GASER L-80 User manual

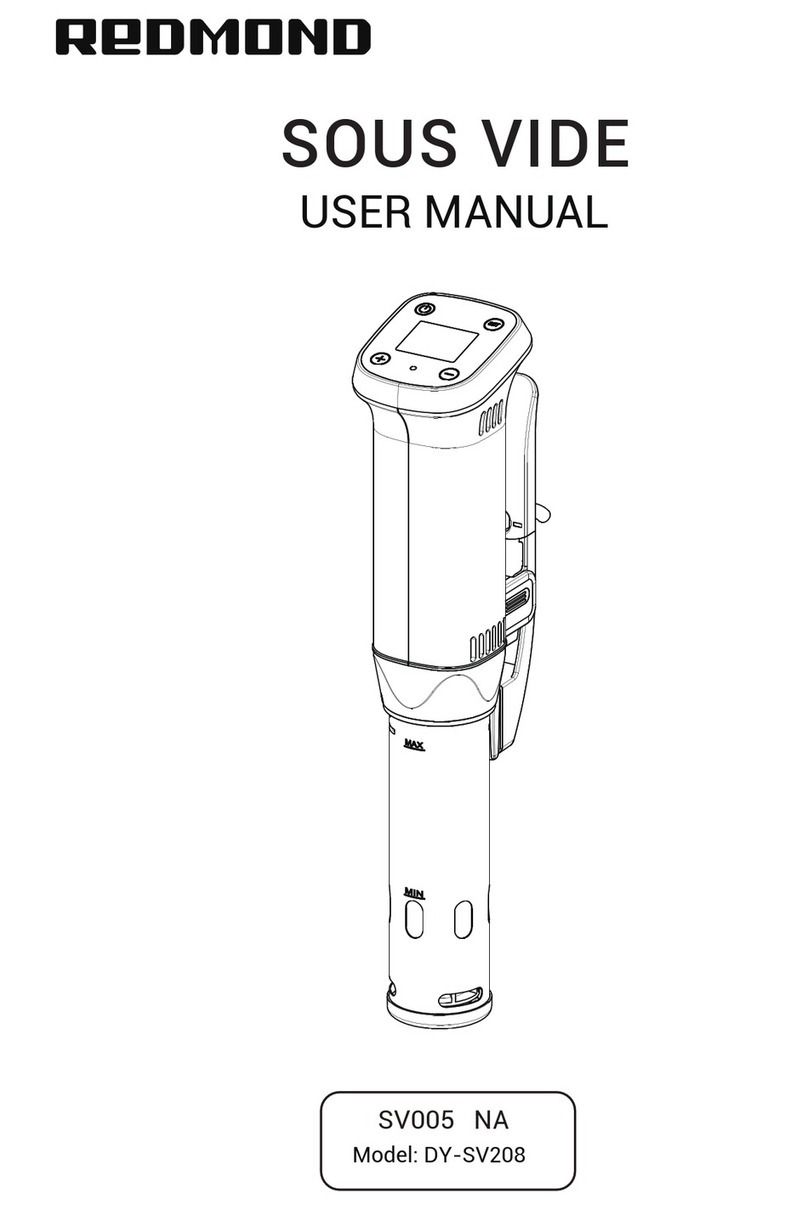

PORTION CUTTING MACHINE FOR

FRESH SAUSAGES

Mod. L-80

-2-

INDEX

1. INDUSTRIAS GASER............................................................................................3

2. EC DECLARATION OF CONFORMITY .................................................................4

3. HYGIENE CERTIFICATE.......................................................................................5

4. INTRODUCTION....................................................................................................6

4.1 Safety...............................................................................................................6

4.2 Hygiene............................................................................................................6

5. TECHNICAL SPECIFICATIONS.............................................................................7

6. RECEIPT AND START-UP.....................................................................................8

6.1 Receipt.............................................................................................................8

6.2 Start-up ............................................................................................................8

7. CLEANING...........................................................................................................11

8. MAINTENANCE...................................................................................................12

9. TROUBLESHOOTING .........................................................................................13

10. GENERAL DIASSEMBLY...................................................................................14

10.1 Overview......................................................................................................14

10.2 Clamp assembly...........................................................................................16

10.3 Crank assembly ...........................................................................................17

-3-

1. INDUSTRIAS GASER

Since its foundation in 1969, INDUSTRIAS GASER has specialised in manufacturing a range of

stainless-steel machinery for the meat industry.

