GasTech GTD2000-Tx User manual

t +61 8 6108 0000 e info@gastech.com w gastech.com

GTD2000-Tx

OPERATOR’S MANUAL

Note

• Inspection and calibration are recommended at least once every 3

months to ensure accurate operation of the Gas detector using

calibration gas depending on the type of gas.

• Negligence of periodic inspection and calibration may cause

malfunction of the device due to the aging of the Sensor.

• Only qualified personnel with professional s ills on Gas detector may

disassemble the unit if necessary.

• For further information on Gas detector inspection and correction,

please contact us at our technical department, e-mail or web site.

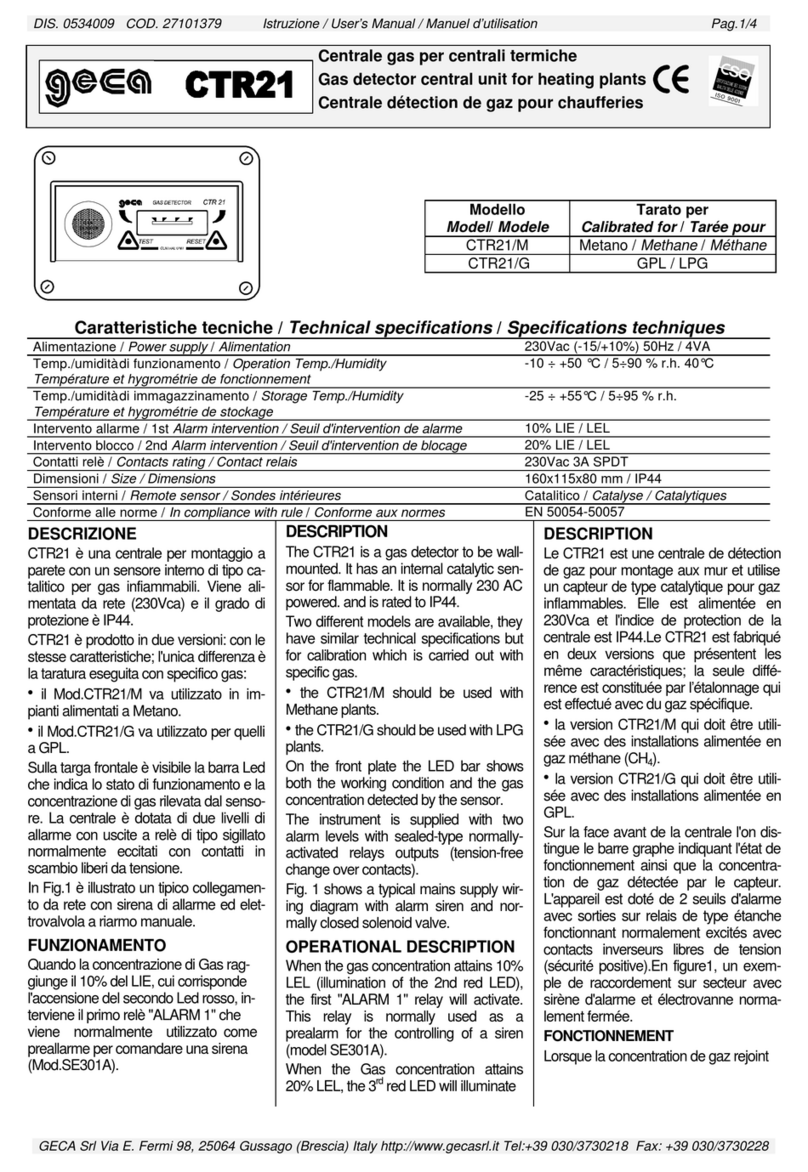

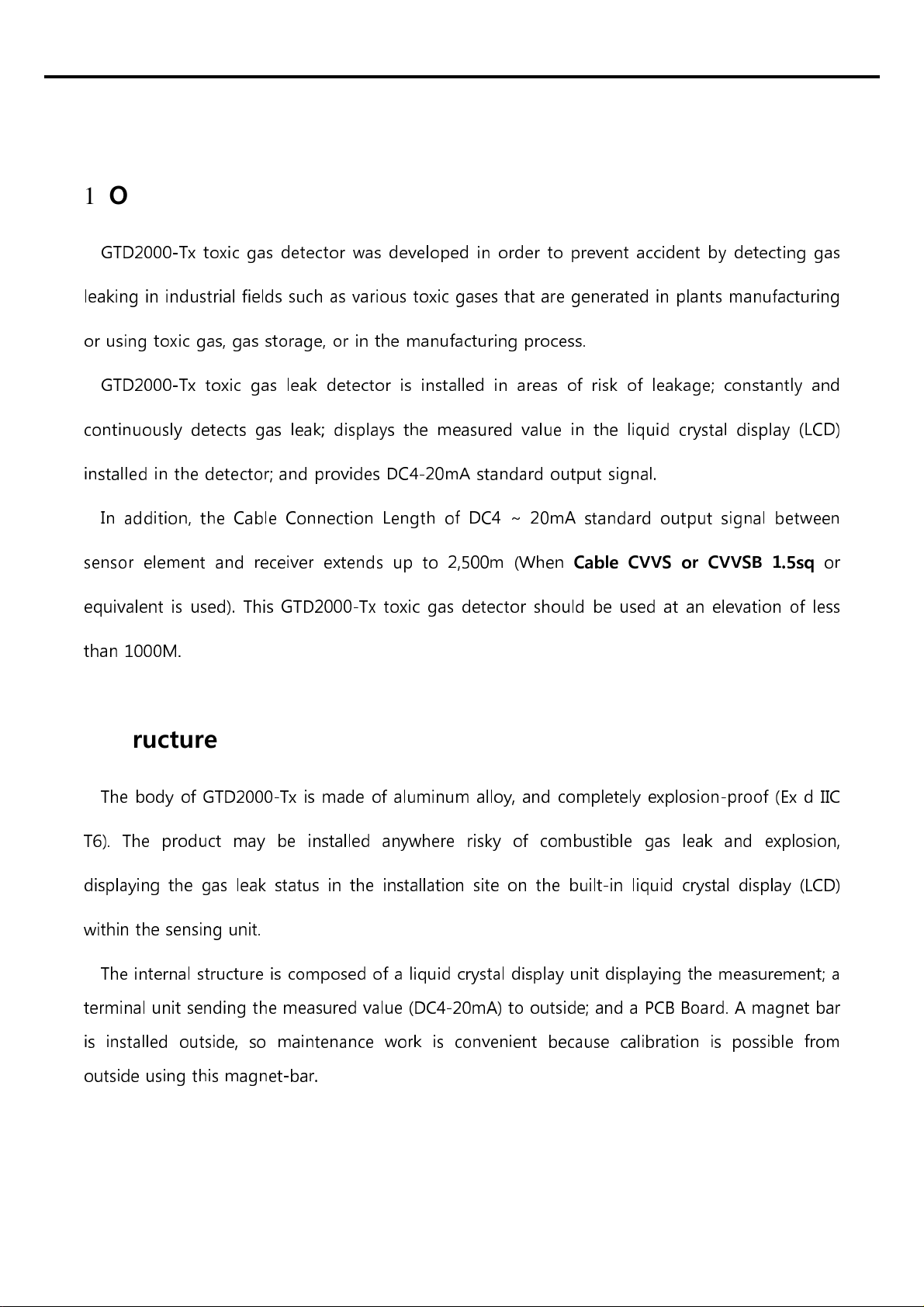

1. Overview

GTD2000-Tx toxic gas detector was developed in order to prevent accident by detecting gas

leaking in industrial fields such as various toxic gases that are generated in plants manufacturing

or using toxic gas, gas storage, or in the manufacturing process

GTD2000-Tx toxic gas leak detector is installed in areas of risk of leakage; constantly and

continuously detects gas leak; displays the measured value in the liquid crystal display (LCD)

installed in the detector; and provides DC4-20mA standard output signal

In addition, the Cable Connection Length of DC4 ~ 20mA standard output signal between

sensor element and receiver extends up to 2,500m (When

Cable CVVS or CVVSB 1.5sq

or

equivalent is used) This GTD2000-Tx toxic gas detector should be used at an elevation of less

than 1000M

2. Structure

The body of GTD2000-Tx is made of aluminum alloy, and completely explosion-proof (Ex d IIC

T6) The product may be installed anywhere risky of combustible gas leak and explosion,

displaying the gas leak status in the installation site on the built-in liquid crystal display (LCD)

within the sensing unit

The internal structure is composed of a liquid crystal display unit displaying the measurement; a

terminal unit sending the measured value (DC4-20mA) to outside; and a PCB Board A magnet bar

is installed outside, so maintenance work is convenient because calibration is possible from

