Gas Detection GTD-2000Tx User manual

GTD-2000Tx

Instruction Manual

Headquarters / Engineering research laboratory :

23 Gunpo Advance d Industry 1-ro(Bugok-dong), Gunpo-si, Gyeonggi-do

Tel +82-31-490-0800 Fax +82-31-490-0801

Yeongnam business office / Plant :

55 Gonghangap-gil 85beon-gil, Gangseogu, Busan Metropolitan City

Tel +51-973-8518 Fax +51-973-8519

www.gastron.com

Read in detail for correct use.

GTD-2000Tx

Instruction Manual

Headquarters / Engineering research laboratory :

23 Gunpo Advance d Industry 1-ro(Bugok-dong), Gunpo-si, Gyeonggi-do

Tel +82-31-490-0800 Fax +82-31-490-0801

Yeongnam business office / Plant :

55 Gonghangap-gil 85beon-gil, Gangseogu, Busan Metropolitan City

Tel +51-973-8518 Fax +51-973-8519

www.gastron.com

Read in detail for correct use.

Gas & Flame

Detection System

GTD-2000Tx

Instruction Manual

www.gastron.com

02_03

In case of a problem after purchasing the product,

please contact the address below.

· Address : 23 Gunpo Advanced Industry 1-ro, Gunpo-si, Gyeonggi-do

· Tel : 031-490-0800

· Fax : 031-490-0801

· URL : www.gastron.com

The present product and the product manual can be changed without advance notice for performance improvement

and use convenience of the product.

* KOSHA GUIDE : P-135/6-2018

Calibration should be executed periodically at periods required by the manufacturer

¥'PSBDDVSBUFPQFSBUJPOPG(BTEFUFDUPSDIFDLVQBOEDBMJCSBUFGPSNPSFUIBOPODFJOFWFSZNPOUIT

( * In reference to KOSHA GUIDE: P-135/6-2018 / 7.2 In-house inspection, section 2)

¥'PSBDDVSBUFPQFSBUJPOPG(BTEFUFDUPSDIFDLVQBOEDBMJCSBUJPOXJUIDBMJCSBUJPOHBTCFGPSF

measurement is recommended.

¥8IFOOPUDBMJCSBUFEJUNBZDBVTFNBMGVODUJPOPGUIFFRVJQNFOUEVFUPQSPCMFNTSFTVMUJOHGSPN

Sensor aging.

¥8IFOUIFQSFTFOUJOTUSVNFOUTIPVMECFEJTNBOUMFEUIPTFXJUIQSPGFTTJPOBMTLJMMTGPS(BTEFUFDUPS

should conduct the operation.

¥'PSQPXFSTVQQMZDBCMFXJSFTQFDJGJDBUJPOTTIPVMECFEFUFSNJOFECZSFGFSSJOHUPUIFJUFNPG-FOHUI

PGJOTUBMMFEDBCMF

¥'PSUIFDPOUFOUTPODIFDLVQBOEDBMJCSBUJPOPG(BTEFUFDUPSQMFBTFVTFPVSDPNQBOZTFOHJOFFSJOH

department , e-mail, or web site.

We sincerely thank you for purchasing the product of Gastron Co. Ltd.

Our Gastron Co.Ltd. is a company specialized in Gas detector and Gas Monitoring System, being recognized

CZNBOZDPOTVNFSTEVFUPUIFCFTURVBMJUZBOEVTFDPOWFOJFODF8FBMXBZTFOBCMFZPVDPOTVNFSTUPGJOE

desired products nearby and are ceaselessly studying and striving for development of Gas detectors satisfying

customers. From now on, solve all anguishes concerning Gas detector with the products of Gastron Co. Ltd,

8F(BTUSPO$PXJMMUBLFBSFTQPOTJCJMJUZBOEHJWFZPVTBUJTGBDUJPO

In the present instruction manual, operation method for Gas detector as well as simple methods for

maintenance and repair, etc. are recorded If you read it in detail and keep it well, for reference when you

have questions, then it will give you much help.

Greetings

Gas & Flame

Detection System

GTD-2000Tx

Instruction Manual

www.gastron.com

02_03

In case of a problem after purchasing the product,

please contact the address below.

· Address : 23 Gunpo Advanced Industry 1-ro, Gunpo-si, Gyeonggi-do

· Tel : 031-490-0800

· Fax : 031-490-0801

· URL : www.gastron.com

The present product and the product manual can be changed without advance notice for performance improvement

and use convenience of the product.

* KOSHA GUIDE : P-135/6-2018

Calibration should be executed periodically at periods required by the manufacturer

¥'PSBDDVSBUFPQFSBUJPOPG(BTEFUFDUPSDIFDLVQBOEDBMJCSBUFGPSNPSFUIBOPODFJOFWFSZNPOUIT

( * In reference to KOSHA GUIDE: P-135/6-2018 / 7.2 In-house inspection, section 2)

¥'PSBDDVSBUFPQFSBUJPOPG(BTEFUFDUPSDIFDLVQBOEDBMJCSBUJPOXJUIDBMJCSBUJPOHBTCFGPSF

measurement is recommended.

¥8IFOOPUDBMJCSBUFEJUNBZDBVTFNBMGVODUJPOPGUIFFRVJQNFOUEVFUPQSPCMFNTSFTVMUJOHGSPN

Sensor aging.

¥8IFOUIFQSFTFOUJOTUSVNFOUTIPVMECFEJTNBOUMFEUIPTFXJUIQSPGFTTJPOBMTLJMMTGPS(BTEFUFDUPS

should conduct the operation.

¥'PSQPXFSTVQQMZDBCMFXJSFTQFDJGJDBUJPOTTIPVMECFEFUFSNJOFECZSFGFSSJOHUPUIFJUFNPG-FOHUI

PGJOTUBMMFEDBCMF

¥'PSUIFDPOUFOUTPODIFDLVQBOEDBMJCSBUJPOPG(BTEFUFDUPSQMFBTFVTFPVSDPNQBOZTFOHJOFFSJOH

department , e-mail, or web site.

We sincerely thank you for purchasing the product of Gastron Co. Ltd.

Our Gastron Co.Ltd. is a company specialized in Gas detector and Gas Monitoring System, being recognized

CZNBOZDPOTVNFSTEVFUPUIFCFTURVBMJUZBOEVTFDPOWFOJFODF8FBMXBZTFOBCMFZPVDPOTVNFSTUPGJOE

desired products nearby and are ceaselessly studying and striving for development of Gas detectors satisfying

customers. From now on, solve all anguishes concerning Gas detector with the products of Gastron Co. Ltd,

8F(BTUSPO$PXJMMUBLFBSFTQPOTJCJMJUZBOEHJWFZPVTBUJTGBDUJPO

In the present instruction manual, operation method for Gas detector as well as simple methods for

maintenance and repair, etc. are recorded If you read it in detail and keep it well, for reference when you

have questions, then it will give you much help.

Greetings

Gas & Flame

Detection System

GTD-2000Tx

Instruction Manual

www.gastron.com

02_03

In case of a problem after purchasing the product,

please contact the address below.

· Address : 23 Gunpo Advanced Industry 1-ro, Gunpo-si, Gyeonggi-do

· Tel : 031-490-0800

· Fax : 031-490-0801

· URL : www.gastron.com

The present product and the product manual can be changed without advance notice for performance improvement

and use convenience of the product.

* KOSHA GUIDE : P-135/6-2018

Calibration should be executed periodically at periods required by the manufacturer

¥'PSBDDVSBUFPQFSBUJPOPG(BTEFUFDUPSDIFDLVQBOEDBMJCSBUFGPSNPSFUIBOPODFJOFWFSZNPOUIT

( * In reference to KOSHA GUIDE: P-135/6-2018 / 7.2 In-house inspection, section 2)

¥'PSBDDVSBUFPQFSBUJPOPG(BTEFUFDUPSDIFDLVQBOEDBMJCSBUJPOXJUIDBMJCSBUJPOHBTCFGPSF

measurement is recommended.

¥8IFOOPUDBMJCSBUFEJUNBZDBVTFNBMGVODUJPOPGUIFFRVJQNFOUEVFUPQSPCMFNTSFTVMUJOHGSPN

Sensor aging.

¥8IFOUIFQSFTFOUJOTUSVNFOUTIPVMECFEJTNBOUMFEUIPTFXJUIQSPGFTTJPOBMTLJMMTGPS(BTEFUFDUPS

should conduct the operation.

¥'PSQPXFSTVQQMZDBCMFXJSFTQFDJGJDBUJPOTTIPVMECFEFUFSNJOFECZSFGFSSJOHUPUIFJUFNPG-FOHUI

PGJOTUBMMFEDBCMF

¥'PSUIFDPOUFOUTPODIFDLVQBOEDBMJCSBUJPOPG(BTEFUFDUPSQMFBTFVTFPVSDPNQBOZTFOHJOFFSJOH

department , e-mail, or web site.

We sincerely thank you for purchasing the product of Gastron Co. Ltd.

Our Gastron Co.Ltd. is a company specialized in Gas detector and Gas Monitoring System, being recognized

CZNBOZDPOTVNFSTEVFUPUIFCFTURVBMJUZBOEVTFDPOWFOJFODF8FBMXBZTFOBCMFZPVDPOTVNFSTUPGJOE

desired products nearby and are ceaselessly studying and striving for development of Gas detectors satisfying

customers. From now on, solve all anguishes concerning Gas detector with the products of Gastron Co. Ltd,

8F(BTUSPO$PXJMMUBLFBSFTQPOTJCJMJUZBOEHJWFZPVTBUJTGBDUJPO

In the present instruction manual, operation method for Gas detector as well as simple methods for

maintenance and repair, etc. are recorded If you read it in detail and keep it well, for reference when you

have questions, then it will give you much help.

Greetings

Gas & Flame

Detection System

GTD-2000Tx

Instruction Manual

www.gastron.com

02_03

In case of a problem after purchasing the product,

please contact the address below.

· Address : 23 Gunpo Advanced Industry 1-ro, Gunpo-si, Gyeonggi-do

· Tel : 031-490-0800

· Fax : 031-490-0801

· URL : www.gastron.com

The present product and the product manual can be changed without advance notice for performance improvement

and use convenience of the product.

* KOSHA GUIDE : P-135/6-2018

Calibration should be executed periodically at periods required by the manufacturer

¥'PSBDDVSBUFPQFSBUJPOPG(BTEFUFDUPSDIFDLVQBOEDBMJCSBUFGPSNPSFUIBOPODFJOFWFSZNPOUIT

( * In reference to KOSHA GUIDE: P-135/6-2018 / 7.2 In-house inspection, section 2)

¥'PSBDDVSBUFPQFSBUJPOPG(BTEFUFDUPSDIFDLVQBOEDBMJCSBUJPOXJUIDBMJCSBUJPOHBTCFGPSF

measurement is recommended.

¥8IFOOPUDBMJCSBUFEJUNBZDBVTFNBMGVODUJPOPGUIFFRVJQNFOUEVFUPQSPCMFNTSFTVMUJOHGSPN

Sensor aging.

¥8IFOUIFQSFTFOUJOTUSVNFOUTIPVMECFEJTNBOUMFEUIPTFXJUIQSPGFTTJPOBMTLJMMTGPS(BTEFUFDUPS

should conduct the operation.

