Gas Detection GDA 3000 User manual

Gas Detection (Australia) Pty Ltd

GDA 3000

Infrared Gas Das Detector

Operating Manual

Manual Revision: 1

Manual Reference Revision: 2

Hardware Version: GIR3000H MAIN Rev1 2012-07-25

© Copyright Gas Detection (Australia) Pty Ltd Apr 2017

Gas Detection (Australia) Pty Ltd Page 2 of 44 M-GDA-3000 Rev 1

Thank you for purchasing this product from Gas Detection (Australia) Pty Ltd

This manual contains information about the method of installation, simple maintenance and

troubleshooting of the GDA 3000 gas detector. Please read it carefully and keep it nearby for

further reference.

If you have any further question about the product, please contact us.

Location: Unit K1, USQ, Baker Street Toowoomba, QLD 4350

Address: PO BOX 597, Darling Heights, QLD 4350

Phone: +61 7 4613 5111

Web: www.gasdetectionaustralia.com.au

Email: sales@gasdetect.com.au

Note:

The calibration period for a sensor will depend on a number of factors such as the

environment in which it is used, operating temperature, humidity, atmospheric pressure and

environmental pollutants.

In all cases we recommend sensors are calibrated in line with target market legislation.

In order for these sensors to maintain operational efficiency and performance it is

recommended that the detector is checked for calibration on 3 monthly periodic cycle.

The calibration should be carried out by fully trained and authorised and approved technicians

approved by GDA.

Gas Detection (Australia) Pty Ltd Page 3 of 44 M-GDA-3000 Rev 1

PROPRIETARY RIGHTS

No part of the hardware or documentation may be reproduced, transmitted, transcribed, stored

in a retrieval system, or translated into any language or computer language, in any form or by

any means, without prior written permission of GDA.

While great efforts have been made to ensure the accuracy and clarity of this document, GDA

assumes no liability resulting from any omissions in this document, or from misuse of the

information contained herein. The information in this document has been carefully checked

and is believed to be entirely reliable with all of the necessary information included. GDA

reserves the right to make changes to any products described herein to improve reliability,

function, or design, and reserves the right to revise this document and make changes from

time to time in content hereof with no obligation to notify any persons of revisions or changes.

GDA does not assume any liability arising out of the application or any use of any product or

circuit described herein; neither does it convey license under its patent rights or the rights of

others.

Gas Detection (Australia) Pty Ltd Page 4 of 44 M-GDA-3000 Rev 1

Table of Contents

1. Introduction ............................................................................................................................6

2. Structure .................................................................................................................................6

3. Specification............................................................................................................................7

4. Name of Components and Main Features.................................................................................8

4.1. Components ....................................................................................................................................8

4.2. Components Description .................................................................................................................9

5. Terminal Wiring Diagram .......................................................................................................11

5.1. Separation of Detector Body and Cover........................................................................................11

5.2. Main PCB Configuration................................................................................................................12

5.2.1 Main PCB configuration ..........................................................................................................12

5.2.2. HART Board configuration .....................................................................................................13

5.3. Main PCB terminal description and wiring method ......................................................................14

5.3.1. RELAY DRIVE TYPE WIRING METHOD ....................................................................................15

5.3.2. 4~20mA SOURCE DRIVE TYPE WIRING METHOD...................................................................16

5.3.3. 4~20mA SINK DRIVE TYPE WIRING METHOD.........................................................................17

5.3.1. Connection method with our main Control Unit ...................................................................18

6. Standard Type outside view and Dimensions..........................................................................19

7. Warning light type: Outside view and Dimensions ..................................................................20

8. Raincover type: Outside view and Dimensions .......................................................................21

9. Menu Configuration Table .....................................................................................................22

10. Detector activation Flow and KEY operation .......................................................................25

10.1. Sensor activation Flow ................................................................................................................25

10.2. Sensor KEY configuration and description ..................................................................................25

11. Detailed Description of Operational States and Menu.........................................................26

11.1. Initial State (Power On)...............................................................................................................26

11.2. Gas Measuring Mode..................................................................................................................26

11.3. How to Set PROGRAMMABLE MODE..........................................................................................27

11.4. How to use Calibration Mode ..................................................................................................... 28

11.4.1. Zero Calibration and Span Calibration .................................................................................28

11.5. How to set alarm in Alarm mode ................................................................................................30

Gas Detection (Australia) Pty Ltd Page 5 of 44 M-GDA-3000 Rev 1

11.6. How to use Test Mode ................................................................................................................33

11.7. How to use IR SENSOR DATA MODE ...........................................................................................34

