Gaspardo FUTURA Series User guide

MASCHIO GASPARDO S.p.A.

*)

Code F07012287 2020-04

EN

*) Valid for EU member countries

USE AND MAINTENANCE

TRANSLATION OF THE

ORIGINAL INSTRUCTIONS

FUTURA

• EXPO T

• FUTURA AVANT

• FUTURA JET

• FUTURA POST

• FUTURA TGZ AVANT

• FUTURA CANNONE

• FUTURA SIRENE

Original manual written in ITALIAN

2Code F07012287

3

Code F07012287

ENGLISH

INDEX

1.0 PREAMBLE ............................................................................................................................................................ 8

1.1 GENERAL INFORMATION ................................................................................................................................ 8

1.1.1 COMPOSITION OF THE MANUAL............................................................................................................ 8

1.1.2 DEFINITIONS............................................................................................................................................. 9

1.1.3 RESPONSIBILITY...................................................................................................................................... 11

1.1.4 COPYRIGHT.............................................................................................................................................. 11

1.1.5 SUMMARY OF PERSONAL PROTECTIVE EQUIPMENT (PPE).............................................................. 11

1.2.1 WARRANTY TERMS AND CONDITIONS ................................................................................................. 13

1.2.2 TERMINATION OF THE WARRANTY ....................................................................................................... 14

1.2.3 ARRANGEMENTS TO BE BORNE BY THE CUSTOMER ........................................................................ 14

1.3 IDENTIFICATION OF THE MACHINE ............................................................................................................... 15

2.0 GENERAL SAFETY INDICATIONS........................................................................................................................ 16

2.1 SAFETY AND INDICATION SIGNS ................................................................................................................... 16

2.1.1 WARNING SIGNS...................................................................................................................................... 16

2.1.2 DANGER SIGNS........................................................................................................................................ 16

2.1.3 INDICATION SIGNS................................................................................................................................... 16

2.2 SAFETY STANDARDS AND INJURY PREVENTION........................................................................................ 20

2.2.1 PROHIBITION OF USING THE MACHINE................................................................................................ 20

2.2.2 SUBJECTS TO BE PROTECTED.............................................................................................................. 20

2.2.3 ZONES OF GREATER DANGER .............................................................................................................. 20

2.2.4

GENERAL USE AND MAINTENANCE RULES .................................................................................................... 20

2.2.5 PHYTOSANITARY PRODUCTS ................................................................................................................ 21

2.2.6 OPERATOR FALLING................................................................................................................................ 23

2.2.7 MACHINE BREAKDOWN .......................................................................................................................... 23

2.2.8 ELECTROCUTION HAZARD..................................................................................................................... 23

2.2.9 FIRE PREVENTION MEASURES.............................................................................................................. 24

2.2.10 FLYING OBJECTS HAZARD ................................................................................................................... 25

2.2.11

SAFETY DISTANCE FROM THE PTO SHAFT...................................................................................................... 25

2.2.12 PROTECTION AND SAFETY DEVICES FITTED ON THE MACHINE.................................................... 25

2.2.13 PERSONNEL QUALIFICATIONS AND DUTIES...................................................................................... 26

2.3 STANDARDS OF REFERENCE ........................................................................................................................ 26

3.0 INFORMATION ON THE MACHINE....................................................................................................................... 27

3.1 INTENDED USE................................................................................................................................................. 27

3.2 DESCRIPTION AND OVERALL DIMENSIONS ................................................................................................. 28

3.3 TECHNICAL DATA AND IDENTIFICATION OF THE COMPONENTS............................................................... 29

3.3.1 TECHNICAL DATA AND SET-UPS ALLOWED .......................................................................................... 30

3.4 MAIN EQUIPMENT ............................................................................................................................................ 33

3.4.1 HYDRAULIC SYSTEM............................................................................................................................... 33

3.4.1.1 HYDRAULIC CONNECTION TO DISTRIBUTORS (FOR HYDRAULIC SYSTEMS)......................... 33

3.4.1.2 OIL SUPPLY FROM THE TRACTOR (FOR HYDRAULIC SYSTEMS).............................................. 33

3.4.2 ELECTRIC SYSTEM.................................................................................................................................. 34

3.4.3 WATER SYSTEM FOR TREATMENT........................................................................................................ 35

3.5 TYRES ............................................................................................................................................................... 37

3.6 NOISE LEVEL.................................................................................................................................................... 37

3.7 VIBRATION LEVEL ............................................................................................................................................ 38

3.8 CONTROLS TO BE CARRIED OUT UPON RECEPTION OF THE MACHINE................................................. 38

3.9 FREQUENCY OF FUNCTIONAL CHECKS ....................................................................................................... 38

3.9.1 MACHINES FOR PROFESSIONAL COMPANY USE................................................................................ 39

3.9.2 MACHINES FOR SUBCONTACTORS ...................................................................................................... 39

3.9.3 LIST OF INSPECTION INTERVENTIONS................................................................................................. 39

3.10 FIRST USE OR PUTTING BACK INTO SERVICE AFTER A LONG IDLE PERIOD........................................ 39

3.11 STORAGE - PUTTING IN GARAGE ................................................................................................................ 40

3.11.1 INTRODUCING ANTIFREEZE LIQUID.................................................................................................... 40

3.12 DEMOLITION AND DISPOSAL........................................................................................................................ 41

3.12.1 GUIDELINES FOR SUITABLE TREATMENT OF WASTE....................................................................... 41

3.12.2 STORING EMPTY PACKAGING.............................................................................................................. 41

3.12.3 WASTE OF ELECTRIC AND ELECTRONIC EQUIPMENT (WEEE)....................................................... 41

3.13 PROHIBITED USE........................................................................................................................................... 42

4Code F07012287

ENGLISH

INDEX

3.14 LIABILITY OF MASCHIO GASPARDO S.P.A. FOR ORGANIC DAMAGE ...................................................... 42

4.0 HANDLING AND TRANSPORT ............................................................................................................................. 43

4.1 LIFTING THE MACHINE WITH ROPES ............................................................................................................ 43

4.2 HANDLING......................................................................................................................................................... 43

4.3 LOADING THE MACHINE ON A VEHICLE AND TRANSPORT ON PUBLIC ROAD ........................................ 44

4.4 TRANSFERRING THE MACHINE IN THE FIELD ............................................................................................. 45

4.5 TRANSIT ON PUBLIC ROADS (ONLY FOR APPROVED MACHINES)............................................................ 45

4.6 STEERING......................................................................................................................................................... 46

4.7 OPERATING LIMIT CONDITIONS..................................................................................................................... 46

4.8 PARKING THE MACHINE.................................................................................................................................. 47

5.0. COUPLING TO THE TRACTOR AND PRELIMINARY ADJUSTMENTS.............................................................. 48

5.1 TYPE OF TRACTOR.......................................................................................................................................... 48

5.1.1 ELECTRIC SYSTEM: CONNECTION........................................................................................................ 48

5.1.2 OIL HYDRAULIC SYSTEM: CONNECTION (IF ANY) ............................................................................... 48

5.1.3 MECHANICAL POWER TAKEOFF (PTO) ................................................................................................. 49

5.1.4 TRAILING HOOK ....................................................................................................................................... 49

5.1.5 HYDRAULIC LIFTER OF THE TRACTOR................................................................................................. 49

5.1.6 PTO SHAFT ............................................................................................................................................... 49

5.2 CONNECTION TO THE TRACTOR................................................................................................................... 52

5.2.1 HOOKING THE SAFETY CHAIN (ONLY IN COUNTRIES WHERE IT IS EXPECTED) ............................ 52

5.2.2 HOOKING THE SAFETY CHAIN WITH BREAKING SYSTEM ................................................................. 52

5.3 STOPPING THE MACHINE ............................................................................................................................... 52

5.4 UNCOUPLING THE MACHINE FROM THE TRACTOR.................................................................................... 53

5.5 DEVICES AGAINST UNAUTHORISED USE ......................................................................................................... 53