¥'PSQPXFSTVQQMZDBCMFXJSFTQFDJGJDBUJPOTTIPVMECFEFUFSNJOFECZSFGFSSJOHUPUIFJUFNPG-FOHUI

PGJOTUBMMFEDBCMF

¥'PSUIFDPOUFOUTPODIFDLVQBOEDBMJCSBUJPOPG(BTEFUFDUPSQMFBTFVTFPVSDPNQBOZTFOHJOFFSJOH

department , e-mail, or web site.

We sincerely thank you for purchasing the product of Gastron Co. Ltd.

Our Gastron Co.Ltd. is a company specialized in Gas detector and Gas Monitoring System, being recognized

CZNBOZDPOTVNFSTEVFUPUIFCFTURVBMJUZBOEVTFDPOWFOJFODF8FBMXBZTFOBCMFZPVDPOTVNFSTUPGJOE

desired products nearby and are ceaselessly studying and striving for development of Gas detectors satisfying

customers. From now on, solve all anguishes concerning Gas detector with the products of Gastron Co. Ltd,

8F(BTUSPO$PXJMMUBLFBSFTQPOTJCJMJUZBOEHJWFZPVTBUJTGBDUJPO

In the present instruction manual, operation method for Gas detector as well as simple methods for

maintenance and repair, etc. are recorded If you read it in detail and keep it well, for reference when you

have questions, then it will give you much help.

Greetings

www.gastron.com

04_05

ContentsContents

GTD-2000Tx

Instruction Manual

7.2.1. Zero Calibration······································································································································· 21

7.2.2. Span Calibration······································································································································ 22

7.3. ALARM Mode ···················································································································································· 23

8. Troubleshooting·························································································································································· 25

8.1. Fault List ····························································································································································· 25

8.2. Recovery List······················································································································································· 25

9. Outline drawing and Dimensions···························································································································· 26

9.1. Standard Type ···················································································································································· 26

9.2. Upon coupling of warning light························································································································ 27

9.3. Upon coupling of Raincover······························································································································ 28

10. Notes before installation··········································································································································· 29

10.1. Selection of installation place(Data from occupational safety and health regulations) ·································· 29

10.2. Selection of installation place(Data from safety management regulations for high-pressure gas) ················ 29

10.3. Notes upon installation······································································································································ 29

11. Revision record···························································································································································· 31

1. Overview ······································································································································································ 6

2. Structure······································································································································································· 6

3. Specification ································································································································································ 7

3.1. Basic Specifications ············································································································································ 7

3.2. Mechanical Specifications ································································································································· 7

3.3. Electrical Specifications (Standard Type)··········································································································· 8

3.4. Environmental Specifications ···························································································································· 8

4. Name and description of each part ························································································································ 9

4.1. Components ······················································································································································ 9

5. Installation···································································································································································· 11

5.1. Detachment of Housing Cover·························································································································· 11

5.2. Main PCB Configuration···································································································································· 12

5.3. LTerminal Configuration ···································································································································· 12

8JSJOHGPS_N"4PVSDF0QFSBUJPO5ZQF ·························································································· 14

8JSJOHGPS_N"4JOL0QFSBUJPO5ZQF······························································································· 14

8JSJOHGPS_N"8JSF4JOL0QFSBUJPO5ZQF···················································································· 15

5.3. Installation Cable Length ··································································································································· 15

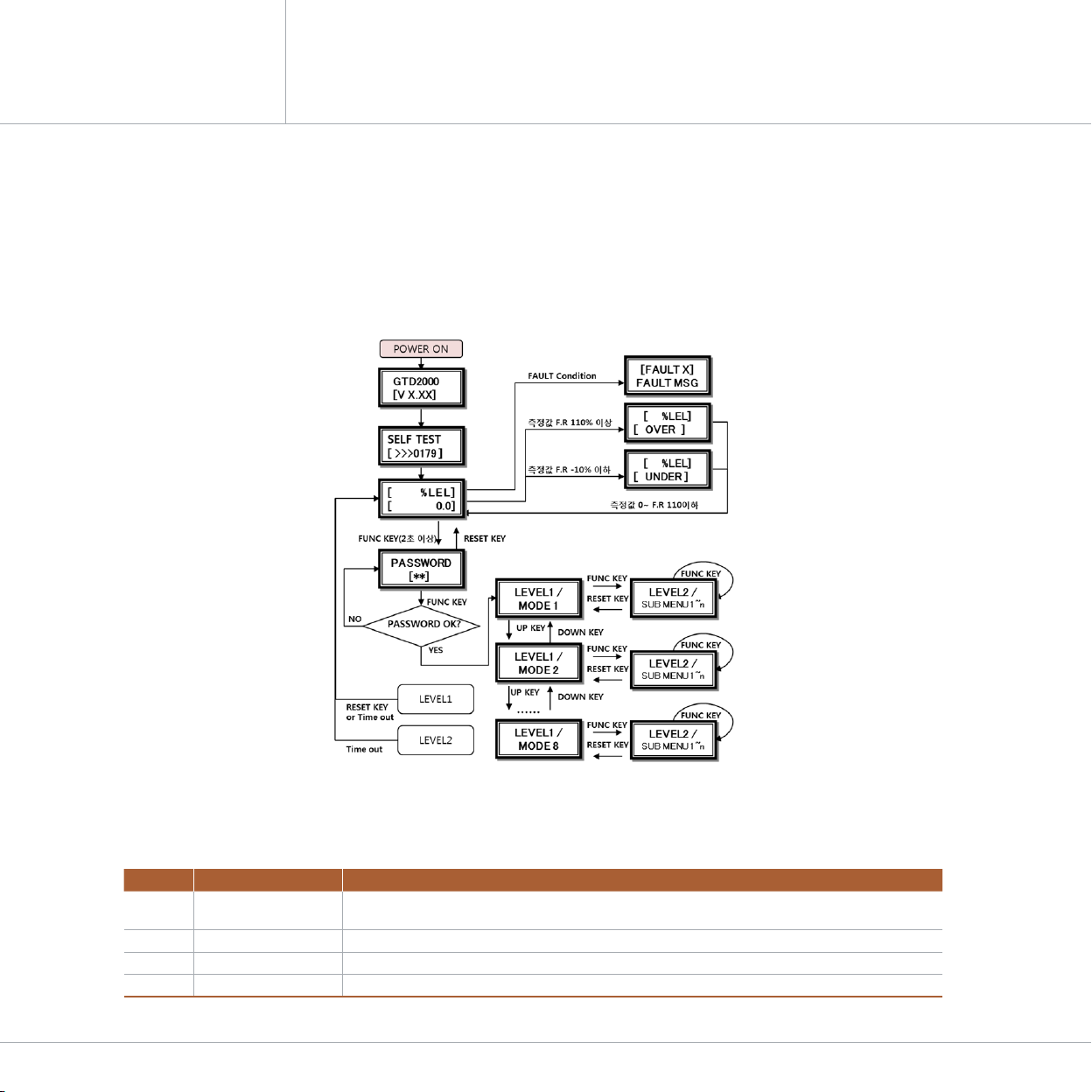

6. Detector Operation Flow ·········································································································································· 17

6.1. Initial Operation Status (Power On) ·················································································································· 17

6.2. Measuring Mode ··············································································································································· 17

6.3. Operation Flow ················································································································································· 18

6.4. Menu Configuration Table ································································································································ 19

7. System Mode ······························································································································································ 20

7.1. PROGRAM MODE ············································································································································· 20

7.2. CALIBRATION MODE········································································································································· 21

www.gastron.com

04_05

ContentsContents

GTD-2000Tx

Instruction Manual

7.2.1. Zero Calibration······································································································································· 21

7.2.2. Span Calibration······································································································································ 22

7.3. ALARM Mode ···················································································································································· 23

8. Troubleshooting·························································································································································· 25

8.1. Fault List ····························································································································································· 25

8.2. Recovery List······················································································································································· 25

9. Outline drawing and Dimensions···························································································································· 26

9.1. Standard Type ···················································································································································· 26

9.2. Upon coupling of warning light························································································································ 27

9.3. Upon coupling of Raincover······························································································································ 28

10. Notes before installation··········································································································································· 29

10.1. Selection of installation place(Data from occupational safety and health regulations) ·································· 29

10.2. Selection of installation place(Data from safety management regulations for high-pressure gas) ················ 29

10.3. Notes upon installation······································································································································ 29

11. Revision record···························································································································································· 31

1. Overview ······································································································································································ 6

2. Structure······································································································································································· 6

3. Specification ································································································································································ 7

3.1. Basic Specifications ············································································································································ 7

3.2. Mechanical Specifications ································································································································· 7

3.3. Electrical Specifications (Standard Type)··········································································································· 8

3.4. Environmental Specifications ···························································································································· 8

4. Name and description of each part ························································································································ 9

4.1. Components ······················································································································································ 9

5. Installation···································································································································································· 11

5.1. Detachment of Housing Cover·························································································································· 11

5.2. Main PCB Configuration···································································································································· 12

5.3. LTerminal Configuration ···································································································································· 12

8JSJOHGPS_N"4PVSDF0QFSBUJPO5ZQF ·························································································· 14

8JSJOHGPS_N"4JOL0QFSBUJPO5ZQF······························································································· 14

8JSJOHGPS_N"8JSF4JOL0QFSBUJPO5ZQF···················································································· 15

5.3. Installation Cable Length ··································································································································· 15

6. Detector Operation Flow ·········································································································································· 17

6.1. Initial Operation Status (Power On) ·················································································································· 17

6.2. Measuring Mode ··············································································································································· 17

6.3. Operation Flow ················································································································································· 18

6.4. Menu Configuration Table ································································································································ 19

7. System Mode ······························································································································································ 20

7.1. PROGRAM MODE ············································································································································· 20

7.2. CALIBRATION MODE········································································································································· 21

www.gastron.com

04_05

ContentsContents

GTD-2000Tx

Instruction Manual

7.2.1. Zero Calibration······································································································································· 21

7.2.2. Span Calibration······································································································································ 22

7.3. ALARM Mode ···················································································································································· 23

8. Troubleshooting·························································································································································· 25

8.1. Fault List ····························································································································································· 25

8.2. Recovery List······················································································································································· 25

9. Outline drawing and Dimensions···························································································································· 26

9.1. Standard Type ···················································································································································· 26

9.2. Upon coupling of warning light························································································································ 27

9.3. Upon coupling of Raincover······························································································································ 28

10. Notes before installation··········································································································································· 29

10.1. Selection of installation place(Data from occupational safety and health regulations) ·································· 29

10.2. Selection of installation place(Data from safety management regulations for high-pressure gas) ················ 29

10.3. Notes upon installation······································································································································ 29

11. Revision record···························································································································································· 31

1. Overview ······································································································································································ 6

2. Structure······································································································································································· 6

3. Specification ································································································································································ 7

3.1. Basic Specifications ············································································································································ 7

3.2. Mechanical Specifications ································································································································· 7

3.3. Electrical Specifications (Standard Type)··········································································································· 8

3.4. Environmental Specifications ···························································································································· 8

4. Name and description of each part ························································································································ 9

4.1. Components ······················································································································································ 9

5. Installation···································································································································································· 11

5.1. Detachment of Housing Cover·························································································································· 11

5.2. Main PCB Configuration···································································································································· 12