outside using this magnet-bar

3. Specification

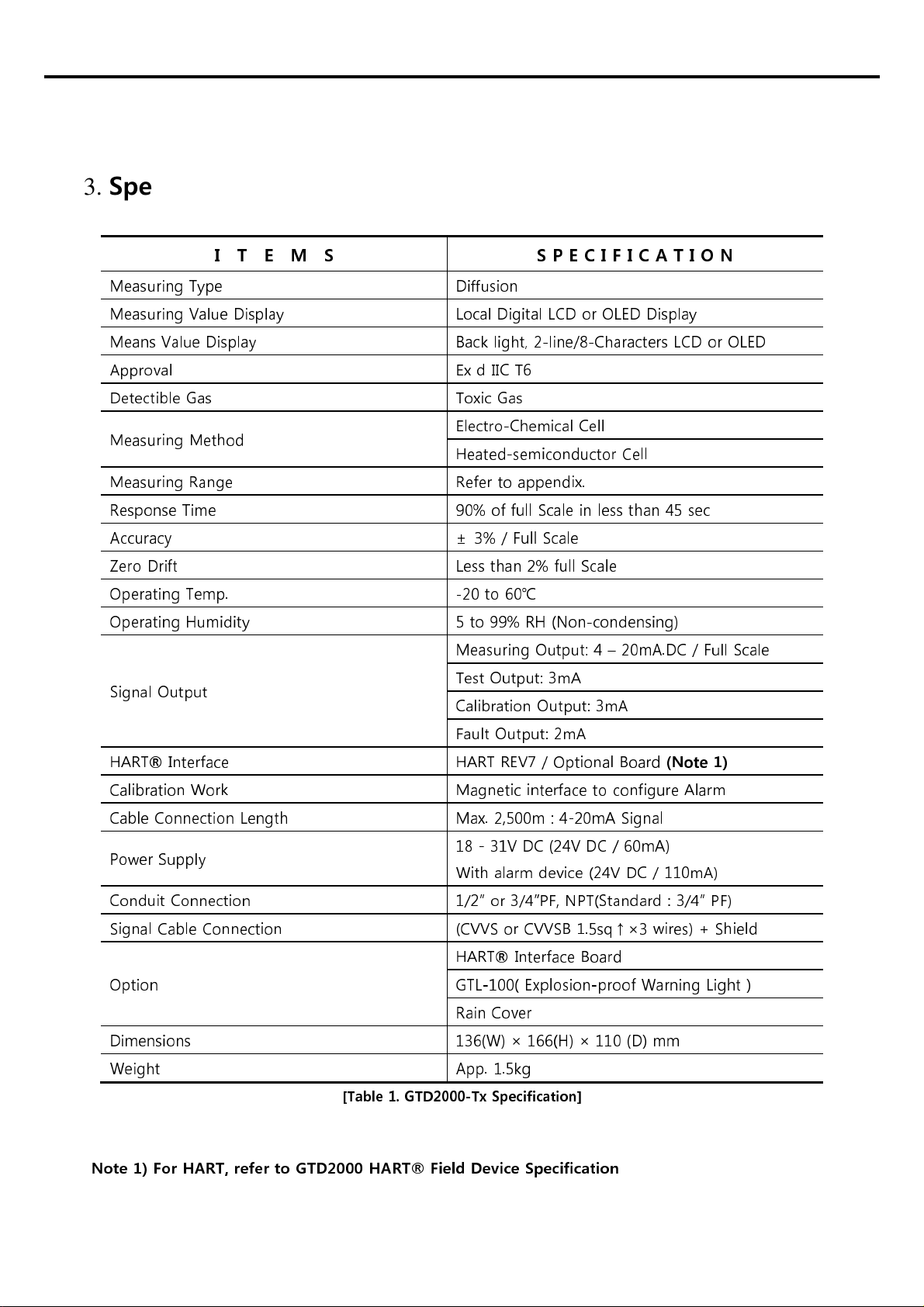

I T E M S S P E C I F I C A T I O N

Measuring Type Diffusion

Measuring Value Display Local Digital LCD or OLED Display

Means Value Display Back light, 2-line/ -Characters LCD or OLED

Approval Ex d IIC T6

Detectible Gas Toxic Gas

Measuring Method Electro-Chemical Cell

Heated-semiconductor Cell

Measuring Range Refer to appendix.

Response Time 90% of full Scale in less than 45 sec

Accuracy ± 3% / Full Scale

Zero Drift Less than 2% full Scale

Operating Temp. -20 to 60℃

Operating Humidity 5 to 99% RH (Non-condensing)

Signal Output

Measuring Output: 4 – 20mA.DC / Full Scale

Test Output: 3mA

Calibration Output: 3mA

Fault Output: 2mA

HART

®

Interface HART REV7 / Optional Board

(Note 1)

Calibration Work Magnetic interface to configure Alarm

Cable Connection Length Max. 2,500m : 4-20mA Signal

Power Supply 1 - 31V DC (24V DC / 60mA)

With alarm device (24V DC / 110mA)

Conduit Connection 1/2” or 3/4”PF, NPT(Standard : 3/4” PF)

Signal Cable Connection (CVVS or CVVSB 1.5sq↑×3 wires) + Shield

Option

HART

®

Interface Board

GTL-100( Explosion-proof Warning Light )

Rain Cover

Dimensions 136(W) × 166(H) × 110 (D) mm

Weight App. 1.5kg

[Table 1. GTD2000-Tx Specification]

Note 1) For HART, refer to GTD2000 HART® Field Device Specification

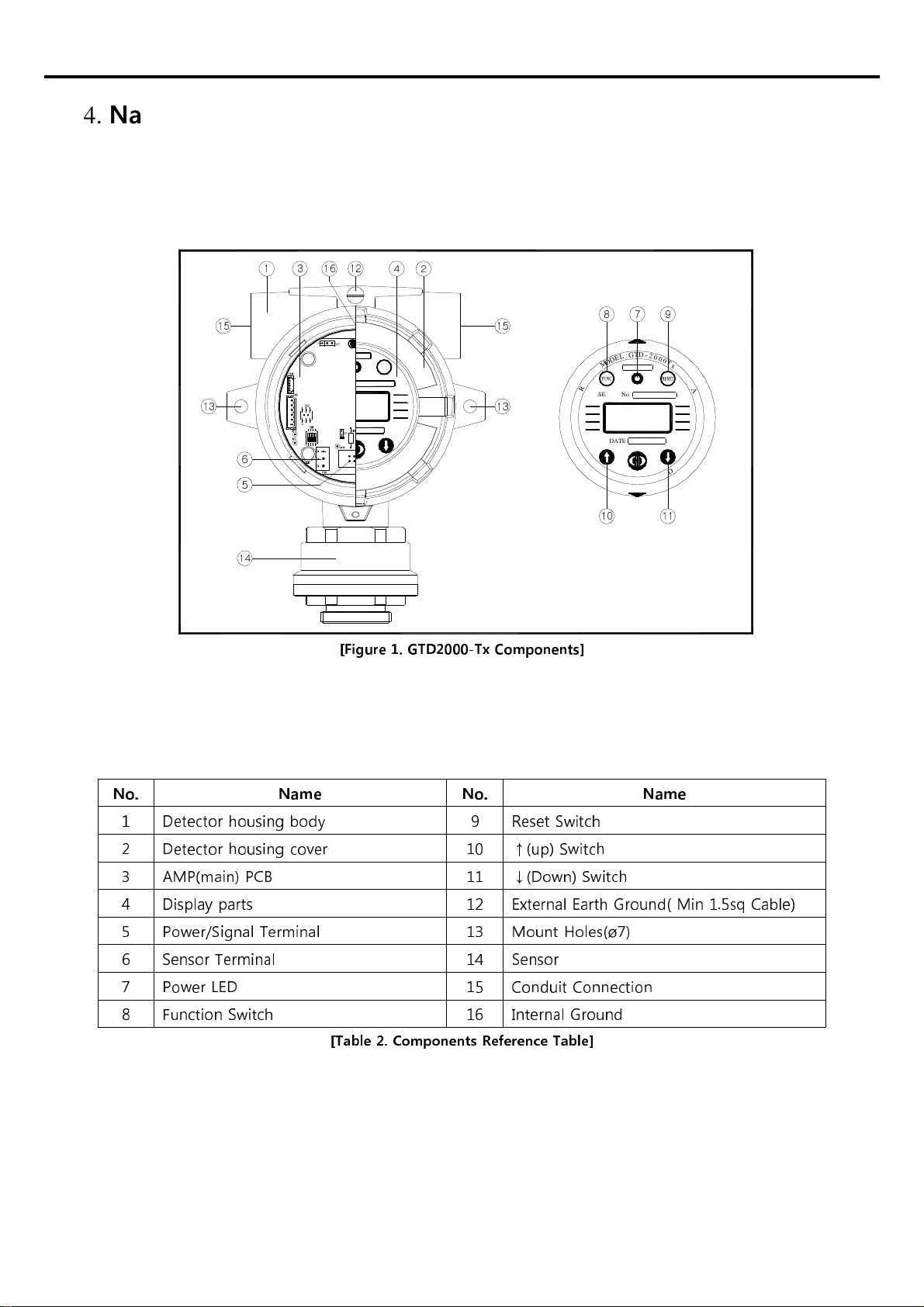

4. Name of Components and Main features

4.1. Components

RESET

12

34

6

7

8 9

10 11

14

13

15

1216

SERIAL No.

DATE

G

:

L

E

D

O

M

x

T

0

0

0

2

-

D

T

R

O

T

C

E

T

E

D

S

R

O

K

N

I

E

D

A

A

E

M

A

G

C

O

.

,

L

T

D

.

G

A

S

T

R

O

N

U

P

T

F

I

L

P

R

E

S

S

L

U

P

T

F

I

P

R

E

S

S

5

15

13

[Figure 1. GTD2000-Tx Components]

No. Name No. Name

1 Detector housing body 9 Reset Switch

2 Detector housing cover 10 ↑(up) Switch

3 AM (main) CB 11 ↓(Down) Switch

4 Display parts 12 External Earth Ground( Min 1.5sq Cable)

5 ower/Signal Terminal 13 Mount Holes(ø7)

6 Sensor Terminal 14 Sensor

7 ower LED 15 Conduit Connection

8 Function Switch 16 Internal Ground

[Table 2. Components Reference Table]