5.5.1 DEVICES AGAINST UNAUTHORISED USE WITH STEERING DRAWBAR............................................ 53

6.0 TECHNICAL SPECIFICATIONS OF THE MACHINE............................................................................................. 54

6.1 WORKSTATIONS............................................................................................................................................... 54

6.2 MANUAL TILTING PARKING FOOT .................................................................................................................. 55

6.3 HYDRAULIC SYSTEM....................................................................................................................................... 55

6.4 ELECTRIC SYSTEM.......................................................................................................................................... 55

6.4.1 SECTION SOLENOID VALVES ................................................................................................................. 55

6.5 WATER SYSTEM FOR TREATMENT................................................................................................................ 56

6.5.1 CONTROL LEVERS................................................................................................................................... 56

6.5.1.1 CONTROL LEVER POSITIONS ........................................................................................................ 57

6.5.2 MAIN TANK ................................................................................................................................................ 58

6.5.3 SPEED INDICATOR................................................................................................................................... 58

6.5.4 DEVIOKIT................................................................................................................................................... 58

6.5.5 PUMP......................................................................................................................................................... 59

6.5.5.1 CHECKING PRESSURE GAUGE ..................................................................................................... 60

6.5.5.2 VOLUMETRIC FLOW CHECK........................................................................................................... 60

6.5.5.3 ACCUMULATOR PRESSURE CHECK.............................................................................................. 60

6.5.6 PREMIXER (IF PRESENT)........................................................................................................................ 60

6.5.7 SYSTEM WASHING WATER TANK........................................................................................................... 61

6.5.8 HAND WASHING TANK............................................................................................................................. 61

6.5.9 DISCHARGE VALVE.................................................................................................................................. 61

6.5.10 HYDRAULIC STIRRER............................................................................................................................ 62

6.5.11 PERFORATED PIPE STIRRER ............................................................................................................... 62

6.5.12 TANK WASHER NOZZLE ........................................................................................................................ 62

6.5.13 CONTROL UNITS .................................................................................................................................... 62

6.5.13.1 PRESSURE REGULATOR COMPONENTS.................................................................................... 63

6.5.13.2 GENERIC OPERATING INDICATIONS........................................................................................... 63

6.5.14 WATER BUTTON PANEL......................................................................................................................... 65

6.5.15 FAN UNIT................................................................................................................................................. 65

6.5.15.1

STEP-UP GEAR AXIAL PULLEY FAN UNIT................................................................................................. 65

6.5.15.2

FRONT AND REAR SUCTION FAN UNITS............................................................................................... 67

6.5.15.3 CANNON FAN UNIT ........................................................................................................................ 67

6.5.15.4 DUAL SUCTION FAN UNIT ............................................................................................................. 70

6.5.16 FILTERS................................................................................................................................................... 71

5

Code F07012287

ENGLISH

INDEX

6.6 OPTIONAL ACCESSORIES............................................................................................................................... 73

6.6.1 BRAVO 180S COMPUTER........................................................................................................................ 73

6.6.2 BRAVO 140 COMPUTER .......................................................................................................................... 73

6.6.3 FLOW METER ........................................................................................................................................... 73

6.6.4 HOSE FOR CROP PROTECTION PRODUCTS ....................................................................................... 73

6.6.5 SOLUBILISER AND JAR WASHER WITH COVER FILTER...................................................................... 74

6.6.6 SPEED SENSOR....................................................................................................................................... 74

6.6.7 TAIL LIGHT KIT .......................................................................................................................................... 74

6.6.8 FILL PIPE ................................................................................................................................................... 74

6.6.9 FAN UNIT ACCESSORIES ........................................................................................................................ 75

6.6.9.1 ELECTRIC PARTITIONS ................................................................................................................... 75

6.6.9.2 BAFFLES ........................................................................................................................................... 75

6.6.9.3 LEAF COVER .................................................................................................................................... 75

6.6.10 ELECTROSTATIC KIT.............................................................................................................................. 75

6.6.11 DOCUMENT HOLDER KIT ...................................................................................................................... 76

6.7 DRAWBARS....................................................................................................................................................... 77

6.7.1 FIXED EYE DRAWBAR WITH HOLE OR FORK....................................................................................... 77

6.7.2 STEERING DRAWBAR.............................................................................................................................. 78

6.7.3 OVERHANG HUBS.................................................................................................................................... 78

6.7.4 DRAWBAR LENGTH VARIATION (WHERE POSSIBLE).......................................................................... 78

6.8 NOZZLES........................................................................................................................................................... 79

6.8.1 TYPE OF NOZZLES .................................................................................................................................. 79

6.8.1.1 NORMAL VOLUME CONE NOZZLES (OVER 300 L/HA) ................................................................. 79

6.8.1.2 LOW VOLUME CONE NOZZLES (FROM 50 TO 150-300 L/HA)...................................................... 79

6.8.1.3 ANTI-DRIFT NOZZLES...................................................................................................................... 80

6.8.2 TECHNICAL INFORMATION ON NOZZLES ............................................................................................. 80

6.8.3 NOZZLE HOLDERS................................................................................................................................... 81

6.8.4 NOZZLES AND DRIFT INTERACTION (FROM TEEJET CATALOGUE) .................................................. 81

6.9 CONVERSION FACTORS ................................................................................................................................ 84

6.9.1 DISTRIBUTION OF LIQUIDS HAVING DIFFERENT DENSITY FROM WATER (LIQUID FERTILISERS)

AND CONVERSION FACTORS.......................................................................................................................... 84

7.0 WORK ADJUSTMENTS ......................................................................................................................................... 85

7.1 ADJUSTING THE TRACKS................................................................................................................................ 85

7.2 ADJUSTING WATER SYSTEM WORKING PRESSURE .................................................................................. 86

7.3 TANK LOADING ................................................................................................................................................. 86

7.3.1 FILLING THROUGH THE QUICK COUPLER WITH THREE-WAY DIVERTER FROM SURFACE WATER

87

7.3.2 FILLING WITH SUCTION FILTER ............................................................................................................. 88

7.3.3 FILLING WITH ANTI-POLLUTION EJECTOR ........................................................................................... 88

7.3.4 FILLING THE CLEAN WATER TANK......................................................................................................... 89

7.4 TEST WITH CLEAN WATER.............................................................................................................................. 89

7.5 USE OF THE MIXER AND PREPARING THE MIXTURE.................................................................................. 90

7.5.1 PREPARING THE MIXTURE..................................................................................................................... 90

7.5.2 MANUAL PRE-MIXING .............................................................................................................................. 91

7.5.3 PREMIXER IN COVER .............................................................................................................................. 91

7.5.4

HOPPER PRE-MIXER WITH JAR WASHER ................................................................................................ 91

7.6 PRODUCT STIRRING IN THE TANK................................................................................................................. 92

8.0 CALIBRATING THE MACHINE .............................................................................................................................. 93

8.1 MAXIMUM CONCENTRATION LIMIT OF PLANT PROTECTION PRODUCT USED....................................... 93

8.2 COVERAGE INTENSITY ................................................................................................................................... 93

8.3 INDEX OF LEAF COVERAGE........................................................................................................................... 93

8.4 DEGREE OF PULVERISATION......................................................................................................................... 93

8.5

LIMIT DISPERSIONS AS FAR AS POSSIBLE ............................................................................................................ 93

8.6 CALIBRATION OF AXIAL FAN ATOMISERS ..................................................................................................... 94

8.7 CANNON ATMISER CALIBRATION................................................................................................................... 94

9.0 TREATMENT........................................................................................................................................................... 95

9.1 OPERATIONS TO BE PERFORMED BEFORE CARRYING OUT TREATMENT.............................................. 95

9.2 TREATMENTS ON TALL TREES....................................................................................................................... 95

6Code F07012287

ENGLISH

INDEX

9.3 HERBACEOUS CROP TREATMENTS.............................................................................................................. 95

