Gasboy SERIES 1000 User manual

SERIES 1000

FUEL MANAGEMENT SYSTEM

OPERATION MANUAL

FOR CANADA

C08948

GASBOY INTERNATIONAL LLC

GASBOY

SERIES 1000

FUEL MANAGEMENT SYSTEM

OPERATION MANUAL

FOR CANADA

Software Version 10

C08948

Rev. 05/29/03

GASBOY INTERNATIONAL LLC

LANSDALE, PA

Copyright 2003 by Gasboy International LLC

All rights reserved.

The information in this document is confidential and proprietary. No further disclosure thereof

shall be made without permission from Gasboy International LLC.

Gasboy International LLC believes that the information in this document is accurate and reliable.

However, we assume no responsibility for its use, nor for any infringements of patents or other

rights of third parties resulting from its use. We reserve the right to make any changes at any time

without notice.

05/29/03 Contents-1

CONTENTS

Section 1: INTRODUCTION

Overview ................................................................................................... 1-1

System Features....................................................................................... 1-2

Standard Features............................................................................... 1-2

Optional Features ................................................................................ 1-3

Documentation/Getting Started................................................................. 1-5

How to Use This Book............................................................................... 1-6

Section 2: FUELING WITH THE SERIES 1000......................................................... 2-1

Section 3: COMMUNICATING WITH THE SERIES 1000

Communication Ports................................................................................ 3-1

Communication Protocol........................................................................... 3-1

Communication Terminations.................................................................... 3-2

Initiating Communication........................................................................... 3-3

LS - Load Sign-on Password..................................................................... 3-4

Lost or Forgotten Password...................................................................... 3-5

Section 4: SERIES 1000 OPERATING MODES

System Modes........................................................................................... 4-1

Entering and Exiting Command Mode....................................................... 4-2

Enter Command Mode - CTRL F......................................................... 4-2

Exit Command Mode- EX Command................................................... 4-2

Override Other Port - CTRL B.............................................................. 4-2

Entering Commands and Other System Input........................................... 4-3

HE - Help Command................................................................................. 4-4

Section 5: SYSTEM MAINTENANCE COMMANDS

Description ................................................................................................ 5-1

System Configuration Parameters ............................................................ 5-2

SC - Load or Change System Configuration............................................. 5-4

Changing the System Configuration .................................................... 5-6

PS - Print System Configuration................................................................ 5-8

LD - Load Date and Time.......................................................................... 5-9

PD - Print Date and Time.......................................................................... 5-10

SD - Load Site Down Time........................................................................ 5-11

PR - Print Program Revision and Date...................................................... 5-12

LK - Load Pin Key ..................................................................................... 5-13

LC - Print Last Card(s) Read..................................................................... 5-14

MO - Display Output By Screen (More) .................................................... 5-16

GASBOY Series 1000

Contents-2 05/29/03

Section 6: CARD VALIDATION COMMANDS

Overview ................................................................................................... 6-1

Card Validation Commands................................................................. 6-1

VA - Validate All Cards.............................................................................. 6-2

VC - Validate a Card ................................................................................. 6-3

Validate a Single Card ......................................................................... 6-3

Validate a String of Assorted Cards..................................................... 6-3

Validate a Range of Cards................................................................... 6-4

IA - Invalidate All Cards............................................................................. 6-5

IC - Invalidate a Card ................................................................................ 6-6

Invalidate a Single Card....................................................................... 6-6

Invalidate a String of Assorted Cards................................................... 6-6

Invalidate a Range of Cards................................................................. 6-7

CC - Check Card Validation...................................................................... 6-8

PV - Print Valid Card List........................................................................... 6-9

PI - Print Invalid Card List.......................................................................... 6-10

Card Validation/Invalidation Error Messages ............................................ 6-11

Section 7: TANK INVENTORY COMMANDS

Description ................................................................................................ 7-1

Tank Inventory Commands.................................................................. 7-1

LI - Load Tank Inventory ........................................................................... 7-2

AI - Add to Tank Inventory......................................................................... 7-3

SI - Subtract from Tank Inventory ............................................................. 7-4

TI - Print Tank Inventory............................................................................ 7-5

LR - Load Inventory Reorder Point ........................................................... 7-6

Section 8: PUMP COMMANDS

Description ................................................................................................ 8-1

Pump Commands................................................................................ 8-1

LP - Load Pump Data................................................................................ 8-2

Defining Unit Price ............................................................................... 8-2

Assigning Timeout Values.................................................................... 8-2

Loading the Data.................................................................................. 8-3

Changing Pump Data........................................................................... 8-4

PP - Print Pump Data................................................................................ 8-5

EP - Enable a Pump.................................................................................. 8-6

DP - Disable a Pump................................................................................. 8-7

AP - Activate a Pump................................................................................ 8-9

IP - Inactivate a Pump............................................................................... 8-10

ZP - Zero Pump Totalizers........................................................................ 8-11

XP - Print Timeouts and Pulses ................................................................ 8-12

Section 9: TRANSACTION COMMANDS

Transaction Printing Options..................................................................... 9-1

Transaction Commands....................................................................... 9-1

Transaction Headings ............................................................................... 9-2

Price Data Format Effect on Headings................................................. 9-2