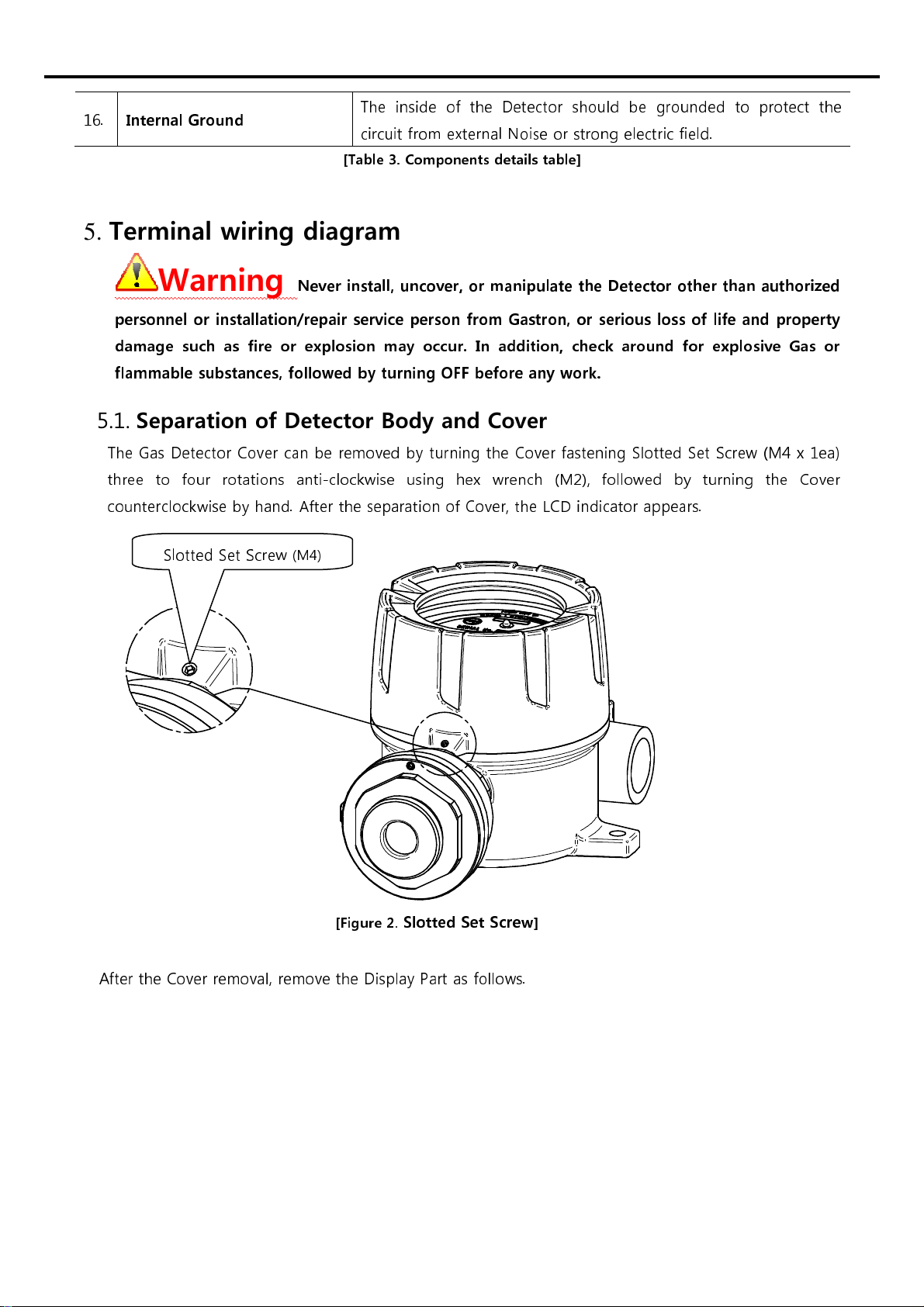

4.2. Description of components

No

. Name Description

1.

Detector Housing Body

rotects Sensor and built-in CB Board from external environment

and shock.

2.

Detector Housing Cover

Is assembled with Detector Housing Body, and has a circular glass

top through which LCD displayed Measuring Value can be seen.

3.

AMP PCB

Amplifies the tiny Output generated by Sensor Element, converts it

to 4-20mA.DC by converting a standard Output, and transmits the

Data to the Display unit.

4.

Display PCB

Displays the Data from AM / Terminal (Transmitter) CB to LCD

display (Measuring Value), and indicates the power status with the

ower Lamp.

5.

Power/Signal Terminal

CN9 is composed of DC18V ~ 31V power supply and a DC 4 ~

20mA standard Output Connection terminal (VISO, +24V, mA,

GND).

6.

Sensor Terminal

CN8 is Sensor Connection Terminal.

7.

Power ED

This Lamp is ON when ower is supplied.

8.

Function Switch

In Measuring Mode, touching this Switch for 2 sec with Magnet-

Bar will enter to Function Setting Mode; or will store changed Data

in Function Setting Mode.

9.

Reset Switch

Touching this Switch once with Magnet-Bar will cancel the

arameter setting, or return to the previous condition.

(Every touch will return the Mode one previous step).

10.

↑(UP) Switch

Touching this Switch once with Magnet-Bar will convert one step

or increase the displayed value in Mode conversion or number

change.

11.

↓(DOWN) Switch

Touching this Switch once with Magnet-Bar will convert one step

or decrease the displayed value in Mode conversion or number

change.

12.

External Earth Ground

The outside of the Detector should be grounded to protect the

circuit from external Noise or strong electric field.

13.

Mount Hole

(

ø

7×2ea)

This Hole is used to secure the Gas Detector on exterior walls and

other installation places.

14.

Sensor

Actually detects the gas leak, which is converted to electric signal

and transmitted AM CB.

15.

Conduit Connection

This is provided for the inlet for power supply and Measuring

Output signal. Cable connector has 3/4 ", 1/2" F or N T

(Default spec. is PF 3/4".)

16.

Internal Ground

The inside of the Detector should be grounded to protect the

circuit from external Noise or strong electric field.

[Table . Components details table]

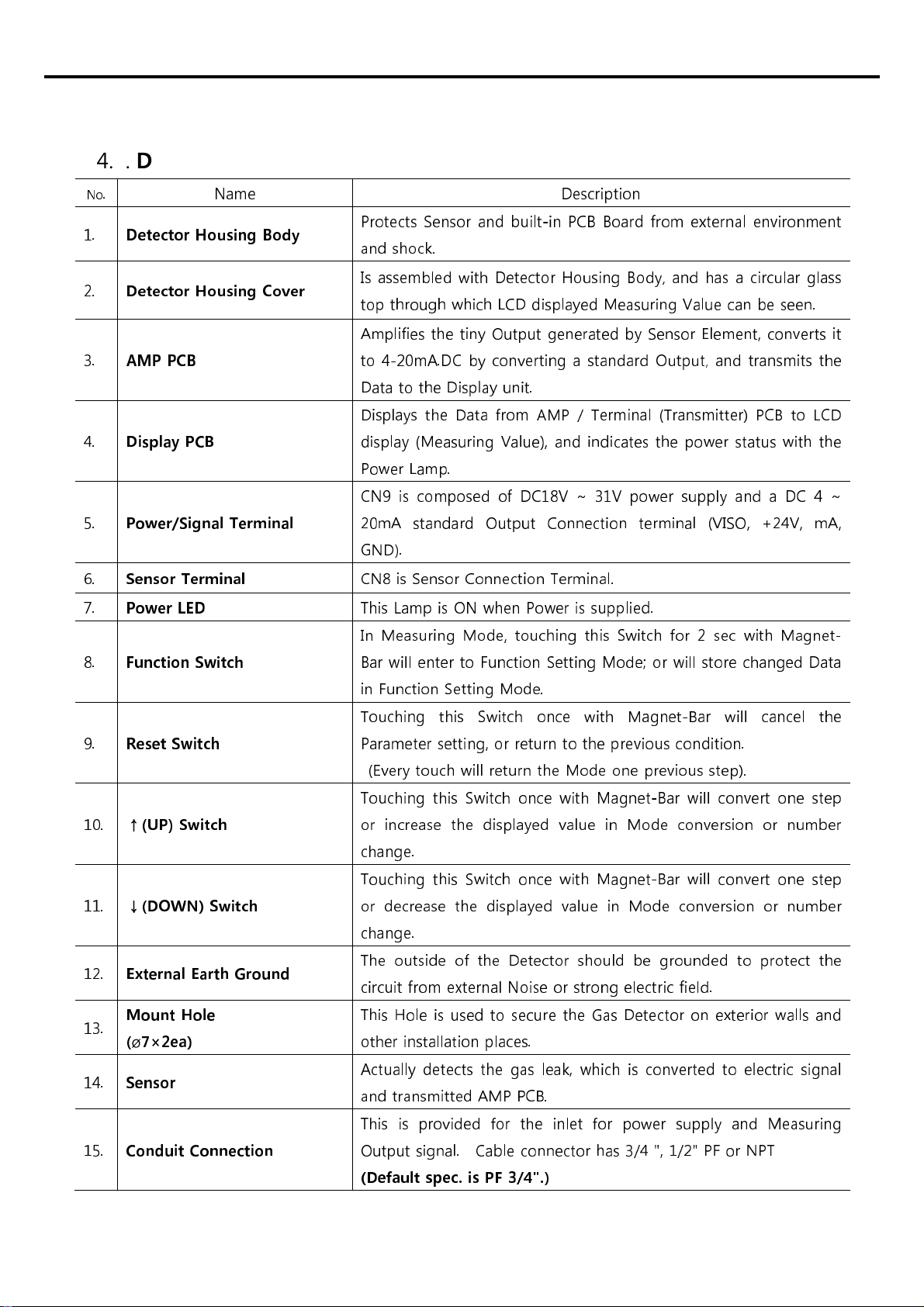

5. Terminal wiring diagram

Warning

Never install, uncover, or manipulate the Detector other than authorized

personnel or installation/repair service person from Gastron, or serious loss of life and property

damage such as fire or explosion may occur. In addition, check around for explosive Gas or

flammable substances, followed by turning OFF before any work.

5.1. Separation of Detector Body and Cover

The Gas Detector Cover can be removed by turning the Cover fastening Slotted Set Screw (M4 x 1ea)

three to four rotations anti-clockwise using hex wrench (M2), followed by turning the Cover

counterclockwise by hand. After the separation of Cover, the LCD indicator appears.

[Figure 2.

Slotted Set Screw

]