10.0 WASHING THE TANKS AND THE SYSTEM ....................................................................................................... 96

10.1 TECHNICAL RESIDUE AND NEED TO WASH THE MACHINE...................................................................... 96

10.2 CIRCUIT WASHER AND TANK WASHER....................................................................................................... 96

10.3 PARTIAL WASHING WITH MAIN TANK FULL................................................................................................. 97

10.4 TOTAL WASHING WITH MAIN TANK EMPTY................................................................................................. 98

10.5 WASHING EMPTY CONTAINERS AND PRE-MIXER TANK ........................................................................... 99

10.6 INTERNAL WASHING...................................................................................................................................... 99

10.7 MACHINE EXTERNAL WASHING................................................................................................................... 99

11.0 CORRECT USE OF THE MACHINE..................................................................................................................... 100

11.1 CHECKING SPRAYING CIRCUIT FILTERS .................................................................................................... 100

11.2 CALCULATION OF WORK PARAMETERS ..................................................................................................... 100

11.2.1 SPEED IN KM/H....................................................................................................................................... 100

11.2.2 CHECKING OPERATING SPEED ........................................................................................................... 100

11.2.3 OPERATING TIME ................................................................................................................................... 100

11.3 OPERATE IN CORRECT WEATHER CONDITIONS ....................................................................................... 100

11.4 CHECKING LEVEL OF TANK .......................................................................................................................... 100

11.5 CHECKING TYRES.......................................................................................................................................... 100

12.0 MAINTENANCE.................................................................................................................................................... 101

12.1 LUBRICANTS: GENERAL GUIDELINES FOR THEIR CORRECT USE. ........................................................ 101

12.1.1 HYGIENE ................................................................................................................................................ 101

12.1.2 STORAGE ............................................................................................................................................... 102

12.1.3 WASTE PRODUCT DISPOSAL............................................................................................................... 102

12.2 ORDINARY MAINTENANCE ........................................................................................................................... 102

12.2.1 CHECKING STATUS OF NOZZLES ........................................................................................................ 102

12.2.2 LIQUID LEAKS FROM NOZZLES AND CLEANING................................................................................ 102

12.2.3 USE OF CHEMICAL FERTILISERS: WASHING ..................................................................................... 102

12.2.4 STEP-UP GEAR LUBRICATION.............................................................................................................. 103

12.3 YEARLY MAINTENANCE ................................................................................................................................ 103

12.3.1 LUBRICATION PUMP OIL LEVEL ........................................................................................................... 103

12.3.2 ADVANCEMENT SPEED SENSOR......................................................................................................... 103

12.3.3 GREASING .............................................................................................................................................. 104

12.3.4 MEMBRANE PUMP ................................................................................................................................. 105

12.3.5 HYDRAULIC STIRRERS ......................................................................................................................... 105

12.3.6 DRAWBAR ............................................................................................................................................... 105

12.4 EXTRAORDINARY MAINTENANCE ............................................................................................................... 105

12.4.1 ELECTRIC SYSTEM................................................................................................................................ 106

12.4.2 TANK ........................................................................................................................................................ 106

12.4.3 REPLACING A HYDRAULIC TUBE ......................................................................................................... 106

12.4.4 REPAIRS.................................................................................................................................................. 107

12.4.4.1 REPAIRING THE POLYETHYLENE TANK...................................................................................... 107

12.4.5 TYRES ..................................................................................................................................................... 108

12.4.5.1 WARNINGS...................................................................................................................................... 108

12.4.5.2 TYRE INFLATION PRESSURE ....................................................................................................... 108

12.4.5.3 LIFTING THE MACHINE BY MEANS OF THE CAR JACK ............................................................. 109

12.4.5.4 WHEEL REPLACEMENT................................................................................................................. 109

12.5 SCHEDULED MAINTENANCE ........................................................................................................................ 110

12.6 DAILY CLEANING AND PERIODIC CHECKS ................................................................................................. 110

12.6.1 FILTER CARTRIDGE CLEANING............................................................................................................ 111

12.6.2 REAR LIGHTS (IF PRESENT)................................................................................................................. 112

13.0 SPARE PARTS ..................................................................................................................................................... 112

14.0 TECHNICAL SUPPORT ....................................................................................................................................... 112

15.0 WATER DIAGRAM ............................................................................................................................................... 113

16.0 TABLES ................................................................................................................................................................ 117

16.1 TROUBLE - CAUSES - REMEDY TABLE........................................................................................................ 117

16.2 ALLOWED OUTFITTING TABLES ................................................................................................................... 118

16.2.1 FUTURA AVANT ALLOWED OUTFITTING TABLES ............................................................................... 118

16.2.2 JET ALLOWED OUTFITTING TABLES.................................................................................................... 120

7

Code F07012287

ENGLISH

INDEX

16.2.3 FUTURA RM/POST ALLOWED OUTFITTING TABLES .......................................................................... 122

16.2.4 FUTURA TGZ AVANT ALLOWED OUTFITTING TABLES ....................................................................... 125

16.2.5 FUTURA CANNONE ALLOWED OUTFITTING TABLES ........................................................................ 127

16.2.6 FUTURA SIRENE ALLOWED OUTFITTING TABLES ............................................................................. 129

16.3 TRAILED ATOMISERS OPTIONAL TABLES ................................................................................................... 131

16.4 ATOMISERS ROAD APPROVAL TABLE ......................................................................................................... 132

16.5 WHEEL BASE TABLE ...................................................................................................................................... 133

16.6 NOZZLE FLOW RATE TABLES FOR ATOMISERS......................................................................................... 134

16.7 LEVER/GUN NOZZLE TABLES....................................................................................................................... 135

16.8 TIGHTENING TORQUES TABLE..................................................................................................................... 135

16.9 ATOMISERS SPREADING TABLES ................................................................................................................ 136

16.10 FAN UNITS RANGE....................................................................................................................................... 144

8Code F07012287

ENGLISH

1.0 PREAMBLE

This User Instructions Manual (hereinafter called Manual) provides useful information to work safely, aiding in the use of

the EXPO T - FUTURA trailed machine.

That which is written hereafter must not be considered a long list of warnings, but rather a series of instructions aimed

at improving machine performance and to prevent damage to persons, objects or animals resulting from incorrect use

procedures.

It is extremely important that whoever transports, installs, commissions, uses, maintains, repairs and dismantles the

machine, carefully references and reads this manual before performing the various operations in order to prevent

incorrect manoeuvres and problems which could jeopardise the integrity of the machine or be dangerous for personal

safety and the environment.

Should any doubts or uncertainties concerning the use of the machine persist after having read this manual, do not hes-

itate to contact the Manufacturer who is available to provide prompt assistance for maximum efciency of the machine.

Lastly, remember that, during all operating phases of the machine, current standards regarding safety, work hygiene

and protection of the environment must always be observed. It is therefore the user's responsibility to make sure that

the machine is operated only in safe conditions for persons and the environment.

This manual is an integral part of the product and must be stored - together with the Declaration of Conformity - in a

safe place to be referenced throughout the life of the machine and in the event of resale it must be attached to it until it

is scrapped.

This manual has been drafted following standards in force at the time it was printed.

THE MANUFACTURER RESERVES THE RIGHT TO MODIFY THE EQUIPMENT WITHOUT PROMPTLY UPDATING

THIS PUBLICATION. IN CASE OF DISPUTE, THE VALID TEXT OF REFERENCE IS THE ITALIAN TEXT.

Some images in this manual show parts or accessories which might be different from those on your machine. Compo-

nents or guards may have been removed to make the representations more clear.

1.1 GENERAL INFORMATION

1.1.1 COMPOSITION OF THE MANUAL

The following symbol is used in the manual to mark and allow to recognise various types of danger:

ATTENTION

DANGER FOR THE HEALTH AND SAFETY OF OPERATORS.

DANGER OF DAMAGE TO THE MACHINE OR TO THE PRODUCT IN PROCESS.