11.8. How to use VERSION MODE........................................................................................................35

11.9. How to set Maintenance Mode...................................................................................................36

11.10. How to configure 485 MODBUS................................................................................................38

11.11. How to configure in Device Mode .............................................................................................39

11.12. How to use INSPECTION MODE.................................................................................................40

11.13. Data initialization......................................................................................................................40

11.14. Correction data initialization ....................................................................................................40

12. Troubleshooting ................................................................................................................41

13. Caution before installation.................................................................................................42

13.1. Selection of installation location (Occupational Safety and Health Law) ...................................42

13.2. Selection of installation location (High Pressure Gas Safety Management Regulations)...........42

13.3. Precaution before installation.....................................................................................................43

14. Revision History .................................................................................................................44

Gas Detection (Australia) Pty Ltd Page 6 of 44 M-GDA-3000 Rev 1

1. Introduction

The GDA-3000 is an infrared(IR)-type gas detector that is developed to prevent serious

accidents caused by gas leaks by detecting a variety of gases in hazardous areas such as

industrial plants, gas storage facilities and factories in the process of producing or consuming

flammable gases, CO or CO2.

When the GDA-3000, IR-type gas detector is installed in locations that may have gas leaks, it

will continuously monitor the ambient level of gas and display the measured gas value on its

integrated LCD or OLED. Additionally, it supplies DC 4-20mA standard output, isolated RS-

485 communication signal, HART and relay contact signal on occurrence of gas alarms.

For standard output of DC 4-20mA, output receiver can support up to 500 meters distance

away from gas detector to receive output signal(When CVVS or CVVSB 2.0 sq↑shield cable

is used). And communication signal of RS-485 can be transmitted up to 1,000 meters (when

RS-485 dedicated line is used).

2. Structure

The body of GDA-3000 is made of aluminium alloy and its structure is designed to be

explosion-proof(Ex d IIC T6). The product can be installed in areas that may have flammable

gas leaks and explosions. The integrated liquid crystal display(LCD or OLED) displays current

gas leakage level on the spot.

The internal structure consists of LCD for gas level, connector delivering output such as

measured value(DC 4-20mA) or isolated RS-485 communication signal(optional), HART

communication and alarm signal, and two PCB boards. The outer structure is composed of

sensing parts for detecting gas leakage and cable inlets (2ea). The gas detector can be

calibrated from outside of the device using magnet-bar, which makes maintenance easier.

Gas Detection (Australia) Pty Ltd Page 7 of 44 M-GDA-3000 Rev 1

3. Specification

ITEMS

SPECIFICATION

Measuring Type

Diffusion

Measuring Value Display

Local digital LCD(OLED) display

Means Value Display

Back light, 2-line/16-characters LCD & OLED

Approval

Ex d IIC T6, IP65

Detectible Gas

Combustible Gas

Carbon Dioxide(CO2)

Carbon monoxide(CO)

Measuring Method

Non-Dispersive Infrared (NDIR Cell)

Measuring Range

Combustible Gas : 0~10,000ppm / 0~100%, LEL /

0~100% VOL

CO2 : 1.0% ~ 100% VOL

CO : 5% ~ 100% VOL,

Response Time

90% of full scale in less than 10 seconds

Accuracy

±3% / Full scale

Zero Drift

Less than 2% full scale

Operating Temperature

-20 to 60°C

Operating Humidity

0 to 99% RH (Non-condensing)

Analogue Signal Output

Measurement output : 4-20mA DC/Full Scale

Diagnostic output : 3mA

Calibration output : 3mA

Faulty output : 2mA

HART ®Interface

HART REV7 / Optional Board (*1)

Alarm Signal Output

SPST Signal of Relay contact : 250V/1A

Calibration Work

Magnetic interface to configure alarm

Cable Connection Length

Max. 500m : 4~20mA signal

Max. 1000m : Isolated RS-485 Signal

Power Supply

18-31V DC (DC 24V normal) / Max. 400mA

Conduit Connection

1/2" or 3/4"PF, NPT(Standard : 3/4" PF)

Signal cable Connection

Power source + current : CVVS or CVVSB

2.0sq↑x 3wires shield

RS-485 communication : 1 par(UL2919 RS-485)

Option

HART ® Interface board

GTL-100 (explosion proof LED)

Rain cover

Dimensions

156(W) x 322(H) x 110(D) mm

Weight

Approx. 3.0kg

[Table 1. GDA3000 Specification ]

*Note 1) Regarding HART, refer to document on GDA 3000 HART®Field Device Specification.