Since 1985 we have constantly developed technology for GASER-brand hamburger-forming

machines, developing a distinctive system based on a SIMPLER, MORE EFFECTIVE AND MORE

ECONOMICAL TECHNIQUE.

In the 1990s, INDUSTRIAS GASER expanded into markets in various countries around the world, and

not just in the hamburger sector.

We are aware that our work would be of no value without the trust of our existing clients and partners

or the interest shown by those who wish to join them.

We thank them all.

INDUSTRIAS GASER GASER EUROPA

Salt, Girona, SPAIN L’viv, UKRAINE

INDUSTRIAS GASER Ctra, Bescanó, 15, Pol. Torre Mirona 17190 Salt (Girona) - Spain

Tel. 34 972 23 65 72 | Fax 34 972 23 63 66 | Whatsapp: (34) 679 49 65 06

email: gaser@gaser.com

GASER EUROPA вул.Б.Лепкого,1 81160 смт.Щирець Пустомитівский р-н Львівська область

Украіна - Ukraine

Tel. 38 (03230) 67251/84

Fax 38 (03230) 67191

email: gasereuropa@gaser.com

For more information about the company and its products: www.gaser.com

-4-

2. EC DECLARATION OF CONFORMITY

We declare under our responsibility that the following machine:

Brand: GASER

Model: L-80

Serial no.

Year of construction:

is in conformity with the following regulations

UNE-EN ISO 12100:2012

UNE-EN ISO 14120:2016

UNE-EN ISO 14121-1:2008

UNE-EN ISO 13849-1:2008/AC:2009

It is forbidden to make any change or modification to the machine without the prior written permission

of our technical department. Use of the machine in these conditions could cause accidents, in which

case INDUSTRIAS GASER S.L. accepts no liability for the improper use of the machine.

Salt,

CARLOS GARGANTA SERRAMITJA

TECHNICAL DIRECTOR INDUSTRIAS GASER S.L.

-5-

3. HYGIENE CERTIFICATE

We declare the machine:

Brand: GASER

Model: L-80

Serial no.

Year of construction:

is in conformity with the following regulations

Regulation (EC) 1935/2004, materials and articles in contact with food, repealing Directives

80/590/EEC and 89/109/EEC.

This means that all of the types of steel and plastic from which the machine is constructed and which

are in contact with the meat comply with the hygiene rules and regulations in force.

* Plastic material: polyethylene terephthalate (PETP), white, density 1.37g/cm3,

Manufactured in accordance with DIN 50014.

* Stainless steel: AISI 304, manufactured in accordance with European regulations EN-10088,

Chemical composition: C≤0.07% Si≤0.75% Mn≤2% Cr=18-19% Ni=8-10%

AISI 316, manufactured in accordance with European regulations EN-10088,

Chemical composition: C≤0.03% Si≤1% Mn≤2% Cr=18.5-16.5% Ni=13-10%

Mo=2.5-2%

Salt,

CARLOS GARGANTA SERRAMITJA

TECHNICAL DIRECTOR INDUSTRIAS GASER S.L.

-6-

4. INTRODUCTION

Before using or handling the machine, you must read this manual carefully. The instructions in this

document are, whenever possible, accompanied by illustrations to help with understanding of how to

start, use and clean the machine.

This manual is subject to amendment.

4.1 Safety

Making any change or modification to the machine without the prior written permission of our technical

department is forbidden. Use of the machine in these conditions could cause accidents, in the event of

which INDUSTRIAS GASER S.L. will accept no liability for improper use of the machine.