In the text there are safety warnings alongside symbols; brief phrases which further exemplify the type of danger. The

warnings guarantee the safety of personnel and prevent damage to the machine or to the product being processed.

The drawings, diagrams, photographs and graphs provided in this manual are not in scale. They are used to integrate

the written information and act as a recapitulation of these, but they are not aimed at providing a detailed representation

of the supplied machine. To provide a more complete view of the machine, for the most part the drawings, photographs

and diagrams are reproduced without protections or guards installed. The following diagrams of the various systems

making up the machine are provided at the end of the manual:

• Hydraulic spraying system diagram.

As part of the machine's essential components is not directly built by the Manufacturer, the manual is integrated with a

series of attached manuals. Some of these consist of photocopies of catalogues, drawings, etc. which therefore main-

tain the identication number and original page numbering (when existing); otherwise they are without numbering. The

list is the following:

• Machine operating manual.

• Computer or control unit manual.

• Pump operating manual.

• Attached manuals.

9

Code F07012287

USE AND MAINTENANCE ENGLISH

Together with this manual, the user is provided with a set of documents certifying the machine's conformity with the ap-

proval requirements and Machinery Standards. In particular, the following is provided:

• Manufacturer's Declaration of Conformity with EC Standards pursuant to the Machinery Directive.

• Certicate of Approval Conformity

• Registration certicate fac-simile.

1.1.2 DEFINITIONS

The following are the denitions of the main terms used in the Manual. We recommend reading them carefully before making

use of the Manual.

• DISPENSING UNIT:.....................................It indicates the complete sprayer fan unit.

• TARGET: .......................................................Zone or part of vegetation which treatment is aimed at and where the dispensed

mixture must be deposited.

• AUTHORISED ASSISTANCE CENTRE:........

The authorised Assistance Centre is the structure, legally authorised by the Manu-

facturer, with qualied personnel to perform all assistance, maintenance and repair

operations, even complex, necessary to keep the machine in perfect working order.

• DRIFT: ...........................................................Atomised liquid mist blown by the wind.

• PPE:...............................................................Personal Protective Equipment, namely items suitable to contain and reduce any

dangers at work.

•

PHYTOSANITARY PRODUCT or AGROCHEMICAL:

.....Otherwise called "pesticide" or "chemical product"; it denes a category of speciali-

ties for treating plant illnesses or capable of regulating their vital processes (exclud-

ing fertilisers). These specialities are diversied according to their function:

• Fungicides or pesticides, if they act against fungi.

• Insecticides or acaricides, if they are against insects.

• Herbicides or weed killers, if they act against weeds.

• Nematicides and fumigants, if they are used for soil decontamination.

• Plant growth regulator, which regulate growth.

• Liquid fertiliser: generally nitrogen-based solutions with a specic weight greater

than 1; they are very aggressive on all unpainted metals and require correction

factors for distribution.

• Urea: soluble granules in water, requires dedicated accessories for distribution.

• Foliar fertiliser: composite solutions that tend to be aggressive on metals.

• RIGHT SIDE: ................................................It refers to the right side of the machine with respect to the direction of advancement.

• LEFT SIDE:...................................................It refers to the left side of the machine with respect to the direction of advancement.

• MACHINE: ....................................................From here on, this term shall refer to the overall trailed sprayer and relative fan unit.

• MESH FILTER: .............................................It indicates the degree of ltration. The smaller the size of the cells the lter mesh

consists of, the greater the ltering power.

• MIXTURE:.....................................................The mixture of the plant protection product (or agrochemical) and water, in the dilu-

tion proportions indicated by the manufacturer of the chemical product.

• OPERATOR:.................................................The person or persons installing, operating, adjusting, maintaining, cleaning, repair-

ing or moving the machinery.

• PTO ...............................................................Power take off 1”3/8 at 540 RPM.

10 Code F07012287

USE AND MAINTENANCE

ENGLISH

• PRESSURE DROP:.....................................Pressure drop along the supply line, caused by physical obstacles (elbows, bottle-

necks, clogged lter cartridges).

• EXPOSED PERSON: ..................................Any person wholly or partially in a danger zone.

• TRAINED PERSONNEL:.............................Personnel who have been informed and trained regarding tasks to be carried out and

the linked dangers.

• QUALIFIED PERSONNEL: .........................Those persons specically trained and qualied to carry out maintenance or repairs

which require a particular knowledge of the machine, of its operation, safety devices,

intervention methods and who are capable of recognising dangers resulting from use

of the machine and therefore able to avoid them.

• PUMP:...........................................................Refers to the pump used for spraying.

• CHEMICAL PRODUCT:...............................This is always a plant protection product or an agrochemical and none other.

• PROTECTIONS:..........................................Safety measures which consist of using specic technical means (Guards and Safe-

ty devices) to protect Operators from Hazards.

• DILUTABLE RESIDUE:................................Amount of mixture contained in the machine circuit before the general valve.

• NON-DILUTABLE RESIDUE:......................Amount of mixture contained in the machine circuit after the general valve and in the

supply valves.

• TECHNICAL RESIDUE:...............................Amount of mixture remaining in the machine (tank and entire hydraulic circuit) when

regular distribution is interrupted by effect of considerable work pressure variations

caused by the air draught.

• GUARD:........................................................Element of a machine specically used to provide Protection by means of a physi-

cal barrier; depending on its construction, it can be called hood, cover, shield, door,

fence, casing, segregation, etc.

• RISK:.............................................................Combination of the probability and the degree of an injury or damage to health that

can arise in a Hazardous Situation.

• HAZARDOUS SITUATION:.........................Any situation in which an Operator is exposed to one or more Hazards.

• ANTI-DRIFT NOZZLE: .................................Sprayer specically designed to make coarse droplets (with or without the incorpora-

tion of air), less sensitive to be blown by the wind.

• USER:............................................................The user is a person, body or company, who purchased or rented the machine and

intends on using it for the use for which it was designed.

• DANGER ZONE:..........................................Any zone within and/or around machinery in which a person is subject to a risk to his

health or safety.

• SENSITIVE ZONE:.......................................Surface of the soil particularly exposed to chemical risk (for example schools, homes,

roads, surface water ways, wells, crops which can be damaged by the product in

use, etc.).

11

Code F07012287

USE AND MAINTENANCE ENGLISH

1.1.3 RESPONSIBILITY

The Manufacturer will not be directly or indirectly liable in case of:

• Improper use of the machine for unintended activities.

• Use by unauthorised, untrained operator without a driver's licence.

• Serious shortcomings in scheduled maintenance.

• Unauthorised modications or interventions.

• Use of non-original and non-specic spare parts.

• Total or partial failure to comply with the instructions provided in this manual.

• Failure to comply with the safety standards provided in this manual.

• Failure to apply the provisions regarding safety, hygiene and health of the workplace.

• Any unforeseeable exceptional events.

ATTENTION

• It is not allowed for persons under the age of 18, the illiterate, persons in altered physical or mental conditions

to use the machine.

• Personnel without an appropriate driver's license or insufciently informed and trained cannot use the machine.

• The operator is responsible for controlling the functionality of the machine and of replacing and repairing parts

subject to wear which might cause damage.

• The customer must instruct the personnel regarding the risk of accidents, on the devices arranged for the

health and safety of the operator, on risks linked to exposure to noise and on general accident-prevention rules

foreseen by international directives and by the legislation of the country where the machine is used.

• In any case the machine must be used exclusively by qualied operators who are obliged to strictly comply with

the technical and accident-prevention instructions contained in this manual.

• The Customer is in charge of identifying and choosing the appropriate/suitable category of PPE.

• Specic pictograms are inserted on the machine, which the operator is in charge of keeping in perfect visual

condition and replacing when no longer legible, as required by EC standards.

• The user must control that the machine is only driven in ideal safety conditions for persons, animals and ob-

jects.

• Any arbitrary modication made to this machine relieves the Manufacturer from all the liability regarding dam-

age to objects or injuries to operators or third parties.

