11.08.05 1.0 all released JG

27.09.05 1.1 all Minor modifications in wording after review JG

12.01.06 1.2 all chapter 11, added:

- Information about setting up aircraft related data

JG

14.02.07 1.3 all new P/N VT-0104 (VT-01 UltraCompact) introduced JG

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 3

1.Table of Contents

Record of Revisions.................................................................................................... 2

1. Table of Contents ................................................................................................... 3

2. Preface: .................................................................................................................. 5

3. Unpacking and part identification............................................................................ 5

3.1. VT-01: .............................................................................................................. 5

3.2. VT-01UltraCompact ......................................................................................... 6

4. Input Devices (human machine interface) .............................................................. 7

4.1. On/Off key........................................................................................................ 7

4.2. Ident key .......................................................................................................... 7

4.3. Mode-key ......................................................................................................... 7

4.4. Double shaft rotary encoder............................................................................. 7

5. Technical data and specifications........................................................................... 8

5.1. General ............................................................................................................ 8

5.2. Certification base ............................................................................................. 9

5.3. Equipment class............................................................................................. 10

5.4. Mode-S transponder level .............................................................................. 10

5.5. Equivalences to FAA TSO-C112 Classes:..................................................... 10

5.6. Limitations...................................................................................................... 10

5.7. Environmental categories............................................................................... 11

5.7.1. VT-01....................................................................................................... 11

5.7.2. VT-01 UltraCompact................................................................................ 12

5.8. Software level................................................................................................. 13

5.9. Telecommunication specifications.................................................................. 13

5.10. Logic of on-Ground interface........................................................................ 13

5.11. CAN-Bus interface ....................................................................................... 13

6. Aircraft installation ................................................................................................ 14

6.1. Installation VT-01 - single-block ..................................................................... 14

6.1.1. Assembling the steering unit and central unit: ......................................... 14

6.1.2. Panel mounting........................................................................................ 15

6.1.3. Static pressure connection ...................................................................... 15

6.1.4. Wiring ...................................................................................................... 16

6.2. Installation VT-01 - two-block......................................................................... 19

6.2.1. Installing the mounting kit / cradle ........................................................... 20

6.2.2. Panel mounting........................................................................................ 20

6.2.3. Static pressure connection ...................................................................... 20

6.2.4. Wiring ...................................................................................................... 21

6.2.5. Cradle handling ....................................................................................... 25

6.3. Installation VT-01 UltraCompact .................................................................... 27

6.3.1. Panel mounting........................................................................................ 27

6.3.2. Static pressure connection ...................................................................... 27

6.3.3. Wiring ...................................................................................................... 27

7. Antenna installation .............................................................................................. 30

7.1. General .......................................................................................................... 30

7.2. Special instructions for antenna installation in composite aircraft .................. 30

7.2.1. Mounting Preparation .............................................................................. 30

7.2.2. Ground Plane Size .................................................................................. 30

8. Antenna cable....................................................................................................... 31

9. Post installation configuration and setup .............................................................. 32

9.1. Setting up pilot specific data .......................................................................... 32

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 4

9.1.1. Flight ID / aircraft registration................................................................... 32

9.1.2. Display contrast....................................................................................... 33

9.1.3. Display illumination.................................................................................. 33

9.2. Setting up password protected data............................................................... 34

9.2.1. Illumination .............................................................................................. 34

9.2.2. LCD contrast............................................................................................ 34

9.2.3. Power-up Mode ....................................................................................... 34

9.2.4. Aircraft data ............................................................................................. 35

10. Determining installed equipment performance ................................................... 38

10.1. Checking equipment installation................................................................... 38

10.2. Equipment performance............................................................................... 38

10.3. Flight test procedures................................................................................... 40

10.3.1. General.................................................................................................. 40

10.3.2. Flight tests instructions .......................................................................... 40

Appendix A - Dimensions ......................................................................................... 41

VT-01 Steering unit and System unit..................................................................... 41

VT-01 Mounting kit (with craddle) ......................................................................... 42

VT-01 UltraCompact ............................................................................................. 43

Appendix B ............................................................................................................... 44

Appendix C ............................................................................................................... 45

Assembling BNC/TNC plugs for AIRCELL 7 coaxial cable ................................... 45

Assembling the Sub-D Connectors for interconnection wiring .............................. 46

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 5

2. Preface:

This manual contains installation information and instructions for the Mode-S transponder VT-01. It

shall be read before installing your VT-01 transponder.

The installation shall be carried out or supervised by a qualified person. Damage caused by

installation by unqualified persons is not covered by the manufacturers warranty.

Safety symbols:

The following symbols and terms are used in this manual:

Warning

Warning statements identify conditions or practices that could result in injury or

loss of life

Caution

Caution statements identify conditions or practices that could result in damage of

this product or other property.

Important note:

Indicates important or usefull information. It is strongly recommended to read,

understand and follow the statement.

3. Unpacking and part identification

3.1. VT-01:

The VT-01 transponder system is supplied with the following:

P/N: VT-0101-()-()-() Steering unit

P/N: VT-0102-()-()-()-070 Central unit Class 2 (71 Watt)

or VT-0102-()-()-()-125 Central unit Class 1 (125 Watt)

Document: 01.0200.10 User’s guide

Document: 01.0200.11 Installation manual (this document)

Available options:

P/N: VT-0103-1-()-() Mounting kit/wiring harness with installation cradle

(required for installation of VT-01 as a two block system with remote

steering unit. It also allows simple and quick installation and removal

of the central unit. VT-01UC cannot be installed as two block

systems).