Transaction Printing with the Link Terminal and Okidata Printer......... 9-2

PT - Print Transactions.............................................................................. 9-3

ST - Print Sorted Transactions.................................................................. 9-4

Introduction

05/29/03 Contents-3

SS - Print Transactions for Specified Number

Within a Field........................................................................................... 9-5

PH - Print Compacted Transactions With Host

Interaction................................................................................................ 9-6

PC - Print Compacted Transactions.......................................................... 9-8

RT - Reset Transaction File...................................................................... 9-9

RP - Reset Transaction Pointer................................................................. 9-10

LN - Load Transaction Number................................................................. 9-11

Obtaining a Printout of Specific Transactions ........................................... 9-12

Transaction Messages.............................................................................. 9-13

Section 10: FUELING RESTRICTION COMMANDS

Description ................................................................................................ 10-1

Fueling Restriction Commands............................................................ 10-1

LF - Load Fuel Authorizations................................................................... 10-2

PF - Print Fuel Authorizations ................................................................... 10-3

LL - Load Fuel Limitations......................................................................... 10-4

PL - Print Fuel Limitations......................................................................... 10-5

Section 11: POLLING TRANSACTION INFORMATION

Methods of Polling..................................................................................... 11-1

Polling Using the PT Command........................................................... 11-1

Polling Using the ST Command........................................................... 11-1

Polling Using a PC or Computer.......................................................... 11-2

OPTIONAL FEATURES

Section 12: ACTIVATE PUMP (AP) DATA ENTRY OPTION

Description ................................................................................................ 12-1

Software Options Affected by Activate Pump

with Data Entries..................................................................................... 12-3

Section 13: DUAL LOCKOUT OPTION

Description ................................................................................................ 13-1

Changes in Standard Commands............................................................. 13-1

Section 14: FUEL ALLOCATION OPTION

Description ................................................................................................ 14-1

Allocation Commands.......................................................................... 14-1

Fuel Allocation Examples..................................................................... 14-2

AO - Allocation Offset................................................................................ 14-3

LA - Load Allocation.................................................................................. 14-4

ML - Multiple Load of Allocation................................................................ 14-5

AA - Add to Allocation ............................................................................... 14-6

MA - Multiple Add to Allocation ................................................................. 14-7

SA - Subtract from Allocation.................................................................... 14-8

MS - Multiple Subtract from Allocation...................................................... 14-9

CA - Check Allocation ............................................................................... 14-10

AT - Configure to Print All Totalizers......................................................... 14-11

NZ - Configure to Print Non-zero Totalizers.............................................. 14-12

GASBOY Series 1000

Contents-4 05/29/03

PA - Print Allocation Table ........................................................................ 14-13

MP - Print Range of Allocation.................................................................. 14-14

Transaction Headings with the Fuel

Allocation Option.................................................................................. 14-15

Section 15: FUEL DELIVERY AND DIPSTICK CARD OPTION

Description ................................................................................................ 15-1

Fuel Deliveries........................................................................................... 15-2

Dipstick Readings...................................................................................... 15-3

Transaction Headings with the Fuel Delivery/

Dipstick Option........................................................................................ 15-4

Section 16: GATE CONTROLLER OPTION

Description ................................................................................................ 16-1

Gate Controller Commands ................................................................. 16-1

LG - Load Gate Timeout ........................................................................... 16-2

PG - Print Gate Timeout............................................................................ 16-3

AG - Activate Gate .................................................................................... 16-4

Transaction Headings with the Gate

Controller................................................................................................. 16-5

Compacted Format with the Gate Controller............................................. 16-5

Changes in Standard Commands............................................................. 16-6

Software Options Affected by Gate

Controller................................................................................................. 16-7

Data Entries on Activate Gate (AG) Command Option........................ 16-7

Compacted Print Format with L/100KM or LPH Option ....................... 16-8

Additional Software Options for Gate

Controller................................................................................................. 16-9

Disable Memory Full Protection........................................................... 16-9

Section 17: LOADABLE BASE PUMP OPTION

Description ................................................................................................ 17-1

Changes in Standard Commands............................................................. 17-2

Section 18: MANUAL KEYPAD ENTRY OPTION

Description ................................................................................................ 18-1

Section 19: L/100KM or LPH OPTION

Description ................................................................................................ 19-1

Vehicle File Commands....................................................................... 19-2

CV - Clear Vehicle File.............................................................................. 19-3

LV - Load/Edit a Vehicle Record............................................................... 19-4

Load a New Vehicle Record................................................................. 19-4

Edit an Existing Vehicle Record........................................................... 19-5

RV - Remove a Vehicle Record ................................................................ 19-7

LO - Load Odometer/Hours....................................................................... 19-8

IV - Initialize Vehicle File........................................................................... 19-9

VF - Print Vehicle File................................................................................ 19-10

LM - Load Maximum Kilometers/Hours Between Fuelings ....................... 19-12

Introduction

05/29/03 Contents-5

LE - Load Ending Odometer/Hours........................................................... 19-13

CR - Check Vehicle Record ...................................................................... 19-14

EC - Enable L/100KM or LPH Calculation and Reasonable

Odometer/Hours Check For All Vehicles ............................................. 19-15

DC - Disable L/100KM or LPH Calculation and Reasonable

Odometer/Hours Check For All Vehicles ............................................. 19-16