The Manufacturer will not be liable for possible inaccuracies in the manual, if attributable to printing, translation or tran-

scription errors. Any integrations to the user instruction manual which the Manufacturer will consider appropriate to send

the Customer must be kept together with the manual, of which they are an essential part.

1.1.4 COPYRIGHT

The copyright of this Manual belongs to the machine Manufacturer. THIS MANUAL CONTAINS TEXTS, DRAWINGS

AND ILLUSTRATIONS OF A TECHNICAL NATURE WHICH CANNOT BE DISCLOSED OR TRANSMITTED TO

THIRD PARTIES, IN WHOLE OR IN PART, WITHOUT THE WRITTEN AUTHORISATION OF THE MACHINE MANU-

FACTURER.

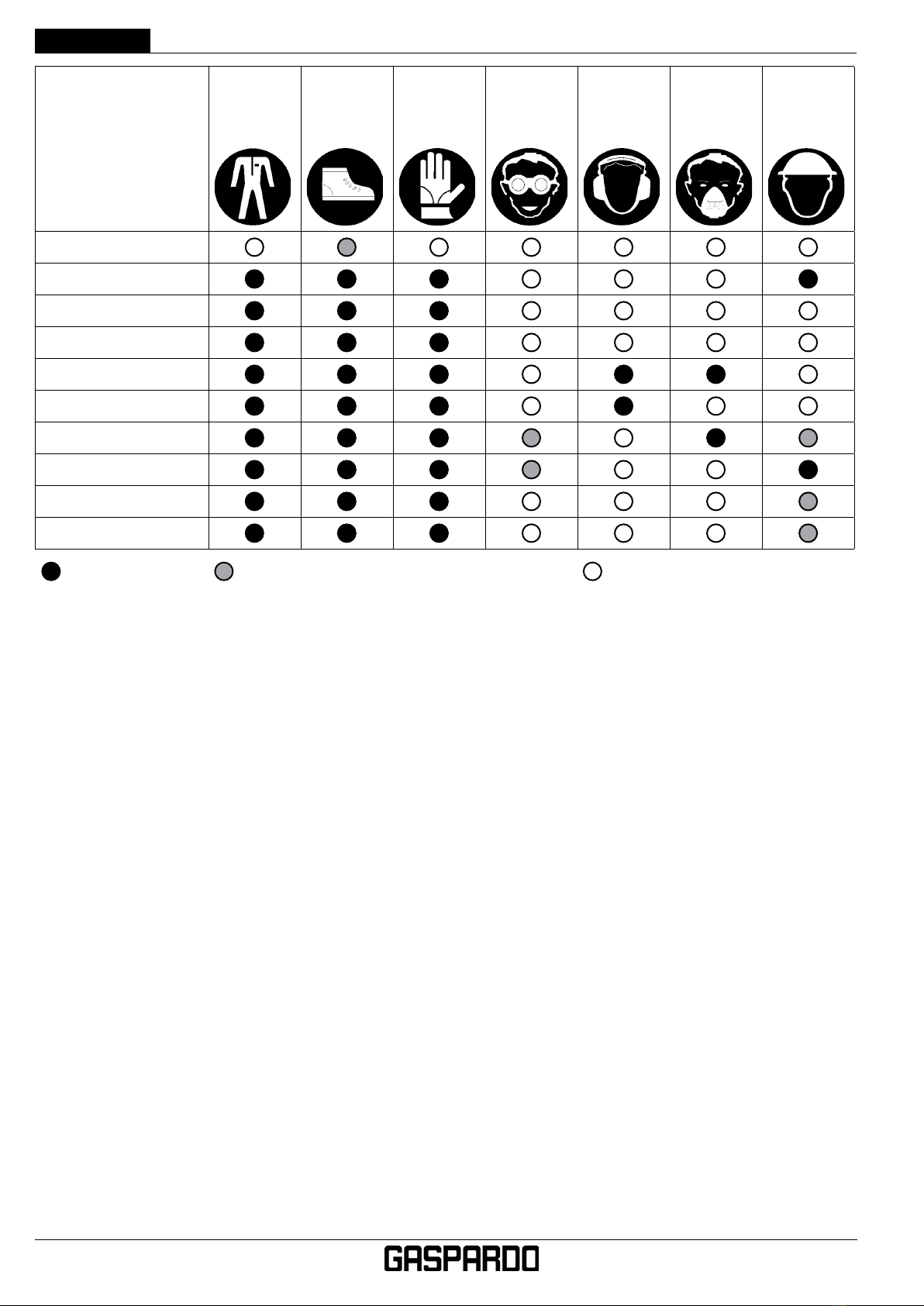

1.1.5 SUMMARY OF PERSONAL PROTECTIVE EQUIPMENT (PPE)

The following table summarises the PPE (Personal Protective Equipment) to be used during the various stages of the

machine life (for each stage it is mandatory to use the PPE and/or to make it available).

The Customer is in charge of identifying and choosing the appropriate and suitable type and category of PPE.

12 Code F07012287

USE AND MAINTENANCE

ENGLISH

Stage

Protective

clothing

Safety

shoes

Gloves Goggles

Safety

guards

protection

Facemask

Hard hat

or

helmet

Transport

Handling

Unpacking

Assembly

Routine use

Adjustments

Cleaning

Maintenance

Dismantling

Demolition

Intended PPE. PPE available or to be used if necessary. PPE not intended.

The PPE used must be CE marked and comply with 89/686/EEC Directive.

The stages in the machine's life (used in the table above) are described below:

• Transport .............. This consists of transferring the machine from one place to another using a specic transport vehi-

cle.

• Handling: .............. This entails transferring the machine from and on the transport vehicle as well as moving it inside

the plant.

• Unpacking: ........... This consists of removing all the materials used to pack the machine.

• Assembly:............. This entails all the assembly interventions which initially prepare the machine to be precision ad-

justed.

• Routine use: ......... Use for which the machine is intended (or considered usual) in relation to its design, construction

and function.

• Adjustments:......... These entail the adjustment, ne tuning and calibration of all those devices which must be adapted

to the normally foreseen operating condition.

• Cleaning: .............. This consists of removing dust, oil and processing residue which could jeopardise the proper opera-

tion and use of the machine, as well as the health/safety of the operator.

• Maintenance:........ This consists of the periodic checks of machine parts subject to wear or which must be replaced.

• Disassembly: ........ This consists of complete or partial disassembly of the machine for any type of need.

• Demolition: This consists of the nal removal of all the machine parts resulting from the nal dismantling opera-

tion, in order to allow recycling or separate waste collection of components as foreseen by legal

standards in force.

Table 1

13

Code F07012287

USE AND MAINTENANCE ENGLISH

ATTENTION

DANGER OF MACHINE FALLING AND DANGER OF GETTING CAUGHT IN MOVING PARTS OF THE MACHINE

POTENTIAL SERIOUS INJURIES OR DEATH

Always keep a safe distance from the moving parts, do not remove the existing protections and always use

protective equipment and appropriate clothing that cannot get caught in moving parts1.2 WARRANTY

The warranty is valid for 12 months against all material defects from the date of delivery of the machine.

Upon delivery, check that the machine has not undergone damage during transport and that the accessories are intact

and complete.

ANY COMPLAINTS MUST BE SENT TO THE DEALER IN WRITTEN FORM WITHIN 8 DAYS OF RECEIPT.

The purchaser can enforce his rights specied in the warranty only if its conditions have been complied with, in particu-

lar when:

• The use limitations of the machine foreseen by the Manufacturer have been complied with.

• No modications or variations have been applied to the machine without written approval by the Manufacturer.

• All the prescribed maintenance interventions have always been performed.

• Original spare parts have always been used.

• It is assured that the personnel in charge of using the machine have the necessary ability and training require-

ments.

The contractual warranty shall not be applied if the above conditions are not complied with, even only partially.

The warranty acknowledges the repair or replacement of parts considered faulty by manufacture, at the unquestionable

opinion of the Manufacturer, only after having veried the defect with the authorised area agent or directly at the Manu-

facturer's headquarters.