P/N: VT-0103-2-()-() Mounting kit/wiring harness without installation cradle

Document: 01.0200.12 Maintenance and repair manual (for avionic repairshops only)

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 6

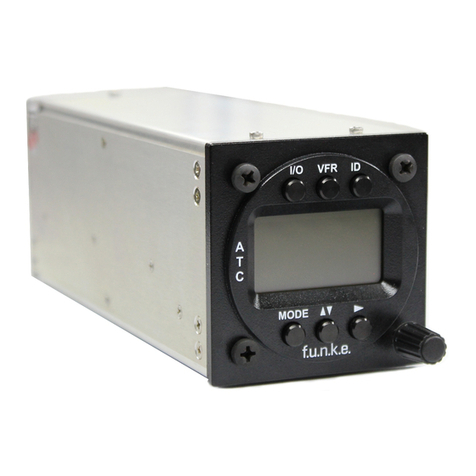

3.2. VT-01UltraCompact

The VT-01 UltraCompact transponder system is supplied with the following:

P/N VT-0104-070 System unit

or VT-0104-070

P/N: VT-0103-2-()-() Mounting kit/wiring harness without installation cradle

Available options:

Document: 01.0200.12 for maintenance and repair manual (for avionic

repairshops only)

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 7

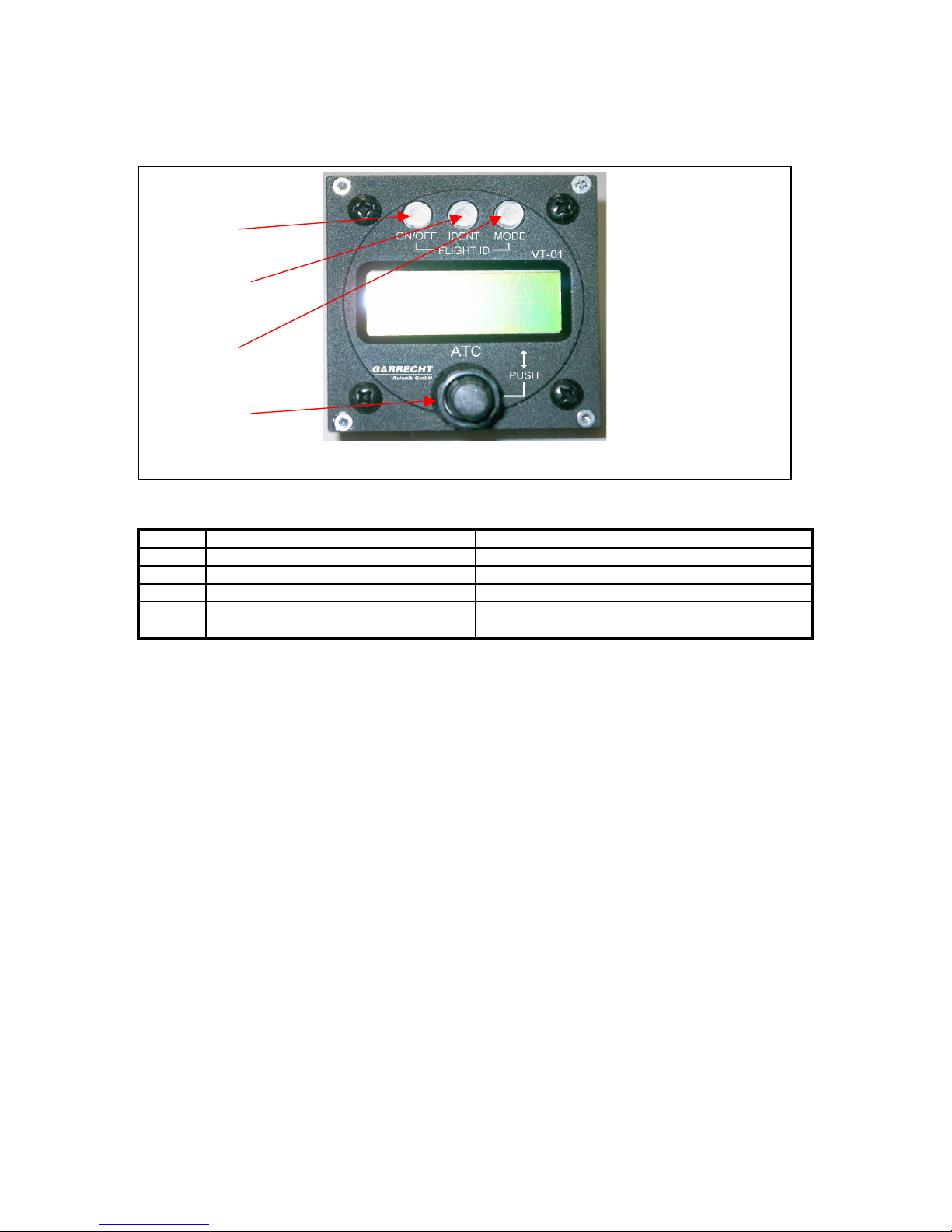

4.Input Devices (human machine interface)

Picture of front panel with Input devices

The system will be operated using the following devices:

Nr. Description Function

1 On/Off key Switches the system On or Off

2 Ident – key Invokes the Ident Mode for 18 sec.

3 Mode – key Selects the operating mode

4 Double shaft encoder with push on

capability for inner knob

Enters or modifies values

4.1. On/Off key

To enable the system, press key 1 shortly. After the start, the unit performs the built in test and shows

the operating mode. For switching off, press key 1 for at least 3 seconds Release the key, when the

LCD becomes blank

4.2. Ident key

Pressing key 2 invokes the ident mode for 18 seconds. Use this function only when the ATC requires

to sqawk ident.

4.3. Mode-key

Key 3 selects the following modes:

• SBY Standby - System is switched on, no replies or squitters will be sent.

• ON Selected reply code will be replied for Mode-A/C interrogations, altitude information is

set to zero, squittering is enabled, Mode-S interrogations will be replied

• ALT Selected reply code will be replied for Mode-A/C interrogations, altitude information is

set to indicated value, squittering is enabled, Mode-S interrogations will be replied

4.4. Double shaft rotary encoder

Main input device for setting values is the double shaft rotary encoder. Rotating the outer knob selects

the position to be modified. Rotating the inner knob changes the selected value.

The edit mode will be started rotating the inner or outer knob of the double shaft encoder.

Pushing the inner knob confirms the selected value and cancels the edit mode (cursor stops blinking).