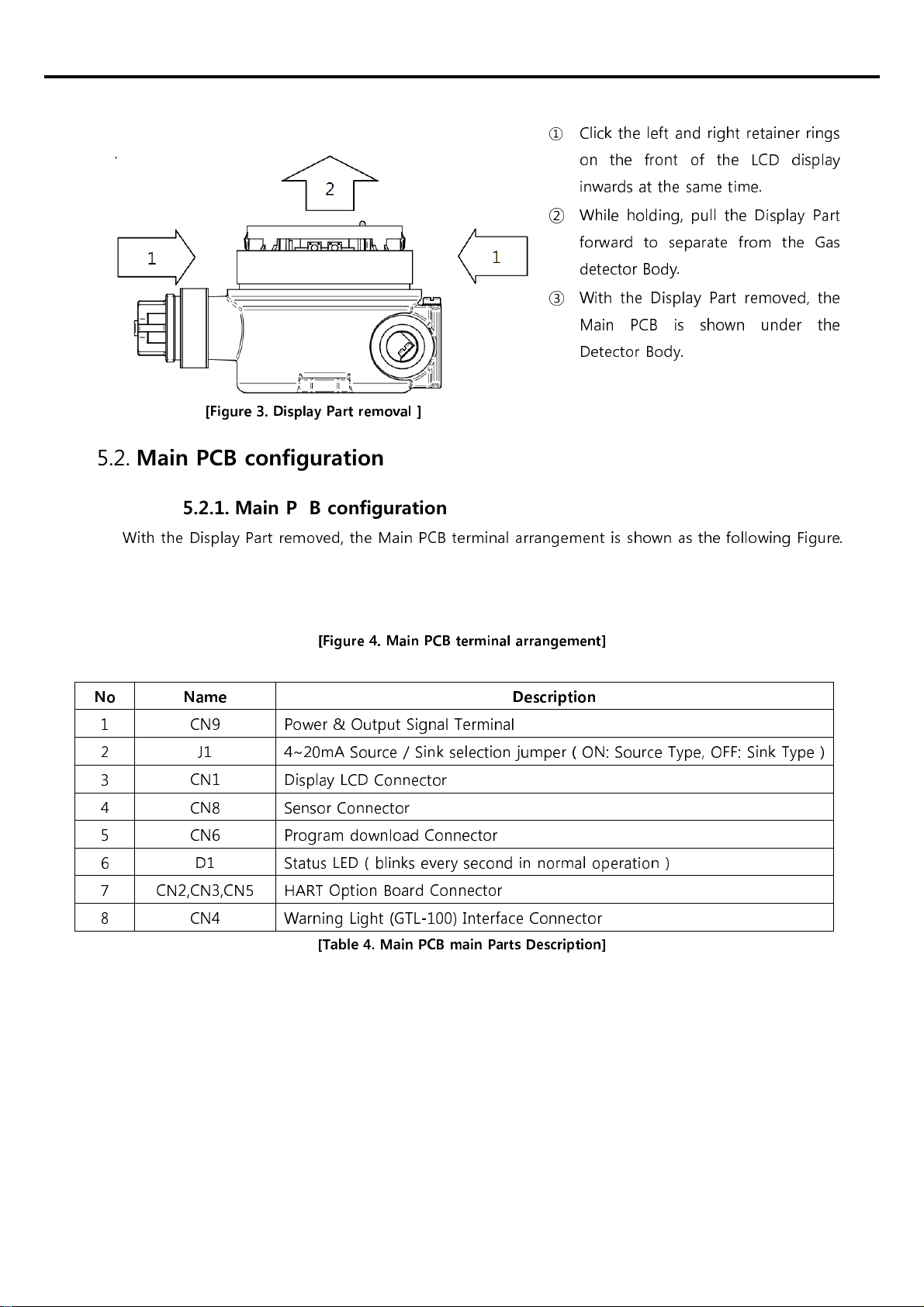

After the Cover removal, remove the Display art as follows.

Slotted Set Screw

(M4)

[Figure . Display Part removal ]

①

Click the left and right retainer rings

on the front of the LCD display

inwards at the same time.

②

While holding, pull the Display art

forward to separate from the Gas

detector Body.

③

With the Display art removed, the

Main CB is shown under the

Detector Body.

5.2. Main PCB configuration

5.2.1. Main PCB configuration

With the Display art removed, the Main CB terminal arrangement is shown as the following Figure.

[Figure 4. Main PCB terminal arrangement]

No Name Description

1 CN9 ower & Output Signal Terminal

2 J1 4~20mA Source / Sink selection jumper ( ON: Source Type, OFF: Sink Type )

3 CN1 Display LCD Connector

4 CN8 Sensor Connector

5 CN6 rogram download Connector

6 D1 Status LED ( blinks every second in normal operation )

7 CN2,CN3,CN5 HART Option Board Connector

8 CN4 Warning Light (GTL-100) Interface Connector

[Table 4. Main PCB main Parts Description]

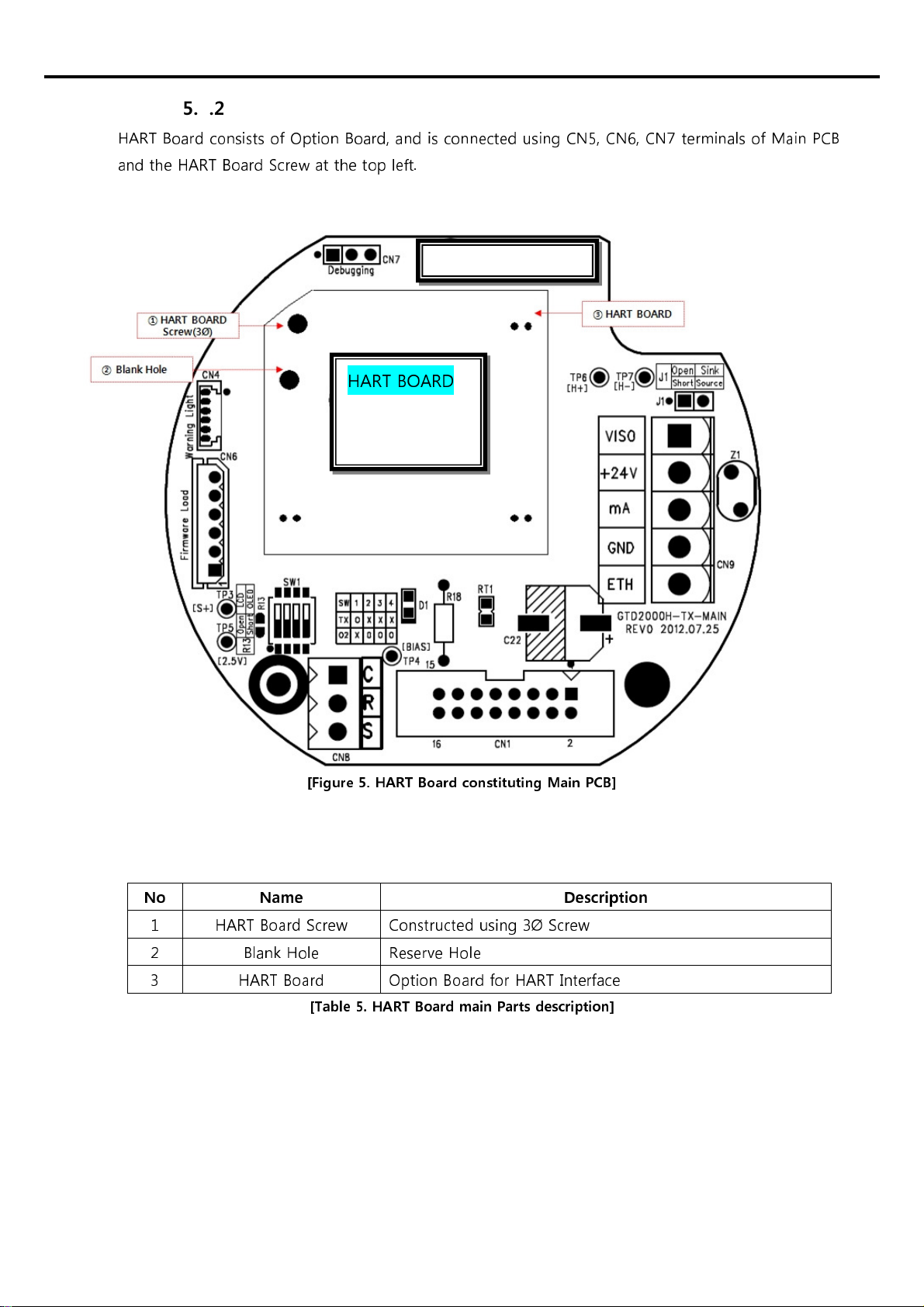

5.2.2. HART Board configuration

HART Board consists of Option Board, and is connected using CN5, CN6, CN7 terminals of Main CB

and the HART Board Screw at the top left.

[Figure 5. HART Board constituting Main PCB]

No Name Description

1 HART Board Screw Constructed using 3Ø Screw

2 Blank Hole Reserve Hole

3 HART Board Option Board for HART Interface

[Table 5. HART Board main Parts description]

HART BOARD

5.3. Main PCB terminal description and wiring method

If you remove the Display art, there is the Terminal Block under the Main CB as shown in the

following Figure 6. The Terminal Block can be removed from Main CB by holding and pulling upward

by hand. Unscrew the 5 terminal set screws above the separated

Terminal Block CN9 (VIS, +, mA, -,

ETH) Connector

counter-clockwise with a

Θ screwdriver; connect DC18-24V power to +, -; connect

Signal Cable to mA; tighten the terminal set screws clockwise to keep the terminals in place; and insert

it like before the removal.

[Figure 6. CN9 Terminal structure]

No CB Silk in Name

Description

4~20mA Source Drive

(J1 Jumper ON)

4~20mA Sink Drive

(J1 Jumper OFF)

1 VISO VIS N.C 4~20mA Sink In(+)

2 +24V + +24V / OWER (+)

3 mA mA 4~20mA Source Out 4~20mA Sink Out(-)

4 GND - GND / OWER (-)

5 ETH ET EARTH

[Table 6. CN9 connector description]

Note1) Be sure to use CVVS or CVVSB 1.5sq↑ Shield Cable before Terminal construction.

Note2) Fasten Terminals based on +24V of 2Pin to connect the 4Pin Terminal of existing

conventional GTD2000-Tx.