5.3. LTerminal Configuration ···································································································································· 12

8JSJOHGPS_N"4PVSDF0QFSBUJPO5ZQF ·························································································· 14

8JSJOHGPS_N"4JOL0QFSBUJPO5ZQF······························································································· 14

8JSJOHGPS_N"8JSF4JOL0QFSBUJPO5ZQF···················································································· 15

5.3. Installation Cable Length ··································································································································· 15

6. Detector Operation Flow ·········································································································································· 17

6.1. Initial Operation Status (Power On) ·················································································································· 17

6.2. Measuring Mode ··············································································································································· 17

6.3. Operation Flow ················································································································································· 18

6.4. Menu Configuration Table ································································································································ 19

7. System Mode ······························································································································································ 20

7.1. PROGRAM MODE ············································································································································· 20

7.2. CALIBRATION MODE········································································································································· 21

www.gastron.com

04_05

ContentsContents

GTD-2000Tx

Instruction Manual

7.2.1. Zero Calibration······································································································································· 21

7.2.2. Span Calibration······································································································································ 22

7.3. ALARM Mode ···················································································································································· 23

8. Troubleshooting·························································································································································· 25

8.1. Fault List ····························································································································································· 25

8.2. Recovery List······················································································································································· 25

9. Outline drawing and Dimensions···························································································································· 26

9.1. Standard Type ···················································································································································· 26

9.2. Upon coupling of warning light························································································································ 27

9.3. Upon coupling of Raincover······························································································································ 28

10. Notes before installation··········································································································································· 29

10.1. Selection of installation place(Data from occupational safety and health regulations) ·································· 29

10.2. Selection of installation place(Data from safety management regulations for high-pressure gas) ················ 29

10.3. Notes upon installation······································································································································ 29

11. Revision record···························································································································································· 31

1. Overview ······································································································································································ 6

2. Structure······································································································································································· 6

3. Specification ································································································································································ 7

3.1. Basic Specifications ············································································································································ 7

3.2. Mechanical Specifications ································································································································· 7

3.3. Electrical Specifications (Standard Type)··········································································································· 8

3.4. Environmental Specifications ···························································································································· 8

4. Name and description of each part ························································································································ 9

4.1. Components ······················································································································································ 9

5. Installation···································································································································································· 11

5.1. Detachment of Housing Cover·························································································································· 11

5.2. Main PCB Configuration···································································································································· 12

5.3. LTerminal Configuration ···································································································································· 12

8JSJOHGPS_N"4PVSDF0QFSBUJPO5ZQF ·························································································· 14

8JSJOHGPS_N"4JOL0QFSBUJPO5ZQF······························································································· 14

8JSJOHGPS_N"8JSF4JOL0QFSBUJPO5ZQF···················································································· 15

5.3. Installation Cable Length ··································································································································· 15

6. Detector Operation Flow ·········································································································································· 17

6.1. Initial Operation Status (Power On) ·················································································································· 17

6.2. Measuring Mode ··············································································································································· 17

6.3. Operation Flow ················································································································································· 18

6.4. Menu Configuration Table ································································································································ 19

7. System Mode ······························································································································································ 20

7.1. PROGRAM MODE ············································································································································· 20

7.2. CALIBRATION MODE········································································································································· 21

www.gastron.com

06_07

/PUF3FGFSUPUIFNFBTVSFEHBTMJTUGPSNFBTVSFEHBTFTBOEUIFJSSBOHFT$POUBDUVTGPSTQFDJBMHBT

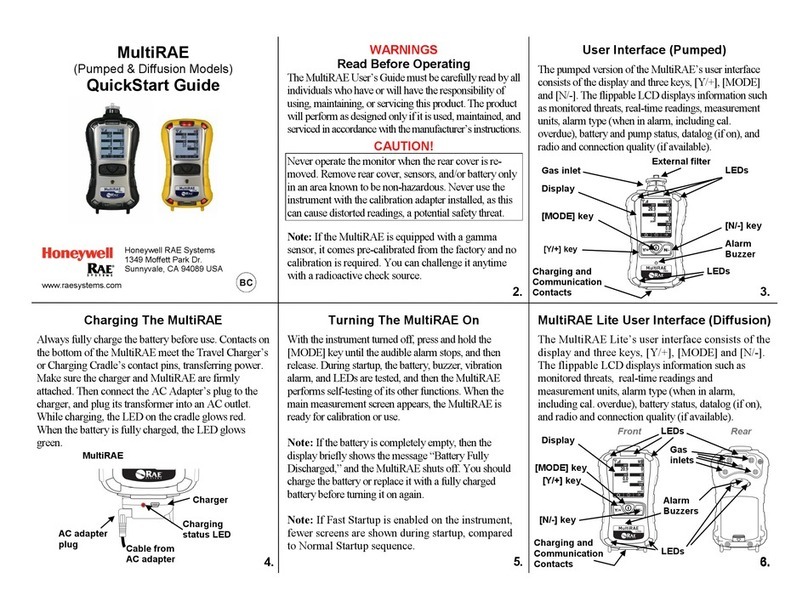

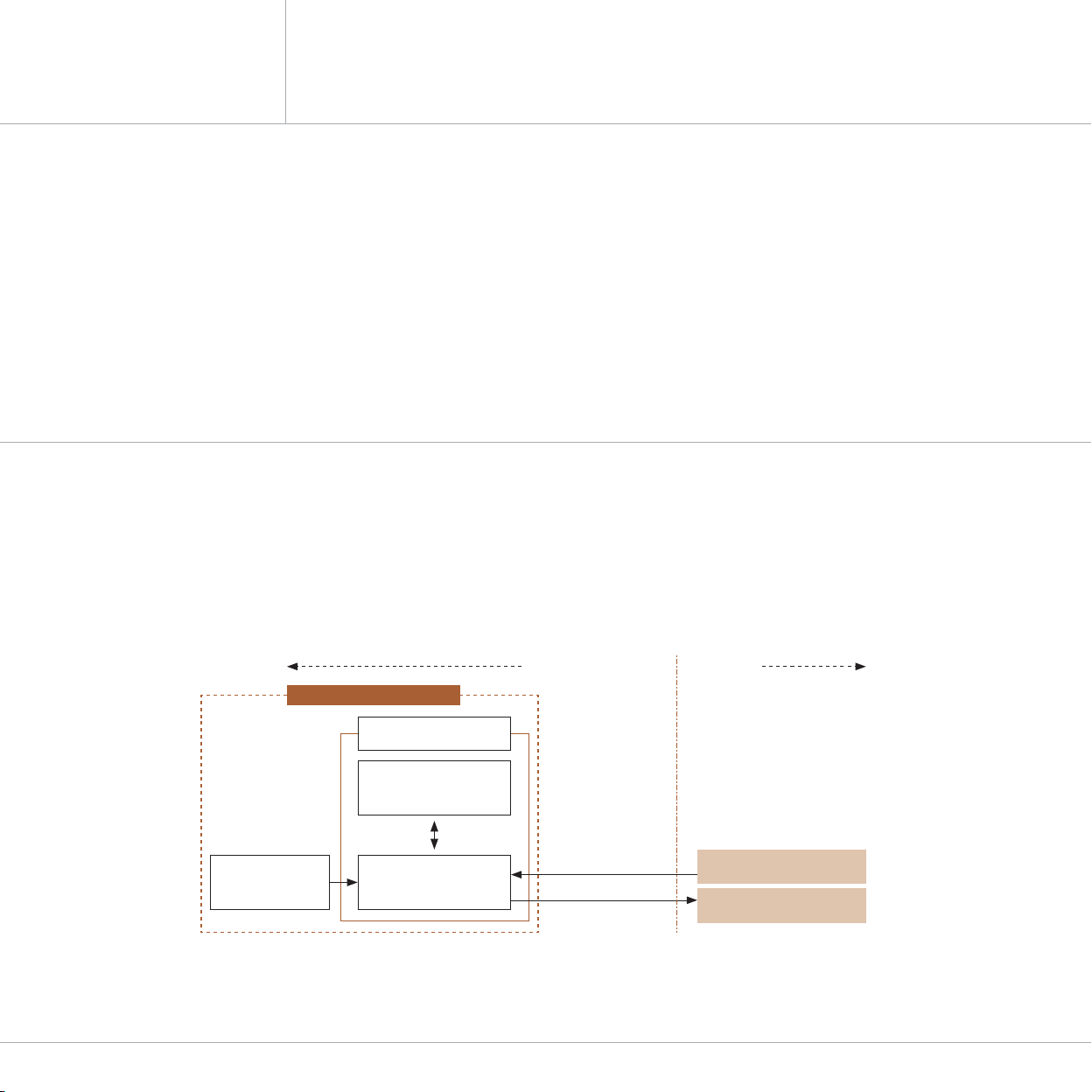

[Figure 1. GTD-2000Tx Overview]

Infrared Gas

Sensor Module

(GSA860TX)

Main Board

(Transmitter)

+24V DC

4-20mA Analog

Signal Output

Display Board

(User Interface)

Transmitter enclosure

Safety Power Supply Unit

(24VDC)

Safety Controller

(PLC or DCS)

GTD-2000Tx Gas Detector

Hazardous Area (Filed) Safe Area

GTD-2000Tx

Instruction Manual

3.1. Basic Specifications

ITEMS SPECIFICATION

Measuring Type Diffusion

Measuring Value Display LCD or OLED Display

Measuring Method

- Electro-Chemical Cell

- Heated-semiconductor Cell)

- Photoionization detector(PID)

Detectable Gas Toxic Gas (Note 1)

Measuring Range $BQBCMFUPEJTQMBZ_/PUF

Accuracy 'VMM3BOHF

Zero Drift 'VMM3BOHF

Response Time Depends on Sensor Module.

Refer to Sensor Specification or Contact in case for Special Gas.

Approvals Classification

KCs: Ex d llC T6,T5,T4, IP65

"5&9*&$&9**(&YE**$(C5_5

SIL2, MED, ABS, DNV

Basic Interface Analog 4-20mA current interface

HART Interface HART REV7 (Option)

Option

HART Board

(5-8BSOJOH-JHIU

Rain Cover

8BSSBOUZ Transmitter 2Year

Sensor 1Year

3.2. Mechanical Specifications

ITEMS SPECIFICATION

Explosion-Proof Type Explosion-Proof Enclosure

Dimension 8)%NN

8FJHIUJODMVEJOH4FOTPS App. 1.5kg

Mounting Type 8BMMNPVOU

Mounting Hole ʡ

Cable inlet 1'PS/15

Body Material Transmitter aluminum alloy

Sensor Stainless Steel (STS316)

GTD-2000Tx toxic gas detector has been developed to detect gas leaked from industrial sites and various toxic gases

generated from factories, gas storages, and manufacturing processes that produce or use toxic gases and to prevent

accidents in advance.

GTD-2000Tx toxic gas detector is installed in areas with gas leak hazards and continuously monitors gas leak. It displays

NFBTVSFNFOUTPOCVJMUJOEJTQMBZT-$%PS0-&%PGUIFEFUFDUPSBOEQSPWJEFT%$_N"TUBOEBSEPVUQVUTJHOBM"MTP

GPS%$_N"TUBOEBSEPVUQVUPVUQVUTJHOBMUSBOTNJTTJPOMFOHUICFUXFFOEFUFDUPSBOESFDFJWFSDBOCFDPOOFDUFEVQ

UPN8IFODBCMF$774PS$774#TRBOEIJHIFSJTVTFE(5%5YGMBNNBCMFHBTEFUFDUPSNVTUCFVTFE

at height below 1,000 m above sea level.