The machine has been designed for use with food products and must be used in the way described in

this manual. Any use other than the specified one will involve risk for the user and for the machine.

INDUSTRIAS GASER S.L. accepts no liability either for damage to the machine or personal injury or

injury to third parties that this use might cause.

4.2 Hygiene

All of the materials used in the manufacture of the machine and which come into contact with food

comply with Regulation 1935/2004. Consequently, the machine has the CE mark.

It is not recommended to use detergents containing chlorine, any of its derivatives or any other product

that could damage the construction materials of the machine.

-7-

5. TECHNICAL SPECIFICATIONS

1. Twists and cuts fresh sausage

2. Produces 100 to 400 pieces/minute

3. Suitable for natural or artificial casing

4. Length of pieces with the standard L-80: 100, 120, 140, 160, 180 mm

5. Length of pieces with the special L-80: 160, 180, 200, 220, 240, 260, 280 mm

6. Sausage diameter from 10 to 35 mm.

7. Manual operation (5 pieces/rotation)

8. Tabletop machine

9. Made from stainless steel and non-toxic plastics (suitable for the meat industry)

10. Easy to maintain and clean

11. Measurements of the machine with packaging 570 × 510 × 240 mm

12. Weight of the machine 10 kg.

-8-

6. RECEIPT AND START-UP

6.1 Receipt

When you receive the machine, you must first check that it is in perfect conditions, without any

damage, dents or knocks.

If there is any problem, we advise you to notify the distributor or INDUSTRIAS GASER S.L. directly.

6.2 Start-up

1. This machine basically comprises the following parts: the chassis, the blades, the eccentrics

and the crank

2. It is important that when you start to portion the product, the machine is completely clean to

ensure its correct functioning.

3. Depending on the length of the product to be prepared, the corresponding pair of eccentrics

will be used (Pos. 2 overview).

3.1. To change the eccentrics, loosen the 5 blade assemblies (page 16) using the knurled nuts

(Pos. 14 overview) and move them to the edge of the rotating plate (Pos. 1 overview) using the

slots. Remove the eccentric fixing knob (Pos. 7 overview) and replace the eccentrics.

Photo 1. Loosen the nuts and slide the

blades out of the way.

Photo 2. Remove the knob.

Photo 3. Remove the eccentrics.

3.2. To fit the eccentrics, tighten the eccentric fixing knob again. Take special care when

putting the blades back in place as the blades must be positioned according to the grooves on the

back face of the rotating plate. Each of these grooves corresponds to a 20 mm increase in the

length of the product. Note that when adjusting the blades, they must close completely when

passing over the widest point of the eccentric (Photos 6.1 and 6.2)

-9-

Photo 4. Fit the eccentrics.

Photo 5. Fit the knob.

Photo 6.1. Adjust blades 1

Photo 6.2. Widest point on the eccentric

(indicated by horizontal mark)

3.3. Once you have adjusted the blades, you must also adjust the position of the sausage

support bars (Pos. 16 overview) so that a thread will pass tangential to them, as shown in Photo 7.

Photo 7.Adjust the sausage support bars

4. To start portioning, place the sausage so that a small amount is held by the clamps (Pos. 1,

Photo 8). You can then start portioning. The sausage will be guided helped by the sausage guide

bar (Pos 3. Overview).

-10-

Photo 8. Positioning sausage

-11-

7. CLEANING

The machine can be cleaned without disassembly. To do this, water at low or medium pressure can be

used with any neutral soap at a temperature of under 40 degrees centigrade.

For deep cleaning, we recommend disassembling the moving parts of the machine and then cleaning

them.

It is important to dry the blades fully every time they are cleaned as if not, they might oxidise.

-12-

8. MAINTENANCE

1. Lubricate the central spindle (Pos. 15 overview) regularly with oil suitable for food-grade use.

2. Regularly check the condition of the blades. Ensure that they are sharp and are not bent. Also

check that the rollers (Pos. 4 clamp assembly) turn correctly.