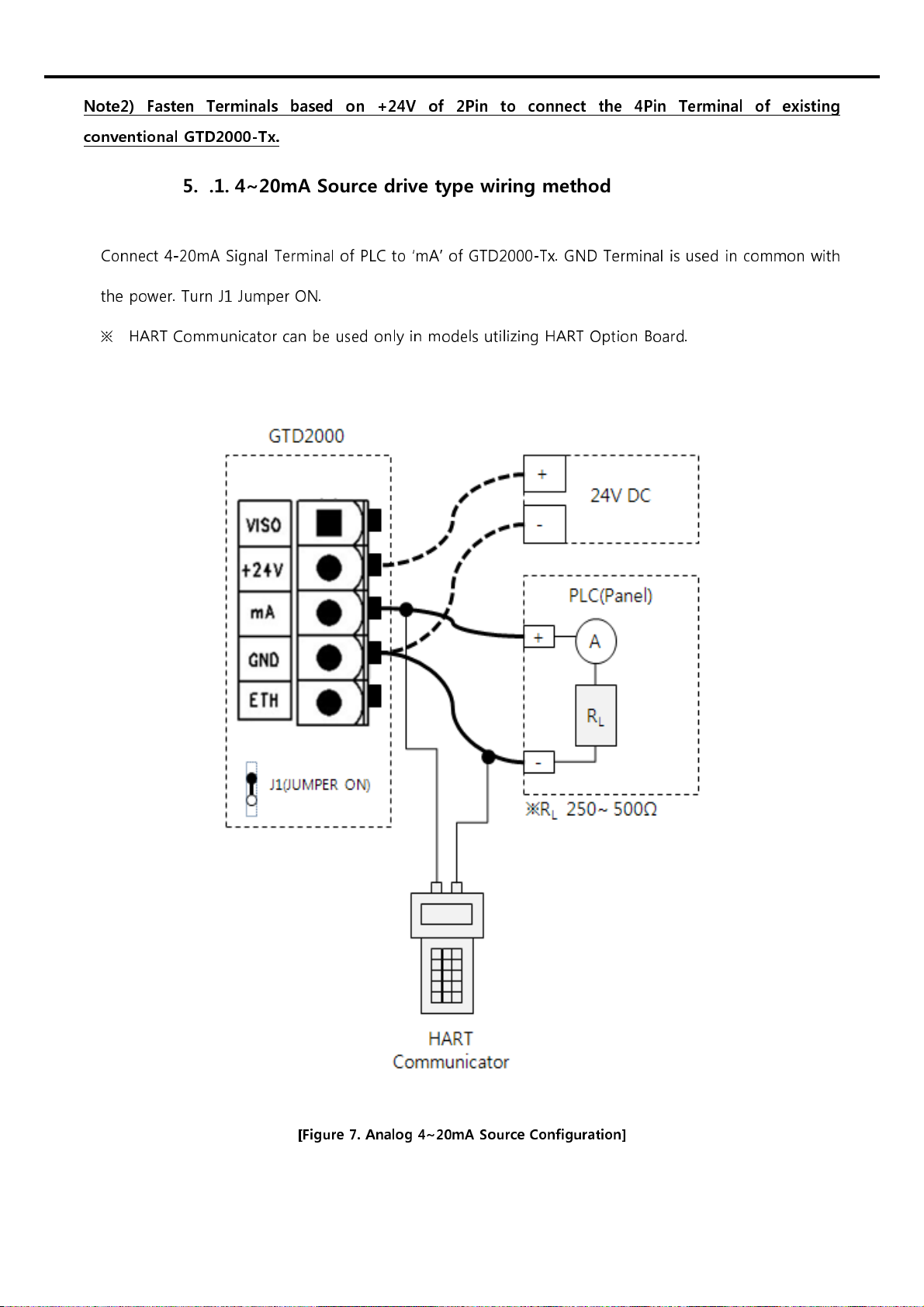

5.3.1. 4~20mA Source dri e type wiring method

Connect 4-20mA Signal Terminal of LC to ‘mA’ of GTD2000-Tx. GND Terminal is used in common with

the power. Turn J1 Jumper ON.

※

HART Communicator can be used only in models utilizing HART Option Board.

[Figure 7. Analog 4~20mA Source Configuration]

5.3.2. 4~20mA Sink dri e type wiring method

Connect 4-20mA Sink Output (+) Terminal of LC to VISO Terminal; and (-) Terminal to ‘mA’ Terminal.

Turn J1 Jumper OFF.

※

HART Communicator can be used only in models utilizing HART Option Board.

[Figure 8. Analog 4~20mA Sink Configuration]

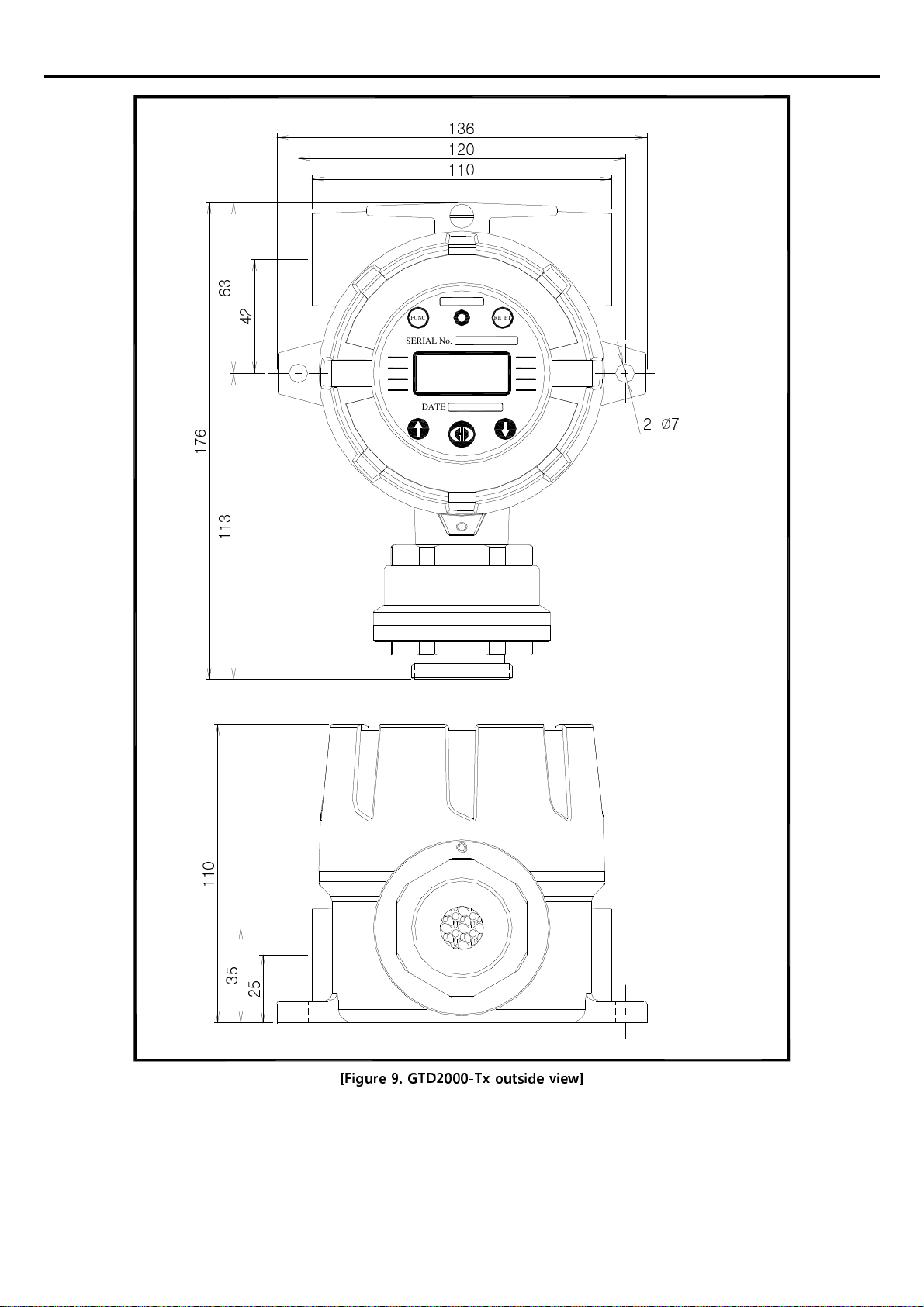

6. Standard Type outside view and Dimensions

1

1

3

2

5

3

5

1

1

0

110

120

136

4

2

6

3

1

7

6

2-

Ø

7

RESET

SERIAL No.

DATE

FUNC

[Figure 9. GTD2000-Tx outside view]

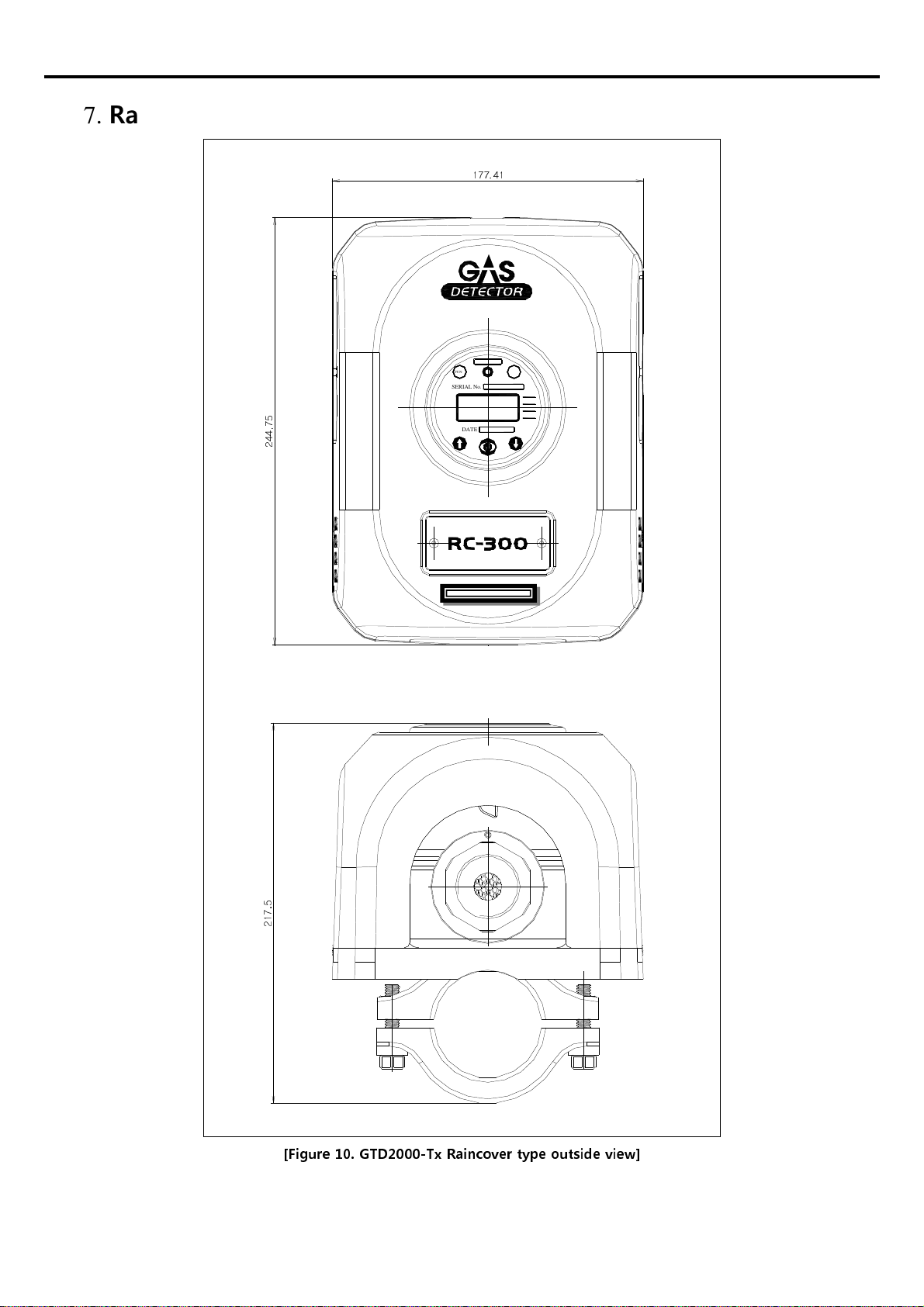

7. Raincover type: Outside view and Dimensions

2

4

4

.