Body of GTD-2000Tx is made of Aluminum alloy and the gas sensor module is made of stainless steel. It consists of a

complete explosion-proof enclosure (Ex d IIC T6). This product can be installed in areas with combustible gas leak and

explosion hazards. It has built-in LCD on the detector to display gas leak status at installed site. It consists of display part

UIBUJOEJDBUFTNFBTVSFNFOUTUFSNJOBMQBSUUIBUPVUQVUNFBTVSFNFOUT%$_N"FYUFSOBMMZBOEB1$#CPBSE

External configuration consists of detector part that monitors gas leak and cable inlets. It uses magnet-bar outside the

main body of detector enabling calibration from the outside of the detector, thus, maintenance is convenient.

2. Structure

1. Overview 3. Specications

www.gastron.com

06_07

/PUF3FGFSUPUIFNFBTVSFEHBTMJTUGPSNFBTVSFEHBTFTBOEUIFJSSBOHFT$POUBDUVTGPSTQFDJBMHBT

[Figure 1. GTD-2000Tx Overview]

Infrared Gas

Sensor Module

(GSA860TX)

Main Board

(Transmitter)

+24V DC

4-20mA Analog

Signal Output

Display Board

(User Interface)

Transmitter enclosure

Safety Power Supply Unit

(24VDC)

Safety Controller

(PLC or DCS)

GTD-2000Tx Gas Detector

Hazardous Area (Filed) Safe Area

GTD-2000Tx

Instruction Manual

3.1. Basic Specifications

ITEMS SPECIFICATION

Measuring Type Diffusion

Measuring Value Display LCD or OLED Display

Measuring Method

- Electro-Chemical Cell

- Heated-semiconductor Cell)

- Photoionization detector(PID)

Detectable Gas Toxic Gas (Note 1)

Measuring Range $BQBCMFUPEJTQMBZ_/PUF

Accuracy 'VMM3BOHF

Zero Drift 'VMM3BOHF

Response Time Depends on Sensor Module.

Refer to Sensor Specification or Contact in case for Special Gas.

Approvals Classification

KCs: Ex d llC T6,T5,T4, IP65

"5&9*&$&9**(&YE**$(C5_5

SIL2, MED, ABS, DNV

Basic Interface Analog 4-20mA current interface

HART Interface HART REV7 (Option)

Option

HART Board

(5-8BSOJOH-JHIU

Rain Cover

8BSSBOUZ Transmitter 2Year

Sensor 1Year

3.2. Mechanical Specifications

ITEMS SPECIFICATION

Explosion-Proof Type Explosion-Proof Enclosure

Dimension 8)%NN

8FJHIUJODMVEJOH4FOTPS App. 1.5kg

Mounting Type 8BMMNPVOU

Mounting Hole ʡ

Cable inlet 1'PS/15

Body Material Transmitter aluminum alloy

Sensor Stainless Steel (STS316)

GTD-2000Tx toxic gas detector has been developed to detect gas leaked from industrial sites and various toxic gases

generated from factories, gas storages, and manufacturing processes that produce or use toxic gases and to prevent

accidents in advance.

GTD-2000Tx toxic gas detector is installed in areas with gas leak hazards and continuously monitors gas leak. It displays

NFBTVSFNFOUTPOCVJMUJOEJTQMBZT-$%PS0-&%PGUIFEFUFDUPSBOEQSPWJEFT%$_N"TUBOEBSEPVUQVUTJHOBM"MTP

GPS%$_N"TUBOEBSEPVUQVUPVUQVUTJHOBMUSBOTNJTTJPOMFOHUICFUXFFOEFUFDUPSBOESFDFJWFSDBOCFDPOOFDUFEVQ

UPN8IFODBCMF$774PS$774#TRBOEIJHIFSJTVTFE(5%5YGMBNNBCMFHBTEFUFDUPSNVTUCFVTFE

at height below 1,000 m above sea level.

Body of GTD-2000Tx is made of Aluminum alloy and the gas sensor module is made of stainless steel. It consists of a

complete explosion-proof enclosure (Ex d IIC T6). This product can be installed in areas with combustible gas leak and

explosion hazards. It has built-in LCD on the detector to display gas leak status at installed site. It consists of display part

UIBUJOEJDBUFTNFBTVSFNFOUTUFSNJOBMQBSUUIBUPVUQVUNFBTVSFNFOUT%$_N"FYUFSOBMMZBOEB1$#CPBSE

External configuration consists of detector part that monitors gas leak and cable inlets. It uses magnet-bar outside the

main body of detector enabling calibration from the outside of the detector, thus, maintenance is convenient.

2. Structure

1. Overview 3. Specications

www.gastron.com

06_07

/PUF3FGFSUPUIFNFBTVSFEHBTMJTUGPSNFBTVSFEHBTFTBOEUIFJSSBOHFT$POUBDUVTGPSTQFDJBMHBT

[Figure 1. GTD-2000Tx Overview]

Infrared Gas

Sensor Module

(GSA860TX)

Main Board

(Transmitter)

+24V DC

4-20mA Analog

Signal Output

Display Board

(User Interface)

Transmitter enclosure

Safety Power Supply Unit

(24VDC)

Safety Controller

(PLC or DCS)

GTD-2000Tx Gas Detector

Hazardous Area (Filed) Safe Area

GTD-2000Tx

Instruction Manual

3.1. Basic Specifications

ITEMS SPECIFICATION

Measuring Type Diffusion

Measuring Value Display LCD or OLED Display

Measuring Method

- Electro-Chemical Cell

- Heated-semiconductor Cell)

- Photoionization detector(PID)

Detectable Gas Toxic Gas (Note 1)

Measuring Range $BQBCMFUPEJTQMBZ_/PUF

Accuracy 'VMM3BOHF

Zero Drift 'VMM3BOHF

Response Time Depends on Sensor Module.

Refer to Sensor Specification or Contact in case for Special Gas.

Approvals Classification

KCs: Ex d llC T6,T5,T4, IP65

"5&9*&$&9**(&YE**$(C5_5

SIL2, MED, ABS, DNV

Basic Interface Analog 4-20mA current interface

HART Interface HART REV7 (Option)

Option

HART Board

(5-8BSOJOH-JHIU

Rain Cover

8BSSBOUZ Transmitter 2Year

Sensor 1Year

3.2. Mechanical Specifications

ITEMS SPECIFICATION

Explosion-Proof Type Explosion-Proof Enclosure

Dimension 8)%NN

8FJHIUJODMVEJOH4FOTPS App. 1.5kg

Mounting Type 8BMMNPVOU

Mounting Hole ʡ

Cable inlet 1'PS/15

Body Material Transmitter aluminum alloy

Sensor Stainless Steel (STS316)

GTD-2000Tx toxic gas detector has been developed to detect gas leaked from industrial sites and various toxic gases

generated from factories, gas storages, and manufacturing processes that produce or use toxic gases and to prevent

accidents in advance.

GTD-2000Tx toxic gas detector is installed in areas with gas leak hazards and continuously monitors gas leak. It displays

NFBTVSFNFOUTPOCVJMUJOEJTQMBZT-$%PS0-&%PGUIFEFUFDUPSBOEQSPWJEFT%$_N"TUBOEBSEPVUQVUTJHOBM"MTP

GPS%$_N"TUBOEBSEPVUQVUPVUQVUTJHOBMUSBOTNJTTJPOMFOHUICFUXFFOEFUFDUPSBOESFDFJWFSDBOCFDPOOFDUFEVQ

UPN8IFODBCMF$774PS$774#TRBOEIJHIFSJTVTFE(5%5YGMBNNBCMFHBTEFUFDUPSNVTUCFVTFE

at height below 1,000 m above sea level.

Body of GTD-2000Tx is made of Aluminum alloy and the gas sensor module is made of stainless steel. It consists of a

complete explosion-proof enclosure (Ex d IIC T6). This product can be installed in areas with combustible gas leak and

explosion hazards. It has built-in LCD on the detector to display gas leak status at installed site. It consists of display part

UIBUJOEJDBUFTNFBTVSFNFOUTUFSNJOBMQBSUUIBUPVUQVUNFBTVSFNFOUT%$_N"FYUFSOBMMZBOEB1$#CPBSE

External configuration consists of detector part that monitors gas leak and cable inlets. It uses magnet-bar outside the

main body of detector enabling calibration from the outside of the detector, thus, maintenance is convenient.

2. Structure

1. Overview 3. Specications

www.gastron.com

06_07

/PUF3FGFSUPUIFNFBTVSFEHBTMJTUGPSNFBTVSFEHBTFTBOEUIFJSSBOHFT$POUBDUVTGPSTQFDJBMHBT

[Figure 1. GTD-2000Tx Overview]

Infrared Gas

Sensor Module

(GSA860TX)

Main Board

(Transmitter)

+24V DC

4-20mA Analog

Signal Output

Display Board

(User Interface)

Transmitter enclosure

Safety Power Supply Unit

(24VDC)

Safety Controller

(PLC or DCS)

GTD-2000Tx Gas Detector

Hazardous Area (Filed) Safe Area

GTD-2000Tx

Instruction Manual

3.1. Basic Specifications

ITEMS SPECIFICATION

Measuring Type Diffusion

Measuring Value Display LCD or OLED Display

Measuring Method

- Electro-Chemical Cell

- Heated-semiconductor Cell)

- Photoionization detector(PID)

Detectable Gas Toxic Gas (Note 1)

Measuring Range $BQBCMFUPEJTQMBZ_/PUF

Accuracy 'VMM3BOHF

Zero Drift 'VMM3BOHF

Response Time Depends on Sensor Module.

Refer to Sensor Specification or Contact in case for Special Gas.

Approvals Classification

KCs: Ex d llC T6,T5,T4, IP65

"5&9*&$&9**(&YE**$(C5_5

SIL2, MED, ABS, DNV

Basic Interface Analog 4-20mA current interface

HART Interface HART REV7 (Option)

Option

HART Board

(5-8BSOJOH-JHIU

Rain Cover

8BSSBOUZ Transmitter 2Year

Sensor 1Year

3.2. Mechanical Specifications

ITEMS SPECIFICATION

Explosion-Proof Type Explosion-Proof Enclosure

Dimension 8)%NN

8FJHIUJODMVEJOH4FOTPS App. 1.5kg

Mounting Type 8BMMNPVOU

Mounting Hole ʡ

Cable inlet 1'PS/15

Body Material Transmitter aluminum alloy

Sensor Stainless Steel (STS316)

GTD-2000Tx toxic gas detector has been developed to detect gas leaked from industrial sites and various toxic gases

generated from factories, gas storages, and manufacturing processes that produce or use toxic gases and to prevent

accidents in advance.

GTD-2000Tx toxic gas detector is installed in areas with gas leak hazards and continuously monitors gas leak. It displays

NFBTVSFNFOUTPOCVJMUJOEJTQMBZT-$%PS0-&%PGUIFEFUFDUPSBOEQSPWJEFT%$_N"TUBOEBSEPVUQVUTJHOBM"MTP

GPS%$_N"TUBOEBSEPVUQVUPVUQVUTJHOBMUSBOTNJTTJPOMFOHUICFUXFFOEFUFDUPSBOESFDFJWFSDBOCFDPOOFDUFEVQ

UPN8IFODBCMF$774PS$774#TRBOEIJHIFSJTVTFE(5%5YGMBNNBCMFHBTEFUFDUPSNVTUCFVTFE

at height below 1,000 m above sea level.