For warranty demands, see the "dealers warranty claim procedure" published on the “www.maschionet.com” website in

the "spare parts" section or by means of the procedure implemented by Dealer.

All requests for repairs or replacement under warranty must be authorised by MASCHIO GASPARDO S.p.A. after hav-

ing inspected the parts for which the intervention is requested.

Labour and travelling expenses are not covered by warranty.

Carriage forward returns are not accepted.

1.2.1 WARRANTY TERMS AND CONDITIONS

• The Manufacturer guarantees its products for a 24-month period for PRIVATE Consumers (NON-professional use of the

machine) who live in the Member states of the European Union, 12 months for other European Users (PROFESSIONAL

use of the machine) and 12 months for ALL Consumers and Users in foreign countries outside of the EU.

• Within the above-mentioned terms, the Manufacturer undertakes to supply spare parts free of charge for those

parts which, in the opinion of the Manufacturer (or by its Representative thereby authorised in written form) present

material or manufacturing defects.

• To verify the validity of the warranty period, the MASCHIO GASPARDO S.p.A. SAT (After-sales Technical Assis-

tance) will ALWAYS ask the Dealer (or nal user Purchaser) for a copy of the invoice, which must clearly indicate

the sale and delivery date of the equipment to the nal Customer.

• The product sent to the Manufacturer for repairs under warranty must include all its original components and not be

tampered with, under penalty of forfeiting the warranty.

• MASCHIO GASPARDO S.p.A. will not be held liable for damage//accidents to the operator or third parties caused

during work.

• Any failures or breakage of our machines which should occur during and/or after the warranty period do not grant

the right to suspend payment of the product already agreed on nor to further deferments.

• The Manufacturer reserves the right to make all the modications deemed necessary to improve its products at any

time without being obliged to apply these modications to the units previously produced, already delivered or in the

nalisation phase

• By accepting the MASCHIO GASPARDO S.p.A. product, the Purchaser implicitly accepts all these clauses, exclud-

ing any expressed or implicit pre-existing condition.

14 Code F07012287

USE AND MAINTENANCE

ENGLISH

1.2.2 TERMINATION OF THE WARRANTY

The warranty cannot be requested in cases of normal wear, carelessness in use, poor maintenance, improper use,

repairs and modications to the machine without written authorisation by MASCHIO GASPARDO S.p.A. or the Manufac-

turer.

Normally consumable materials excluded from the warranty: Gaskets, membranes, seal rings, pipes, nozzles, oil, tyres.

Clear cases of negligent use: Working speed beyond the dispensing tables published in the manual (or too high related

to the condition of the soil).

Maintenance: The warranty terminates if the maintenance tables indicated in this manual are not respected, regarding

the frequency of controls and interventions, washing of the machine and of the circuit at the end of treatment.

Repairs: The warranty terminates if the maintenance table indicated in this manual are not respected, regarding the

frequency of controls and interventions, washing of the machine and of the circuit at the end of treatment. The use of

spare parts not approved by the Manufacturer invalidates any warranty and releases the Manufacturer or Dealer from

all the liability regarding malfunctioning or accidents.

Improper use: The designed use of MASCHIO GASPARDO S.p.A. machinery is indicated in this Manual. Any other use

is prohibited and not covered by warranty. The removal or modication of guards and protections releases the Manufac-

turer from all liability for damage caused to objects and/or persons.

Using with unintended corrosive chemical products. For example, galvanised material and copper hydroxide or nitrogen

fertilisers which use special paint.

1.2.3 ARRANGEMENTS TO BE BORNE BY THE CUSTOMER

The machine is delivered complete and does not require any operations by the user customer bar:

• tractor-machine connection via pin and drawbar (or three-point linkage, if any) and PTO shaft.

• positioning on the tractor of the remote control unit and possibly connection of the power cable of electrical and/or

electronic devices.

• hydraulic pipe connection.

The user customer is aware of their responsibility in using equipment potentially able to harm people and damage prop-

erty and environment if it is used and a careless and incorrect manner. Carefully read all the operating instructions and

simulate treatments with water only to acquire familiarity with the controls.

15

Code F07012287

USE AND MAINTENANCE ENGLISH

022c181

Fig. 2

022c181

MASCHIO GASPARDO S.p.A.

Via Marcello, n. 73 − 35011 Campodarsego (PD) − ITALY

S / N

TYPE

(bar)

Pmax

(l)

Rated Volume

Capacità nominale

(kW)

Rated Power

Potenza nominale

F20200124 Made in Italy

PRODUCTION YEAR

ANNO DI PRODUZIONE

(kg)

Max. unladen mass

Max. massa a vuoto

(kg)

Max. laden mass

Max. massa pieno carico

(rpm) ; (giri/min)

PTO

Presa di forza

(1)

(7)

(5)(4)

(2)

Fig. 1

Fig. 3

Fig. 4

(6)

(8)

MASCHIO GASPARDO S.P.A.

S1a

e3*____(appr. nr.)

ZNP(VIN Maschio Gaspardo)

620

kg

A-

0 :

130

kg

A-

1 :

620

kg

A-

2 :

---

kg

T-1 T-2 T-3

B-1 --- --- ---

B-2 --- --- ---

B-3 --- --- ---

B-4 --- --- ---

MASCHIO GASPARDO S.p.A.

ViaMarcello, n. 73 − 35011 Campodarsego (PD) − ITALY

F20201004

Macchina prodotta in regime di essibilità

Maschine gemäß dem Flexibilitätssystem produziert

N°

N°omologazione

Typgenehmigungsnummer

Motore

Motor

Annodi produzione

Baujahr

Marca

Marke

Rimorchiabile

Anhängelast

Assale3

Achse3

Assale2

Achse2

Assale1

Achse1

Massatot. ammessa (kg)

Zul.Gesamtgewicht (zul. − staat)

Matricola

Fahrgestellnummer

N°omologazione

Abenr

T.V.V.

Massamax

Maxachsl. (zul. −staat)

(kg)

MASCHIO GASPARDO S.P.A.

S1a

e3*____(appr. nr.)

ZNP(VIN Maschio Gaspardo)

620

kg

A-0 :

130

kg

A-1 :

620

kg

A-2 :

---

kg

T-1

T-2

T-3

B-1

---

---

---

B-2

---

---

---

B-3

---

---

---

B-4

---

---

---

FXXXXXXXX

MASCHIO GASPARDOS.p.A.