7

5

177.41

2

1

7

.

5

RESET

SERIAL No.

DATE

FUNC

[Figure 10. GTD2000-Tx Raincover type outside view]

8. Menu Configuration Table

evel1 evel2 DEFAU T

NAME PARAMETER

ROGRAM

MODE

GAS TY E

(Gas Type)

[DEFIN./USER] DEFIN.

GAS SEL

(Gas Select)

See Table 8 COMB.

UNIT SEL

(Unit Select)

%/%LEL/ M/ B

%LEL

D- OINT

(Decimal Point)

0.100/1.00/10.0/100 100

HIGH SCL

(High Scale)

1~10000 100

ASSWORD 00~99 00

CALIBRA.

MODE

(Calibration Mode)

CALIBRA.

[ZERO]

(Calibration Zero)

ZERO CAL

[NO,YES]

[NO]

ZERO GAS

[ 0]

ZERO >>>>

[SUCCESS / FAIL]

CAL. DATA

[ 0/ FAIL]

CALIBRA.

[S AN]

(Calibration Span)

S AN CAL

[NO , YES] [NO]

S AN GAS

[ 0]

S AN SET

[ 50/ FAIL] 50

S AN >>>>

[SUCCESS / FAIL ]

CAL. DATA

[ 0]

ALARM MODE

ALM USED

(Alarm Used)

[OFF / ON] OFF

AL LATCH

(Alarm atch)

[OFF / ON] OFF

A1 LEVEL

(Alarm-1 evel)

[1 ~ 9999] 20

A1 TY E

(Alarm-1 Type)

[INC / DEC] INC

A1 DBAND

(Alarm-1 Dead Band)

[0.0 ~ 10.0%F] 1.0

A1 TIME

(Alarm-1 Time)

[0~ 60]SEC 1

A2 LEVEL

(Alarm-2 evel)

[1 ~ 9999] 40

A2 TY E

(Alarm-2 Type)

[INC / DEC] INC

A2 DBAND

(Alarm-2 Dead Band)

[0.0 ~ 10.0%F] 1.0

A2 TIME

(Alarm-2 Time)

[0~ 60]SEC 1

SENSOR MODE

SEN. OUT

(Sensor Output)

[ X.X mV ] -

SEN. S/T

(Sensor sensitivity)

[ X.X ] -

MZ / MS

(Manual Zero/Span)

X.X / XX.X 1.0 / -100.0

AZ / AS

(Auto Zero / Auto Span)

X.X / XX.X 1.0 / -100.0

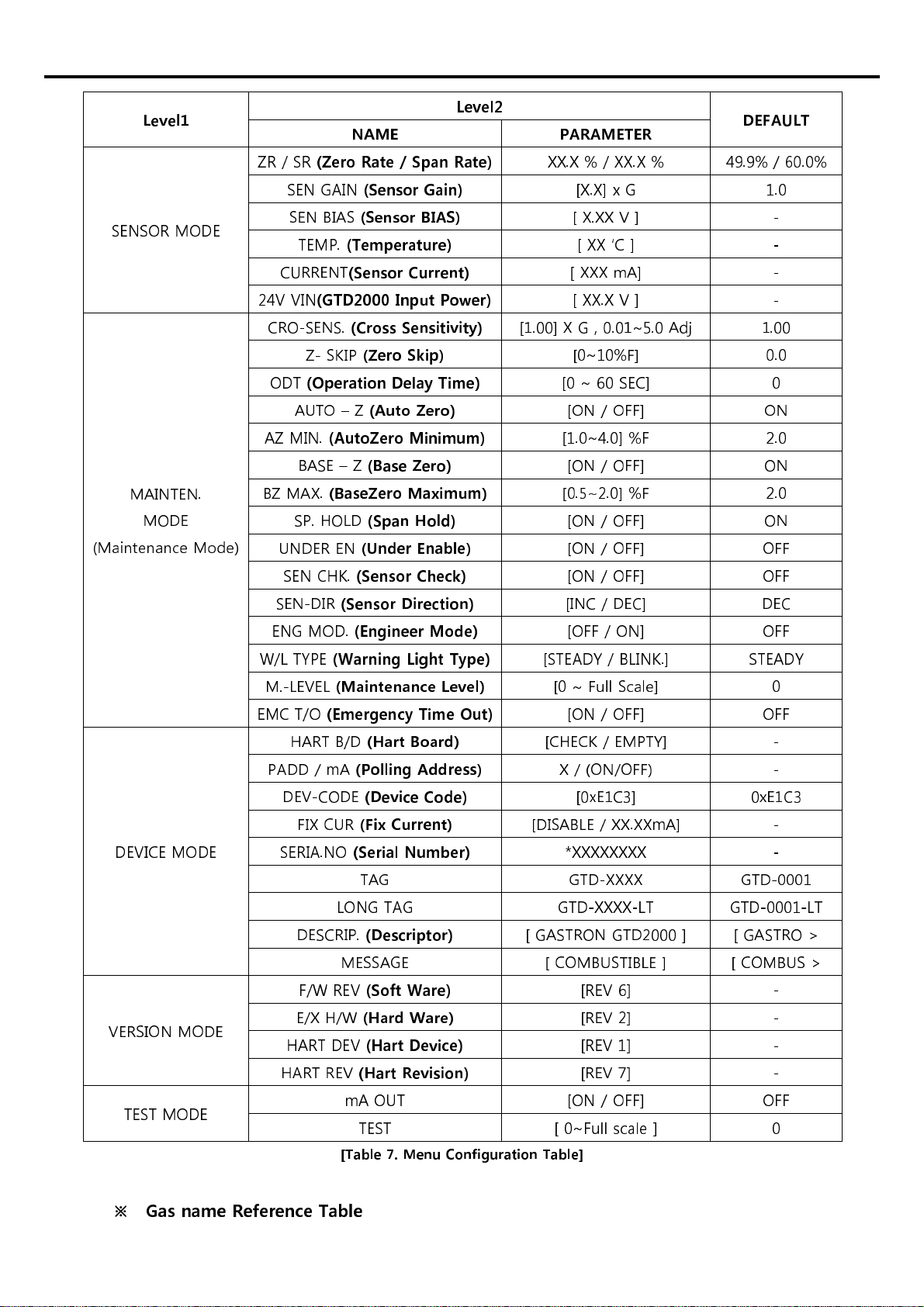

evel1

evel2 DEFAU T

NAME PARAMETER

SENSOR MODE

ZR / SR

(Zero Rate / Span Rate)

XX.X % / XX.X % 49.9% / 60.0%

SEN GAIN

(Sensor Gain)

[X.X] x G 1.0

SEN BIAS

(Sensor BIAS)

[ X.XX V ] -

TEM .

(Temperature)

[ XX ‘C ] -

CURRENT

(Sensor Current)

[ XXX mA] -

24V VIN

(GTD2000 Input Power)

[ XX.X V ] -

MAINTEN.

MODE

(Maintenance Mode)

CRO-SENS.

(Cross Sensitivity)

[1.00] X G , 0.01~5.0 Adj 1.00

Z- SKI

(Zero Skip)

[0~10%F] 0.0

ODT

(Operation Delay Time)

[0 ~ 60 SEC] 0

AUTO – Z

(Auto Zero)

[ON / OFF] ON

AZ MIN.

(AutoZero Minimum)

[1.0~4.0] %F 2.0

BASE – Z

(Base Zero)

[ON / OFF] ON

BZ MAX.

(BaseZero Maximum)

[0.5~2.0] %F 2.0

S . HOLD

(Span Hold)

[ON / OFF] ON

UNDER EN

(Under Enable)

[ON / OFF] OFF

SEN CHK.

(Sensor Check)

[ON / OFF] OFF

SEN-DIR

(Sensor Direction)

[INC / DEC] DEC

ENG MOD.

(Engineer Mode)

[OFF / ON] OFF

W/L TY E

(Warning ight Type)

[STEADY / BLINK.] STEADY

M.-LEVEL

(Maintenance evel)

[0 ~ Full Scale] 0

EMC T/O

(Emergency Time Out)

[ON / OFF] OFF

DEVICE MODE

HART B/D

(Hart Board)

[CHECK / EM TY] -

ADD / mA

(Polling Address)

X / (ON/OFF) -

DEV-CODE

(Device Code)

[0xE1C3] 0xE1C3

FIX CUR

(Fix Current)

[DISABLE / XX.XXmA] -

SERIA.NO

(Serial Number)

*XXXXXXXX -

TAG GTD-XXXX GTD-0001

LONG TAG GTD-XXXX-LT GTD-0001-LT

DESCRI .

