gassero GSR-20-HC User manual

INSTALLATION AND USER MANUAL

TR

50

70

90

115

125

150

COMMERCIAL

HEAT PUMP

GSR-20-HC

GSR-30-HC

GSR-38-HC

GSR-45-HC

GSR-63-HC

CONTENT

1

ATTENTION !

Before installing/mounting the heat pump please read this user

manual carefully!

Otherwise heat pump may be damaged, which may result in serious

injury or even death for service personel and user.

Heat pump shall be installed and start up by qualified personel

approved by GASSERO.

1. FEATURES/BENEFITS

2

Wide Application Ranges

The domestic hot water heat pump is designed for offering central hot water for bigger houses, as well as

commercial buildings such as hotels, offices, schools, hospitals, apartments etc. The hot water outlet range

is wide from 20℃to 60℃, meeting demands for most hot water project. The performance is at wide ambient

temperature range from -10~43℃. Modular control system is available to meet the demand of huge hot

water projects.

Durable and Long Life

High efficiency compressor for all units, with durable features against high temperature and high pressure

for long life. The coaxial coil heat exchangers are durable for anti-corrsion, hard water, high pressure and

unexpected freeze caused by power cut-off.

Strong Cabinet

Standard unit fabrication consists of heavy gage galvanized sheet metal cabinet construction that provides

maximum strength. All interior sheet metal surfaces are powder-painted for maximum corrosion protection to

ensure resilience for long term vitality. Compact, stackable cabinets are designed to minimize installation

space.

Full Consideration for Noise Control

Compressor rubber feet are specially selected for reducing vibration. Specially, compressor sound jacket is

available for every unit. Well-balanced fans and fan motors, with the optimized fan holder, contributes to

the low noise operation. The cabinet inside is insulated to reduce noise transmission.

Reliable Design and Strict Quality Control

Standard safety features for the refrigerant circuitinclude high-pressure switch and low-pressure switch to

detect loss of refrigerant, as well as deficient water flow. Equipment safety features include water loop

temperature monitoring, voltage protection, water coil freeze protection. All safety features are tested and

run at the factory to assure proper operation of all components and safety switches. All components are

carefully designed and selected for endurance, durability, and carefree day-to-day operation. Each unit is

fully tested in performance and safety before exit factory.

Simple Maintenance and Serviceability

Full access for maintenance or service is provided

from the maintenance panel, for better flexibility in confined space. Easy removal of the control box from

the unit provides access to all refrigerant components. The refrigerant circuit is easily tested and serviced

though the use of high and low pressure ports integral to the refrigerant.

The installation, commissioning and maintenance of the system should only be done by qualified

technician with adequate knowledge of the relevant standards and local regulations as well as

experience with similar systems.

Please make sure the water flow is sufficient all the time.

All ground line connections must be prepared in accordance with relevant local regulations.

To reduce the risk of electrical insulation faults, you first make the connection of the protective

conductor of the heat pump safe according to local regulations.

When installation,make sure that the inside wires are apart from hot or moving parts [eg:

compressor, fan] of the system to avoid damage to the wires.

Anti-freezing measures must be well done to avoid damage to the water system and the heat pump

water heat exchanger.

Please make sure the lifting and transportation are safely done according to the heat pump

size and weight.

It is very dangerous work done at the facility without previously cutting off the electricity from the

main power source.

When installing the system, please ensure that no contaminants enter the water cycle.

2. NOTES / PRECAUTIONS

3

3. MODEL NUMBER NOMENCLATURE

GSR-30-HC

Commercial Heat Pump (Heating / Cooling)

Capacity (20 kW-30kW-38kW-45kW-63kW)

4. TECHNICAL DATA

4.1. TECHNICAL TABLE

Measuring condition: Dry/wet bulb temp 20ºC/15ºC; Water inlet/outlet temp 15ºC/55ºC.