Transaction Processing............................................................................. 19-17

L/100KM Transaction Processing........................................................ 19-17

LPH Transaction Processing................................................................ 19-18

Transaction Headings ............................................................................... 19-20

L/100KM Option................................................................................... 19-20

LPH Option .......................................................................................... 19-20

Changes in Standard Commands............................................................. 19-21

L/100KM (or LPH) Messages.................................................................... 19-23

Section 20: MULTI-LEVEL PASSWORD OPTION

Description ................................................................................................ 20-1

CP - Super User Authorization of Commands........................................... 20-2

Section 21: PUMP SWITCH TIMER OPTION

Description ................................................................................................ 21-1

Changes in Standard Commands............................................................. 21-2

Section 22: REASONABLE ODOMETER/HOURS CHECK OPTION

Description ................................................................................................ 22-1

Vehicle File Commands....................................................................... 22-2

CV - Clear Vehicle File.............................................................................. 22-3

LV - Load a Vehicle Record ...................................................................... 22-4

RV - Remove a Vehicle Record ................................................................ 22-5

LO - Load Odometer/Hours....................................................................... 22-6

VF - Print Vehicle File................................................................................ 22-7

LM - Load Maximum Kilometers Between Fuelings.................................. 22-8

CR - Check Vehicle Record ...................................................................... 22-9

Changes in Standard Commands............................................................. 22-10

Transaction Headings with the Reasonable

Odometer/Hours Check....................................................................... 22-12

Reasonable Odometer/Hours Messages.................................................. 22-12

Section 23: RECEIPT PRINTER OPTION

Description ................................................................................................ 23-1

Fueling Procedure..................................................................................... 23-2

GR - Get Receipt Command..................................................................... 23-3

Changes in Standard Commands............................................................. 23-4

Additional Receipt Printer Option - Multiple Receipts................................ 23-6

Receipt Printer Messages......................................................................... 23-8

Section 24: SUPERVISOR CARD OPTION

Description ................................................................................................ 24-1

Mag Card Systems............................................................................... 24-1

Optical Card Systems .......................................................................... 24-2

Fueling with a Supervisor Card................................................................. 24-3

GASBOY Series 1000

Contents-6 05/29/03

Section 25: TANK MONITOR INTERFACE

Description ................................................................................................ 25-1

TM - Tank Monitor Link Command............................................................ 25-2

Terminate Tank Monitor Communications Link......................................... 25-3

ENQ (CTRL E) Termination................................................................. 25-3

Timeout Termination............................................................................ 25-4

Tank Monitor Error Messages................................................................... 25-5

Section 26: PREVENTIVE MAINTENANCE................................................................ 26-1

Section 27: RECEIPT PRINTER MAINTENANCE

Printer Description..................................................................................... 27-1

Switches and Settings............................................................................... 27-1

Printer Status Board............................................................................. 27-2

Status Board Switches......................................................................... 27-2

Status Board Lamps............................................................................. 27-3

Controller Board DIP Switch Settings .................................................. 27-3

Accessing the Printer for Maintenance or Service .................................... 27-4

Changing the Paper .................................................................................. 27-4

Removing the Paper ............................................................................ 27-4

Installing the Paper .............................................................................. 27-5

Changing the Ribbon................................................................................. 27-5

Removing Old Ribbon Spools.............................................................. 27-5

Installing New Ribbon Spools .............................................................. 27-6

Adjusting Cutter Blades............................................................................. 27-7

Adjust After Incomplete Cuts................................................................ 27-7

Adjust After Paper Jams ...................................................................... 27-7

Appendix A COMMERCIAL FUELING NETWORK (CFN)

Appendix B SETUP OF PERIPHERAL EQUIPMENT

INDEX

WARRANTY

Introduction

05/29/03 Contents-7

FIGURES AND TABLES

Figures

27-1 Card System with Receipt Printer................................................................................ 27-1

27-2 Printer Status Board.................................................................................................... 27-2

27-3 DIP Switches............................................................................................................... 27-3

27-4 Printer Side View......................................................................................................... 27-4

27-5 Ribbon Installation Sequence...................................................................................... 27-6

27-6 Cutter Bar Adjustment Screw...................................................................................... 27-7

Tables

27-1 Status Board Switches ................................................................................................ 27-2

27-2 Status Board Lamps.................................................................................................... 27-3

27-3 DIP Switch Settings..................................................................................................... 27-3

05/29/03 1-1

Section 1

INTRODUCTION

This manual provides descriptions and operating procedures for your GASBOY Series 1000 Fuel

Management System. It also contains information for users of the Commercial Fueling Network

(CFN). These users have differences in their Series 1000 systems that are documented in

Appendix A of this book. This CFN is not to be confused with the GASBOY CFN system.

You should review this manual before your system start-up and reference it as you operate the

system.

OVERVIEW

The GASBOY Series 1000 Fuel Management System is a card-activated, microprocessor-based

fuel control and data acquisition system.

The Series 1000 System is designed to gather and record specific information about your fuel

management operation. You set up the Series 1000 by defining your configuration (tanks, pumps,

etc.). See Documentation/Getting Started later in this section.