3. Check the condition of the surface of the eccentrics.

4. Regularly check the condition of the blade springs (Pos. 8 and 9 clamp assembly) to ensure

they open and close correctly.

5. Regularly check the condition of the crank bearing (Pos. 3 crank assembly) and the central

support (Pos. 10 overview).

-13-

9. TROUBLESHOOTING

A list is provided below of the problems that might occur with the machine, their potential causes and

how to solve them.

Problem

Cause

Solution

The blades do not cut

Springs (Pos. 8 and 9 clamp

assembly) worn out or in poor

condition

Replace affected springs

Clamps in clamp assembly bent

Straighten the blade if possible If

this is not possible, it must be

replaced

Ablade has come loose

Replace the affected blade

assembly

Blunt blade

Sharpen the blade (a special

diamond file is required)

Crank hard to turn

The spindle (Pos. 15 overview)

is not well lubricated

Lubricate with oil suitable for

food-grade use

The surface of the eccentrics is

not smooth.

Replace the eccentric

The rollers do not turn

1. If they are still round, lubricate

with oil suitable for food use

2. If they are not still round,

replace the effected rollers and

lubricate with oil suitable for

food-grade use

Interior crank bearing (Pos. 4

overview) in poor condition

Replace bearing

-14-

10. GENERAL DISASSEMBLY

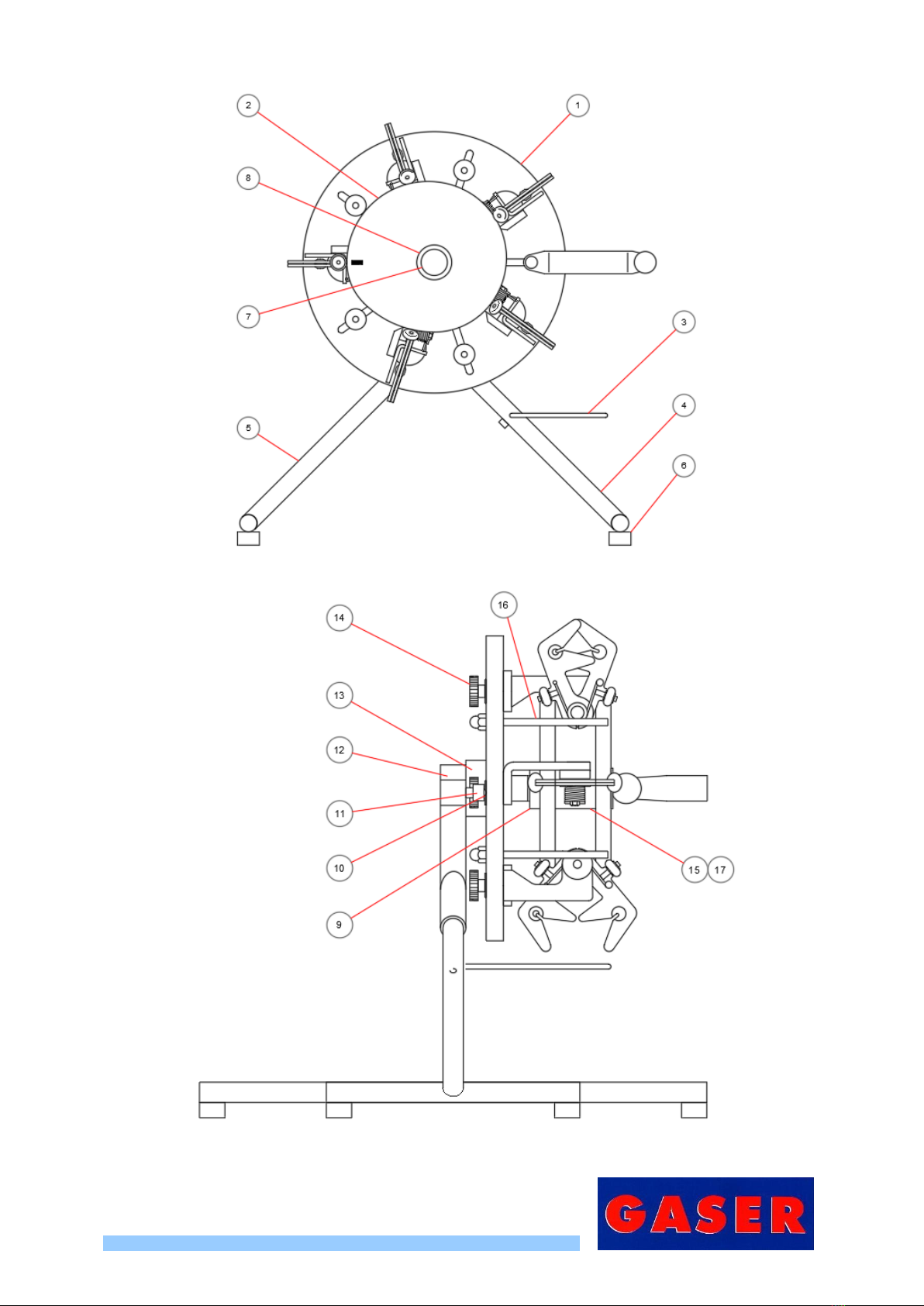

10.1 Overview

Number

Description

Reference

Units

1

STANDARD ROTATING PLATE

SPECIAL ROTATING PLATE

80030200

80030200-EE

1

1

2

ECCENTRIC

PLEASE CONSULT

2

3

STANDARD SAUSAGE GUIDE BAR

SPECIAL SAUSAGE GUIDE BAR

80010400

80010400-E

1

1

4

LONG BASE

80010200

1

5

SHORT BASE

80010300

1

6

RUBBER BASE

SI0226B250820N

4

7

ECCENTRIC FIXING KNOB

33000200

1

8

ECCENTRIC FIXING WASHER

80030500

1

9

ECCENTRIC FIXING RING

80030600

1

10

BEARING Ø8mmAISI-304

SI0109B08

1

11

ROTATING PLATE SUPPORT

80010500

1

12

STANDARD MAIN SUPPORT CHASSIS

SPECIAL MAIN SUPPORT CHASSIS

80010100

80010100-EE

1

1

13

ROTATING PLATE SUPPORT

80030300

1

14

KNURLED NUT SUPPORT. CENTRAL PLATE

00100200

5

15

MAIN SPINDLE

80030100

1

16

SAUSAGE SUPPORT BAR

80030700

4

17

ECCENTRIC SEPARATOR

80030400

1

18

BRAND STICKER L-80