GSR-20-HC GSR-30-HC GSR-38-HC GSR-45-HC GSR-63-HC

Heating Capacity kW

19 30 38 45 63

Power Supply V/Ph/Hz

380/3/50 380/3/50 380/3/50 380/3/50 400/3/50

Input Power kW

4,55 7,2 9,2 10,8 16

Running Current A

7,83 12 15,84 18,6 27,5

Max. Input Power kW

6,37 10,08 12,88 16,2 24

Max. Running Current A

10,97 18,36 22,18 27,89 42

Refrigerant

R410a R410a R410a R410a R410a

Compressor

Panasonic Panasonic Panasonic Panasonic Panasonic

Compressor Type

Scroll Scroll Scroll Scroll Scroll

Compressor Quantity

12223

Outlet Water Temp °C

55 55 55 55 55

Max. Outlet Water Temp °C

60 60 60 60 60

Min. Outlet Water Temp °C 77777

Hot Water Yield L/h

408 645 817 967 1354

Water Flow m³/h 4,1 6,4 8,2 9,7 13,5

Condenser

Tube in shell Tube in shell Tube in shell Tube in shell Tube in shell

Water Pressure Drop Kpa 50 55 55 55 55

Water Connection Tube mm

DN25 Dn40 Dn40 Dn40 Dn50

Noise dB(A)

<57 <58 <60 <61 <63

Electric Protection

IIIII

Mechanical Protection

IPX4 IPX4 IPX4 IPX4 IPX4

Net/Gross Weight kg

119/137 236/279 249/294 268/316 428/490

Dimension mm

816x690x965 1450x702x950 1450x730x1064 1450x730x1266 2150x772x1291

Packing Dimension mm

840x750x1100 1525x805x1110 1525x805x1220 1525x805x1420 2250x865x1450

5

5. DIMENSION

GSR-30-HC / GSR-38-HC / GSR-45-HCGSR-20-HC

High Pressure Gauge

Low Pressure Gauge

Water Outlet

Water Inlet

Wire ControllerCable Hole

Power Cable Hole

High Pressure Gauge (system2)

Low Pressure Gauge (system 2)

Wire Controller Cable Hole

Power Cable Hole

High Pressure Gauge (system1)

Low Pressure Gauge (system 1)

Water Outlet

Water Inlet

MODEL L (mm) W (mm) H (mm) A (mm) B (mm)

GSR-20-HC

752 690 965 470 785

GSR-30-HC

1450 702 950 755 708

GSR-38-HC

1450 702 1064 755 708

GSR-45-HC

1450 702 1266 755 708

6

MODEL L (mm) W (mm) H (mm) A (mm) B (mm)

GSR-63-HC 2150 772 1291 757,5 680

Water Inlet

Water Outlet

Wire Controller Cable Hole

Power Cable Hole

High Pressure Gauge

(system1/system2/system3)

Low Pressure Gauge

(system 1/system2/system3)

GSR-63-HC

7

6. PERFORMANS EĞRİLERİ

GSR-20-HC

1

3

2

4

5

Isıtma Kapasitesi Eğrileri

Ortam Sıcaklığı °C

Isıtma Kapasitesi ( W )

Dönüş Suyu

Sıc. 30°C

Dönüş Suyu

Sıc. 35°C

Dönüş Suyu

Sıc. 40°C

Dönüş Suyu

Sıc. 50°C

Dönüş Suyu

Sıc. 55°C

1-

2-

3-

4-

5-

Dönüş Suyu

Sıc. 30°C

Dönüş Suyu

Sıc. 35°C

Dönüş Suyu

Sıc. 40°C

Dönüş Suyu

Sıc. 50°C

Dönüş Suyu

Sıc. 55°C

1-

2-

3-

4-

5-

Ortam Sıcaklığı °C

COP Eğrileri

COP

1

3

2

4

5

Heating Capacity Curves

Heating Capacity (W)

Ambient Temp. (℃)

1. Return Water

Temp. 30°C

2. Return Water

Temp. 35°C

3. Return Water

Temp. 40°C

4. Return Water

Temp. 50°C

5. Return Water

Temp. 55°C

1. Return Water

Temp. 30°C

2. Return Water

Temp. 35°C

3. Return Water

Temp. 40°C

4. Return Water

Temp. 50°C

5. Return Water

Temp. 55°C

COP

Ambient Temp. (℃)

COP Curves

8

GSR-30-HC

Dönüş Suyu

Sıc. 30°C

Dönüş Suyu

Sıc. 35°C

Dönüş Suyu

Sıc. 40°C

Dönüş Suyu

Sıc. 50°C

Dönüş Suyu

Sıc. 55°C

1-

2-

3-

4-

5-

Dönüş Suyu

Sıc. 30°C

Dönüş Suyu

Sıc. 35°C

Dönüş Suyu

Sıc. 40°C

Dönüş Suyu

Sıc. 50°C

Dönüş Suyu

Sıc. 55°C

1-

2-

3-

4-

5-

Isıtma Kapasitesi Eğrileri

Ortam Sıcaklığı °C

Ortam Sıcaklığı °C

COP Eğrileri

Isıtma Kapasitesi ( W )