Once your Series 1000 is operational, a typical scenario might be: A valid user drives his vehicle

into the fueling area. He places his card into the Series 1000, which reads and validates it. If a

second card is required, he then inserts it and the system validates that card. Then, the system

requests various pieces of information depending on the coding on the card (i.e., personal

identification numbers, odometer readings, etc.) Then it asks which pump he will be using. If

everything checks out within the system, the pump is activated and the fueling process begins.

When the fueling process ends and the user replaces the pump nozzle in its holder, the Series

1000 records transaction information in memory, and prints it out at the data terminal or logger, if

setup permits. Based on the transaction information, the Series 1000 decrements the tank

inventory and increments the pump totalizers.

GASBOY Series 1000

1-2 05/29/03

SYSTEM FEATURES

Using a data terminal, or computer with interface, connected to one of two communications ports,

you can issue commands and retrieve information from the Series 1000.

Standard Features

The standard features of this system include:

● 24-hour, unattended, controlled access to your fuel dispensing equipment.

● Standard Series 1000 simultaneously controls two hose outlets and can be expanded in two

hose increments to control up to eight. Supports pulsing rates of dollar (one penny per

pulse); or quantity (1, 10, 100, 250, 500, or 1000 pulses per unit of product). The pulse rate

selection switch is located in an area sealable by weights and measures for retail

applications.

● Visual prompting messages displayed on an eye-level 20-character liquid crystal display

(LCD) to guide the user through the fueling sequence.

● Access to the system restricted individually by card number or, optionally, by an additional 4-

digit field. CFN systems users are restricted via a 7-digit card number and no additional

fields.

● Controlled access to product type, using nine loadable authorization codes, card encoded.

● Limits on amount of fuel dispensed in a transaction, using 10 loadable limit codes, card

encoded.

● Automatic, immediate, transaction printing for hard copy backup or audit trail. Printing

includes: transaction number, date, time, card number, identification field #1 (e.g., employee

number), identification field #2 (e.g., vehicle number), pump used, fuel type and quantity

dispensed, price data (unit and total, if configured), odometer reading, and a transaction

status message.

● Automatic recording and storage of all transactions in system memory for later recall.

● Transaction printing in a variety of formats to meet your information requirements.

● Printing and storage of pricing data. Available options depend on pulser type. With dollar

pulsers, the system can print unit price only or both unit and total price. With quantity pulsers,

the system can print only unit and total price.

● Two asynchronous ports (both configurable to RS-232 or RS-422) for terminal and/or

computer communications.

● For additional report processing, the ability to interface with communications and report

software for IBM, and compatible, personal computers. Software is extra.

● A perpetual fuel inventory, maintained for up to eight tanks. Inventory adjustments are

automatically made with each transaction and can be adjusted at the data terminal to ensure

maximum inventory accuracy.

● Maintains up to eight resettable pump totalizers.

Introduction

4019 1-3

● A magnetic stripe insertion reader or an optional optical card reader. Optical readers are not

supported for CFN systems.

● An emergency shutdown button on the cabinet face to quickly shut down dispensing

equipment in case of emergency.

● Built-in AC and RS-422 transient protection reduces problems caused by power surges.

● To safeguard the system in a power failure, AC and DC power fail detect, deadman timer,

and pump control fail-safe circuits ensure an orderly shutdown so the system can return to

normal operation upon restoration. The system clock and memory are backed by batteries to

maintain the time and transaction data during power failures.

Optional Features

In addition to the standard features, your Series 1000 may have one or a combination of these

available options:

● Activate Pump (AP) Data Entry Option - allows you to enter card data (Card, ID Field 1,

and ID Field 2) and an odometer/hours reading at the data terminal before activating a pump.

● Dual Lockout Option - allows you to restrict system access by locking out a second 4-digit

field of your choice (in addition to card number). Dual lockout is not supported for

Commercial Fueling Network (CFN) systems.

● Extended Pump Timeouts Option - allows you to extend the standard maximum timeout

from 180 seconds to 3600 seconds (1 hour).

● Fuel Allocation Option - allows you to allocate predetermined amounts of fuel to a set

number of users.

● Fuel Delivery and Dipstick Option - enables you to accept and record fuel delivery and

dipstick reading data using special cards at the Series 1000.

● Gate Controller Option - enables you to use a dedicated Series 1000 to control a gate.

● Hours Option - Provides prompts at the LCD for users who record fuel consumption by an

hour meter instead of an odometer.

● Loadable Base Pump Option - allows you to assign different starting pump numbers for

sites having more than one Series 1000.

● Manual Keypad Entry Option - provides an additional field that allows you to request

specific input from the Series 1000 user. This option is a standard feature for Commercial

Fueling Network (CFN) systems.

● L/100KM (or LPH) Option - calculates and maintains liters-per-100 kilometers tallies for a

set number of your vehicles. This option can also be ordered to calculate liters-per-hour for

users’ equipment operating on an hour meter.

● Multi-Level Password Option - allows two levels of password access: super user, which

can access all commands; and standard user, which can access only commands authorized

by the super user.

GASBOY Series 1000

1-4 05/29/03

● Pump Switch Timer Option - allows you to prevent fueling at a pump when the handle has

been left on from a previous transaction.

● Reasonable Odometer/Hours Check Option - provides an odometer validity check for a set

number of your vehicles. This option can also be ordered to provide a reasonable hours

check for users’ equipment operating on an hour meter.