1

2

3

4

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 8

5.Technical data and specifications

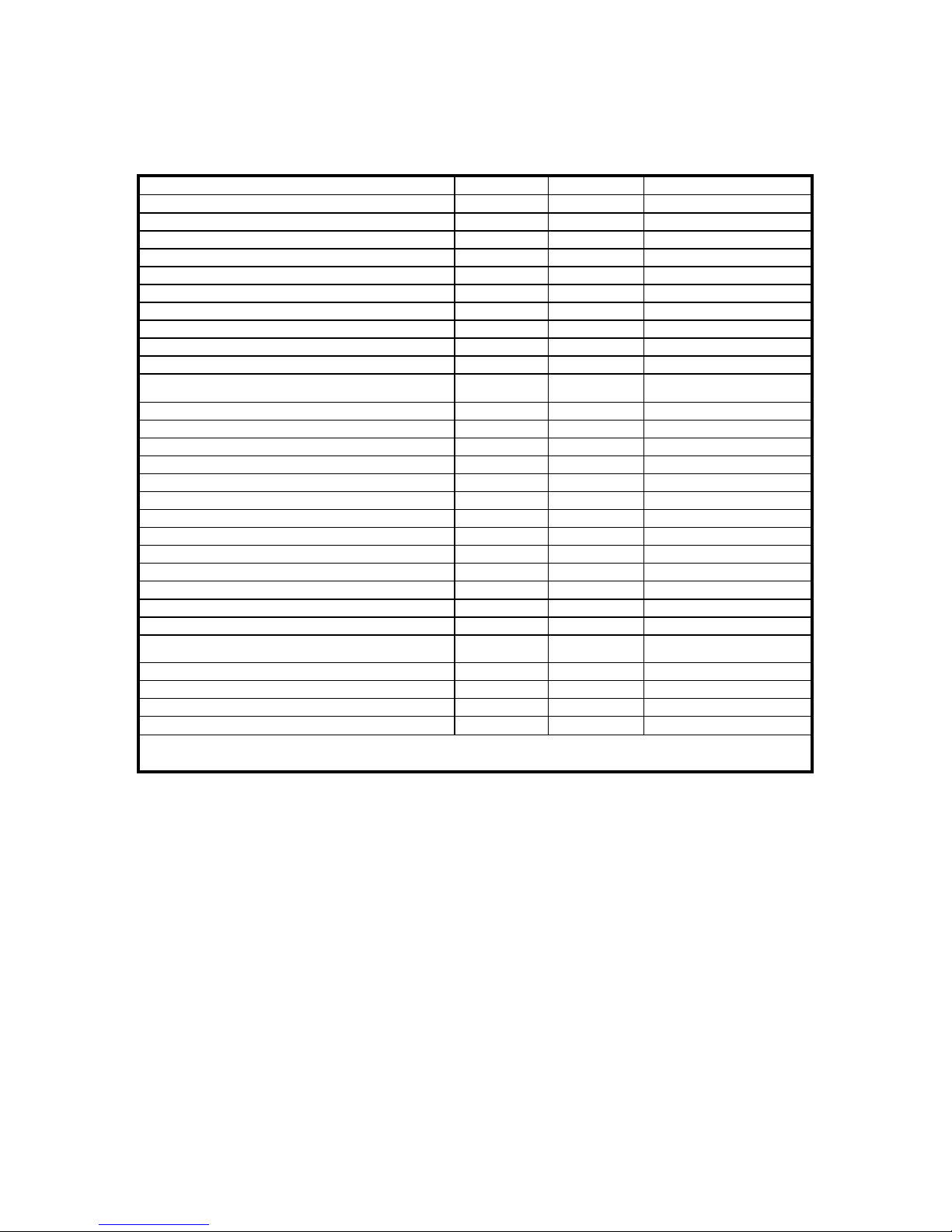

5.1.General

Technical characteristics Data

Mechanical

VT-01

Dimensions

Mounting

Weights

VT-01 UltraCompact

Dimensions

Mounting

Weight

Steering unit :65x65x34,5 mm (w/o. connectors)

Central unit: 65x65x128 mm (w/o. connectors)

57 mm panel mount

Steering unit: 0,21 kg

Central unit: 0,61 kg

61,5 x 61,5 x 170mm

57 mm panel mount

0,57 kg

Environmental

Max. Altitude

Temperature

Cooling

Vibration

Shock

50.000 ft (internal alticoder limited to 40.000ft)

(see also limitiations chap. 5.6)

-20°C - +55°C

passive, no auxiliary cooling required

DO160D Cat. S, Curve M

Operational: 6g, crash safety: 20g

Electrical

Voltage (nom.):

Voltage (operational)

Current (nom.)

@ 13,8 V and 1200 A/C replies/sec.

Standby (sqitters active)

RF-power @ antenna

Replyrate:

Output Impedance

max. VSWR

13,8 V DC

9 to 32 V DC

VT-0102-()-()-()-070

VT-0104-070: 0,35 A

VT-0102-()-()-()-125

VT-0104-125: 0,45 A

VT-0102-()-()-()-070

VT-0104-070: 0,16 A

VT-0102-()-()-()-125

VT-0104-125: 0,17 A

VT-0102-()-()-()-070

VT-0104-070: > 70 Wp

VT-0102-()-()-()-125

VT-0104-125: > 125 Wp

min. 1200/s Mode-A/C

min. 50/s Mode-S

50 Ohms

1,5:1

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 9

Interfaces:

Human machine interface / User input

capablity

The system provides 3 buttons and a twinaxle

rotary encoder for inputting values and selecting

operational modes. System messages and

entered values are displayed on a 2 lines / 12

characters LCD display.

Automatic input capability:

On Ground interface:

The system detects the input of an “on ground”

switch. If the aircraft’s frame does not supply

such an information, the input channel will be set

to “airborne” always (ref. to chapter 5.10).