COP

1

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

Isıtma Kapasitesi Eğrileri

Ortam Sıcaklığı °C

Ortam Sıcaklığı °C

COP Eğrileri

Heating Capacity Curves

Heating Capacity (W)

Ambient Temp. (℃)

1. Return Water

Temp. 30°C

2. Return Water

Temp. 35°C

3. Return Water

Temp. 40°C

4. Return Water

Temp. 50°C

5. Return Water

Temp. 55°C

1. Return Water

Temp. 30°C

2. Return Water

Temp. 35°C

3. Return Water

Temp. 40°C

4. Return Water

Temp. 50°C

5. Return Water

Temp. 55°C

COP

Ambient Temp. (℃)

COP Curves

9

GSR-38-HC

Isıtma Kapasitesi ( W )

COP

Isıtma Kapasitesi Eğrileri

Ortam Sıcaklığı °C

Ortam Sıcaklığı °C

COP Eğrileri

1

2

3

4

5

1

2

3

4

5

Dönüş Suyu

Sıc. 30°C

Dönüş Suyu

Sıc. 35°C

Dönüş Suyu

Sıc. 40°C

Dönüş Suyu

Sıc. 50°C

Dönüş Suyu

Sıc. 55°C

1-

2-

3-

4-

5-

Dönüş Suyu

Sıc. 30°C

Dönüş Suyu

Sıc. 35°C

Dönüş Suyu

Sıc. 40°C

Dönüş Suyu

Sıc. 50°C

Dönüş Suyu

Sıc. 55°C

1-

2-

3-

4-

5-

1

2

3

4

5

1

2

3

4

5

Heating Capacity Curves

Heating Capacity (W)

Ambient Temp. (℃)

1. Return Water

Temp. 30°C

2. Return Water

Temp. 35°C

3. Return Water

Temp. 40°C

4. Return Water

Temp. 50°C

5. Return Water

Temp. 55°C

1. Return Water

Temp. 30°C

2. Return Water

Temp. 35°C

3. Return Water

Temp. 40°C

4. Return Water

Temp. 50°C

5. Return Water

Temp. 55°C

COP

Ambient Temp. (℃)

COP Curves

10

GSR-45-HC

1

2

3

4

5

1

2

3

1

2

3

4

5

4

5

1

2

3

4

5

COP

Isıtma Kapasitesi ( W )

Isıtma Kapasitesi Eğrileri

Ortam Sıcaklığı °C

COP Eğrileri

Ortam Sıcaklığı °C

Dönüş Suyu

Sıc. 30°C

Dönüş Suyu

Sıc. 35°C

Dönüş Suyu

Sıc. 40°C

Dönüş Suyu

Sıc. 50°C

Dönüş Suyu

Sıc. 55°C

1-

2-

3-

4-

5-

Dönüş Suyu

Sıc. 30°C

Dönüş Suyu

Sıc. 35°C

Dönüş Suyu

Sıc. 40°C

Dönüş Suyu

Sıc. 50°C

Dönüş Suyu

Sıc. 55°C

1-

2-

3-

4-

5-

Heating Capacity Curves

Heating Capacity (W)

Ambient Temp. (℃)

1. Return Water

Temp. 30°C

2. Return Water

Temp. 35°C

3. Return Water

Temp. 40°C

4. Return Water

Temp. 50°C

5. Return Water

Temp. 55°C

1. Return Water

Temp. 30°C

2. Return Water

Temp. 35°C

3. Return Water

Temp. 40°C

4. Return Water

Temp. 50°C

5. Return Water

Temp. 55°C

COP

Ambient Temp. (℃)

