GasTech G-Shield Fire User manual

G-Shield Instruction Manual

Version 12

1 Introduction

The G-Shield Fire is a gas detection system that attaches to a vehicle. It has a Human

Machine Interface (HMI), two Sensor Platforms, and two G-Pods. One G-Pod detects

Hydrogen Cyanide (HCN) and the other detects Carbon Monoxide (CO).

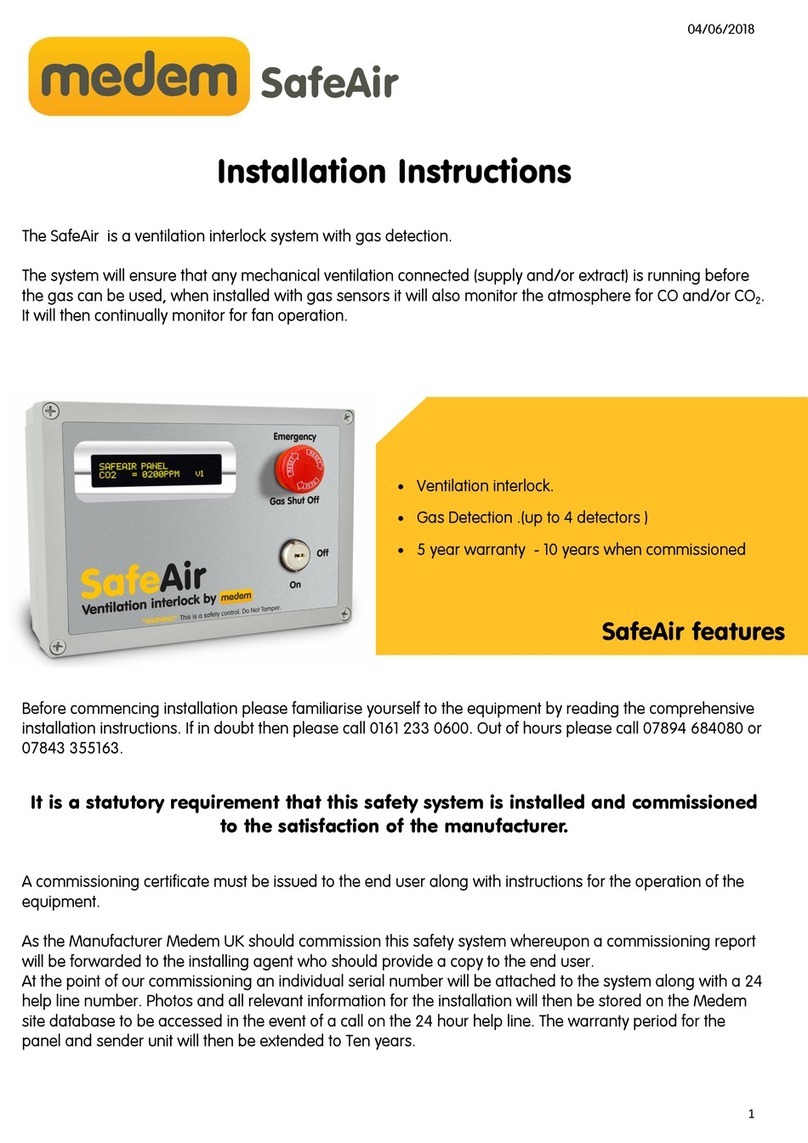

Figure 1. G-Shield Fire HMI shown in optional enclosure with two Sensor Platforms and a G-Pod.

2 Method of Operation

The HMI, Sensor Platforms, and G-Pods communicate by MODBUS RTU over RS-485.

This design allows multiple G-Pods to communicate with a single HMI. The G-Shield

Fire is configured for two G-Pods.

3 For Your Safety

WARNING: You must obey the instructions for the safe installation, use, and

maintenance of this equipment.

4 Further Information

Please tell us if you want help with this equipment.

Head Oce: Gastech, 24 Baretta Road, Wangara, WA 6065, Australia.

Note: Modification of this equipment is strictly prohibited without written permission

from Gastech Australia Pty Ltd.

G-Shield Instruction Manual

Version 13

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . .

Method of Operation . . . . . . . . . . . . . . . . . . . .

For Your Safety . . . . . . . . . . . . . . . . . . . . . .

Further Information . . . . . . . . . . . . . . . . . . . . .

