Gast 0211 Series Manual

KEEPTHISDOCUMENTFORFUTUREREFERENCE

70-180 G325PL (Rev. C)

0211 SERIES LUBRICATED LABORATORY

VACUUM PUMPS & COMPRESSORS

OPERATION & MAINTENANCE MANUAL

CONTENTS:

General Information and Installation....................................................................................................... 2

Operation and Maintenance..................................................................................................................... 3

Exploded View and Parts Ordering Information ..................................................................................... 4

Shutdown Procedures, Service Kit Installation, and Troubleshooting Guide ......................................... 5

Warranty and Authorized Service Facilities ............................................................................................ 6

Visitusatourwebsite

www .gastmfg.com

2

This is the hazard alert symbol: m. When you see this

symbol, be aware that personal injury or property damage is

possible. The hazard is explained in the text following the

symbol. Read the information carefully before proceeding.

The following is an explanation of the three

different types of hazards:

mDANGER Severe personal injury or death will

occur if hazard is ignored.

mWARNING Severe personal injury or death can

occur if hazard is ignored.

mCAUTION Minor injury or property damage can

occur if hazard is ignored.

GENERAL INFORMATION

mDANGER Do not pump flammable or explosive

gases or operate the unit in an

atmosphere containing them. Use only

in a well-ventilated area.

mCAUTION Required ambient temperature is 0˚ to

40˚C (32˚F to 100˚F). For operation at

higher temperatures, consult the factory.

mCAUTION All electrical products generate heat. Do

not touch unit during operation or until it

has cooled.

mCAUTION Do not block flow of cooling air over unit

in any way.

mCAUTION Do not operate units above recommended

pressure or vacuum duties. To do so will

damage unit.

This rotary unit is a precision product, with specified clearances

of only .002" at top and .0025"-.0035" at ends of rotor.Vanes

compensate for their own wear and should supply 5,000

-15,000 hours of operation, depending upon application.

Remember that it is designed for pumping only clean, dry air.

Protect it against entry of dirt and excessive moisture.

INSTALLATION

mWARNING Disconnect power source before installing

and/or servicing. Failure to do so could result

in electrical shock, personal injury or death.

mWARNING To avoid risk of electrocution do not use this

product in an area where it could come in

contact with water or other liquids. If exposed

to the elements it must be weather protected.

To reduce noise and vibration use shock mounts, or a

vibration-isolated mounting surface that will not resonate.

Plumbing

To prevent flow restriction, use pipe and fittings that are

same size as or larger than threaded ports. Note that ports

are not designed to support plumbing.

mWARNING Improper wiring can result in electric shock.

All power to motor must be de-energized

and disconnected before servicing.

Wiring

Refer to motor nameplate for wiring diagram. Building

must conform to all required safety codes. Check that

voltage at power outlet agrees with motor nameplate.

Lubrication

Proper lubrication is necessary for normal service life.Vanes

ride on a film of oil that fills clearances and provides a seal.

Gast lubricating oil is available in convenient quart containers

from the factory or Gast representatives (order part #AD220).

A high-detergent 10-wt. automotive engine oil may be used.

In locations over 100˚F, use high-detergent 20-wt. oil.

Oil is automatically metered during unit operation, but oil

supply in siphon jar must be monitored and replenished as

needed. Refer to exploded view. Keep jar filled to fill line on

jar. Temperatures, operating vacuum and/or pressure, and

oil level determines lubrication rate.

Moisture Trap

Moisture, either liquid or vapor, will damage unit.

Install a trap if moisture could be drawn into unit.

OPERATION

mWARNING Solid or liquid material exiting unit can

cause eye or skin damage. Keep away

from air stream.

mWARNING Some models are equipped with glass jars.

If an alternate material is not used, proper

measures should be taken to guard against

fragmenting of breaking of glass. If hazard

is ignored severe personal injury or death

can occur.

mCAUTION Do not allow corrosive gases or particulate

material to enter unit. Water vapor, oil-based

contaminants, or other liquids must be

filtered out. Contact the factory when using in

an application other than air.