Gas Detection (Australia) Pty Ltd Page 8 of 44 M-GDA-3000 Rev 1

4. Name of Components and Main Features

4.1. Components

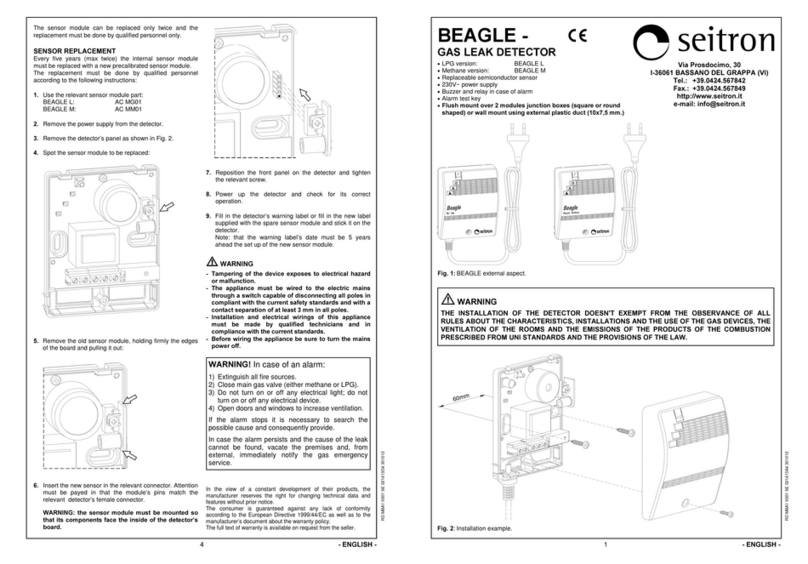

[Figure 1. GDA 3000 Components]

No.

Name

No.

Name

1

HOUSING

14

RESET SWITCH

2

MAIN PCB

15

↑ SWITCH

3

DISPLAY PCB

16

↓ SWITCH

4

POWER/SIGNAL TERMINAL

17

EXTERNAL EARTH (4sq ↑)

5

ALARM SIGNAL TERMINAL

18

MOUNT HOLES (2-Ø7)

6

RS-485 SIGNAL TERMINAL

19

COVER FIXED SCREW

7

SENSOR TERMINAL

20

SENSOR THREAD

8

POWER SWITCH

21

CABLE INLET

9

POWER LED LAMP

22

INTERNAL EARTH (2sq ↑)

10

TROUBLE LED LAMP

23

RS-485 Module or HART Module (Option)

11

ALARM1 LED LAMP

24

Relay Contact Type Selection

12

ALARM2 LED LAMP

25

Warning Light Connector

13

FUNCTION SWITCH

26

Program Downloading Connector

[Table 2. Components Reference Table]

Gas Detection (Australia) Pty Ltd Page 9 of 44 M-GDA-3000 Rev 1

4.2. Components Description

No.

Name of component

Description

1

Housing

Protecting sensors and PCB boards equipped inside the

device housing against environmental variations and shocks

2

Main PCB

Amplifying the output signal generated by sensor, converting it

to standard output of DC 4-20mA and transmitting converted

signal. And transmitting isolated RS-485 communication signal

and alarm relay contact signal. Also delivering data which will

be shown in display panel.

3

Display PCB

Showing data sent by main PCB in LCD or OLED. Also

displaying current event status with using power lamp, alarm

lamp and trouble lamp.

4

Power/Signal Terminal

CN12 is composed of connection terminal for supplying DC18-

24V power and connection terminal for standard output (viso,

+, mA, -).

5

Alarm signal Terminal

CN8 is an alarm signal connection terminal which outputs relay

contacts of trouble, alarm1 and alarm 2.

6

RS-485 signal terminal

CN3 is a signal connection terminal(A,B) for isolated RS-485

communication.

7

Sensor terminal

C10 is a sensor connection terminal(RD, WH, BK, BE).

8

Power on/off switch

Turning on or off power of gas detector. The switch should be

turned off when cable work or A/S is performed. After finishing

those works, the switch can be on.

9

Power lamp

When power switch turns on, this power lamp light will be on.

10

Trouble lamp

When fault occurs in circuit or sensor sensitivity, the trouble

lamp will be on.

11

Alarm1 lamp

The alarm1 lamp turns on when the measured value of gas

becomes over alarm1 level on gas leakage.

12

Alarm2 lamp

The alarm2 lamp turns on when the measured value of gas

becomes over alarm2 level on gas leakage

13

Function switch

In order to set parameters, this function switch is used to allow

the device to enter program mode by touching it with magnet-

bar for 2 seconds or more(Program mode, Calibration mode

and Test mode are also provided). The switch is also used to

input and set data.