Body of GTD-2000Tx is made of Aluminum alloy and the gas sensor module is made of stainless steel. It consists of a

complete explosion-proof enclosure (Ex d IIC T6). This product can be installed in areas with combustible gas leak and

explosion hazards. It has built-in LCD on the detector to display gas leak status at installed site. It consists of display part

UIBUJOEJDBUFTNFBTVSFNFOUTUFSNJOBMQBSUUIBUPVUQVUNFBTVSFNFOUT%$_N"FYUFSOBMMZBOEB1$#CPBSE

External configuration consists of detector part that monitors gas leak and cable inlets. It uses magnet-bar outside the

main body of detector enabling calibration from the outside of the detector, thus, maintenance is convenient.

2. Structure

1. Overview 3. Specications

www.gastron.com

08_09

3.3. Electrical Specifications (Standard Type)

ITEMS SPECIFICATION

Input Voltage(Standard)

$VTUPNFSTVQQMJFE146NVTUNFFU

requirements IEC1010-1 and CE

Marking requirements.

Absolute min:

Nominal:

Absolute max:

Ripple maximum allowed:

18V

24V

31V

1V pk-pk

8BUUBHF Max. wattage:

Max. current:

8!7%$

150mA @+24 VDC

Analog output Current

0-20mA(500 ohms max load)

"MMSFBEJOHTN"

Measured-value signal:

4mA(Zero) to 20mA(Full Scale)

Fault:

-&-

-&-

0WFS-&-

Maintenance:

0mA

4mA - 20mA

20mA - 21.4mA

22mA

3mA

Analog output current ripple & noise max V"

8JSJOHSFRVJSFNFOU Power CVVS or CVVSB with shield

Analog CVVS or CVVSB with shield

Signal Transmission Distance

(Cable Connection Length) Analog 2500m

EMC Protection: Complies with EN50270

No ITEMS SPECIFICATION

1Housing Body Protects PCB Board built in Sensor and Housing from external environmental change and shock.

2Housing Cover It is assembled with Detector Housing Body.

Top surface is built with circular glass to enable monitoring of measurement displayed on LCD.

3MAIN PCB Amplifies fine outputs generated from Sensor Element to transmit

BDPOWFSUFEPVUQVUJO_N"%$TUBOEBSE*UTFOETEBUBUPEJTQMBZQBSU

4Display PCB Displays data sent from MAIN/ Terminal (Transmitter) PCB on LCD and

displays power status with a power lamp.

5Power/Signal Terminal $/DPOTJTUTPG%$7QPXFSTVQQMZBOE%$_N"TUBOEBSEPVUQVU

connection terminal (VISO, +24V, mA, GND, ETH).

6Sensor Terminal CN8 is Sensor Connection Terminal.

7Power LED Lamp that turns on upon power supply.

8Function Key It is used to enter function setting mode from gas measuring mode by contacting magnet-bar for

2 sec or longer. It is also used to save changed data from function setting mode.

3.4. Environmental Specifications

ITEMS SPECIFICATION

Operation Temperature Transmitter UP

Sensor Refer to Sensor Specification

Storage Temperature Transmitter UP

Sensor Refer to Sensor Specification

Operation Humidity Transmitter UP3)/PODPOEFOTJOH

Sensor Refer to Sensor Specification

Pressure Range 90 to 110KPa

Max. air velocity 6m/s

[Figure 2. GTD-2000Tx Components]

GTD-2000Tx

Instruction Manual 3. Specications 4. Name and Description of Each Part

4.1. Components

www.gastron.com

08_09

3.3. Electrical Specifications (Standard Type)

ITEMS SPECIFICATION

Input Voltage(Standard)

$VTUPNFSTVQQMJFE146NVTUNFFU

requirements IEC1010-1 and CE

Marking requirements.

Absolute min:

Nominal:

Absolute max:

Ripple maximum allowed:

18V

24V

31V

1V pk-pk

8BUUBHF Max. wattage:

Max. current:

8!7%$

150mA @+24 VDC

Analog output Current

0-20mA(500 ohms max load)

"MMSFBEJOHTN"

Measured-value signal:

4mA(Zero) to 20mA(Full Scale)

Fault:

-&-

-&-

0WFS-&-

Maintenance:

0mA

4mA - 20mA

20mA - 21.4mA

22mA

3mA

Analog output current ripple & noise max V"

8JSJOHSFRVJSFNFOU Power CVVS or CVVSB with shield

Analog CVVS or CVVSB with shield

Signal Transmission Distance

(Cable Connection Length) Analog 2500m

EMC Protection: Complies with EN50270

No ITEMS SPECIFICATION

1Housing Body Protects PCB Board built in Sensor and Housing from external environmental change and shock.

2Housing Cover It is assembled with Detector Housing Body.

Top surface is built with circular glass to enable monitoring of measurement displayed on LCD.

3MAIN PCB Amplifies fine outputs generated from Sensor Element to transmit

BDPOWFSUFEPVUQVUJO_N"%$TUBOEBSE*UTFOETEBUBUPEJTQMBZQBSU

4Display PCB Displays data sent from MAIN/ Terminal (Transmitter) PCB on LCD and

displays power status with a power lamp.

5Power/Signal Terminal $/DPOTJTUTPG%$7QPXFSTVQQMZBOE%$_N"TUBOEBSEPVUQVU

connection terminal (VISO, +24V, mA, GND, ETH).

6Sensor Terminal CN8 is Sensor Connection Terminal.

7Power LED Lamp that turns on upon power supply.

8Function Key It is used to enter function setting mode from gas measuring mode by contacting magnet-bar for

2 sec or longer. It is also used to save changed data from function setting mode.

3.4. Environmental Specifications

ITEMS SPECIFICATION

Operation Temperature Transmitter UP

Sensor Refer to Sensor Specification

Storage Temperature Transmitter UP

Sensor Refer to Sensor Specification

Operation Humidity Transmitter UP3)/PODPOEFOTJOH

Sensor Refer to Sensor Specification

Pressure Range 90 to 110KPa

Max. air velocity 6m/s

[Figure 2. GTD-2000Tx Components]

GTD-2000Tx

Instruction Manual 3. Specications 4. Name and Description of Each Part

4.1. Components

www.gastron.com

08_09

3.3. Electrical Specifications (Standard Type)

ITEMS SPECIFICATION

Input Voltage(Standard)

$VTUPNFSTVQQMJFE146NVTUNFFU

requirements IEC1010-1 and CE

Marking requirements.

Absolute min:

Nominal:

Absolute max:

Ripple maximum allowed:

18V

24V

31V

1V pk-pk

8BUUBHF Max. wattage:

Max. current:

8!7%$

150mA @+24 VDC

Analog output Current

0-20mA(500 ohms max load)

"MMSFBEJOHTN"

Measured-value signal:

4mA(Zero) to 20mA(Full Scale)

Fault:

-&-

-&-

0WFS-&-

Maintenance:

0mA

4mA - 20mA

20mA - 21.4mA

22mA

3mA

Analog output current ripple & noise max V"

8JSJOHSFRVJSFNFOU Power CVVS or CVVSB with shield

Analog CVVS or CVVSB with shield

Signal Transmission Distance

(Cable Connection Length) Analog 2500m

EMC Protection: Complies with EN50270

No ITEMS SPECIFICATION

1Housing Body Protects PCB Board built in Sensor and Housing from external environmental change and shock.

2Housing Cover It is assembled with Detector Housing Body.

Top surface is built with circular glass to enable monitoring of measurement displayed on LCD.

3MAIN PCB Amplifies fine outputs generated from Sensor Element to transmit

BDPOWFSUFEPVUQVUJO_N"%$TUBOEBSE*UTFOETEBUBUPEJTQMBZQBSU

4Display PCB Displays data sent from MAIN/ Terminal (Transmitter) PCB on LCD and

displays power status with a power lamp.

5Power/Signal Terminal $/DPOTJTUTPG%$7QPXFSTVQQMZBOE%$_N"TUBOEBSEPVUQVU

connection terminal (VISO, +24V, mA, GND, ETH).

6Sensor Terminal CN8 is Sensor Connection Terminal.

7Power LED Lamp that turns on upon power supply.

8Function Key It is used to enter function setting mode from gas measuring mode by contacting magnet-bar for

2 sec or longer. It is also used to save changed data from function setting mode.

3.4. Environmental Specifications

ITEMS SPECIFICATION

Operation Temperature Transmitter UP

Sensor Refer to Sensor Specification

Storage Temperature Transmitter UP

Sensor Refer to Sensor Specification

Operation Humidity Transmitter UP3)/PODPOEFOTJOH

Sensor Refer to Sensor Specification

Pressure Range 90 to 110KPa

Max. air velocity 6m/s

[Figure 2. GTD-2000Tx Components]

GTD-2000Tx

Instruction Manual 3. Specications 4. Name and Description of Each Part

4.1. Components

www.gastron.com

08_09

3.3. Electrical Specifications (Standard Type)

ITEMS SPECIFICATION

Input Voltage(Standard)

$VTUPNFSTVQQMJFE146NVTUNFFU

requirements IEC1010-1 and CE

Marking requirements.

Absolute min:

Nominal:

Absolute max:

Ripple maximum allowed:

18V

24V

31V

1V pk-pk

8BUUBHF Max. wattage:

Max. current:

8!7%$

150mA @+24 VDC

Analog output Current

0-20mA(500 ohms max load)

"MMSFBEJOHTN"

Measured-value signal:

4mA(Zero) to 20mA(Full Scale)

Fault:

-&-

-&-

0WFS-&-

Maintenance:

0mA

4mA - 20mA

20mA - 21.4mA

22mA

3mA

Analog output current ripple & noise max V"

8JSJOHSFRVJSFNFOU Power CVVS or CVVSB with shield

Analog CVVS or CVVSB with shield

Signal Transmission Distance

(Cable Connection Length) Analog 2500m

EMC Protection: Complies with EN50270

No ITEMS SPECIFICATION

1Housing Body Protects PCB Board built in Sensor and Housing from external environmental change and shock.

2Housing Cover It is assembled with Detector Housing Body.

Top surface is built with circular glass to enable monitoring of measurement displayed on LCD.

3MAIN PCB Amplifies fine outputs generated from Sensor Element to transmit

BDPOWFSUFEPVUQVUJO_N"%$TUBOEBSE*UTFOETEBUBUPEJTQMBZQBSU

4Display PCB Displays data sent from MAIN/ Terminal (Transmitter) PCB on LCD and

displays power status with a power lamp.

5Power/Signal Terminal $/DPOTJTUTPG%$7QPXFSTVQQMZBOE%$_N"TUBOEBSEPVUQVU

connection terminal (VISO, +24V, mA, GND, ETH).

6Sensor Terminal CN8 is Sensor Connection Terminal.

7Power LED Lamp that turns on upon power supply.

8Function Key It is used to enter function setting mode from gas measuring mode by contacting magnet-bar for

2 sec or longer. It is also used to save changed data from function setting mode.