Via Marcello, n. 73 - 35011 Campodarsego(PD) - ITALY

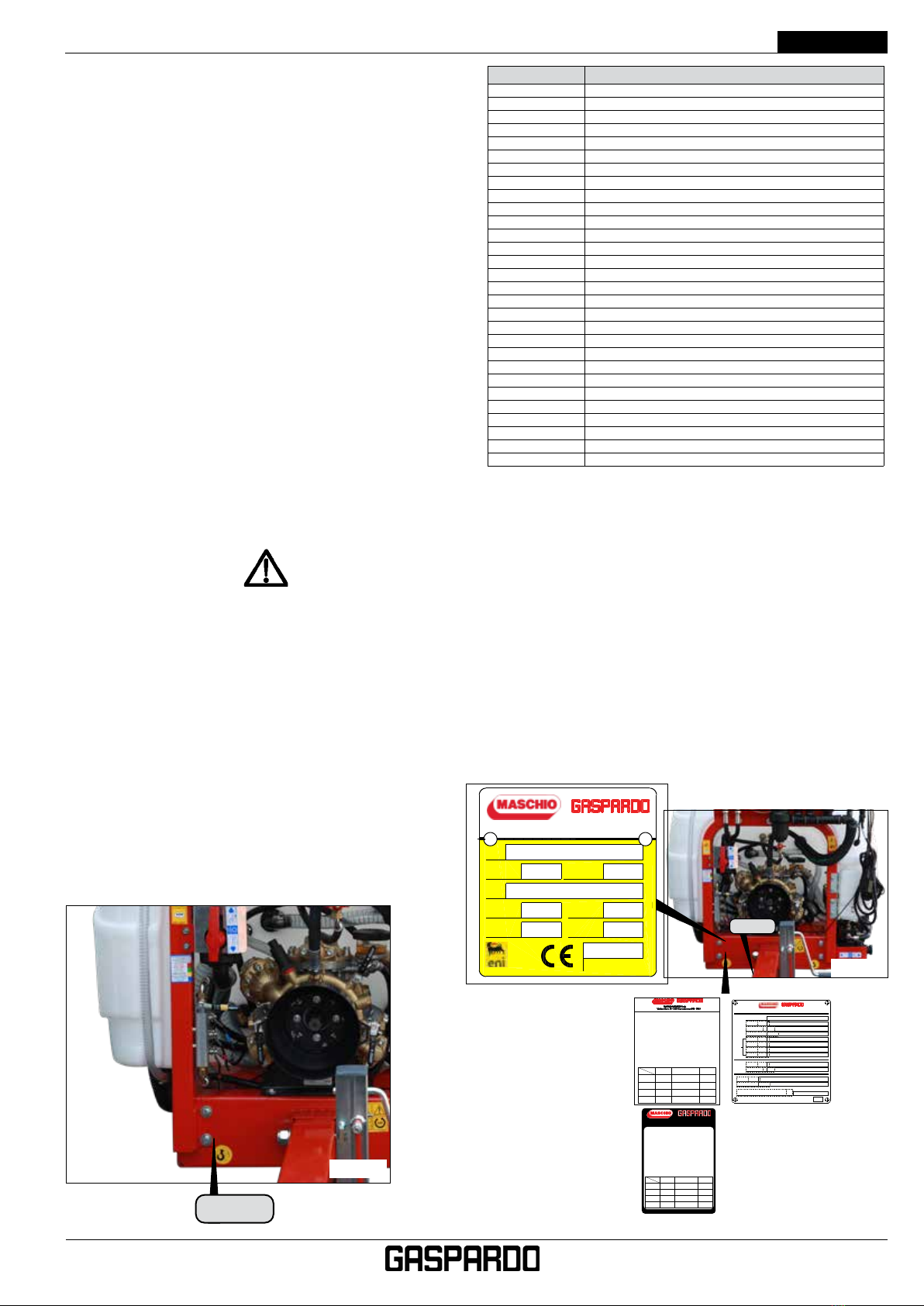

1.3 IDENTIFICATION OF THE MACHINE

The machine is identiable by the CE plate on which the fol-

lowing data are stamped:

1. Type: machine model acronym.

2. Code: machine identication code.

3. No.: CE plate progressive number.

4. Unladen mass: empty weight of the machine at the

highest level of outtting.

5. Total allowed mass: total weight of the machine at the

highest level of outtting with tank completely full.

6. Max press: maximum pressure of the spray system

expressed in bar.

7. Tank nominal capacity: expressed in litres.

8. Year: Machine's year of production.

The CE plate (Fig. 1) is placed at the front of the frame and

cannot be removed, modied or made poorly visible.

Trailed machines approved for public road circulation (in Italy,

France, Germany, etc.) are identied by the frame’s punched

serial number (e.g. 022c181), on the frame (Pic. 2) and on

the drawbar (Fig. 3), and by suitable aluminium plate showing

the legally required data (Fig. 4).

(The plate shown in the picture is an example, it may undergo

changes based on the country of destination of the machine).

For road circulation comply with the instructions of chapter

4.0 “HANDLING AND TRANSPORT”.

ATTENTION

The manufacturer Maschio Gaspardo S.p.a. SHALL NOT

be deemed in any way liable in the event a machine

produced and marketed WITHOUT road conformity

suitable to the country of utilisation travels on public

roads. Alternatively and in the event the same machine

is possibly approved as a "unique piece" by the right-

ful owner, only the latter and whoever is acting for them

(qualied engineer, agency, etc.) shall be responsible for

the machine.

Maschio Gaspardo is only liable for their own and direct road

conformity declarations made on brand new and regularly

numbered machines.

0N = Atomiser machines designation

U93006PO70

= Machine name

In detail:

U93 = FUTURA commercial model

006 = Model with 600 litres tank

010 = Model with 1000 litres tank

011 = Model with 1100 litres tank

016 = Model with 1600 litres tank

020 = Model with 2000 litres tank

030 = Model with 3000 litres tank

PO = Model VENTOLA POST

AV = Model VENTOLA AVANT

PJ = Model VENTOLA JET

AF = Model VENTOLAAVANT TGZ ORCHARD

AT = Model VENTOLAAVANT TGZ VINEYARD

DS = Model VENTOLA SIRENE

CC = Model VENTOLA CANNONE

CD = Model VENTOLA CANNONE

CA = Model VENTOLA CANNONE

45, 70, 80, 90: Fan diameters

TYPE MODEL DESCRIPTION

0N U93006PO70 FUTURA POST 600

0N U93010PO80 FUTURA POST 1000

0N U95010PO80 FUTURA POST 1000 LOW

0N U93016PO80 FUTURA POST 1600

0N U93016PO90 FUTURA POST 1600

0N U93020PO80 FUTURA POST 2000

0N U93020PO90 FUTURA POST 2000

0N U93030PO90 FUTURA POST 3000

0N U93006AV70 FUTURA AVANT 600

0N U93010AV80 FUTURA AVANT 1000

0N U93016AV80 FUTURA AVANT 1600

0N U93020AV80 FUTURA AVANT 2000

0N U93010PJ80 FUTURA JET 1000

0N U93016PJ80 FUTURA JET 1600

0N U93020PJ80 FUTURA JET 2000

0N U93006AF70 FUTURAAVANT TGZ 600 orchard

0N U93010AF80 FUTURAAVANT TGZ 1000 orchard

0N U93016AF80 FUTURAAVANT TGZ 1600 orchard

0N U93020AF80 FUTURAAVANT TGZ 2000 orchard

0N U93010AT80 FUTURA AVANT TGZ 1000 vineyard

0N U93016AT80 FUTURA AVANT TGZ 1600 vineyard

0N U93020AT80 FUTURA AVANT TGZ 2000 vineyard

0N U93016DS80 FUTURA SIRENE 1600

0N U93020DS80 FUTURA SIRENE 2000

0N U93030DS80 FUTURA SIRENE 3000

0N U93011CC45 FUTURA CANNONE 1100

0N U93016CD45 FUTURA CANNONE 1600

0N U93020CA45

FUTURA CANNONE 2000

0N U93030CA45 FUTURA CANNONE 3000

16 Code F07012287

USE AND MAINTENANCE

ENGLISH

2.0 GENERAL SAFETY INDICATIONS

2.1 SAFETY AND INDICATION SIGNS

The described signs are afxed on the machine. Keep them clean and replace them if detached or illegible. Carefully

read that described and memorise their meaning.