14

Reset switch

Reset switch can be used to cancel setting parameter or return

back to previous state by touching it once with magnet bar.

(Each time it is touched with magnet bar, the mode will be

switched back to the immediate previous mode)

15

↑(Up) switch

This switch is used to transit mode or adjust number by

touching it with magnet bar. The mode will be switched in a

forward direction and the number in an increasing direction.

Gas Detection (Australia) Pty Ltd Page 10 of 44 M-GDA-3000 Rev 1

16

↓(Down) switch

This switch is used to transit mode or adjust number by

touching it with magnet bar. The mode will be switched in a

backward direction and the number in a decreasing direction.

17

External earth

The gas detector must be connected to ground via the external

earth point to protect it against external noises or high voltage.

18

Mount hole(ø7×2ea)

These holes are used to fix the gas detector on wall or other

installed places.

19

Cover fixed

screw(M4)

The gas detector’s housing body and housing cover must be

fixed with hex sockethead cap screw after they are assembled

in order to prevent separation which might be caused by

external shocks.

20

Sensor thread

Attachment places where IR gas Sensor(Detector) is attached.

21

Cable inlet

These cable inlets are used to supply power and input & output

measured data signal during installation. PF 3/4" is basically

provided.

22

Internal earth

The gas detector must be connected to ground via the internal

earth point to protect it against external noises or high voltage.

23

RS-485 Module /

HART Module

(Optional)

This is a connector which enables the detector to communicate

with PC or PLC through isolation-type RS-485 communication

protocol or HART. To activate RS-485 communication,

communication address must be assigned to the detector

properly.(the value is set to be 1 by default) For using HART,

polling-address and tag no. must be set appropriately.

24

Relay Contact

Type Selection

It enables the user to select relay contact between A and B.

When the detector is not ENERGIZER MODE, it will operate

with A contact(Normal Open) if the spot marked by A silk is

connected by jumper wire. It will operate with B contact(Normal

Close) if the spot marked by B silk is connected by jumper.

The other way, when the detector is ENERGIZER MODE, it will

operate with B contact if the spot marked by A silk is

connected by jumper wire. It will operate with A contact(Normal

Close) if the spot marked by B silk is connected by jumper.

25

Warning Light

Connector

(Optional)

This connector will be connected only if LED needs to be used.

26

Program Downloading

Connector

The connector enables the user to download program to the

product.

[Table 3. Detailed Description about components of the GDA-3000]

Gas Detection (Australia) Pty Ltd Page 11 of 44 M-GDA-3000 Rev 1

5. Terminal Wiring Diagram

WarningNever install, uncover, or manipulate the Detector other than

authorized

personnel or installation/repair service person from GDA, or serious loss of life and property

damage such as fire or explosion may occur. In addition, check around for explosive Gas or

flammable substances, followed by turning OFF before any work.

5.1. Separation of Detector Body and Cover

The Gas Detector Cover can be removed by turning the Cover fastening Slotted Set Screw

(M4 x 1ea) three to four rotations anti-clockwise using hex wrench (M2), followed by turning

the Cover counterclockwise by hand. After the separation of Cover, the LCD indicator

appears.

[Figure 2. Slotted Set Screw]

After the Cover removal, remove the Display Part as follows.

1. Click the left and right retainer

rings on the front of the LCD

display inwards at the same

time.

2. While holding, pull the Display

Part forward to separate from

the Gas detector Body.

3. With the Display Part removed,

the Main PCB is shown under

the Detector Body.

[Figure 3. Display Parts removal ]

Gas Detection (Australia) Pty Ltd Page 12 of 44 M-GDA-3000 Rev 1

5.2. Main PCB Configuration

5.2.1 Main PCB configuration

With the Display Part removed, the Main PCB terminal arrangement is shown as the following

Figure.

[Figure 4. Main PCB terminal arrangement ]

No.

Name

Description

1

CN12

Power & Output Signal Terminal

2

J4

4~20mA Source / Sink selection jumper

( ON: Source Type, OFF: Sink Type )

3

CN11

Display LCD Connector

4

CN10

Sensor Connector

5

CN6

Program download Connector

6

D1

Status LED ( blinks every second in normal operation )

7

CN1,CN2,CN4

HART Option Board Connector

8

CN5

Warning Light(GTL-100) Interface Connector

[Table 4. Main PCB main Parts Description]

Gas Detection (Australia) Pty Ltd Page 13 of 44 M-GDA-3000 Rev 1

5.2.2. HART Board configuration

HART Board consists of Option Board, and is connected using CN5, CN6, CN7 terminals of

Main PCB and the HART Board Screw at the top left.