3.4. Environmental Specifications

ITEMS SPECIFICATION

Operation Temperature Transmitter UP

Sensor Refer to Sensor Specification

Storage Temperature Transmitter UP

Sensor Refer to Sensor Specification

Operation Humidity Transmitter UP3)/PODPOEFOTJOH

Sensor Refer to Sensor Specification

Pressure Range 90 to 110KPa

Max. air velocity 6m/s

[Figure 2. GTD-2000Tx Components]

GTD-2000Tx

Instruction Manual 3. Specications 4. Name and Description of Each Part

4.1. Components

www.gastron.com

10_11

No NAME DESCRIPTIONS

9Reset Key To cancel or return to the previous status during Parameter setting, use the Magnet-Bar and

touch once.

10 ¬61,FZ

(Each touch returns to the previous status by one unit.)

During conversion of mode or number, use the Magnet-Bar and touch once. Each touch converts

or increases displayed value by one unit.

11 %08/,FZ During conversion of mode or number, use the Magnet-Bar and touch once. Each touch converts

or increases displayed value by one unit.

12 External Earth Ground

It must be grounded to outside of detector for protection from external noise or strong electric

field.

- Use a conductor that is 4 mm or longer when coupling ground line.

13 Mount Hole Hole to fix the gas detector on external wall or other installation sites.

14 Sensor It is a site that detects actual gas leak. It converts the amount of gas leak into electrical signal and

transmits to the Main PCB.

15 Conduit Connection It is supplied for inlet of power supply and measurement output signal for the detector during

JOTUBMMBUJPO'PSDBCMFJOMFU1'PS/15BSFQSFQBSFE

16 Internal Ground

It must be grounded to inside of detector for protection from external noise or strong electric

field.

- Use a conductor that is 4 mm or longer when coupling ground line.

[Table 1. GTD-2000Tx Description of Configuration]

GTD-2000Tx

Instruction Manual 5. Installation

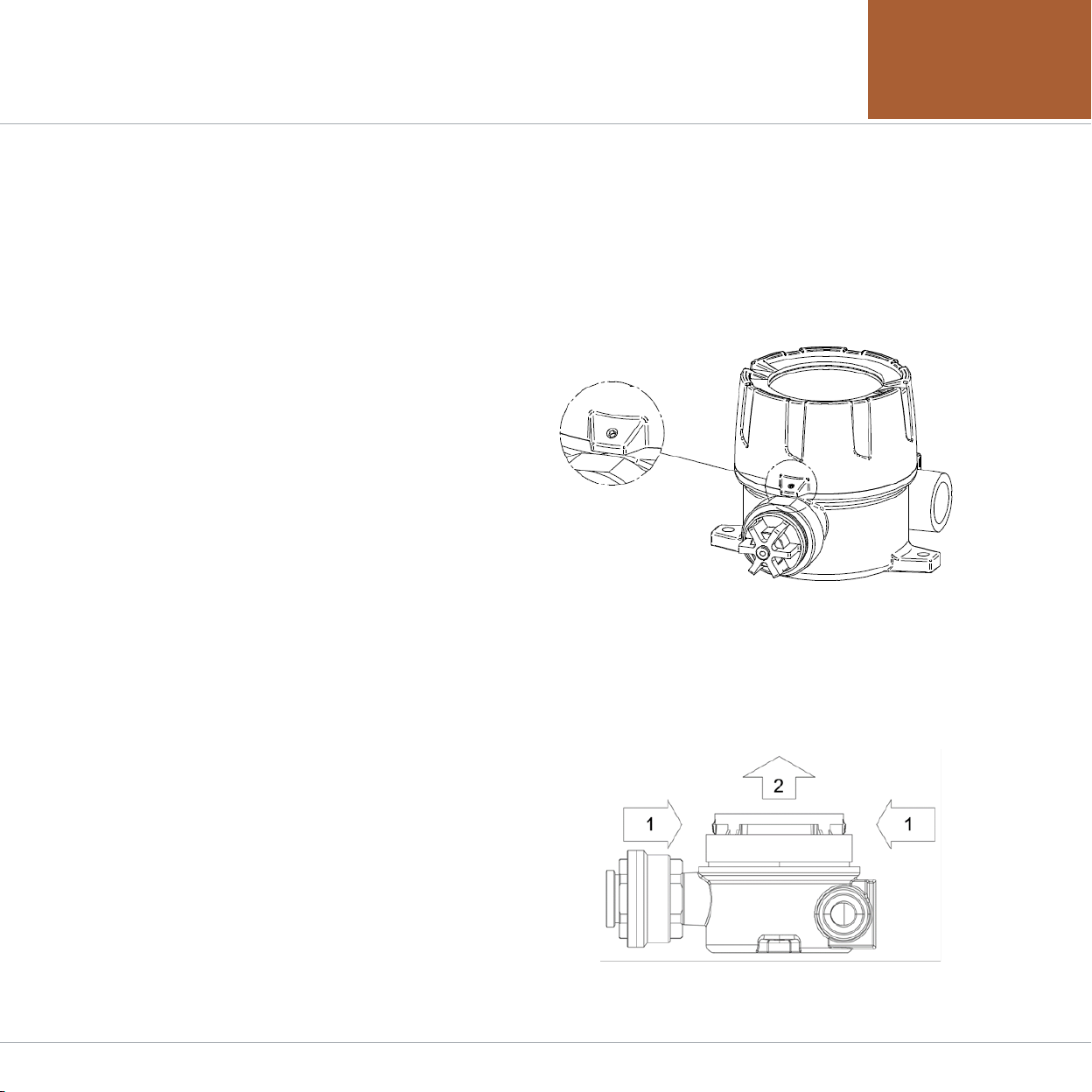

5.1. Detachment of Housing Cover

¥"GUFSEFUBDIJOHUIFDPWFSEJTBTTFNCMFUIFEJTQMBZQBSUT

as below.

˝ 1VTIJOMFGUBOESJHIUGJYJOHSJOHTMPDBUFEPOGSPOUTJEF

of LCD at the same time.

˞ 8IJMFQVTIJOHQVMMUIFEJTQMBZQBSUTUPXBSETUIFGSPOU

to detach from gas detector body.

˟ "GUFSEFUBDIJOHUIFEJTQMBZQBSUTUIF.BJO1$#JT

installed at the bottom part of the detector body.

It is prohibited for an individual, other than an approved user or a technician responsible for installation and repair from

the head office, to install a gas leak detector on site or open the cover of the installed gas leak detector and manipulate

it. This may cause serious loss of life and property from fire, explosion, and etc. In addition, please check whether there

is any remaining explosive gas or combustible material in the surroundings. Power must be turned off before performing

work.

¥8BSOJOH%POPUPQFOXIFOFMFDUJDBMDVSSFOUJT

flowing>

¥5VSOUIFTMPUUFETFUTDSFX.YFBGJYJOHUIFDPWFS

QBSUPGNBJOCPEZ_UVSOTDPVOUFSDMPDLXJTFDDX

using a hex wrench (M2) then turn the cover of gas

leak detector ccw to detach the cover.

8IFOUIFDPWFSJTEFUBDIFE-$%BQQFBST

[Figure 4. Display Part Detaching Method]

[Figure 3. Slotted Set Screw]

4. Name and Description of Each Part

www.gastron.com

10_11

No NAME DESCRIPTIONS

9Reset Key To cancel or return to the previous status during Parameter setting, use the Magnet-Bar and

touch once.

10 ¬61,FZ

(Each touch returns to the previous status by one unit.)

During conversion of mode or number, use the Magnet-Bar and touch once. Each touch converts

or increases displayed value by one unit.

11 %08/,FZ During conversion of mode or number, use the Magnet-Bar and touch once. Each touch converts

or increases displayed value by one unit.

12 External Earth Ground

It must be grounded to outside of detector for protection from external noise or strong electric

field.

- Use a conductor that is 4 mm or longer when coupling ground line.

13 Mount Hole Hole to fix the gas detector on external wall or other installation sites.

14 Sensor It is a site that detects actual gas leak. It converts the amount of gas leak into electrical signal and

transmits to the Main PCB.

15 Conduit Connection It is supplied for inlet of power supply and measurement output signal for the detector during

JOTUBMMBUJPO'PSDBCMFJOMFU1'PS/15BSFQSFQBSFE

16 Internal Ground

It must be grounded to inside of detector for protection from external noise or strong electric

field.

- Use a conductor that is 4 mm or longer when coupling ground line.

[Table 1. GTD-2000Tx Description of Configuration]

GTD-2000Tx

Instruction Manual 5. Installation

5.1. Detachment of Housing Cover

¥"GUFSEFUBDIJOHUIFDPWFSEJTBTTFNCMFUIFEJTQMBZQBSUT

as below.

˝ 1VTIJOMFGUBOESJHIUGJYJOHSJOHTMPDBUFEPOGSPOUTJEF

of LCD at the same time.

˞ 8IJMFQVTIJOHQVMMUIFEJTQMBZQBSUTUPXBSETUIFGSPOU

to detach from gas detector body.

˟ "GUFSEFUBDIJOHUIFEJTQMBZQBSUTUIF.BJO1$#JT

installed at the bottom part of the detector body.

It is prohibited for an individual, other than an approved user or a technician responsible for installation and repair from

the head office, to install a gas leak detector on site or open the cover of the installed gas leak detector and manipulate

it. This may cause serious loss of life and property from fire, explosion, and etc. In addition, please check whether there

is any remaining explosive gas or combustible material in the surroundings. Power must be turned off before performing

work.

¥8BSOJOH%POPUPQFOXIFOFMFDUJDBMDVSSFOUJT

flowing>

¥5VSOUIFTMPUUFETFUTDSFX.YFBGJYJOHUIFDPWFS

QBSUPGNBJOCPEZ_UVSOTDPVOUFSDMPDLXJTFDDX

using a hex wrench (M2) then turn the cover of gas

leak detector ccw to detach the cover.

8IFOUIFDPWFSJTEFUBDIFE-$%BQQFBST

[Figure 4. Display Part Detaching Method]

[Figure 3. Slotted Set Screw]

4. Name and Description of Each Part

www.gastron.com

10_11

No NAME DESCRIPTIONS

9Reset Key To cancel or return to the previous status during Parameter setting, use the Magnet-Bar and

touch once.

10 ¬61,FZ

(Each touch returns to the previous status by one unit.)

During conversion of mode or number, use the Magnet-Bar and touch once. Each touch converts

or increases displayed value by one unit.

11 %08/,FZ During conversion of mode or number, use the Magnet-Bar and touch once. Each touch converts

or increases displayed value by one unit.

12 External Earth Ground

It must be grounded to outside of detector for protection from external noise or strong electric

field.

- Use a conductor that is 4 mm or longer when coupling ground line.

13 Mount Hole Hole to fix the gas detector on external wall or other installation sites.

14 Sensor It is a site that detects actual gas leak. It converts the amount of gas leak into electrical signal and

transmits to the Main PCB.

15 Conduit Connection It is supplied for inlet of power supply and measurement output signal for the detector during

JOTUBMMBUJPO'PSDBCMFJOMFU1'PS/15BSFQSFQBSFE

16 Internal Ground

It must be grounded to inside of detector for protection from external noise or strong electric

field.

- Use a conductor that is 4 mm or longer when coupling ground line.