COP Curves

11

GSR-63-HC

Dönüş Suyu

Sıc. 30°C

Dönüş Suyu

Sıc. 35°C

Dönüş Suyu

Sıc. 40°C

Dönüş Suyu

Sıc. 50°C

Dönüş Suyu

Sıc. 55°C

1-

2-

3-

4-

5-

Dönüş Suyu

Sıc. 30°C

Dönüş Suyu

Sıc. 35°C

Dönüş Suyu

Sıc. 40°C

Dönüş Suyu

Sıc. 50°C

Dönüş Suyu

Sıc. 55°C

1-

2-

3-

4-

5-

Isıtma Kapasitesi Eğrileri

Ortam Sıcaklığı °C

Ortam Sıcaklığı °C

COP Eğrileri

Isıtma Kapasitesi ( W )

COP

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

Heating Capacity Curves

Heating Capacity (W)

Ambient Temp. (℃)

1. Return Water

Temp. 30°C

2. Return Water

Temp. 35°C

3. Return Water

Temp. 40°C

4. Return Water

Temp. 50°C

5. Return Water

Temp. 55°C

1. Return Water

Temp. 30°C

2. Return Water

Temp. 35°C

3. Return Water

Temp. 40°C

4. Return Water

Temp. 50°C

5. Return Water

Temp. 55°C

COP

Ambient Temp. (℃)

COP Curves

12

7. SYSTEM DIAGRAM

Heating Mode Water inlet

Water outlet

High pressure switch

Low pressure switch

4 way valve

Suction accumulator

Compressor

Evaporator

(fin-tube)

2 way

thermal

expansion

valve

Condenser

(Tube in shell)

Water inlet

Water outlet

Defrosting Mode

High pressure switch

Low pressure switch

4 way valve

Suction accumulator

Compressor

Condenser

(fin-tube)

2 way

thermal

expansion

valve

Evaporator

(Tube in shell)

13

8. COMPONENTS

Compressor

The dependable flexible compressor,

with optimized R410a system, can

achieve high water temperature up to

60℃,while ensures long life of the

compressor.

4-Way valve

The reliable 4way valve can avoid

gas mixing, and ensure stable

defrosting.

Condenser

The Tube in shell heat exchanger as

condenser, with bigger heat exchanging

area and higher efficiency.

Thermal expansion valve

The 2way thermostatic expansion valve

ensures high efficiency when heating,

moreover, ensures high efficiency when

defrosting.

Evaporator

The hydrophilic fin-tube heat exchanger

has big heat exchanging area and

rational fin distance, thus significantly

improves heating and defrosting

efficiency.

Fan

The exterior motor fan, with 5fan blades,

is strictly balanced. The 5 fan blades run

slower, and make sure high air volume,

thus largely brings down the noise.