Logic = 0: on ground condition

Suppression interface:

The system provides an suppression interface to

prevent interference with other instruments

installed in the same aircraft (such as DME):

Impedances:

DC: -0,4 V to + 30 V: 7,2 kOhms

DC: < -0,4 V: 1 kOhms

AC: 1 kOhms

Levels:

output: 10 V

input: 7 V - 30 V

Alitcoder capability

The system contains an integral digital alticoder

to provide data about pressure altitude for Mode

C information in 100 ft steps. It’s line has to be

connected to the aircraft’s static pressure

system.

Range: -1000ft to + 40.000ft

Self test routines (BIT)

After powering on, the system runs several

internal self test routines permanently. In case of

errors, the user gets warned visble and audible

and depending on the level of error, the system

stops operating with a permanent error

message.

5.2. Certification base

ETSO-2C112a

EUROCAE ED-73B

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 10

5.3. Equipment class

Class 1: If using central unit VT-0102-()-()-()-125

If using system unit VT-0104-125

Class 2: If using central unit VT-0102-()-()-()-070

If using system unit VT-0104-070

5.4. Mode-S transponder level

Level 2se Mode-S transponder

5.5. Equivalences to FAA TSO-C112 Classes:

If using central unit VT-0102-()-()-()-125 or

If using system unit VT-0104-125: Equal to FAA TSO C112 Class: 2A1 120 010

If using central unit VT-0102-()-()-()-070 or

If using system unit VT-0104-070 Equal to FAA TSO C112 Class: 2B1 020 010

5.6.Limitations

1. To reach the required minimum RF peak power, the use of an antenna cable with a total loss

of less or equal 2,5 dB is required.

2. The range of the internal alticoder is limited to a maximum altitude of 40.000 ft.

3. The system using the CLASS 2 central unit (P/N: VT-0102-()-()-()-070) or the system unit

VT-0104-070 may be operated in aircraft not exceeding a maximum speed of 175 kts, a

maximum altitude of 15.000 ft and a MTOW of 5700 kg.

4. The system using the CLASS 1 central unit (P/N: VT-0102-()-()-()-125) or the system unit

VT-0104-125 may be operated in aircraft not exceeding a maximum speed of 250 kts, a

maximum altitude of 50.000 ft and a MTOW of 5.700 kg.