[Table 1. GTD-2000Tx Description of Configuration]

GTD-2000Tx

Instruction Manual 5. Installation

5.1. Detachment of Housing Cover

¥"GUFSEFUBDIJOHUIFDPWFSEJTBTTFNCMFUIFEJTQMBZQBSUT

as below.

˝ 1VTIJOMFGUBOESJHIUGJYJOHSJOHTMPDBUFEPOGSPOUTJEF

of LCD at the same time.

˞ 8IJMFQVTIJOHQVMMUIFEJTQMBZQBSUTUPXBSETUIFGSPOU

to detach from gas detector body.

˟ "GUFSEFUBDIJOHUIFEJTQMBZQBSUTUIF.BJO1$#JT

installed at the bottom part of the detector body.

It is prohibited for an individual, other than an approved user or a technician responsible for installation and repair from

the head office, to install a gas leak detector on site or open the cover of the installed gas leak detector and manipulate

it. This may cause serious loss of life and property from fire, explosion, and etc. In addition, please check whether there

is any remaining explosive gas or combustible material in the surroundings. Power must be turned off before performing

work.

¥8BSOJOH%POPUPQFOXIFOFMFDUJDBMDVSSFOUJT

flowing>

¥5VSOUIFTMPUUFETFUTDSFX.YFBGJYJOHUIFDPWFS

QBSUPGNBJOCPEZ_UVSOTDPVOUFSDMPDLXJTFDDX

using a hex wrench (M2) then turn the cover of gas

leak detector ccw to detach the cover.

8IFOUIFDPWFSJTEFUBDIFE-$%BQQFBST

[Figure 4. Display Part Detaching Method]

[Figure 3. Slotted Set Screw]

4. Name and Description of Each Part

www.gastron.com

10_11

No NAME DESCRIPTIONS

9Reset Key To cancel or return to the previous status during Parameter setting, use the Magnet-Bar and

touch once.

10 ¬61,FZ

(Each touch returns to the previous status by one unit.)

During conversion of mode or number, use the Magnet-Bar and touch once. Each touch converts

or increases displayed value by one unit.

11 %08/,FZ During conversion of mode or number, use the Magnet-Bar and touch once. Each touch converts

or increases displayed value by one unit.

12 External Earth Ground

It must be grounded to outside of detector for protection from external noise or strong electric

field.

- Use a conductor that is 4 mm or longer when coupling ground line.

13 Mount Hole Hole to fix the gas detector on external wall or other installation sites.

14 Sensor It is a site that detects actual gas leak. It converts the amount of gas leak into electrical signal and

transmits to the Main PCB.

15 Conduit Connection It is supplied for inlet of power supply and measurement output signal for the detector during

JOTUBMMBUJPO'PSDBCMFJOMFU1'PS/15BSFQSFQBSFE

16 Internal Ground

It must be grounded to inside of detector for protection from external noise or strong electric

field.

- Use a conductor that is 4 mm or longer when coupling ground line.

[Table 1. GTD-2000Tx Description of Configuration]

GTD-2000Tx

Instruction Manual 5. Installation

5.1. Detachment of Housing Cover

¥"GUFSEFUBDIJOHUIFDPWFSEJTBTTFNCMFUIFEJTQMBZQBSUT

as below.

˝ 1VTIJOMFGUBOESJHIUGJYJOHSJOHTMPDBUFEPOGSPOUTJEF

of LCD at the same time.

˞ 8IJMFQVTIJOHQVMMUIFEJTQMBZQBSUTUPXBSETUIFGSPOU

to detach from gas detector body.

˟ "GUFSEFUBDIJOHUIFEJTQMBZQBSUTUIF.BJO1$#JT

installed at the bottom part of the detector body.

It is prohibited for an individual, other than an approved user or a technician responsible for installation and repair from

the head office, to install a gas leak detector on site or open the cover of the installed gas leak detector and manipulate

it. This may cause serious loss of life and property from fire, explosion, and etc. In addition, please check whether there

is any remaining explosive gas or combustible material in the surroundings. Power must be turned off before performing

work.

¥8BSOJOH%POPUPQFOXIFOFMFDUJDBMDVSSFOUJT

flowing>

¥5VSOUIFTMPUUFETFUTDSFX.YFBGJYJOHUIFDPWFS

QBSUPGNBJOCPEZ_UVSOTDPVOUFSDMPDLXJTFDDX

using a hex wrench (M2) then turn the cover of gas

leak detector ccw to detach the cover.

8IFOUIFDPWFSJTEFUBDIFE-$%BQQFBST

[Figure 4. Display Part Detaching Method]

[Figure 3. Slotted Set Screw]

4. Name and Description of Each Part

www.gastron.com

12_13

5. Installation5. Installation

GTD-2000Tx

Instruction Manual

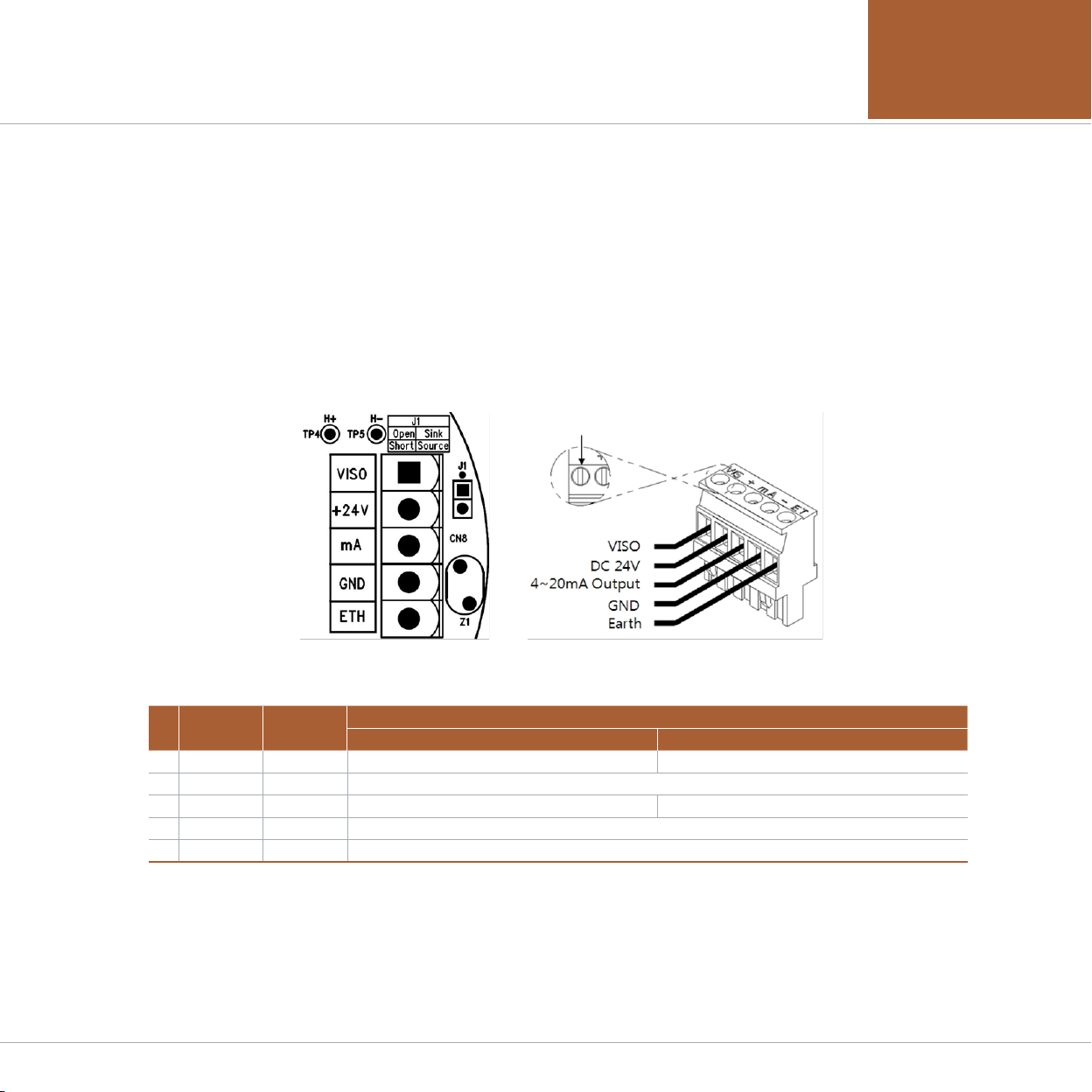

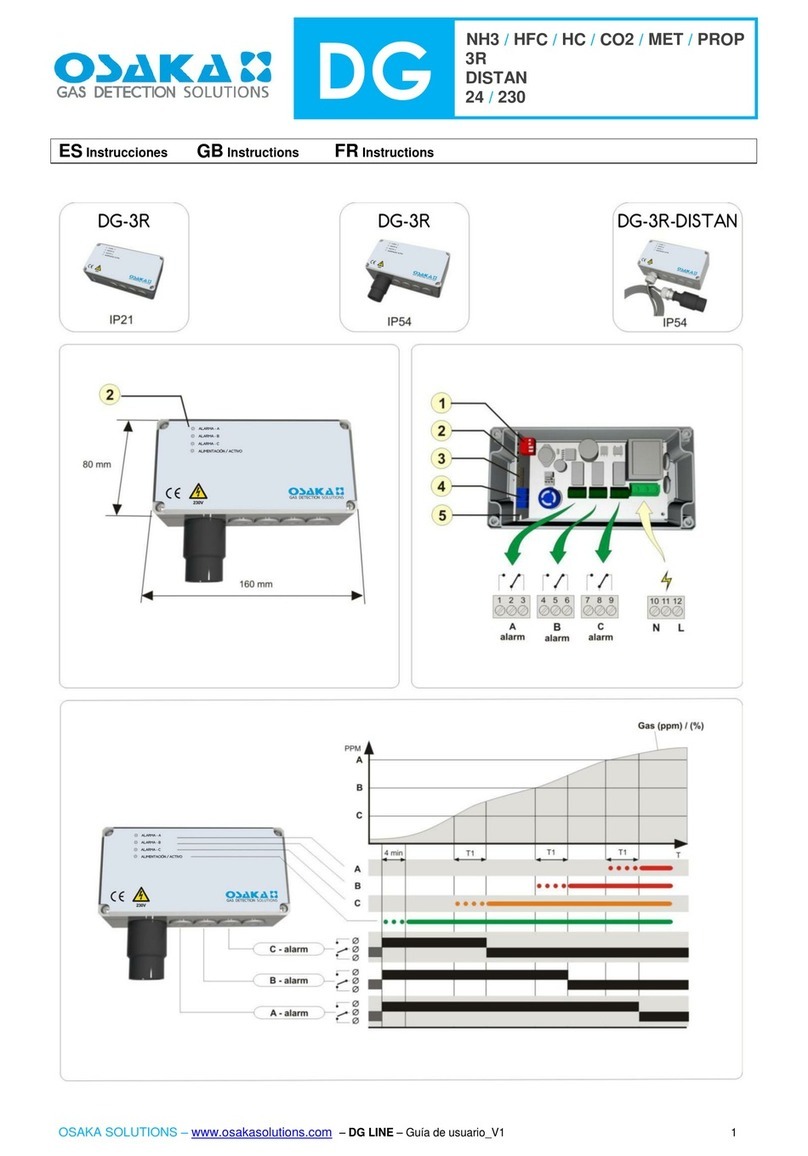

5.2. Main PCB Configuration

¥"GUFSEFUBDIJOHUIFDPWFSUIF.BJO1$#UFSNJOBMMBZPVUBQQFBSTBTTIPXOJOUIFGJHVSFCFMPX

[Table 2. Main PCB Key Part Description]

No NAME DESCRIPTION

1CN9 Power & Output Signal Terminal

2J1 _N"4PVSDF4JOL4FMFDUJPO+VNQFS0/4PVSDF5ZQF0''4JOL5ZQF

3CN1 Display LCD Connector

4CN8 Sensor Connector

5CN6 Program download Connector

6D1 Status LED (Flashes in 1 sec interval during normal operation)

7OC1,OC2,OC3 HART Option Board Connector

8CN4 8BSOJOHMJHIU(5-*OUFSGBDF$POOFDUPS

[Figure 5. Main PCB Terminal Layout]

5.3. Terminal Configuration

¥8BSOJOH5VSOPGGQPXFSCFGPSFDPOOFDUJOHQPXFSUFSNJOBM

¥"GUFSEJTBTTFNCMJOHEJTQMBZQBSUTUIFSFJTBUFSNJOBMCMPDLJOUIF.BJO1$#BTTIPXOJOUIFGJHVSFCFMPX

Holding it with hands and pulling towards ceiling detaches it from the Main PCB.