Performance is reduced by lower atmospheric pressure

at high altitudes. Consult a Gast distributor for details.

Performance Parameters

20" Hg Max. Vacuum (27" intermittent*)

1.3 CFM open flow.

20 PSI Max. Pressure (25 PSI intermittent*)

1.3 CFM open flow.

Intermittent duty is defined as: 10 minutes or less ON,

and 10 minutes or more OFF.

3

Starting

Before starting:

•If unit is extremely cold let it warm up to 0˚C (32˚F).

•Remove any plastic plugs from inlet or outlet ports.

MAINTENANCE

If motor fails to start, or it slows down under load, turn

unit off and unplug it. Make sure that voltage at power

outlet agrees with motor nameplate. Examine plug, cord,

and switch for deterioration.

This unit requires lubrication. Failure to maintain

proper level of oil (10 wt. H.D. Gast Part # AD220) in

siphon oiler will cause unit to malfunction.

Regular inspection and periodic flushing can prevent

damage and unnecessary repairs. Dirty filters restrict

airflow and cause overheating and noise.

Regularly check:

• Lubricating oil supply.

• Cleanliness of filters. Clean with Gast AH255B

Flushing Solvent (or equivalent*).

* Non-flammable, non-water based, or an oil based

solvent.

Filter Inspection and Replacement

mWARNING Unit surfaces may become very hot during

operation. Do not touch these parts until unit

has been turned off and allowed to cool.

Flush unit with GastAH255B Flushing Solvent (or equivalent*)

and refer to exploded view during following procedure.

1. Turn off unit and isolate from power source.

2. Release all pressure and vacuum from unit.

3. Remove glass filter/muffler jar.

4. Remove cartridges from intake and exhaust filters

and inspect them.

a. Check for cuts and excessive foreign material.

1) If any of these conditions exists, replace immediately.

2) If filters look serviceable, go to step 5.

5. Clean them with compressed air and recheck for

above conditions.

a. If any of these conditions from step 4 show up,

then replace immediately.

6. Re-assemble.

Flushing

Often, unit trouble can be corrected by flushing rather than

by disassembly. Noise or inefficiency is often due to a stuck

vane caused by dirt or excessive lubrication.

mDANGER Do not use kerosene or other combustible

solvents to flush unit. Hazardous vapors

from flushing, fire, or explosion could result

and cause personal injury or death.

mWARNING Flush unit in a well-ventilated area. Eye

protection is recommended. Keep face

away from exhaust port.

Follow these steps to flush this unit:

1.Disconnect from power source .

2.Remove all plumbing and accessories connected to

inlet and exhaust ports.

3.Remove filter/muffler assembly.

4.Reconnect power source and start up unit. Stay away

from exhaust stream.

5.Add flushing solvent while unit is running.

Note : If using liquid solvent, pour several table-

spoons directly into intake port; or if using

Gast Part # AH255B, spray solvent for 5-10

seconds (recommended: repeat 2-3 times)

directly into intake port.

While adding solvent, listen for changes in motor

sounds in unit.

a. If motor sounds smooth out, go to step 6.

b. If motor sounds don’t smooth out, install Service

Kit (see Service Kit Installation instructions).

6.Plug inlet and continue to run unit for 45 seconds.

Keep away from spray area.

7.Turn unit off.

8.Turn unit over onto its ports and drain any remaining

solvent.

9.Turn unit upright, squirt a few drops of oil into inlet port.

10.Reinstall plumbing and accessories.

11.Run unit for approximately 5 seconds to spread a

film of oil on internal parts.

12.Remove filter elements.

13.Clean them with same solvent used to flush unit, or

with soap and water.

14.Dry them completely before reinstalling.

IMPORT ANT: If unit overheats or is noisy, stop unit

immediately for repair. Return unit to

closest Authorized Service Facility, or

perform following rebuild procedures,

using Service Kit part # K217.

After solvent has passed through unit, replace filter

assemblies. Before putting unit back into service, ensure

that any external accessories such as relief valves and

gauges have not been damaged.