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 11

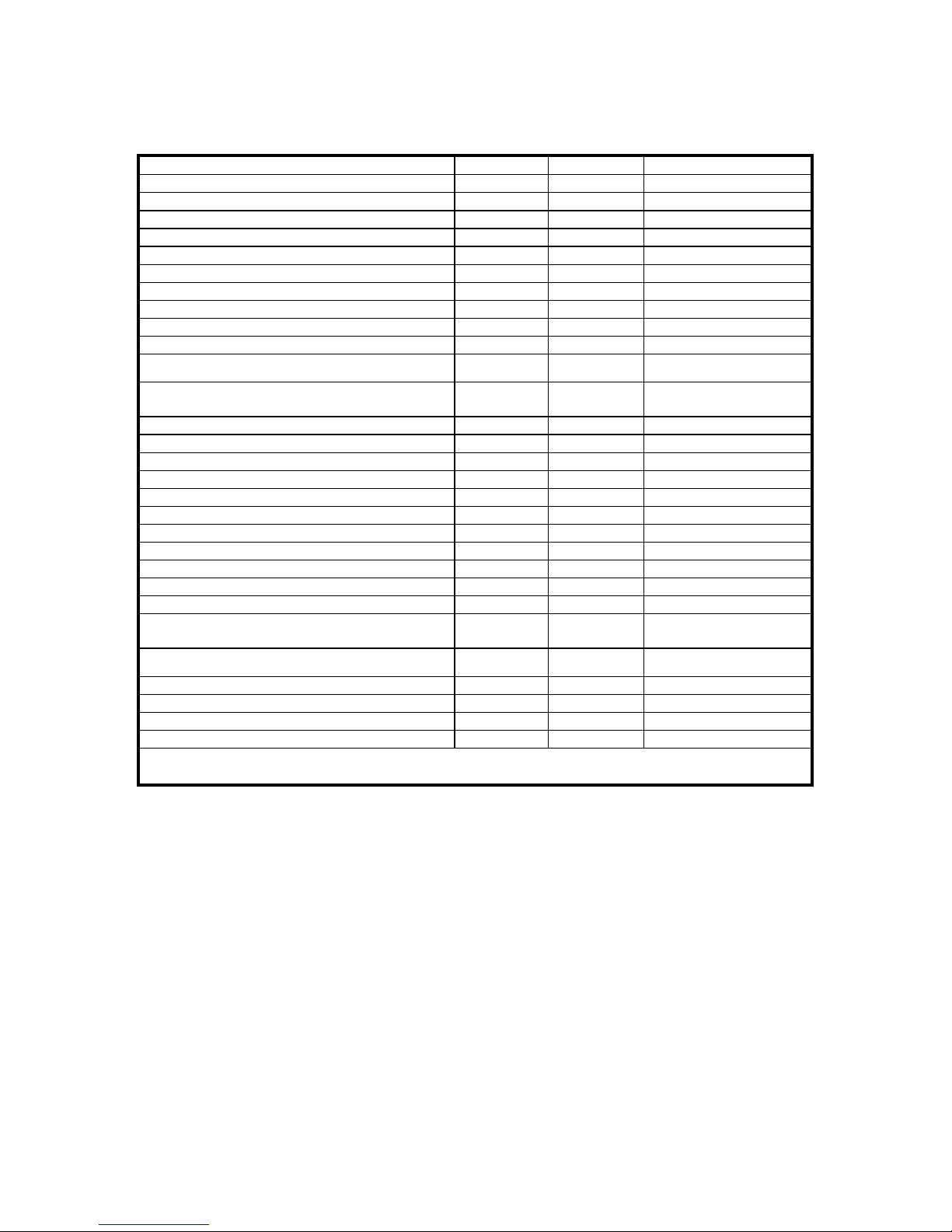

5.7. Environmental categories

5.7.1. VT-01

Section Category Conditions

Temperature / Altitude D1 4.0 D1

Low ground survival temperature 4.5.1 D1 -55°C

Low operating temperature 4.5.1 D1 -20°C

High ground survival Temperature 4.5.2 D1 +85°C

High Short-time Operating Temperature 4.5.2 D1 +70°C

High Operating Temperature 4.5.3 D1 +55°C

In .Flight Loss of Cooling 4.5.4 Z No auxiliary cooling required

Altitude 4.6.1 D1 50.000 ft.*

Temperature Variation 5.0 B 5°C / minute

Humidity 6.0 A

Shock 7.0 B 6 G operational shocks

20 G crash safety

Vibration 8.0 S Vibration curve M

Explosion Profness 9.0 X

Water Profness 10.0 X

Fluids Susceptibilities 11.0 X

Sand and Dust 12.0 X

Fungus Resistance 13.0 X

Salt Spray 14.0 X

Magnetic Effect 15.0 Z Less than 0.3 m

Power Input (DC) 16.0 B

Voltage Spike Conducted 17.0 B

Audio Frequency Conducted Susceptibility 18.0 B

Induced Signal Susceptibility 19.0 A

Radio Frequency Susceptibility 20.0 T

Emission of RF 21.0 B compliant with CAT M except

of harmonics of 1090 MHz

Lightning Induced Transient Susceptibility 22.0 A2XXX

Lightning Direct Effects 23.0 X

Icing 24.0 X

Electrostatic Discharge (ESD) 25.0 A

* see chapter 5.6 for restrictions

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 12

5.7.2. VT-01 UltraCompact

Section Category Conditions

Temperature / Altitude D1 4.0 D1

Low ground survival temperature 4.5.1 D1 -55°C

Low operating temperature 4.5.1 D1 -20°C

High ground survival Temperature 4.5.2 D1 +85°C

High Short-time Operating Temperature 4.5.2 D1 +70°C

High Operating Temperature 4.5.3 D1 +55°C

In .Flight Loss of Cooling 4.5.4 Z No auxiliary cooling required

Altitude 4.6.1 D1 50.000 ft.*

Temperature Variation 5.0 B 5°C / minute

Humidity 6.0 A

Shock 7.0 B 6 G operational shocks

20 G crash safety

Vibration 8.0 U2

R

Vibration curve F/F1

Vibration curve B/B1

Explosion Profness 9.0 X

Water Profness 10.0 X

Fluids Susceptibilities 11.0 X

Sand and Dust 12.0 X

Fungus Resistance 13.0 X

Salt Spray 14.0 X

Magnetic Effect 15.0 Z Less than 0.3 m

Power Input (DC) 16.0 B

Voltage Spike Conducted 17.0 B

Audio Frequency Conducted Susceptibility 18.0 B

Induced Signal Susceptibility 19.0 A

Radio Frequency Susceptibility 20.0 S

T

radiated susc.

conducted susc.

Emission of RF 21.0 B compliant with CAT M except

of harmonics of 1090 MHz

Lightning Induced Transient Susceptibility 22.0 A2XXX

Lightning Direct Effects 23.0 X

Icing 24.0 X

Electrostatic Discharge (ESD) 25.0 A

* see chapter 5.6 for restrictions

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 13

5.8. Software level

The software level for VT-01 has been determined to be

Level D:

Software whose anomalous behavior, as shown by the system safety assessment process,

would cause or contribute to a failure of system function resulting in a minor failure condition

for the aircraft.

5.9. Telecommunication specifications

Emission power: with central unit VT-0102-()-()-()-125 or

system unit VT-0104-125: 250 Watts max.

with central unit VT-0102-()-()-()-070 or

system unit VT-0104-070: 200 Watts max.