¥-PPTFOUFSNJOBMGJYJOHTDSFXTMPDBUFEBUUPQQBSUPGEFUBDIFEUFSNJOBMCMPDL$/7*4N"&5)$POOFDUPSCZ

UVSOJOHDDXVTJOHBǞESJWFS$POOFDU%$_7QPXFSUPBOEUIFODPOOFDUTJHOBMDBCMFUPN"5JHIUFOUFSNJOBM

fixing screws clockwise (cw) so that terminal does not leave the track then insert Main PCB as the same condition

before disassembly.

¥6TJOH0$0$BOE0$TIPXOJOUIFMBZPVUBCPWF)"35PQUJPOCPBSEDBOCFBUUBDIFEBOEʡ4DSFXIPMFT

located at top left of HART option board are used for fixing.

[Figure 6. CN9 Terminal Configuration]

[Table 3. CN9 Terminal Detailed Description]

NO PCB SILK PIN NAME DESCRIPTION

4~20mA Source Drive (J1 Jumper ON) 4~20mA Sink Drive (J1 Jumper OFF)

1VISO VIS N.C _N"4JOL*O

2+24V +7108&3

3mA mA _N"4PVSDF0VU _N"4JOL0VU

4GND -(/%108&3

5ETH ET EARTH

¥6TF$774PS$774#TR¬4IJFME$BCMFGPSUFSNJOBMDPOGJHVSBUJPO

¥ 5PDPOOFDU1JOUFSNJOBMGSPNUIFFYJTUJOHPME(5%5YNPEFMDPOOFDUUFSNJOBMTJOSFGFSFODFUPQJO

which is +24V.

Terminal mounting screw

www.gastron.com

12_13

5. Installation5. Installation

GTD-2000Tx

Instruction Manual

5.2. Main PCB Configuration

¥"GUFSEFUBDIJOHUIFDPWFSUIF.BJO1$#UFSNJOBMMBZPVUBQQFBSTBTTIPXOJOUIFGJHVSFCFMPX

[Table 2. Main PCB Key Part Description]

No NAME DESCRIPTION

1CN9 Power & Output Signal Terminal

2J1 _N"4PVSDF4JOL4FMFDUJPO+VNQFS0/4PVSDF5ZQF0''4JOL5ZQF

3CN1 Display LCD Connector

4CN8 Sensor Connector

5CN6 Program download Connector

6D1 Status LED (Flashes in 1 sec interval during normal operation)

7OC1,OC2,OC3 HART Option Board Connector

8CN4 8BSOJOHMJHIU(5-*OUFSGBDF$POOFDUPS

[Figure 5. Main PCB Terminal Layout]

5.3. Terminal Configuration

¥8BSOJOH5VSOPGGQPXFSCFGPSFDPOOFDUJOHQPXFSUFSNJOBM

¥"GUFSEJTBTTFNCMJOHEJTQMBZQBSUTUIFSFJTBUFSNJOBMCMPDLJOUIF.BJO1$#BTTIPXOJOUIFGJHVSFCFMPX

Holding it with hands and pulling towards ceiling detaches it from the Main PCB.

¥-PPTFOUFSNJOBMGJYJOHTDSFXTMPDBUFEBUUPQQBSUPGEFUBDIFEUFSNJOBMCMPDL$/7*4N"&5)$POOFDUPSCZ

UVSOJOHDDXVTJOHBǞESJWFS$POOFDU%$_7QPXFSUPBOEUIFODPOOFDUTJHOBMDBCMFUPN"5JHIUFOUFSNJOBM

fixing screws clockwise (cw) so that terminal does not leave the track then insert Main PCB as the same condition

before disassembly.

¥6TJOH0$0$BOE0$TIPXOJOUIFMBZPVUBCPWF)"35PQUJPOCPBSEDBOCFBUUBDIFEBOEʡ4DSFXIPMFT

located at top left of HART option board are used for fixing.

[Figure 6. CN9 Terminal Configuration]

[Table 3. CN9 Terminal Detailed Description]

NO PCB SILK PIN NAME DESCRIPTION

4~20mA Source Drive (J1 Jumper ON) 4~20mA Sink Drive (J1 Jumper OFF)

1VISO VIS N.C _N"4JOL*O

2+24V +7108&3

3mA mA _N"4PVSDF0VU _N"4JOL0VU

4GND -(/%108&3

5ETH ET EARTH

¥6TF$774PS$774#TR¬4IJFME$BCMFGPSUFSNJOBMDPOGJHVSBUJPO

¥ 5PDPOOFDU1JOUFSNJOBMGSPNUIFFYJTUJOHPME(5%5YNPEFMDPOOFDUUFSNJOBMTJOSFGFSFODFUPQJO

which is +24V.

Terminal mounting screw

www.gastron.com

12_13

5. Installation5. Installation

GTD-2000Tx

Instruction Manual

5.2. Main PCB Configuration

¥"GUFSEFUBDIJOHUIFDPWFSUIF.BJO1$#UFSNJOBMMBZPVUBQQFBSTBTTIPXOJOUIFGJHVSFCFMPX

[Table 2. Main PCB Key Part Description]

No NAME DESCRIPTION

1CN9 Power & Output Signal Terminal

2J1 _N"4PVSDF4JOL4FMFDUJPO+VNQFS0/4PVSDF5ZQF0''4JOL5ZQF

3CN1 Display LCD Connector

4CN8 Sensor Connector

5CN6 Program download Connector

6D1 Status LED (Flashes in 1 sec interval during normal operation)

7OC1,OC2,OC3 HART Option Board Connector

8CN4 8BSOJOHMJHIU(5-*OUFSGBDF$POOFDUPS

[Figure 5. Main PCB Terminal Layout]

5.3. Terminal Configuration

¥8BSOJOH5VSOPGGQPXFSCFGPSFDPOOFDUJOHQPXFSUFSNJOBM

¥"GUFSEJTBTTFNCMJOHEJTQMBZQBSUTUIFSFJTBUFSNJOBMCMPDLJOUIF.BJO1$#BTTIPXOJOUIFGJHVSFCFMPX

Holding it with hands and pulling towards ceiling detaches it from the Main PCB.

¥-PPTFOUFSNJOBMGJYJOHTDSFXTMPDBUFEBUUPQQBSUPGEFUBDIFEUFSNJOBMCMPDL$/7*4N"&5)$POOFDUPSCZ

UVSOJOHDDXVTJOHBǞESJWFS$POOFDU%$_7QPXFSUPBOEUIFODPOOFDUTJHOBMDBCMFUPN"5JHIUFOUFSNJOBM

fixing screws clockwise (cw) so that terminal does not leave the track then insert Main PCB as the same condition

before disassembly.

¥6TJOH0$0$BOE0$TIPXOJOUIFMBZPVUBCPWF)"35PQUJPOCPBSEDBOCFBUUBDIFEBOEʡ4DSFXIPMFT

located at top left of HART option board are used for fixing.

[Figure 6. CN9 Terminal Configuration]

[Table 3. CN9 Terminal Detailed Description]

NO PCB SILK PIN NAME DESCRIPTION

4~20mA Source Drive (J1 Jumper ON) 4~20mA Sink Drive (J1 Jumper OFF)

1VISO VIS N.C _N"4JOL*O

2+24V +7108&3

3mA mA _N"4PVSDF0VU _N"4JOL0VU

4GND -(/%108&3

5ETH ET EARTH

¥6TF$774PS$774#TR¬4IJFME$BCMFGPSUFSNJOBMDPOGJHVSBUJPO

¥ 5PDPOOFDU1JOUFSNJOBMGSPNUIFFYJTUJOHPME(5%5YNPEFMDPOOFDUUFSNJOBMTJOSFGFSFODFUPQJO

which is +24V.

Terminal mounting screw

www.gastron.com

12_13

5. Installation5. Installation

GTD-2000Tx

Instruction Manual

5.2. Main PCB Configuration

¥"GUFSEFUBDIJOHUIFDPWFSUIF.BJO1$#UFSNJOBMMBZPVUBQQFBSTBTTIPXOJOUIFGJHVSFCFMPX

[Table 2. Main PCB Key Part Description]

No NAME DESCRIPTION

1CN9 Power & Output Signal Terminal

2J1 _N"4PVSDF4JOL4FMFDUJPO+VNQFS0/4PVSDF5ZQF0''4JOL5ZQF

3CN1 Display LCD Connector

4CN8 Sensor Connector

5CN6 Program download Connector

6D1 Status LED (Flashes in 1 sec interval during normal operation)

7OC1,OC2,OC3 HART Option Board Connector

8CN4 8BSOJOHMJHIU(5-*OUFSGBDF$POOFDUPS

[Figure 5. Main PCB Terminal Layout]

5.3. Terminal Configuration

¥8BSOJOH5VSOPGGQPXFSCFGPSFDPOOFDUJOHQPXFSUFSNJOBM

¥"GUFSEJTBTTFNCMJOHEJTQMBZQBSUTUIFSFJTBUFSNJOBMCMPDLJOUIF.BJO1$#BTTIPXOJOUIFGJHVSFCFMPX

Holding it with hands and pulling towards ceiling detaches it from the Main PCB.

¥-PPTFOUFSNJOBMGJYJOHTDSFXTMPDBUFEBUUPQQBSUPGEFUBDIFEUFSNJOBMCMPDL$/7*4N"&5)$POOFDUPSCZ

UVSOJOHDDXVTJOHBǞESJWFS$POOFDU%$_7QPXFSUPBOEUIFODPOOFDUTJHOBMDBCMFUPN"5JHIUFOUFSNJOBM

fixing screws clockwise (cw) so that terminal does not leave the track then insert Main PCB as the same condition

before disassembly.

¥6TJOH0$0$BOE0$TIPXOJOUIFMBZPVUBCPWF)"35PQUJPOCPBSEDBOCFBUUBDIFEBOEʡ4DSFXIPMFT