2.1.1 WARNING SIGNS

1. Before starting to use the machine, carefully read the instruction manual.

2. Before performing maintenance operations, stop the machine and refer to the instruction manual.

2.1.2 DANGER SIGNS

3. Do not lubricate during motion.

4. Poisoning hazard. Do not drink.

5. Do not dispose of residual liquids to the environment.

6. Do not smoke.

7. Risk of inhaling toxic and poisonous substances. Put on an anti-dust facemask before exiting the cab.

8. Do not place your hands close to rotating parts.

9. Crushing hazard. Keep away from moving parts.

10. Tubes with high pressure uids. Pay attention to the oil jet should the hoses brake. Read the instruction manual.

11. Prohibition of other persons present during use of the machine. This machine must be used by one operator alone.

12. Forbidden to climb onto or be transported by the machine during work and/or transfer phases.

13. Poisoning hazard. Forbidden to climb onto the tank.

14. Forbidden to go into the tank or to put parts of the body inside.

15. Wear the personal protective equipment (PPE) indicated in the pictogram.

16. Prohibition to use when it is windy.

17. Use an operating pressure lower than indicated in red on the pressure gauge.

18. Do not place your hands close to the moving PTO shaft.

19. Make sure of the correct sense of rotation and number of revolutions of the tractor's PTO.

20. It is forbidden to stand between the machine and the tractor.

21. Danger of side skidding.

22. Environmental damage hazard. It is severely forbidden to release the product into the environment.

23. Parking wedges.

24. Do not remove the protection device with fan in motion.

25. Material ejected from the machine; remain at a safe distance

2.1.3 INDICATION SIGNS

26. Greasing point.

27. Coupling point for hoisting from above.

28. Tyre ination pressure.

29. Clean water in circuit washing tank.

30. Clean water in hand washing tank.

31. Wash the circuit.

32. Water suction pipe union from external source.

33 Lifting the machine by means of the car jack

ATTENTION

LACK OF WARNINGS OF DANGER ON THE MACHINE

POTENTIAL SERIOUS INJURIES OR DEATH

The Manufacturer will not be held liable should the safety pictograms supplied with the machine be missing,

illegible or moved from their original position.

Immediately replace the safety pictograms provided with the machine should they be missing, unreadable or

moved from their original position

17

Code F07012287

USE AND MAINTENANCE ENGLISH

1 2 3 4 5 6 7

14

1716

15 15 15 15 15

1211109

8

26

20

19

18

27

27 22 28

13

30

29

U32150596

LAVARE CON CURA LA MACCHINA DOPO OGNI

TRATTAMENTO FACENDO CIRCOLARE ACQUA PULITA

e PULIRE I FILTRI DI ASPIRAZIONE E MANDATA

L’OMISSIONE DI TALE OPERAZIONE FA DECADERE LA GARANZIA.

- PLEASE WASH CAREFULLY THE SPRAYER CIRCUIT USING CLEAN

WATER AFTER EACH TREATMENT and CLEAN THE SUCTION AND

DELIVERY FILTERS.

THE OMISSIONE OF THIS OPERATION NULL AND VOIDS ALL WARRANTIES.

- DIE MASCHINE IST NACH JEDEM ARBEITSGANG MIT SAUBEREM

WASSER ZU SPÜLEN. DER SAUG- UND DER DRUCKFILTER SIND ZU

REINIGEN.

BEI NICHT BEACHTUNG ERLISCHT DIE GARANTIE.

- LAVER LA MACHINE AVEC SOIN APRES TOUT TRAITEMENT EN

FAISANT CIRCULER EAU PROPRE et NETTOYEZ LES FILTRES

D’ASPIRATION ET DE REFOULEMENT.

L'OMISSION DE CETTE OPÉRATION FERA DÉCHOIR N'IMPORTE

QUELLE GARANTIE.

- LAVAR CUIDADOSAMENTE EL EQUIPO DESPUES DE CADA

APLICACION, USANDO AGUA LIMPIA, LIMPIANDO LOS FILTROS DE

ASPIRACIONY DE ENVIO.

LA OMISION DE ESTA OPERACION ANULA TODA GARANTIA.

ADESIVO 110x110mm

Serigraa blu su PVC bianco

- ПОСЛЕ КАЖДОЙ ОБРАБОТКИ ТЩАТЕЛЬНО ПРОМОЙТЕ КОНТУР

ОПРЫСКИВАТЕЛЯ ЧИСТОЙ ВОДОЙ И ОЧИСТИТЕ ВСАСЫВАЮЩИЕ

И ФИЛЬТРЫ ПОДАЧИ. ГАРАНТИЯ НЕ ДЕЙСТВИТЕЛЬНА, ЕСЛИ ЭТА

ПРОЦЕДУРА НЕ ДЕЛАЕТСЯ.

31

21

24 25

Fig. 5

27

33

18 Code F07012287

USE AND MAINTENANCE

ENGLISH

10

23

10

23

24

13

13

24 25

14

14

25

Fig. 6

Fig. 7

Fig. 8

Fig. 9

19

Code F07012287

USE AND MAINTENANCE ENGLISH

27

27

27

32

32

27

27

27

Fig. 10

Fig. 11

Fig. 12

Fig. 13

33

20 Code F07012287

USE AND MAINTENANCE

ENGLISH

2.2 SAFETY STANDARDS AND INJURY

PREVENTION

Pay attention to the danger signs carried in the various

chapters of this manual.

There are three levels of danger signs:

• DANGER: This sign warns that if the operations de-

scribed are not carried out correctly, they may cause

serious injuries, death or long-term health risks.

• ATTENTION: This sign warns that if the operations

described are not carried out correctly, they may cause

serious injuries, death or long-term health risks.

• CAUTION: This sign warns that if the operations de-

scribed are not carried out correctly, they may cause

damage to the machine.

Carefully read all the instructions before using the machine;

should any doubts arise, directly contact the Manufacturer

Dealer technicians.

The Manufacturer declines any responsibility for failure

to comply with the safety and injury prevention standards

described below:

During operation and maintenance, use adequate personal

protective equipment, e.g.:

Coverall Gloves Footwear Goggles Helmet

Facemask Ear muffs

2.2.1 PROHIBITION OF USING THE MACHINE

The machine cannot be used by the following persons:

• Individuals below 18 years of age.

• Individuals without driver's licence.

• Individuals without an instruction certicate and not suf-

ciently trained.

• Individuals with physical disabilities unable to perform

the needs of the machine.

• Individuals under the effect of medicine or disabling

substances such as alcohol, drugs and similar.

• Individuals with severe mental-physical stress.

2.2.2 SUBJECTS TO BE PROTECTED

Safety is intended for:

• Operator.

• Other individuals (collaborators or persons present during

the action).

• Property (the cultivated eld and crops).

• Close or boundary areas.

• Air and surface or groundwater.

• Animals and insects not targeted.

2.2.3 ZONES OF GREATER DANGER

There are danger zones in and around the machine, espe-

cially when it is ready for use.

Do not pass or stop in these zones. These zones are indi-

cated with the specic warning pictograms described above,

which put on guard against residual risks impossible to

eliminate with constructive solutions.

The main danger zones are:

• In the vicinity of moving parts.

• Near the mixer (if present) due to the chemical products

used.

• Underneath hoisted and non-propped components.

• Near the fan.

• All areas where the machine ejects the working spray of

the nozzles and the fan’s air ow.

• Behind the fan and in the areas near the fan.

2.2.4

GENERAL USE AND MAINTENANCE RULES

• The machine should not be used in sectors other than

agriculture.

• The machine must be used by one operator only seated

in the tractor's driving cab, with seat belts fastened.

• Any use other than that specied is considered improper.

• The machine must be used exclusively by authorised,

instructed and appropriately trained personnel. The op-

erator in charge, as well as having read and understood

the instructions contained in this manual, must have

sufcient preparation related to the correct use of the

machine and must have a driver's licence. The operator

is reminded to contact the manufacturer should doubts

arise concerning use of the machine and the interpreta-

tion of this manual.

• The manual must always be within reach to be able to

be consulted to verify the operating cycle. Should it be

lost or damaged, ask for a replacement copy from the

Manufacturer or your dealer.

• The operator must make sure that no person or animal

is within the range of action of the machine while operat-

ing. Never drive the machine near persons stopped or

passing through its range of action.

• Do not use the machine if you are tired, ill, or under the

effect of alcohol, medicine or drugs.

• This machine is normally used during the day. If ex-

ceptionally night-time use or in conditions with reduced

visibility is required, the supplied lighting system must be

used or, if necessary, a supplementary lighting system.

• Any arbitrary modications made to this machine

releases the Manufacturer from all liability regarding

damage or injuries which may arise to operators, third

parties or objects.

• Carefully check the machine every time you activate it.

• The Manufacturer cannot foresee all reasonably unfore-

seeable misuse which can entail a potential hazard.

• The signs applied to the machine supply a series of im-

portant indications: complying with them is for your safety.

This manual suits for next models

7