Emission class: 12M0M1D

Frequency: 1090 MHz

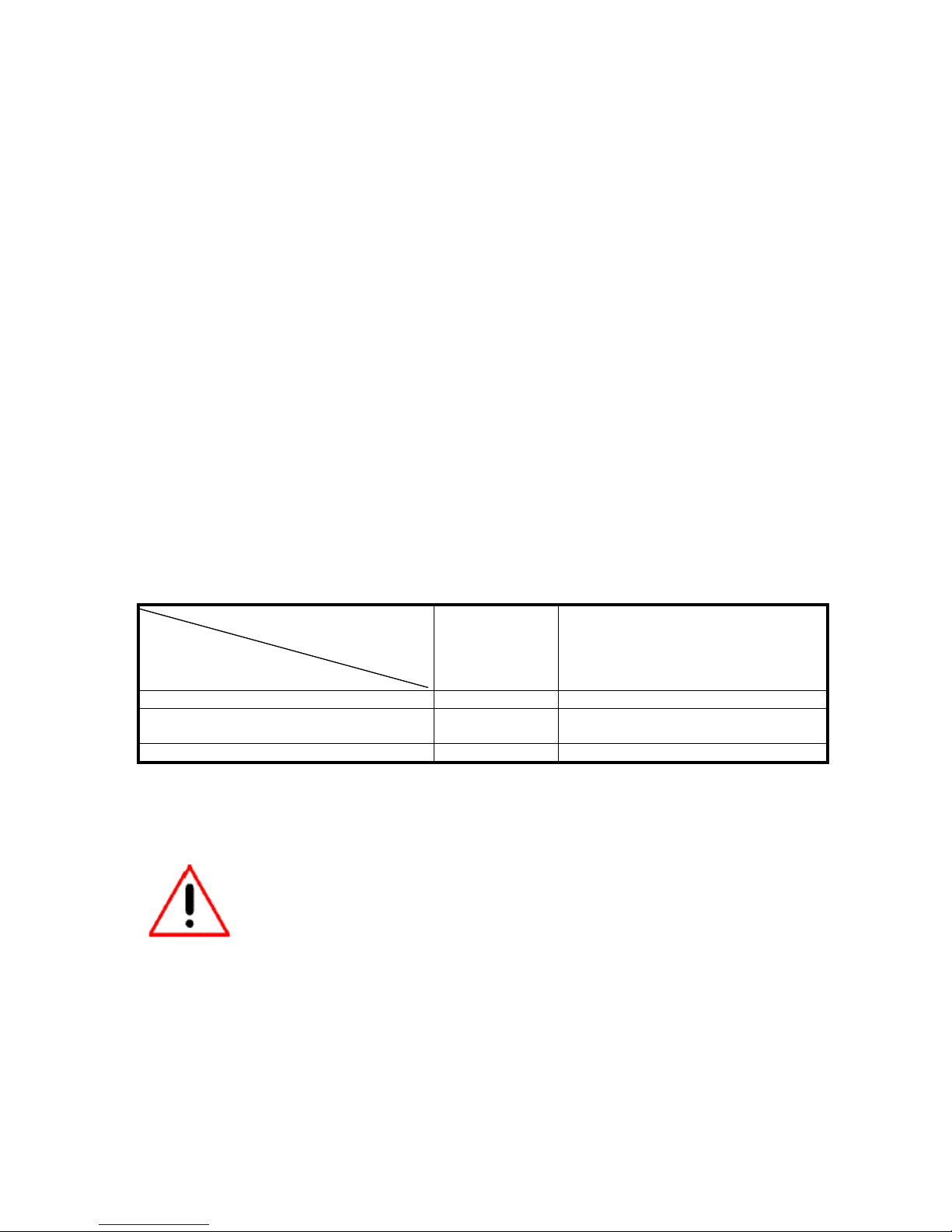

5.10. Logic of on-Ground interface

The transponder has an on-ground interface, which should be connected to your aircraft installation, if

an adequate signal will be provided. The following table shows the system behaviour for different

configurations and input at the interface

on ground configuration in Menu

on ground switch settings

NO YES

no on-ground switch present airborne -

on ground - on ground

airborne - airborne

on ground: system replies not to Mode-A/C and Mode-S "all-call" interrogations, squitters active

airborne: system replies to all interrogations, squitters active

Do not install an manual on ground switch in the cockpit of your aircraft. If no

adequate on ground switch is provided in the airframe, leave the on ground

input unconnected.

5.11.CAN-Bus interface

The system provides a CAN-Bus interface for communication between steering unit and

central unit. A detailed description of the interface can be obtained by the manufacturer (for

system integrators or OEMs only).

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 14

6. Aircraft installation

The VT-01 provides maximum levels of flexibility. Depending on the space in your cockpit you can

have a single-block or two-block equipment installation. The two-block system requires a mounting

kit/cradle (PN # VT-0103-1-()-() ) to carry the central unit. It allows a quick installation and removal of

the complete central unit without using tools. If each aircraft in a fleet carries a steering unit and a

mounting cradle, the central unit can be interchanged between all aircraft. All aircraft related data is

stored in the steering unit, which always remains in an aircraft.

General: All installation work shall be performed in accordance with the

acceptable methods, techniques and practices for aircraft alterations,

inspections and repair, shown in FAA documents AC 43.13-1B and AC 43.13-

2A (see www.faa.gov to obtain this documents free of charge in digital form).

6.1. Installation VT-01 - single-block

To install as a single-block system, the following steps need to be performed:

6.1.1. Assembling the steering unit and central unit:

Before attaching the steering unit to the central unit, Check if the pressure

connector, the steering unit plug and the central unit plug are clean. If not,

remove all foreign bodies from the parts.

Replace the Quicklock

terminals in the back of the

steering unit with screws (4-

40), if installed.