● Receipt Printer Option - allows you to obtain a fueling transaction receipt.

● Supervisor Card Option - allows you to use a specially encoded supervisor card to

manually enter card information at the Series 1000 keypad.

● Tank Monitor Interface - enables you to communicate with a GASBOY TMS 500 or a

Veeder-Root TLS, or an EBW AutoStik tank monitoring system using the Series 1000 as an

interface.

If problems arise or if you need assistance or information on options, call your authorized service

representative or GASBOY customer service at 1-800-444-5529.

Introduction

4019 1-5

DOCUMENTATION/GETTING STARTED

The following documentation is provided with the Series 1000 Fuel Management System:

● Installation Manual, C08922

● Card Encoding Manual, C08924

● Card Encoding Manual for Commercial Fueling Networks, C08370

● Operation Manual, C08923

● Diagnostic Manual, C08925

In addition, your authorized service representative (ASR) is provided with the following manual:

● Start-up Manual, C08921

When you get to this point, we assume:

● your system has been installed and tested (Reference: Installation Manual).

● your ASR has started up your system, and helped you perform necessary tests (Reference:

Start-up Manual).

● your ASR has helped you with your initial configuration (Reference: Start-up Manual and

Operation Manual)

When you configure your system you need to know:

- number of pumps (outlets)

- number of tanks

- pulser type

- pulses per liter or dollar (penny pulsing)

- fuels and fuel codes

- fuel code authorizations and limitations

- communications port settings

- site shutdown start and end times

- the type of lockout file you wish to create

Your ASR will help you perform these commands:

SC configure your system

MO allows you to view data one screen at a time on your CRT (if desired)

RT initialize transaction file

LN load starting transaction number

LD load system date and time

LK load 4-digit PIN key (assigned on card layout)

SD load shutdown start and end times

LI load initial inventory for each tank

LR load an inventory reorder point for each tank

LP assign specific fuels, tanks, totalizer readings, and timeouts to your pumps

LL assign maximum fuel quantities to limitation codes

LF assign fuel codes to authorization codes

VA or IA validate or invalidate all cards depending on the type of card file you’ve chosen

(negative or positive)

● Your cards should be encoded (Reference: Card Encoding Manual or Card Encoding Manual

for Commercial Fueling Networks, C08370).

GASBOY Series 1000

1-6 05/29/03

HOW TO USE THIS BOOK

This book is written in first person aimed at the system operator. Reviewing these items will help

you as you use this book:

● We use the term, the system to describe the Series 1000.

● When procedures say you, we infer that you are the system operator at the data terminal.

● When we say the user, we infer that the user is the person currently at the Series 1000 card

system.

● Nearly all of the procedures in this book are initiated and entered from the data terminal.

● When we say on the Series 1000 keypad, we mean you enter data at the card reader.

● When we say, the system displays, we are generally referring to the data terminal display.

When we refer to display messages on the Series 1000, we usually say on the LCD display.

● When we tell you to press keys, either on the data terminal or on the Series 1000 keypad, we

use the key name (i.e., RETURN, ENTER, etc.). The control key (CTRL) is always pressed

with another key. When you see a sequence like CTRL C, it means press the CTRL and C

keys together.

● Data you enter in examples is shown in bold type. All examples shown in this manual are for

the standard Series 1000. See Appendix A for CFN system examples.

● When you see the symbol ↵in examples it means to press RETURN after the entry of data.

● Appendix A in this manual covers information and system differences for members of the

Commercial Fueling Network (CFN) using this system in their network. CFN, in this case,

should not be confused with GASBOY’s CFN System.

The Commercial Fueling Network logo appears throughout this manual to

indicate when a standard Series 1000 command or procedure is handled

differently for Commercial Fueling Network users. When you see the

Commercial Fueling Network logo (shown at right) on a page, refer to the

appropriate subheading in the Appendix for more information.

05/29/03 2-1

Section 2

FUELING WITH THE SERIES 1000

The GASBOY Series 1000 System is designed to guide even untrained users effortlessly through

the operation of the system. A series of prompts, which appear on the Liquid Crystal Display

(LCD), guides the user through the fueling transaction. For additional reference, operating

instructions are printed on the cabinet face.

A typical fueling using a Series 1000 (magnetic or optical card) is accomplished as follows:

1. Position your vehicle adjacent to the fuel dispensing equipment. Be sure to note the

odometer reading (if your system uses this feature).

In its idle state, the Series 1000 LCD display alternates between an ENTER CARD message

and a personalized system message.

2. If you are using a two-card optical system, place the two optical cards on top of each other

(order does not matter) with the cut corner to the left and towards the reader and insert them

into the reader as one card. Skip to Step 6.

If you are using magnetic cards, insert your card fully into the card reader with the magnetic

stripe facing down and to the left. The LCD displays: REMOVE CARD

3. Remove the card. If you leave a card in the reader for more than five seconds, an alarm

sounds to remind you to remove it. If you are using a one-card system, skip to Step 7.

4. If you are using a two-card system, the LCD displays: ENTER SECOND CARD.

5. Insert the second card fully into the card reader with the magnetic stripe facing down and to

the left. The LCD displays: REMOVE CARD.