(Descriptor)

[ GASTRON GTD2000 ] [ GASTRO >

MESSAGE [ COMBUSTIBLE ] [ COMBUS >

VERSION MODE

F/W REV

(Soft Ware)

[REV 6] -

E/X H/W

(Hard Ware)

[REV 2] -

HART DEV

(Hart Device)

[REV 1] -

HART REV

(Hart Revision)

[REV 7] -

TEST MODE mA OUT [ON / OFF] OFF

TEST [ 0~Full scale ] 0

[Table 7. Menu Configuration Table]

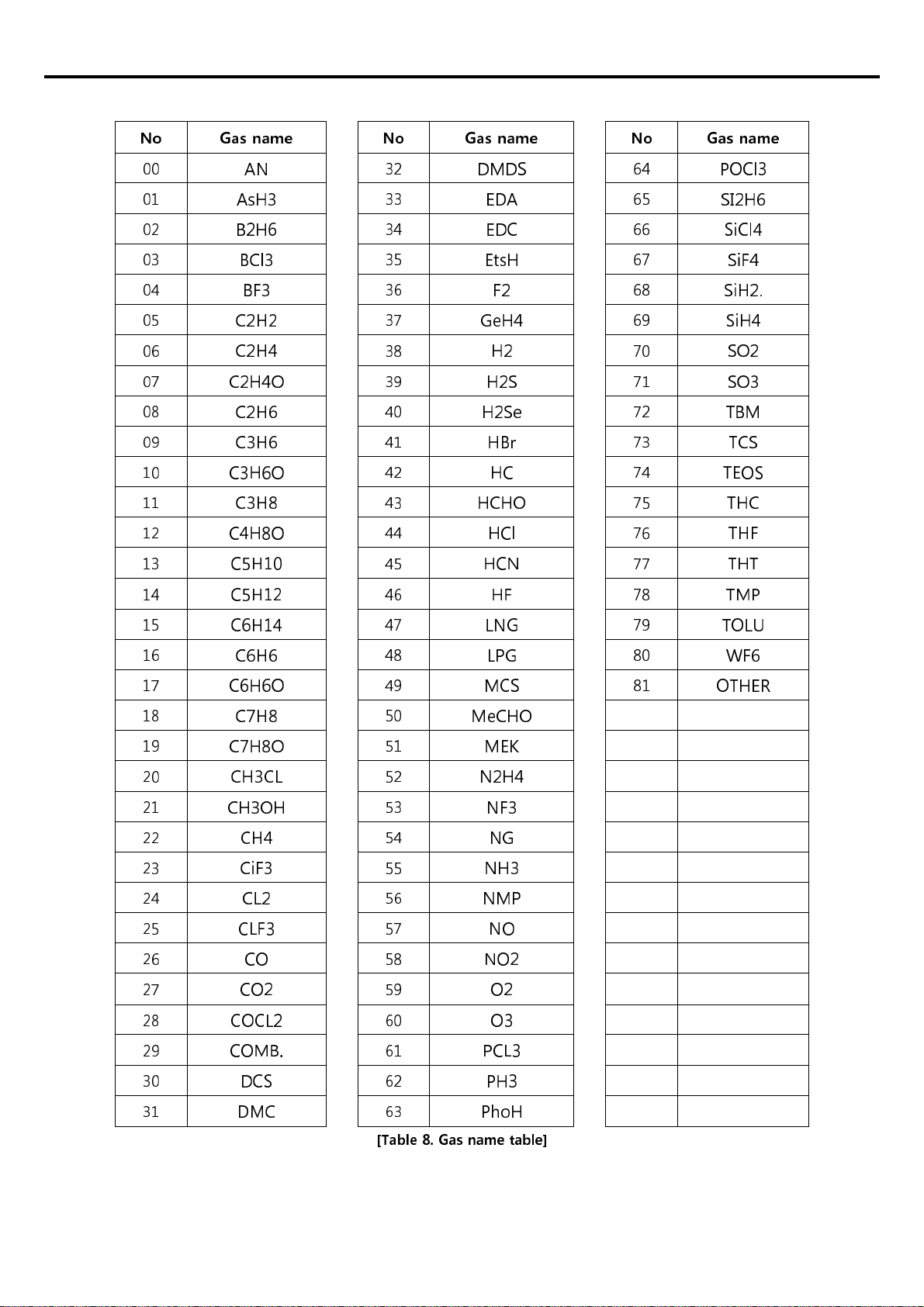

※

Gas name Reference Table

No Gas name No Gas name No Gas name

00

AN

32

DMDS

64

POCl3

01

AsH3

33

EDA

65

SI2H6

02

B2H6

34

EDC

66

SiCl4

03

BCl3

35

EtsH

67

SiF4

04

BF3

36

F2

68

SiH2.

05

C2H2

37

GeH4

69

SiH4

06

C2H4

38

H2

70

SO2

07

C2H4O

39

H2S

71

SO3

08

C2H6

40

H2Se

72

TBM

09

C3H6

41

HBr

73

TCS

10

C3H6O

42

HC

74

TEOS

11

C3H8

43

HCHO

75

THC

12

C4H8O

44

HCl

76

THF

13

C H10

45

HCN

77

THT

14

C H12

46

HF

78

TMP

15

C6H14

47

LNG

79

TOLU

16

C6H6

48

LPG

80

WF6

17

C6H6O

49

MCS

81

OTHER

18

C7H8

50

MeCHO

19

C7H8O

51

MEK

20

CH3CL

52

N2H4

21

CH3OH

53

NF3

22

CH4

54

NG

23

CiF3

55

NH3

24

CL2

56

NMP

25

CLF3

57

NO

26

CO

58

NO2

27

CO2

59

O2

28

COCL2

60

O3

29

COMB.

61

PCL3

30

DCS

62

PH3

31

DMC

63

PhoH

[Table 8. Gas name table]

9. Detector activation Flow and K Y operation

9.1. Sensor activation Flow

- Timeout of Level1 and Level2 is 10 seconds, and 1 hour in the Calibration and Test Mode of Level2.

[Figure 11. Sensor workflow]

9.2. Sensor KEY configuration and description

Item Name Description

FUNC Function Key

Sensor Mode entry function (more than 2 seconds of touch with Magnet-

bar in Measuring Mode). Entry to the next step of Level2 and storage of

setting value.

RESET Reset Key Moving back to the previous step before the entered LEVEL

↑

Up Key Change to the next step after LEVEL1, and plus change of Level2 setting.

↓

Down Key Change to previous step before LEVEL1; minus change of Level2 setting.

※

Sensor ower ON followed by simultaneous input of Reset Key and Function Key will result in Factory

Set in internal setting.

10. Initial status and Menu description

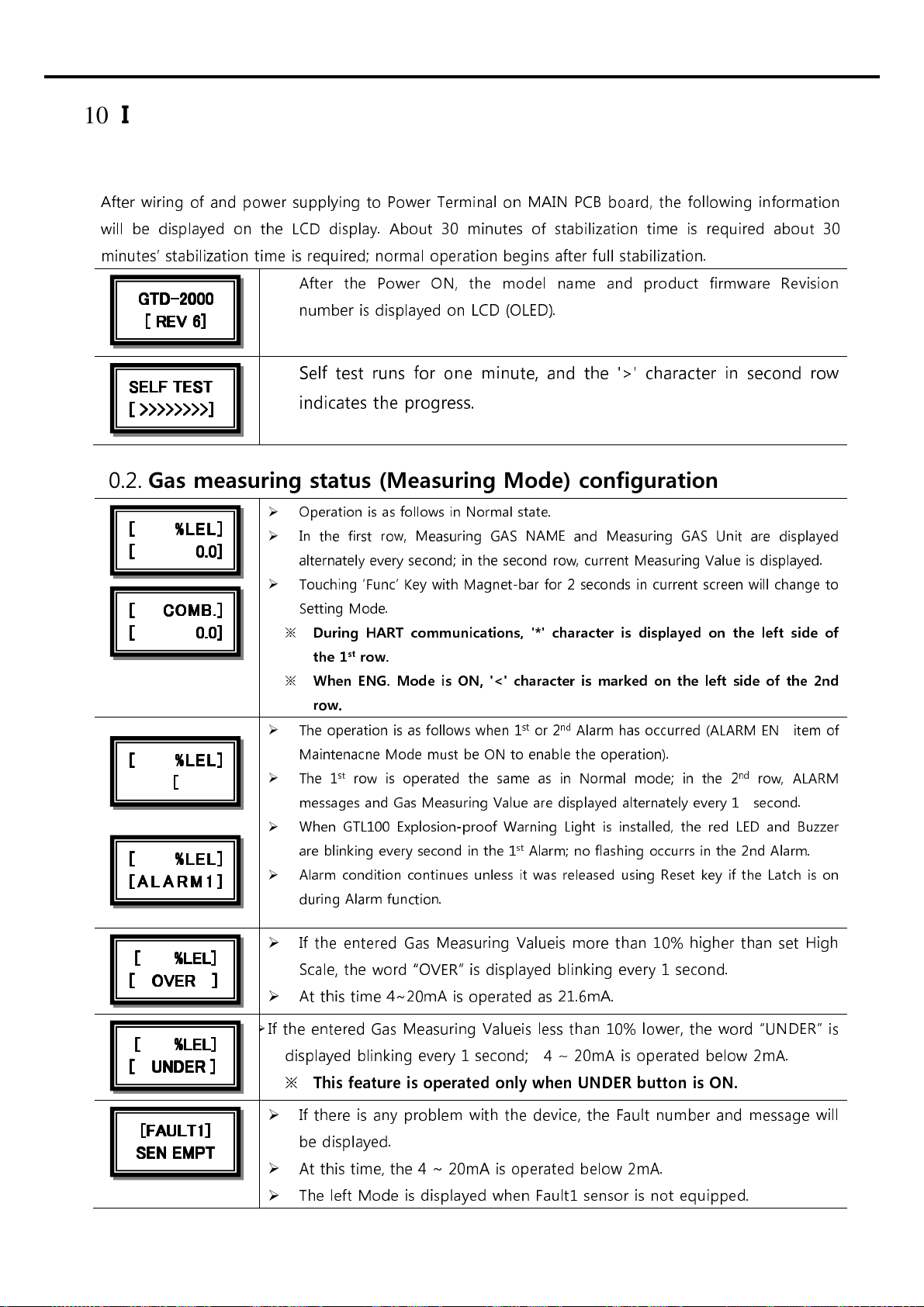

10.1. nitial operation status (Power On)

After wiring of and power supplying to ower Terminal on MAIN CB board, the following information

will be displayed on the LCD display. About 30 minutes of stabilization time is required about 30

minutes’ stabilization time is required; normal operation begins after full stabilization.

After the ower ON, the model name and product firmware Revision

number is displayed on

LCD (OLED).

Self test runs for one minute, and the '>' character in second row

indicates the progress.

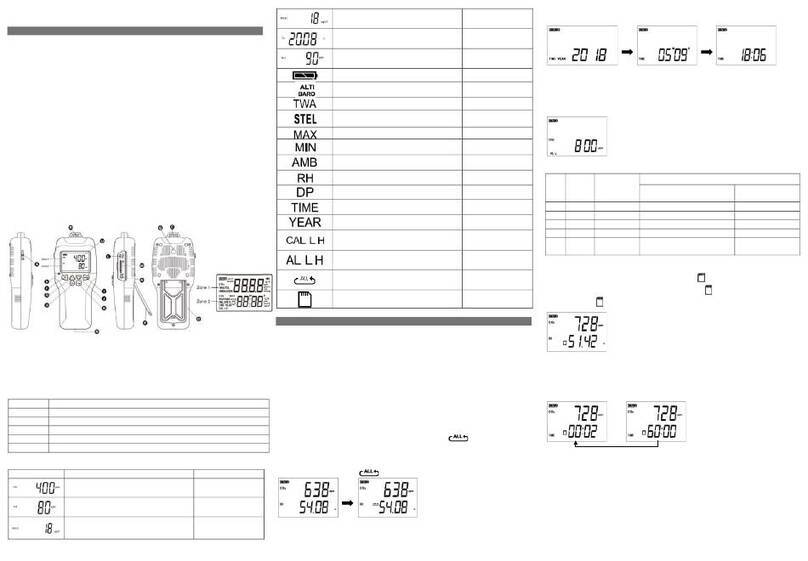

10.2. Gas measuring status (Measuring Mode) configuration

Oper tion is s follows in Norm l st te.