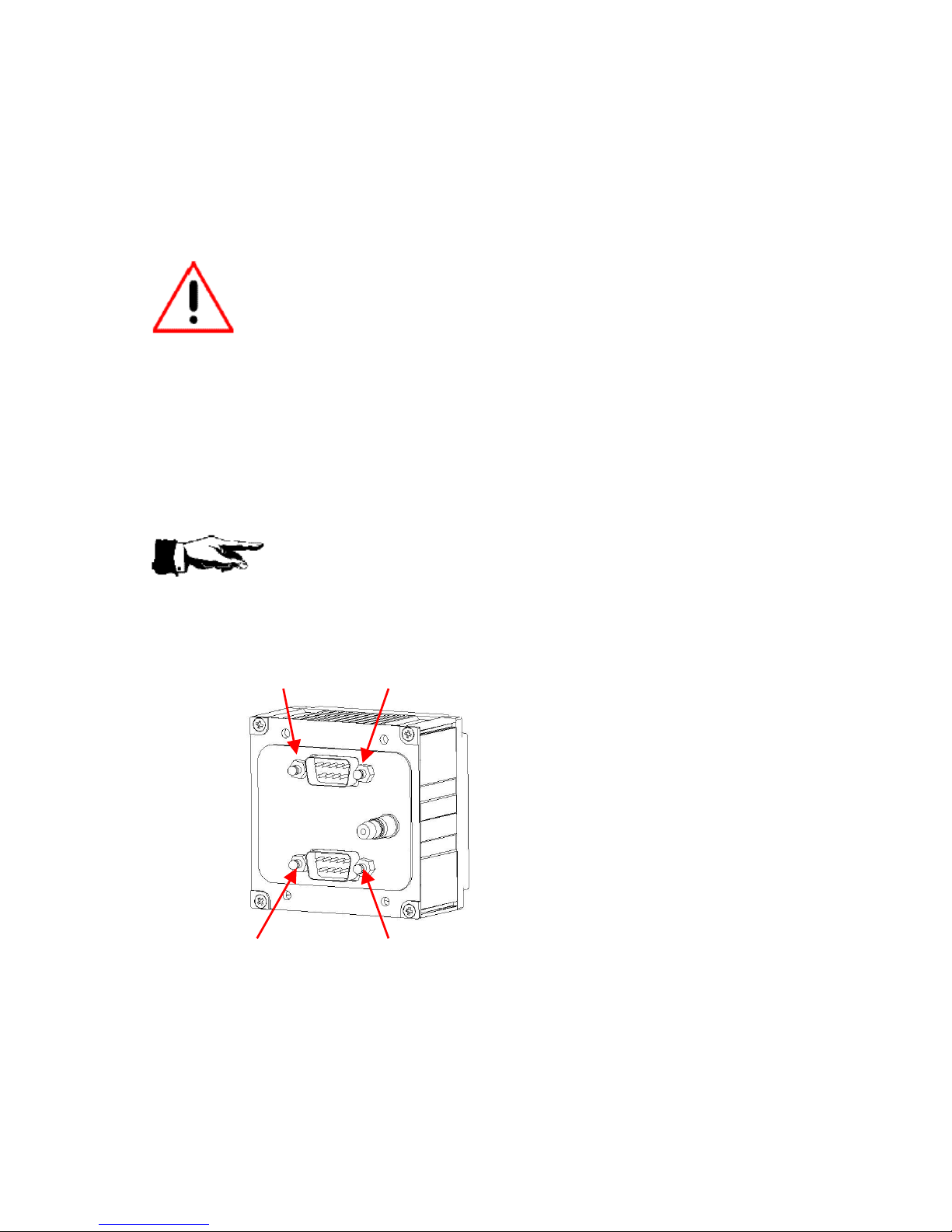

Rear view of steering unit

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 15

Replace the screws (4-40) in the back of

the central unit with quicklock terminals, if

installed

Rear view of central unit

1. Assemble mating pressure

connector and plug for both units

in the correct orientation

2. Push the steering unit (1) onto the

central unit (2) . Use the 4 screws

(3) to fasten both units.

6.1.2. Panel mounting

Determine a suitable position in the instrument panel that is in view of the pilot in command.

When choosing a position for installation, always be sure not to damage structural devices of

the airframe.

Cut a 57mm (2 ¼ inch) diameter hole with 4 x 4.1mm holes for the mounting screws (see chapter 15

for detailed locations). A minimum space of 65.5mm x 65.5mm behind the panel cut out is required for

clearence with adjacent instruments. A depth of 205mm is recommended to accomodate the

transponder and electrical connectors.

6.1.3. Static pressure connection

The system contains an integral alticoder. Connect the static pressure line of the aircraft to the

connector on back of the central unit.

Front of central unit

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 16

The integral alticoder supplies data immediatly after switching on the VT-01. No warm up period is

required. For calibration of the internal alticoder, an instruction will be provided by the manufacturer to

qualified installers.

6.1.4. Wiring

Wiring electrical components shall be performed by qualified personal only to

prevent damages and hazardous situations that could result in loss of life.

All wires (except the antenna line) related to the VT-01 in single-block configuration

are connected to one SUB-D 9 pin connector on the back of the central unit.

Ensure that the Sub-D connector is fastened to the housing of the central unit

correctly before operating the unit in flight.

The following subchapters describe the different lines required for operating the transponder.

DO NOT POWER ON THE TRANSPONDER WITH THE ANTENNA

DISCONNECTED !!!

Damage to the RF unit caused by a disconnected antenna can be

determined by the manufacturer and is not covered by the manufacturers warranty.

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 17

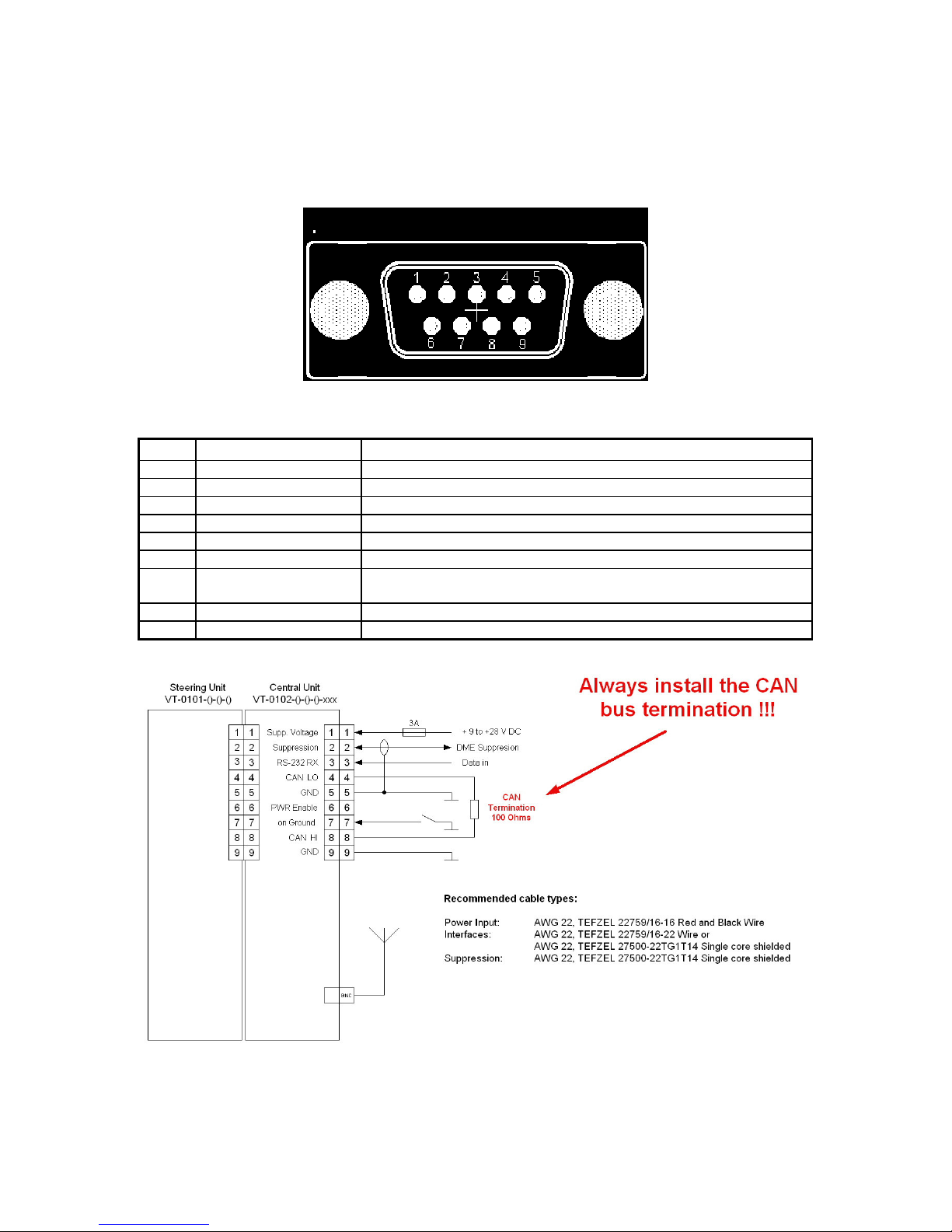

6.1.4.1. Connector wiring

Wire the female plug to be connected to the connector (CN3) on the back of the central unit as

described in the following table. Refer to chapter 17 for a proper cable installation and assembling of

the connector.