4

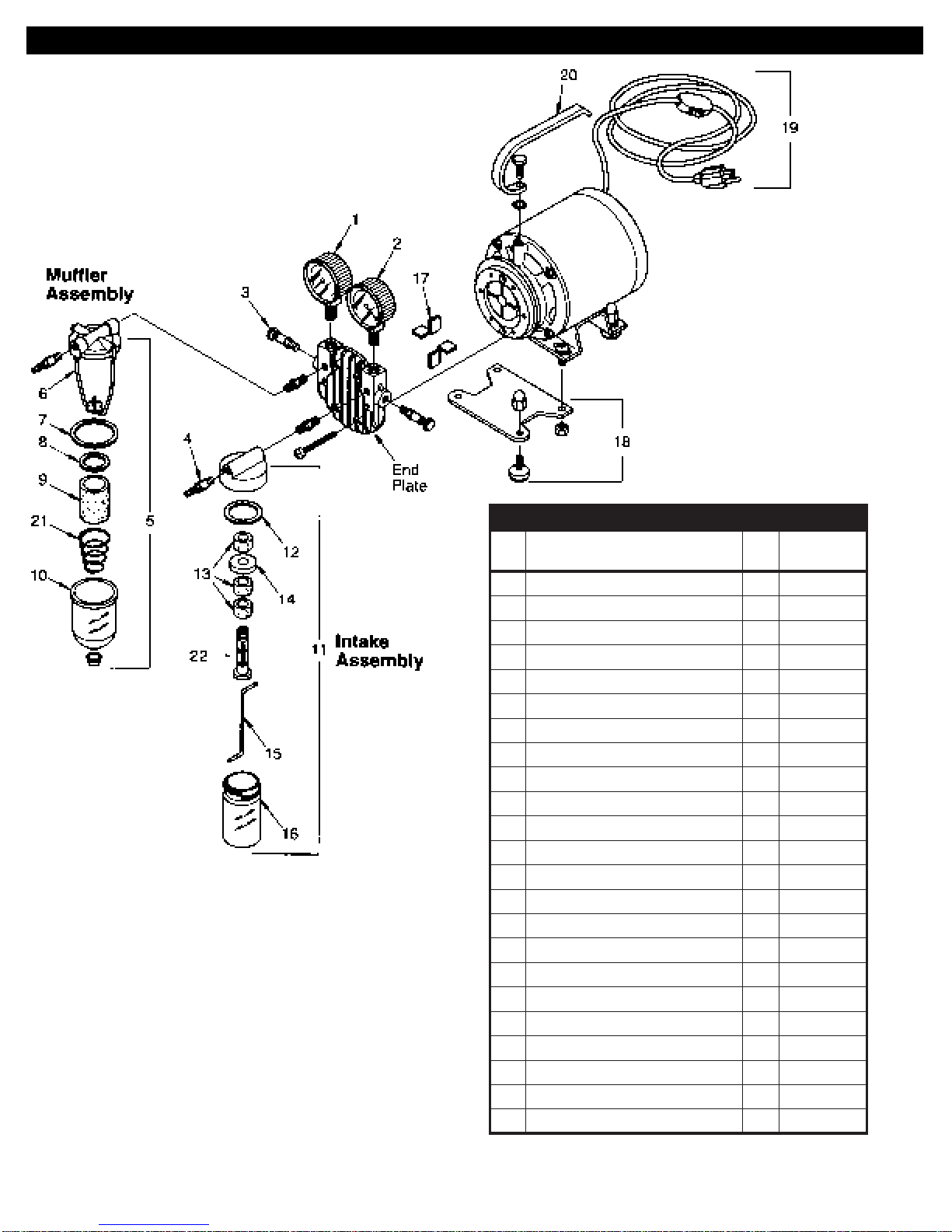

EXPLODED VIEW & PARTS ORDERING INFORMATION

NOITAMROFNIGNIREDROSTRAP

feRoN noitpirceDytQ G54V-1120 U54V-1120

1eguaGerusserP1B446AA

2eguaGmuucaV1046AA

3rotalugeR2A689AA

4elppiNesoH2C452AA

5parTliO&retliFteltuO1B085BA

6ylbmessAliaB&revoC1B985BA

•

7teksaGraJ1285BA

8teksaGtnemelE1585BA

9tnemelE1485BA

01lwoBssalG1385BA

11ylbmessAretliFliO1J086AA

•

21teksaGrevoC1196AA

•

31tleFretliF3B386AA

•

41tleFrotarapeS1896AA

•

51kciWreliO1996AA

61raJssalG134-096AA

•

71enaV4B543AA

81ylbmessAtroppuStooF1631CA

91ylbmessAgulP&hctiwS,droC1698AA

02eldnaH1471CA

12gnirpS1685BA

22metStroppuS1908AA

tiKecivreS1712K

•

.tiKecivreSnidedulcnistrapsetoneD etelpmocevigesaelp,strapgniredrorognidnopserrocnehW .rebmunlairesdnaledom

5

EDIUGGNITOOHSELBUORT

melborProfnosaeR

woLhgiH pmuP gnitaehrevO rotoM daolrevOmuucaVerusserPmuucaVerusserP

ytridretliFXXtapmupXX

ytridrelffuMXtapmupXX

despallocenilmuucaVXtapmupXX

hgihoottesevlavfeileRXXXX

woloottesevlavfeileRXX

enilerusserp/muucavdeggulPXXtapmuptapmupXX

gnikcitssenaVXX

MPRhgihootragninnuRXXXX

)ecalper(nrowsenaVXX

)ecalper(nrowlaestfahSXX

pmupniredwoptesfforotsuDXXXX

yltcerrocderiwtonrotoMXXX

SERVICE KIT INSTALLATION & TROUBLESHOOTING GUIDE

SHUT-DOWN PROCEDURES

Proper shutdown procedure must be followed to prevent

damage. Failure to do so may result in premature unit failure.

Gast Manufacturing Laboratory units are constructed of

ferrous metals, which are subject to rust and corrosion when

pumping condensable vapors such as water.

This unit requires lubrication. Failure to maintain proper

oil level (10 wt. H.D./Gast part #AD220) in reservoir will

cause unit to malfunction.

Follow these steps below to assure correct shutdown