6. Remove the card(s) from the reader.

7. If your system uses the receipt printer option, go to Step 8.

If your system uses PINs, go to Step 9.

If your system uses odometer readings only, go to Step 10.

If your system uses none of these, go to Step 11.

8. If you have the receipt printer option and a prior transaction (with quantity) receipt is

available, the LCD displays: RECEIPT? 1=YES 0=NO.

To print a transaction receipt, press 1and ENTER. The LCD displays: RECEIPT IS

PRINTING. If you have requested multiple receipts, they print out one after the other. The

system goes to idle and you must reinsert your card(s) to begin a fueling transaction.

If you do not want a receipt, press 0 and ENTER. Skip to Step 9. For more on receipt

printing, see Section 23.

GASBOY Series 1000

2-2 05/29/03

9. If you are required to enter a Personal Identification Number (PIN), the LCD displays: ENTER

P.I.N.

Using the keypad, enter your PIN number and press ENTER. To ensure security, an asterisk

(*) appears for each digit you press. If you make a mistake while entering your PIN, press

CLEAR and enter it again.

You have three tries to enter the correct PIN. After the third unsuccessful try, the display

returns to ENTER CARD and you must start again at Step 2.

If your system uses the Auto Pin Lockout feature, the card is automatically locked out

(invalidated) after the third unsuccessful PIN entry.

10. If you are required to enter an odometer reading, the LCD displays: ENTER ODOMETER or

ENTER HOURS.

Use the keypad to enter the mileage/time that appears on your vehicle’s odometer or hour

meter (up to six digits, no tenths). The digits appear as they are entered. If you make a

mistake, press CLEAR and enter the reading again. When you enter the correct reading,

press ENTER. The LCD prompts: SELECT PUMP

10. Enter the desired pump number (one digit), and press ENTER.

If the pump is available and you are authorized to use it, the LCD displays: PUMP #x IS

READY and you may proceed to dispense fuel.

If PUMP #x IS READY is not displayed, one of the following messages appears:

NO SUCH PUMP

PUMP IN USE!

PUMP DISABLED

INVALID FUEL

You have three tries to select a correct pump. If, after three attempts, the system does not

display PUMP #x IS READY, the display returns to ENTER CARD and you must begin again

at Step 2.

11. When you finish fueling your vehicle, turn off the fuel dispenser handle and return the nozzle

to its holder. The transaction information is automatically recorded in the system’s memory

for later recall. If you are using the Direct Printout feature, the transaction information is

also printed on the data terminal or logger.

Transaction information includes transaction number, card number, identification field 1,

identification field 2, date, time, pump number, product type, quantity dispensed, unit price

and/or unit and total price (if configured), odometer/hours reading, and transaction message.

13. If you have the receipt printer option and you wish to have a receipt, insert and remove your

card. The LCD displays: RECEIPT? 1=YES 0=NO.

To print a transaction receipt, press 1and ENTER. The LCD displays: RECEIPT IS

PRINTING. Multiple receipts print out one after the other. The system goes to idle.

