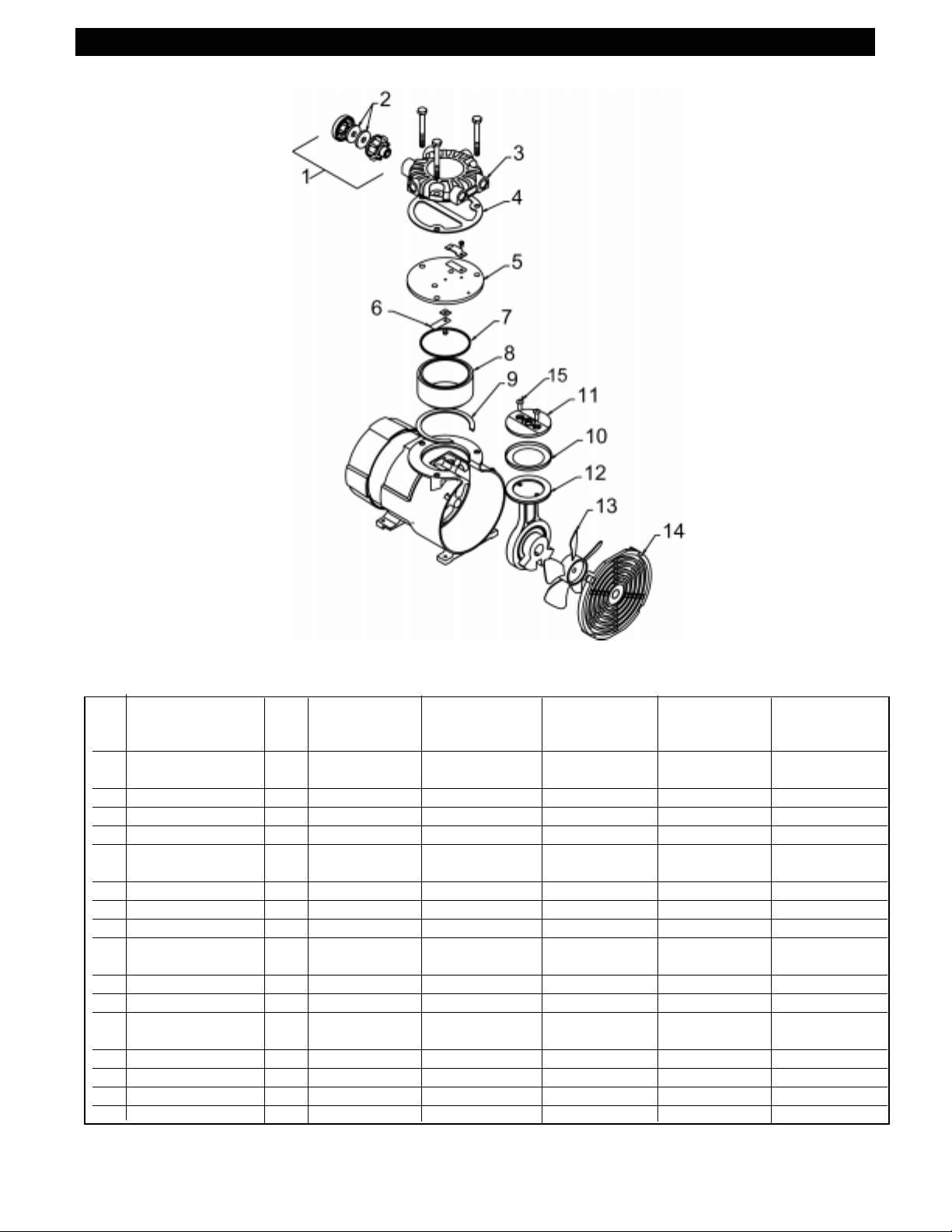

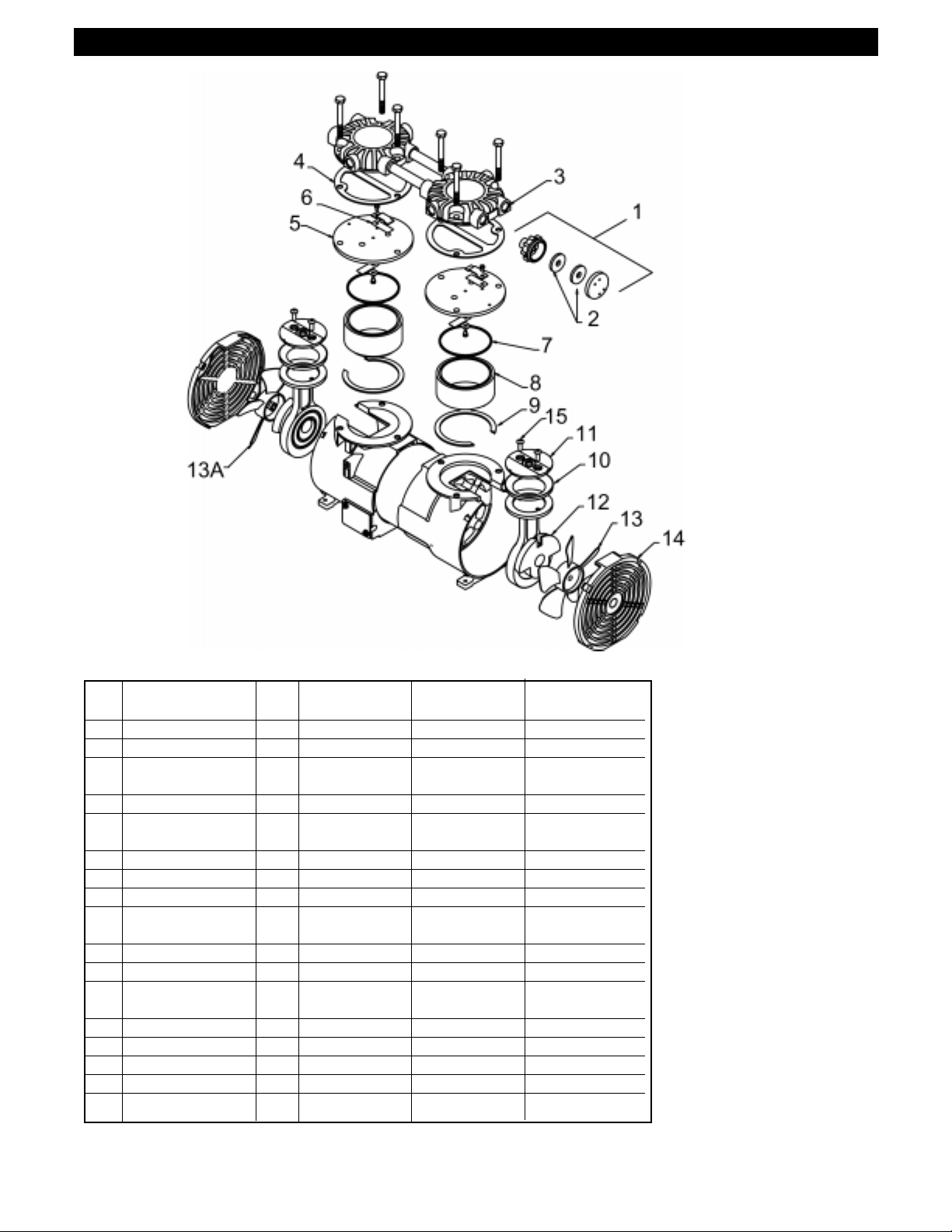

1. Disconnect electrical power to pump.

2. Disconnect air supply and vent all air lines to release

pressure or vacuum.

3. Remove the head bolts and remove head.

4. Remove the cylinder. Remove shims under the

cylinder and remove the two hex head screws on the

retainer plate. Remove retainer plate from cup.

5. Place shims under cylinder, (NOTE: Be sure to

replace all the shims as they are matched to the

cylinder and rod assembly height dimensions) install

over rod assembly.

6. Position cup and retainer plate on top of the cylinder.

With the palm of the hand, gently press retainer and cup

down into cylinder.

7. Align holes in retainer and cup with holes in rod, using

two screws with locking compound (Loctite grade 222)

applied. Reinstall retainer plate and new cup, torque

screws to 30 in. lbs.