and storage between use:

1.Disconnect plumbing after using unit.

2.Allow unit to run open for at least 5 minutes.

3.Refill oil reservoir to proper level.

4.Cover inlet port (vacuum side) and run unit for 1-3

minutes.

5.Shutdown unit under vacuum.

6.Disconnect unit from power source.

7.Plug open ports to prevent dirt or other contaminants

from entering unit.

Unit is ready for storage.

SERVICE KIT INSTALLATION

Note: Gastwillnotguaranteeperformance ofa field-rebuilt

unit. Return unit to a GastAuthorized Service

Facility, or perform following rebuild procedures.

Service kit contains four vanes, filter element, element

gasket, jar gasket, cover gasket, three filter felts, separator

felt, and wick.

Follow these steps to install kit.

Pump Disassembly

mWARNING Disconnect unit from power source and

vent all air lines to unit to remove pressure

before servicing it. Failure to do so can

result in severe personal injury or death.

1.Remove muffler jar and muffler assembly.

2.Remove filter jar and filter assembly.

3.Remove six (6) Phillips-head screws from end plate.

4.Remove end plate.

5.Remove old vanes in rotor.

6.Clean unit with solvent (Gast Part # AH255B).

7.Check exposed surfaces of rotor, vanes, pump body,

and end plate for scoring.

•If no scoring, continue with service kit installation.

•If severe damage, return unit to closest Authorized

Service Facility.

Pump Re-assembly

8.Re-lubricate inside of unit with 5-6 drops of oil.

9. Install new vanes supplied with kit. Be careful to install

vanes into rotor with machined surface toward body bore.

10.Re-install unit end plate with six (6) Phillips-head

screws. Torque screws to 40 in-lb.

11.Re-install new filter element on support stem.