In the first row, Me suring GAS NAME nd Me suring GAS Unit re displ yed

ltern tely every second; in the second row, current Me suring V lue is displ yed.

Touching ‘Func’ Key with M gnet-b r for 2 seconds in current screen will ch nge to

Setting Mode.

※

During HART communications, '*' character is displayed on the left side of

the 1

st

row.

※

When ENG. Mode is ON, '<' character is marked on the left side of the 2nd

row.

The oper tion is s follows when 1

st

or 2

nd

Al rm h s occurred (ALARM EN item of

M inten cne Mode must be ON to en ble the oper tion).

The 1

st

row is oper ted the s me s in Norm l mode; in the 2

nd

row, ALARM

mess ges nd G s Me suring V lue re displ yed ltern tely every 1 second.

When GTL100 Explosion-proof W rning Light is inst lled, the red LED nd Buzzer

re blinking every second in the 1

st

Al rm; no fl shing occurrs in the 2nd Al rm.

Al rm condition continues unless it w s rele sed using Reset key if the L tch is on

during Al rm function.

If the entered Gas Measuring Valueis more than 10% higher than set High

Scale, the word “OVER” is displayed blinking every 1 second.

At this time 4~20mA is operated as 21.6mA.

If the entered Gas Measuring Valueis less than 10% lower, the word “UNDER” is

displayed blinking every 1 second; 4 ~ 20mA is operated below 2mA.

※

This feature is operated only when UNDER button is ON.

If there is any problem with the device, the Fault number and message will

be displayed.

At this time, the 4 ~ 20mA is operated below 2mA.

The left Mode is displayed when Fault1 sensor is not equipped.

[FAULT1]

[FAULT1][FAULT1]

[FAULT1]

SEN EMPT

SEN EMPTSEN EMPT

SEN EMPT

[ %LEL]

[ %LEL][ %LEL]

[ %LEL]

[ UNDER ]

[ UNDER ][ UNDER ]

[ UNDER ]

[ %LEL]

[ %LEL][ %LEL]

[ %LEL]

[ OVER ]

[ OVER ][ OVER ]

[ OVER ]

[ %LEL]

[ %LEL][ %LEL]

[ %LEL]

[

[[

[ A LA R M1

ALAR M 1ALAR M 1

A LA R M1 ]

]]

]

[ %LEL]

[ %LEL][ %LEL]

[ %LEL]

[

[ [

[

[ COMB.]

[ COMB.][ COMB.]

[ COMB.]

[ 0.0]

[ 0.0][ 0.0]

[ 0.0]

[ %LEL]

[ %LEL][ %LEL]

[ %LEL]

[ 0.0]

[ 0.0][ 0.0]

[ 0.0]

SELF TEST

SELF TESTSELF TEST

SELF TEST

[

[[

[

>

>>

>>>>>>>>

>>>>>>>>>>>>>>

>>>>>>>]

]]

]

GTD

GTDGTD

GTD-

--

-2000

2000 2000

2000

[ REV 6]

[ REV 6][ REV 6]

[ REV 6]

Table of contents

Other GasTech Gas Detector manuals

GasTech

GasTech D-Guard2 User manual

GasTech

GasTech F-Guard-UV-IR-HD User manual

GasTech

GasTech G-Shield Fire User manual

GasTech

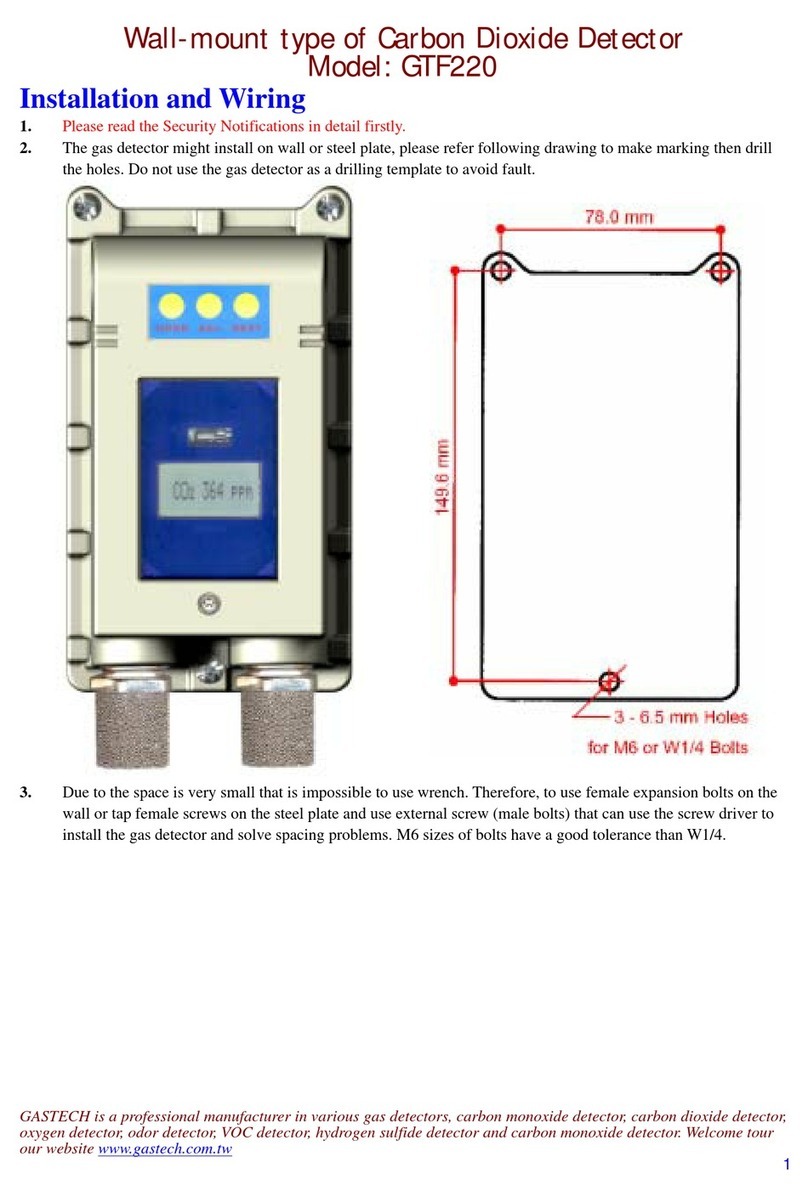

GasTech GTF220 User manual

GasTech

GasTech D-Guard2 User manual

GasTech

GasTech Cannonball 3 User manual

GasTech

GasTech F-GUARD UVIR User manual

GasTech

GasTech D-Guard User manual

GasTech

GasTech D-Guard2S User manual

GasTech

GasTech F-Guard-IR3-H2 User manual

Popular Gas Detector manuals by other brands

Honeywell

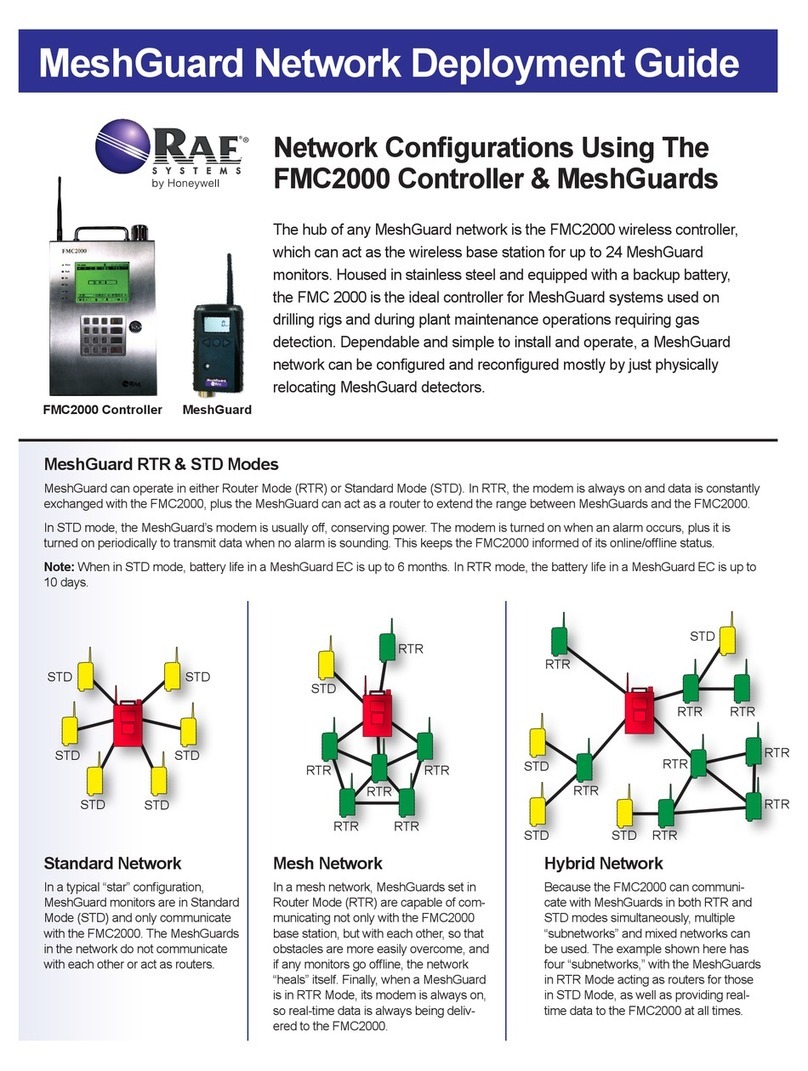

Honeywell Rae Systems MeshGuard Deployment guide

CPVan

CPVan CP-WG01W user guide

Riken Keiki

Riken Keiki SP-220 Series operating manual

RKI Instruments

RKI Instruments GX-86A instruction manual

FORENSICS DETECTORS

FORENSICS DETECTORS FD-91 quick start guide

ZyAura

ZyAura ZG906CMONP operating instructions