Components Photo Features/Advantages

14

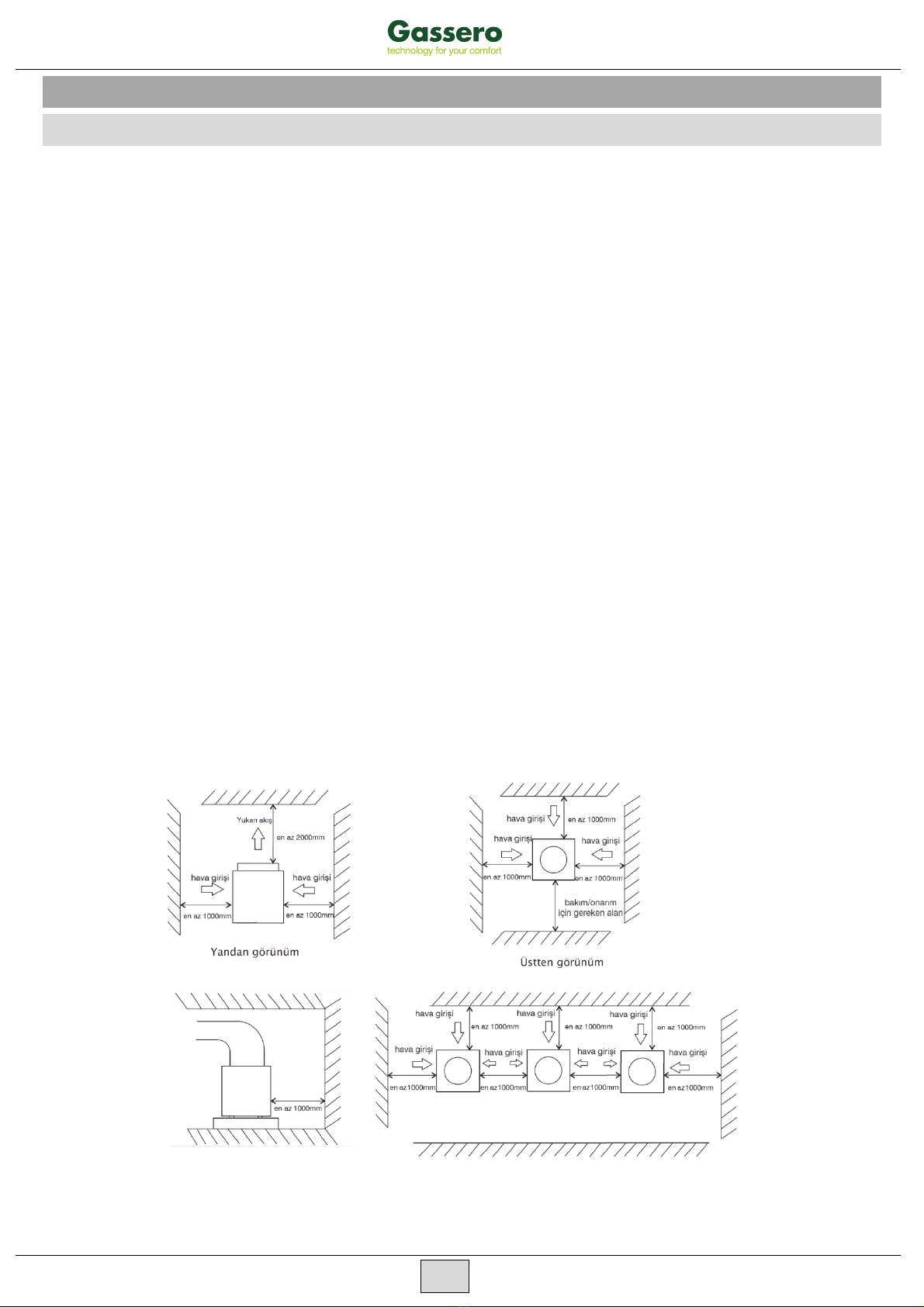

9.1. HEAT PUMP UNIT INSTALLATION

The heat pump unit should be installed in a ventilated place, with enough space for air inlet and outlet,

while without thermal radiation or other heat source. Besides, the air outlet should not be against the

wind.

Generally, the vertical air flow type heat pump does not need anything for sheltering. The motor and

other internal components have been all waterproof. A shelter is required to avoid snow burying onto the

heat pump in heavily snowy area.

Please make sure the rated voltage 380V or 400V is stably accessible to the heat pump, otherwise

the performance would be influenced.

The foundation of the heat pump can be cement or steel structure. Anti-vibration rubber and aflat

foundation should be taken into account. The foundation structure can be flexibly designed

according to the working weight of the heat pump(Please see the technical data in this manual.)

Water drainage should be available near the installation location for draining water in an effective

way.

Do not install the heat pump in aplace where there is polluting or corrosive material like oil,

flammable and explosive gas and sulfide etc. Keep it far away from sands, falling leaves and area

with high-frequency equipment.

The foundation should be heightened to avoid the water inflow in rainy season and snow burying in

winter if it is installed in the open air.

Installation in balcony or on roof-top must be accordance with the allowable stress of the building

structure.

The heat pump should be fixed firmly on the base. The bearing capability of the frame should be as

three times of weight as the heat pump unit. Reliable measures should be taken to keep the fastener

stable. The unit base should be fixed firmly by expansion bolts to ensure the entire unit stand

erectly after installation.

The unit location should avoid typhoon and earthquake damage. The heat pump should not be

installed in the air in case of crash accident.

The installation should be carried out at the place of unobstructed ventilation of the air outlet.

(The inlet and outlet of the air blower are illustrated in the following diagram). The installation

space should be referred as follows:

▲An exhaust duct should be

connected to the heat pump air outlet

if there is a barrier above the air outlet.

▲A certain distance should be kept among the heat pumps

and it should be at least 1 meter when several heat pumps

are installed side by side.

9. INSTALLATION

15

9.2. WATER TANK INSTALLATION

The water tank should be put in a place where ambient temperature is higher than 0ºC.

It can be installed either outdoors or on the roof-top (some elements such as the size of water tank

and the bearing capability of the building should be considered). Installation on roof-top should be

based on support such as crossbeam or pillar.