PA0230L80

1

19

CE STICKER

PA0230L80CE

1

-15-

Diagram 1, Standard overview 1

Diagram 2, Standard overview 2

-16-

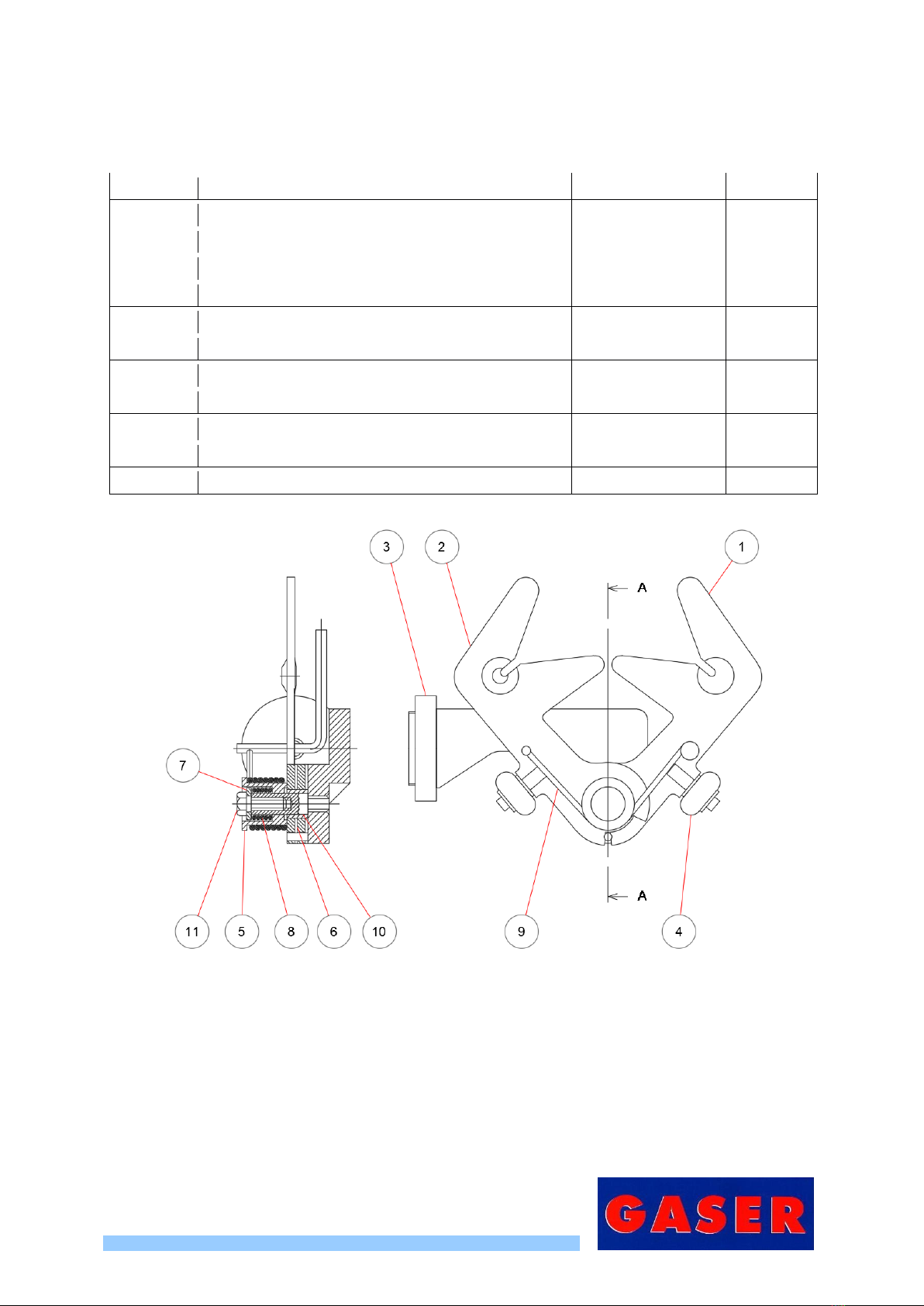

10.2 Clamp assembly

Ref.88510000

Number

Description

Reference

Units

1

OUTER CUTTING CLAMP

80020100

1

2

INNER CUTTING CLAMP

80020200

1

3

CLAMP SUPPORT

80023300

1

4

ROLLER

80020700

2

5

CUTTING CLAMPAXLE SLEEVE

80020800

1

6

CLAMP SPREADER WASHER

80020900

2

7

CLAMP SPINDLE SLEEVE INNER WASHER

80021000

1

8

COMPRESSING CLAMP INNER SPRING

SI011415121.64

1

9

COMPRESSING CLAMP OUTER SPRING

SI0114T1.8

1

10

INNER CLAMP SLEEVE

SI0409A081108

1

11

DIN933 HEX SCREW M8x40 INAISI-304

FE0108M080400933

1

Diagram 3, Clamp assembly

-17-

10.3 Crank assembly

Standard model ref. 88540000

Special model ref. 88540000-EE

Position

Description

Reference

Units

1

CRANK AXLE

80040100

1

2

STANDARD CRANK ARM

SPECIAL CRANK ARM

80040200

80040200-E

1

1

3

BEARING Ø4 AISI-304

SI0109B04

1

4

CRANK HANDLE

SI0612I601080M10

1

Diagram 4. Crank assembly

-18-

Table of contents

Other GASER Kitchen Appliance manuals