[Figure 5. HART Board constituting Main PCB]

No.

Name

Description

1

HART Board Screw

Constructed using 3Ø Screw

2

Blank Hole

Reserve Hole

3

HART Board

Option Board for HART Interface

[Table 5. HART Board main Parts description ]

Gas Detection (Australia) Pty Ltd Page 14 of 44 M-GDA-3000 Rev 1

5.3. Main PCB terminal description and wiring method

If you remove the Display Part, there is the Terminal Block under the Main PCB as shown in

the following Figure 6. The Terminal Block can be removed from Main PCB by holding and

pulling upward by hand. Unscrew the 5 terminal set screws above the separated Terminal

Block CN12 (VIS, +, mA, -, ETH) Connector counter-clockwise with a Θ screwdriver; connect

DC18-24V power to +, -; connect Signal Cable to mA; tighten the terminal set screws

clockwise to keep the terminals in place; and insert it like before the removal.

[Figure 6. CN12 Terminal structure]

No.

PCB Silk

Pin

Name

Description

4~20mA Source Drive

(J1 Jumper ON)

4~20mA Sink Drive

(J1 Jumper OFF)

1

VISO

VIS

N.C

4~20mA Sink In(+)

2

+24V

+

+24V / POWER (+)

3

mA

mA

4~20mA Source Out

4~20mA Sink Out(-)

4

GND

-

GND / POWER (-)

5

ETH

ET

EARTH

[Table 6. CN12 connector description ]

Note 1) Be sure to use CVVS or CVVSB 2.0sq↑ Shield Cable before Terminal construction.

Note 2) Fasten Terminals based on +24V of 2Pin to connect the 4Pin Terminal of existing

conventional GDA3000.

Gas Detection (Australia) Pty Ltd Page 15 of 44 M-GDA-3000 Rev 1

5.3.1. RELAY DRIVE TYPE WIRING METHOD

The Relay drive type of GDA-3000 can be operated by two ways.

There is De-Energized Mode and Energized Mode.

Main PCB is marked A, B silk to set Relay drive type and connect using Jumper as you want

Relay drive type.

[Figure 7. Main PCB Relay part Configuration]

Drive type

A Contact

B Contact

De-Energized

Connect Jumper to (A-C)

Connect Jumper to (B-C)

Energized

Connect Jumper to (B-C)

Connect Jumper to (A-C)

[Table 7. Relay drive type description]

Note 1) Be sure to use the same J1, J2, J3.

Note 2) Conventional GDA-3000 can be operated DE-Energized Mode.

Gas Detection (Australia) Pty Ltd Page 16 of 44 M-GDA-3000 Rev 1

5.3.2. 4~20mA SOURCE DRIVE TYPE WIRING METHOD

Connect 4-20mA Signal Terminal of PLC to ‘mA’ of GDA3000. GND Terminal is used in

common with the power. Turn J4 Jumper ON.

※HART Communicator can be used only in models utilizing HART Option Board.

[Figure 8. Analog 4~20mA Source Configuration]

Gas Detection (Australia) Pty Ltd Page 17 of 44 M-GDA-3000 Rev 1

5.3.3. 4~20mA SINK DRIVE TYPE WIRING METHOD

Connect 4-20mA Sink Output (+) Terminal of PLC to VISO Terminal; and (-) Terminal to ‘mA’

Terminal. Turn J4 Jumper OFF.

※HART Communicator can be used only in models utilizing HART Option Board.

[Figure 9. Analog 4~20mA Sink Configuration ]

Gas Detection (Australia) Pty Ltd Page 18 of 44 M-GDA-3000 Rev 1

5.3.1. Connection method with our main Control Unit

Connect CN12 (VISO,+, mA, -, ET) Connection Terminal of the Gas Detector and the Control

Unit with reference to the Figure below. (See product manual for each Control Unit.)

(GTC-100A Series Control unit)

(GTC-200A/210A Series Control unit)

(GTC-510A/520A Series Control unit)

Gas Detection (Australia) Pty Ltd Page 19 of 44 M-GDA-3000 Rev 1

6. Standard Type outside view and Dimensions

[Figure 10. GDA3000 outside view]

Gas Detection (Australia) Pty Ltd Page 20 of 44 M-GDA-3000 Rev 1

7. Warning light type: Outside view and Dimensions

[Figure 11. GDA3000 Warning Light type outside view]

Table of contents

Other Gas Detection Gas Detector manuals