The water tank should not be installed lower than the foundation of the heat pump; It is suggested

to install the heat pump, the water tank and the circulation pump at the same level. Besides, the

height difference between the heat pump and the water tank should be no more than 2meters,

when water tank position is higher than that of the heat pump.

Do not install the water tank in apollutive or corrosive area.

The reasonable allocation of the heat pump and water tank volume should deploy by 1/0.6 as

maximum. Please refer to the following:

MODEL GSR-20-HC GSR-30-HC GSR-38-HC GSR-45-HC GSR-63-HC

TANK VOLUME 3000 L 4500 L 6000 L 8000 L 12500 L

9.3 WATER PIPING INSTALLATION

Drainpipe and overflow pipe should be installed near the gutter or the sinkhole for draining water more

efficiently. Discharge valve is necessary on the drainpipe.

Service valve needs to be installed before the magnet-valves on the system pipeline for further

inspection.

The pressure of the water outlet should be between 0.3MPa and 0.6MPa.

It is recommended to use metal pipeline such as stainless steel pipes, internal-plastic pipes,

internal stainless steel pipes or copper pipes etc; Telescopic issue of the pipeline between heat

pump unit and water tank should be considered if plastic pipeline such as PPR pipe and ABS pipe

etc. is used.

In winter, heat preservation may need to be carried out for the water supply valve and the stop

valve of the system (according to local ambient temperature) for avoiding icing of the water supply

pipe and the valves.

Keep the water pipes straight and the pipeline allocation reasonable; Reduce pipe turnings as

many as possible to reduce water resistance.

Prevent the pipeline and the connectors from water leakage.

The water pressure bearing capability of each part of the piping system should be tested after the

installation is finished; Drainage should be done to create aclean interior system.

Measures of heat preservation for the hot water pipeline need to be conducted after assuring no

water leakage.

16

Isıtma Devresi

If this appliance is

installed for house heating

(or cooling), to ensure the

appliance to operate

correctly, we recommend

the installation of a buffer

tank in any case, the

buffer tank is not only

installed as hydraulic

speparator for volume

flow in the heat pump

circuit, but primarily as

the heat source for

defrosting the evaporator.

Shut-Off Valve

Solenoid Valve

Check Valve

Elec Heater

Water Pump

Y-Shape Filter

Flow Switch

Heat Pump

Controller

Heat Pump

Dinning Hall

Guest Room

Sauna Room

Water

Pump

Filter

Filter Solenoid Valve

Flow Switch

(can omit)

Drainage

Water Tank

Check Valve Elec Heater

(can omit)

Heating / Cooling Circuit

1Heat pump

2Heat pump controller

3Butffer tank

4Circulation pump

5Non-return valve

6Shut-off valve

7Drain valve

8Filter

9Expansion vessel

10 Safety pressure valve

11 Air vent valve

12 Pump (heating or cooling circuit)

17

Model

Power

Cable

Water

Pump

Solenoid

Valve

Sensor

GSR-20-HC

5x4mm² 3x1,5mm² 3x1,0mm² 2x0,35mm²

GSR-30-HC

5x6mm² 3x1,5mm² 3x1,0mm² 2x0,35mm²

GSR-38-HC

5x6mm² 3x1,5mm² 3x1,0mm² 2x0,35mm²

GSR-45-HC

5x6mm² 3x1,5mm² 3x1,0mm² 2x0,35mm²

GSR-63-HC

5x10mm² 3x2,5mm² 3x1,0mm² 2x0,35mm²

9.4. RECOMMENDED WIRE SPECIFICATION

9.5. WIRE CONTROL INSTALLATION

The wired controller is originally fixed on the maintenance door of the machine; please refer to below steps if

you want to install it on the wall:

1. Take down the controller from the machine. Please pay attention that the communication wire is

connected with the circuit board, separate them from where they match.

2. Use a screwdriver to open the clip as picture 1, separate the controller as 2 parts, as picture 2

3. On the wall that you are going to install the controller, drill 2 holes at a level parallel to the sight line as

picture 3.

The hole distance is 60mm, diameter is 8mm.