Other manuals for SERIES 1000

1

Table of contents

Other Gasboy Control System manuals

Popular Control System manuals by other brands

Cabrinha

Cabrinha 2010 Powerdrive IDS manual

DSPPA

DSPPA MAG2189 manual

Skov

Skov DOL Technical user guide

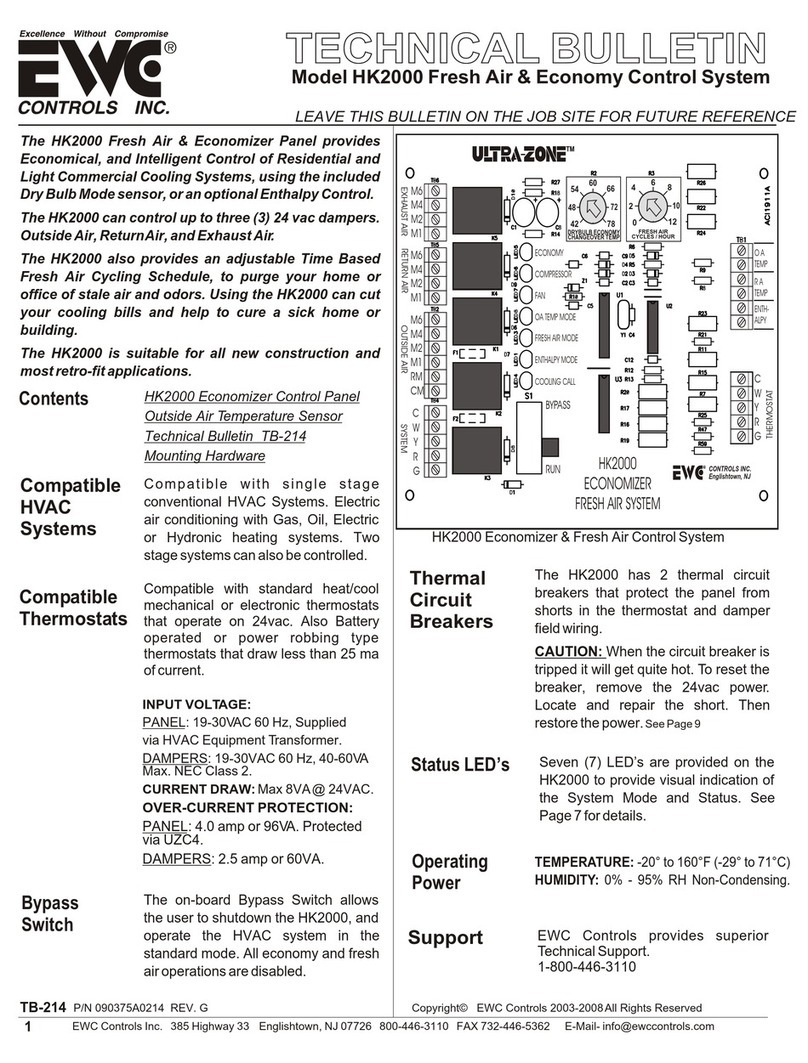

EWC Controls

EWC Controls ULTRA-ZONE HK2000 Technical bulletin

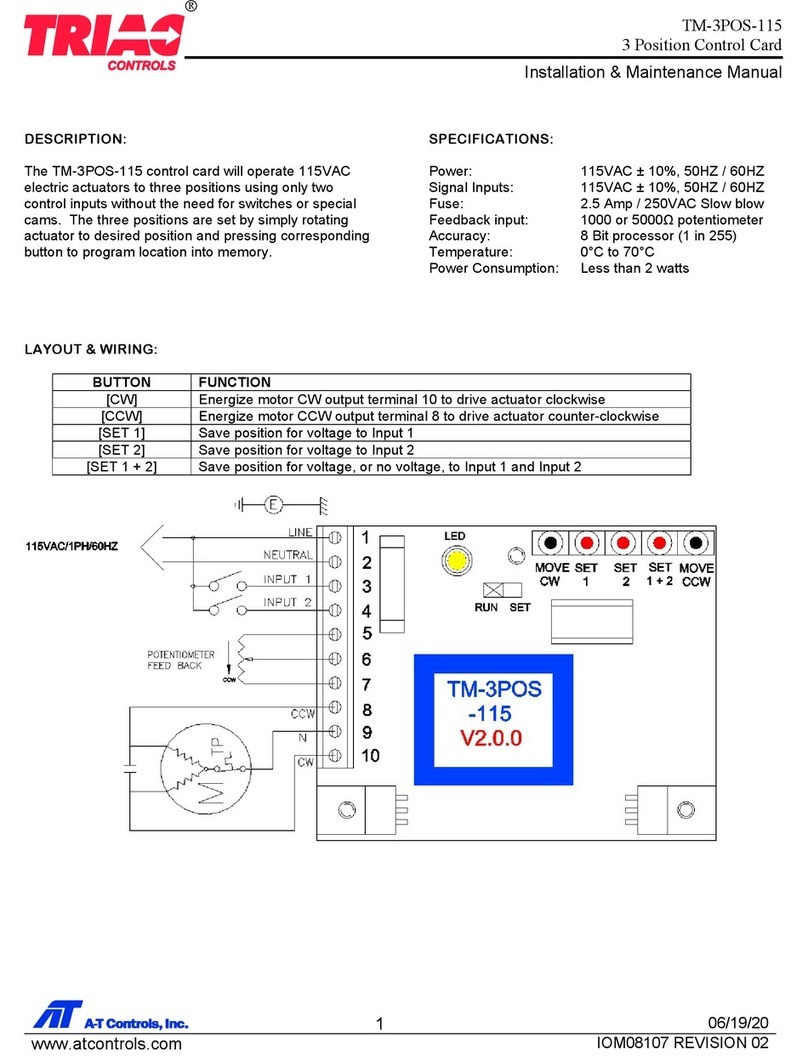

A-T Controls

A-T Controls TRIAG M-3POS-115 Installation & maintenance manual