viewed from the back of the SUB-D 9 female connector

Pin Function Additional Information

1 +9V - + 28V DC Connect to aircraft primary power source

2 mutual suppression Connect to DME suppression bus (use shielded line)

3 RS-232 RX For ADS-B (Data in)

4 CAN-LO Not used in single-block installation, terminate as shown below

5 GND Connect to common GND of airframe

6 Pwr_enable Not used in single-block installation, do not connect

7 On Ground Do not connect, if no on-ground signal is provided by aircraft

installation

8 CAN-HI Not used in single-block installation, terminate as shown below

9 GND Connect to common GND of airframe

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 18

6.1.4.2. Power supply

The transponder is supplied by the aircrafts’s primary power source (10 V to 28 V DC). The system

provides protection against reverse polarity. Always install a Fuse !!!

6.1.4.3. Suppression interface

The suppression line needs to be wired to other avionic components working in the 962..1213 MHz

frequency band, such as DME or TACAN, to suppress any replies from the transponder that void the

capabilty of such systems while operating.

The suppression line provides IN and OUT capability to prevent data transmission either to the

transponder or other equipment.

Wiring the suppression line requires a qualified avionic technician or

engineer to prevent any kind of malfunction of the installed equipment. All

equipment connected to the suppression line must be re-inspected and re-

approved before operation. Refer to chapter 5 for specifications of the

suppression interface.

6.1.4.4. On-ground interface

If your aircraft installation provides an on-ground signal, it should be connected to this pin. The

tranponder replies only to discretely addressed Mode-S interrogations if the on-ground signal is

present. The permament emission of squitters will not be effected.

Refer to chapter 5.10 for logic table of this interface.

6.1.4.5. RS-232 interface

This interface is intended for ADS-B applications. It may be used for connecting a GPS receiver to

broadcast the current position with extended squitters.

Minimum recommended NMEA sentences are $GPRMC, $GPGGA, $GPGSA. The baud rate is 4800

bps.

6.1.4.6. CAN-Bus interface

The CAN-Bus interface is used for communication between steering unit and

central unit. If the one-block configuration will be installed, a resistor (100

ohms) must be used for proper termination of the bus. A missing termination

results in COMM error and malfunction of the system.

For pinout refer to the wiring diagram shown on the previous page.

6.1.4.7. Antenna connection

Connect the BNC plug of the antenna line to the connector in the back of the central unit. Be sure that

the plug has been fastened to prevent disconnection caused by vibration

DO NOT POWER ON THE TRANSPONDER WITH THE ANTENNA

DISCONNECTED !!!

Damage to the RF unit caused by a disconnected antenna can be

determined by the manufacturer and is not covered by the manufacturers warranty.

Refer to chapter 9 for details about installing a transponder antenna in your aircraft.

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 19

6.2. Installation VT-01 - two-block

To install as a two-block system, the following steps need to be performed:

Unfasten the 4 Screws (3) and remove the

steering unit (1) from the central unit (2).

Fasten a shoulder washer (5) with

screws (4) on each side of the central

unit.

Replace the quick lock terminals in back

of the central unit with screws.

Rear view of central unit

Front of central unit

Front of central unit

Garrecht Avionik GmbH VT-01 Transponder Installation Manual - english -

Document: 01.0200.11E

Revision: 1.3 20

Replace the screws in the back of the

steering unit with quick lock terminals.

Rear view of steering unit

6.2.1. Installing the mounting kit / cradle

Select a suitable place for installation of the mounting kit / cradle (P/N # VT-0103-1-()-() ) in your

aircraft. Consider the space needed for inserting / removing the central unit. In order to remove make

sure it is possible to reach and operate the lock device on the end of the cradle .

The maximum distance between steering unit and central unit is limited by the data interface cable

used for communication between the system. It shall not exceed 10 metres in length.

Fasten the mounting kit to the airframe using 4 x M4x5 screws

6.2.2. Panel mounting

Determine a suitable position in the instrument panel that is in view of the pilot in command.

When choosing a position for installation, always be sure not to damage structural devices of

the airframe.

Cut a 57mm (2 ¼ inch) diameter hole with 4 x 4.1mm holes for the mounting screws (see chapter 15

for detailed locations). A minimum space of 65.5mm x 65.5mm behind the panel cut out is required for

clearence with adjacent instruments. A depth of 50mm is recommended to accomodate the steering

unit and electrical connectors.

6.2.3. Static pressure connection

The steering unit contains an integral alticoder. Connect the static pressure line of the aircraft to the

connector on back of the steering unit.

The integral alticoder supplies data immediatly after switching on the VT-01. No warm up period is

required. For calibration of the internal alticoder, an instruction will be provided by the manufacturer to

qualified installers.

Other manuals for VT-01

1

Table of contents

Other Garrecht Avionik Marine Radio manuals

Popular Marine Radio manuals by other brands

F.u.n.k.e.

F.u.n.k.e. TRT800H-LCD Operation and installation

Trig Avionics

Trig Avionics TT31 Modification Instructions

Garmin

Garmin VHF 300 - Marine Radio Quick reference guide

Sailor

Sailor UAIS1900 Technical manual

MicroAir Avionics

MicroAir Avionics T2000SFL user manual

stabo

stabo stabo RTM 100 quick start guide