12.Insert one end of wick up through assembly center.

13.Bend upper 3/4" of wick 90˚.

14.Insert it into exit port as filter assembly is replaced.

15.Bend lower end 90˚ so it lies submerged in oil at

bottom of jar.

16.Clean jar and element with solvent.

17.Install jar gasket.

18.Re-assemble muffler element.

inc.

6

YOUR WARRANTY

Gast finished products, when properly installed and operated under normal conditions of use, are warranted by Gast to

be free from defects in material and workmanship for a period of twelve (12) months from the date of purchase from

Gast or an authorized Gast Representative or Distributor. In order to obtain performance under this warranty, the

buyer must promptly (in no event later than thirty (30) days after discovery of the defect) give written notice of the

defect to Gast Manufacturing Incorporated, PO Box 97, Benton Harbor Michigan USA 49023-0097 or an authorized

Service Center (unless specifically agreed upon in writing signed by both parties or specified in writing as part of a

Gast OEM Quotation). Buyer is responsible for freight charges both to and from Gast in all cases.

This warranty does not apply to electric motors, electrical controls, and gasoline engines not supplied by Gast. Gast’s

warranties also do not extend to any goods or parts which have been subjected to misuse, lack of maintenance,

neglect, damage by accident or transit damage.

THIS EXPRESS WARRANTY EXCLUDESALL OTHER WARRANTIES OR REPRESENTATIONS EXPRESSED

OR IMPLIED BY ANY LITERATURE, DATA, OR PERSON. GAST’S MAXIMUM LIABILITY UNDER THIS

EXCLUSIVE REMEDY SHALL NEVER EXCEED THE COST OF THE SUBJECT PRODUCTAND GAST

RESERVES THE RIGHT, AT ITS SOLE DISCRETION, TO REFUND THE PURCHASE PRICE IN LIEU OF

REPAIR OR REPLACEMENT.

GAST WILL NOT BE RESPONSIBLE OR LIABLE FOR INDIRECT OR CONSEQUENTIAL DAMAGES OF

ANY KIND, however arising, including but not limited to those for use of any products, loss of time, inconvenience,

lost profit, labor charges, or other incidental or consequential damages with respect to persons, business, or property,

whether as a result of breach of warranty, negligence or otherwise. Notwithstanding any other provision of this

warranty, BUYER’S REMEDY AGAINST GAST FOR GOODS SUPPLIED OR FOR NON-DELIVERED GOODS

OR FAILURE TO FURNISH GOODS, WHETHER OR NOT BASED ON NEGLIGENCE, STRICT LIABILITY OR

BREACH OF EXPRESS OR IMPLIED WARRANTY IS LIMITED SOLELY, AT GAST’S OPTION, TO

REPLACEMENT OF OR CURE OF SUCH NONCONFORMING OR NON-DELIVERED GOODS OR RETURN

OF THE PURCHASE PRICE FOR SUCH GOODSAND IN NO EVENT SHALL EXCEED THE PRICE OR

CHARGE FOR SUCH GOODS. GAST EXPRESSLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR USE OR PURPOSE WITH RESPECT TO THE GOODS SOLD. THEREARE

NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTIONS SET FORTH IN THIS WARRANTY,

notwithstanding any knowledge of Gast regarding the use or uses intended to be made of goods, proposed changes or

additions to goods, or any assistance or suggestions that may have been made by Gast personnel.

Unauthorized extensions of warranties by the customer shall remain the customer’s responsibility.

CUSTOMER IS RESPONSIBLE FOR DETERMINING THE SUITABILITY OF GAST PRODUCTS FOR

CUSTOMER’S USE OR RESALE, OR FOR INCORPORATING THEM INTO OBJECTS OR APPLICATIONS

WHICH CUSTOMER DESIGNS, ASSEMBLES, CONSTRUCTS OR MANUFACTURES.

This warranty can be modified only by authorized Gast personnel by signing a specific, written description of any

modifications.

This manual suits for next models

2

Table of contents

Other Gast Water Pump manuals