1. Place the plastic screws of the enclosure into the hole, and use the tapping screw (ST4*16 D-1)

enclosed to fix the back cover of controller on the wall, as picture 4

2. Match the front and back covers perfectly, as picture 5, make sure that it is fixed firmly on the wall.

3. Connect the communication wire well.

Arka Kapak Ön Kapak

İletişim Kablosu Çıkışı

12

34

5

6

The Back Cover The Front Cover

Outlet of the communication wire

Attention:

Please don't use keen-edged things to hit the controller face and keys, or it may cause damage.

When the controller is fixed on the wall, don't pull the communication wire, or it may cause poor contact.

18

10. COMMISSIONING

10.1. PREPARATION BEFORE COMMISSIONING

Inspection on the heat pump

Check if the outside case and the inside system of the heat pump have been damaged during the

transportation. Check if there is still air inside the water system. If yes, use the air vents on the water system

and the circulation pumps, to discharge the air out.

Inspection on the power source system

Make sure the power source is accordance with the specification in the manual or on the heat pump

nameplate. Make sure all power connections and control circuit are in place. Make sure the wiring , grounding

and all terminals are strong and reliable.

Inspection on the piping system

Check if the water piping system, including water supply pipe, return water pipe, pressure gauge,

thermometer, valves, water level switch are installed correctly. Please open all the valves which should be

opened, and close all that should be closed before the commissioning. Make sure the heat preservation

of the water system is in good condition.

10.2. COMMISSIONING

The commissioning should be carried out by profession.

Comprehensive inspection of the entire system should be identified as meeting the requirements, and

the water level inside the tank is higher than the cycling heating outlet and the water outlet, before the

commissioning.

After power on the electricity, turn on the heat pump by pressing the on/off key on the wire control panel.

Please check if the fan and the circulation pump are running in the right direction. If not, shut down the

power supply and adjust the phase-order. Make sure the compressor current is in normal range, without

abnormal sound.

Check the circulation pump and all other parts meet the requirement. The whole system can be put into

use after the pre-operation for aperiod of time.

18

11. CONTROL PANEL

ON/OFF

Press the key for 1second to turn on or turn off the unit as the controller is unlocked. Press

the key to return the main interface as in any other settings. Press the key

for 5seconds to unlock as the controller is locked.

FUNCTION

In the main interface, the key is for status query.

UP / DOWN

Page up and down, query or modify parameters.

Query or set parameters together with “Function” key.

Press “+” and “-”to set the water temperature of current mode as the unit is turned on.

CLOCK AND TIMER KEY

Press “timer” for 5 seconds to set clock.

Long press “time” key to enter timer setting, together with “+”and “-”to set ON/OFF

timer , totally two ON/OFF periods can be set.

19

11.2. OPERATION

Lock and unlock

Press “ON/OFF”key for 5seconds to unlock the

controller after abeep of the buzzer.

Lock automatically after 60 seconds without operation.

Homepage

Lock keys

Unlock keys

Within 60 seconds without operation

5 Secconds

℃℃

℃℃

℃℃

℃℃

OFF state

ON state

1seconds

℃℃

1seconds

OFF state

℃℃

7.2.2 ON/OFF switch

Water temperature setting

When the heat pump is switched on, Press “+” and

“ -” to set the water temperature of current mode as

the unit is turned on.

Mode switch

Press “+” for 5seconds to switch the mode.

7.2.5 Manual defrosting

Press “-“ for 5seconds to enter manual defrosting

(coil temp >defrosting quit temp (H6))

To quit manual defrosting, long Press “ON/OFF”key

or wait till the defrosting time reaches the maximum

defrosting duration (parameter H5)

Heating mode

Cooling mode

℃℃

5seconds

℃℃

Homepage

Manual defrosting

Quit defrosting

5 seconds

5seconds (or defrosting exit condition achieved)

℃℃

℃℃

℃℃

This manual suits for next models

4

Table of contents

Other gassero Heat Pump manuals

Popular Heat Pump manuals by other brands

American Standard

American Standard 4A7A5 Installer's guide

ClimateMaster

ClimateMaster Ultra Classic VT 072 Installation, operation & maintenance instructions

Lochinvar

Lochinvar AMICUS HT Series Installation, commissioning and service manual

Robur

Robur GAHP A indoor Instructions for installation, use and maintenance manual

Carrier

Carrier 50ZHB Owner's information manual

Cool Energy

Cool Energy inverPool CE-iVP6 Installation and user guide