Gast finished products, when properly installed and operated under normal conditions of use, are warranted by Gast to

be free from defects in material and workmanship for a period of twelve (12) months from the date of purchase from

Gast or an authorized Gast Representative or Distributor. In order to obtain performance under this warranty, the buyer

must promptly (in no event later than thirty (30) days after discovery of the defect) give written notice of the defect to

Gast Manufacturing Incorporated, PO Box 97, Benton Harbor Michigan USA 49023-0097 or an authorized Service

Center (unless specifically agreed upon in writing signed by both parties or specified in writing as part of a Gast OEM

Quotation). Buyer is responsible for freight charges both to and from Gast in all cases.

This warranty does not apply to electric motors, electrical controls, and gasoline engines not supplied by Gast. Gast’s

warranties also do not extend to any goods or parts which have been subjected to misuse, lack of maintenance,

neglect, damage by accident or transit damage.

THIS EXPRESS WARRANTY EXCLUDES ALL OTHER WARRANTIES OR REPRESENTATIONS EXPRESSED OR

IMPLIED BY ANY LITERATURE, DATA, OR PERSON. GAST’S MAXIMUM LIABILITY UNDER THIS EXCLUSIVE

REMEDY SHALL NEVER EXCEED THE COST OF THE SUBJECT PRODUCT AND GAST RESERVES THE RIGHT,

AT ITS SOLE DISCRETION, TO REFUND THE PURCHASE PRICE IN LIEU OF REPAIR OR REPLACEMENT.

GAST WILL NOT BE RESPONSIBLE OR LIABLE FOR INDIRECT OR CONSEQUENTIAL DAMAGES OF ANY KIND,

however arising, including but not limited to those for use of any products, loss of time, inconvenience, lost profit, labor

charges, or other incidental or consequential damages with respect to persons, business, or property, whether as a

result of breach of warranty, negligence or otherwise. Notwithstanding any other provision of this warranty, BUYER’S

REMEDY AGAINST GAST FOR GOODS SUPPLIED OR FOR NON-DELIVERED GOODS OR FAILURE TO FURNISH

GOODS, WHETHER OR NOT BASED ON NEGLIGENCE, STRICT LIABILITY OR BREACH OF EXPRESS OR

IMPLIED WARRANTY IS LIMITED SOLELY, AT GAST’S OPTION, TO REPLACEMENT OF OR CURE OF SUCH

NONCONFORMING OR NON-DELIVERED GOODS OR RETURN OF THE PURCHASE PRICE FOR SUCH GOODS

AND IN NO EVENT SHALL EXCEED THE PRICE OR CHARGE FOR SUCH GOODS. GAST EXPRESSLY DISCLAIMS

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE OR PURPOSE WITH RESPECT

TO THE GOODS SOLD.THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTIONS SET

FORTH IN THIS WARRANTY, notwithstanding any knowledge of Gast regarding the use or uses intended to be made

of goods, proposed changes or additions to goods, or any assistance or suggestions that may have been made by Gast

personnel.

Unauthorized extensions of warranties by the customer shall remain the customer’s responsibility.

CUSTOMER IS RESPONSIBLE FOR DETERMINING THE SUITABILITY OF GAST PRODUCTS FOR CUSTOMER’S

USE OR RESALE, OR FOR INCORPORATING THEM INTO OBJECTS OR APPLICATIONS WHICH CUSTOMER

DESIGNS, ASSEMBLES, CONSTRUCTS OR MANUFACTURES.

This warranty can be modified only by authorized Gast personnel by signing a specific, written description of any

modifications.

WARRANTY

5

8. Insert O-ring in groove in cylinder.

9. Install new valve plate, head gasket (note gasket

orientation), and head on cylinder so ports are in

original orientation.

10. Install and snug all head bolts by hand, then in a

cross pattern, torque all three bolts using 20 in. lb.

increments until you reach 70-80 in. lbs. on each bolt.

Before restarting product, check that all external

accessories such as relief valves and gauges are

not damaged.

If PUMP still does not produce proper vacuum or

pressure, send unit to a Gast Authorized Service

Facility for repair.