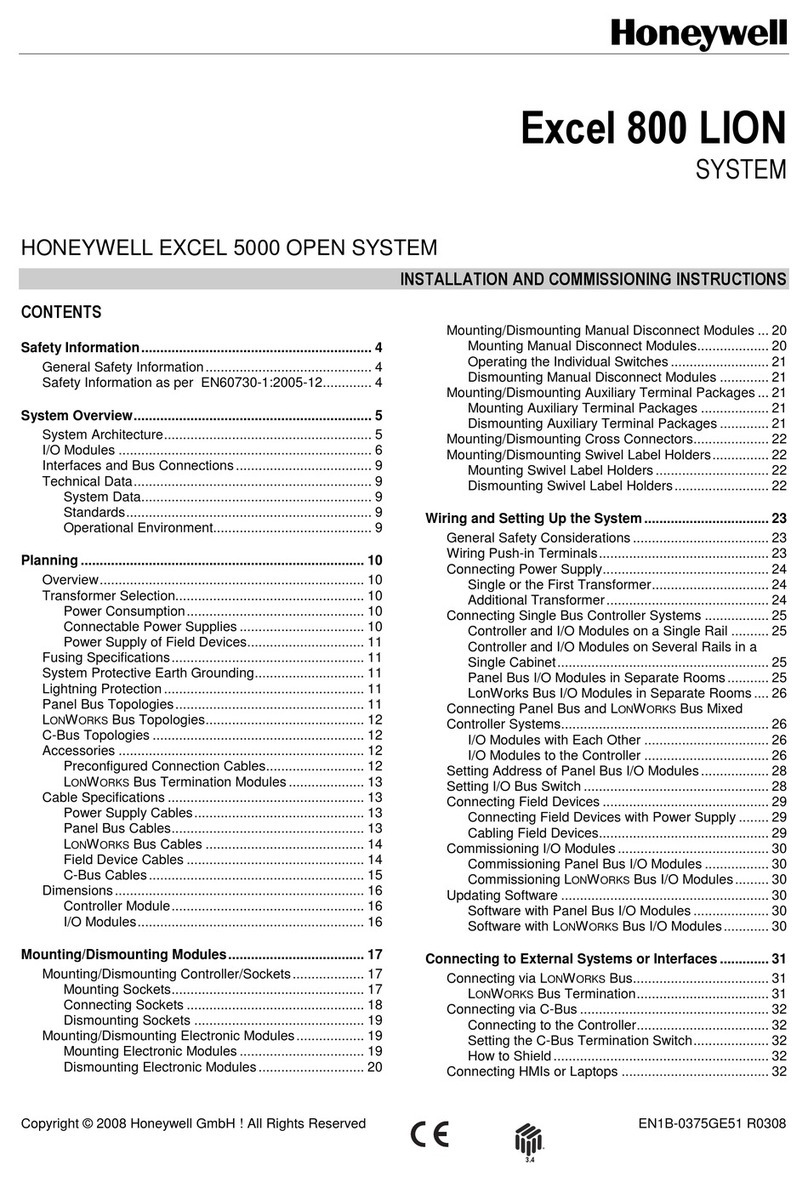

Honeywell

Honeywell Excel 800 LION Installation and commissioning instructions

HEIDENHAIN

HEIDENHAIN ITNC 530 - CONVERSATIONAL PROGRAMMING Service manual

UCS

UCS C-SV 4A user manual

STEPCRAFT

STEPCRAFT M Series operating manual

Fröling

Fröling Lambdatronic SP 3200 Service manual

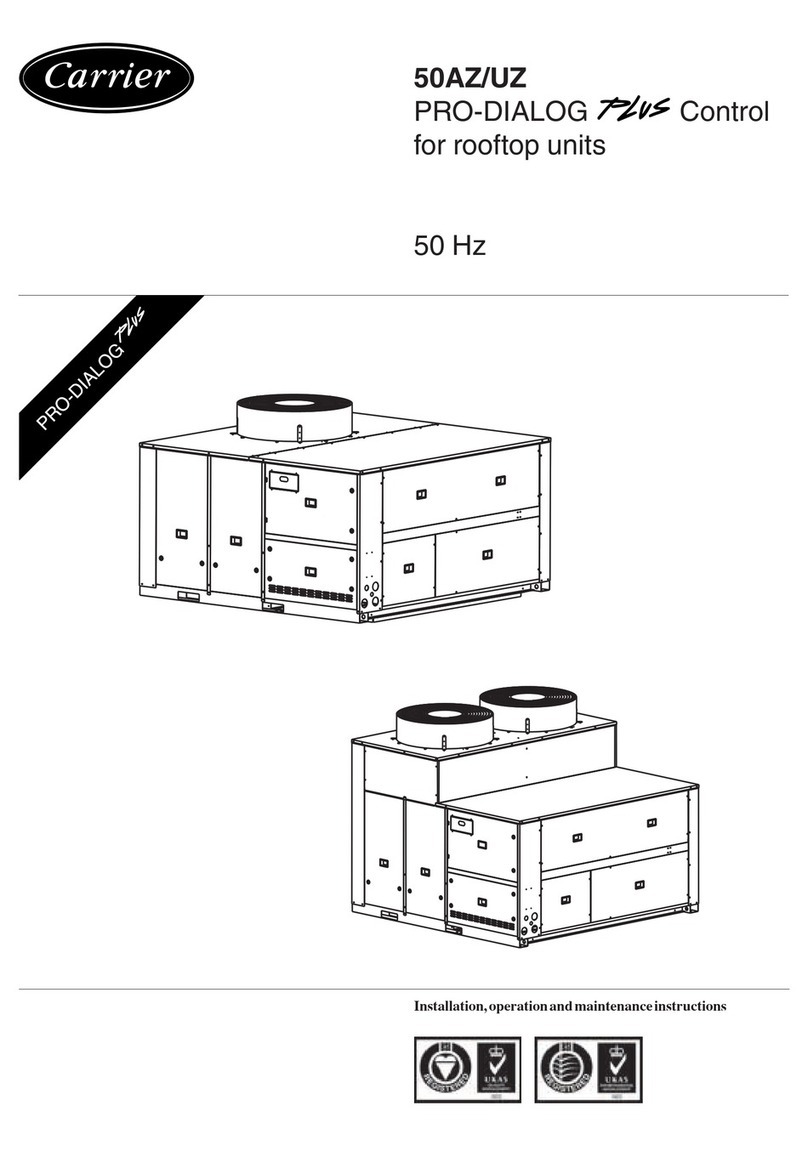

Carrier

Carrier PRO-DIALOG PLUS 50AZ Installation, operation and maintenance instructions

Daintree

Daintree WWD2-4SM installation guide