List of Figures . . . . . . . . . . . . . . . . . . . . . . .

Keywords and Symbols Used in This Manual . . . . . . . . . . . .

Intended use . . . . . . . . . . . . . . . . . . . . . . .

Safety Precautions . . . . . . . . . . . . . . . . . . . . .

What is in the Box? . . . . . . . . . . . . . . . . . . . . .

. HMI . . . . . . . . . . . . . . . . . . . . . . . . .

. Sensor Platform. . . . . . . . . . . . . . . . . . . . .

. G-Pod . . . . . . . . . . . . . . . . . . . . . . . .

Installation Information . . . . . . . . . . . . . . . . . . .

. HMI Installation . . . . . . . . . . . . . . . . . . . .

. Sensor Platform Installation . . . . . . . . . . . . . . . .

. G-Pod Installation . . . . . . . . . . . . . . . . . . .

Electrical Installation . . . . . . . . . . . . . . . . . . . .

. HMI Power Inputs . . . . . . . . . . . . . . . . . . .

. Sensor Platform Connections. . . . . . . . . . . . . . . .

. Sensor Platform Termination Resistor . . . . . . . . . . . . .

. Relay Connections . . . . . . . . . . . . . . . . . . .

. Wiring Diagram . . . . . . . . . . . . . . . . . . . .

. Cable Information . . . . . . . . . . . . . . . . . . .

HMI Operation . . . . . . . . . . . . . . . . . . . . . .

. HMI Power On. . . . . . . . . . . . . . . . . . . . .

. Information . . . . . . . . . . . . . . . . . . . . . .

. Settings . . . . . . . . . . . . . . . . . . . . . . .

. Incorrect PIN . . . . . . . . . . . . . . . . . . . . .

. Change PIN . . . . . . . . . . . . . . . . . . . . .

. Test Relays . . . . . . . . . . . . . . . . . . . . . .

. Gas Alarms - Alarm Levels. . . . . . . . . . . . . . . . .

. Gas Alarms - No Active Alarms . . . . . . . . . . . . . . .

. Gas Alarms - Warning Alarm Active. . . . . . . . . . . . . .

. Gas Alarms - Danger Alarm Active . . . . . . . . . . . . .

. Gas Alarms - Mutable Alarms . . . . . . . . . . . . . . .

G-Shield Instruction Manual

Version 14

Calibration . . . . . . . . . . . . . . . . . . . . . . .

. Calibration Reminder . . . . . . . . . . . . . . . . . .

. Response Test. . . . . . . . . . . . . . . . . . . . .

. HCN G-Pod Response Test . . . . . . . . . . . . . . . .

. CO G-Pod Response Test . . . . . . . . . . . . . . . . .

. HCN G-Pod Zero Calibration . . . . . . . . . . . . . . . .

. HCN G-Pod Span Calibration . . . . . . . . . . . . . . . .

. CO G-Pod Zero Calibration . . . . . . . . . . . . . . . .

. CO G-Pod Span Calibration . . . . . . . . . . . . . . . .

. Cancel Calibration . . . . . . . . . . . . . . . . . . .

. Calibration Due . . . . . . . . . . . . . . . . . . . .

Error Messages . . . . . . . . . . . . . . . . . . . . . .

. Communications Error . . . . . . . . . . . . . . . . . .

Specifications . . . . . . . . . . . . . . . . . . . . . .

. Electrical . . . . . . . . . . . . . . . . . . . . . .

. Construction . . . . . . . . . . . . . . . . . . . . .

. Environmental . . . . . . . . . . . . . . . . . . . . .

. G-Pod Dimensions . . . . . . . . . . . . . . . . . . .

. Sensor Platform Dimensions . . . . . . . . . . . . . . . .

. HMI Dimensions . . . . . . . . . . . . . . . . . . . .

. HMI Enclosure Dimensions . . . . . . . . . . . . . . . .

Spare Parts List . . . . . . . . . . . . . . . . . . . . . .

Maintenance . . . . . . . . . . . . . . . . . . . . . . .

. Clean the Splash Guard . . . . . . . . . . . . . . . . .

. Dummy Plug . . . . . . . . . . . . . . . . . . . . .

Gastech Policy Statements . . . . . . . . . . . . . . . . . .

G-Shield Instruction Manual

Version 15

5 List of Figures

Figure . G-Shield Fire HMI shown in optional enclosure with two Sensor Platforms and a G-Pod.

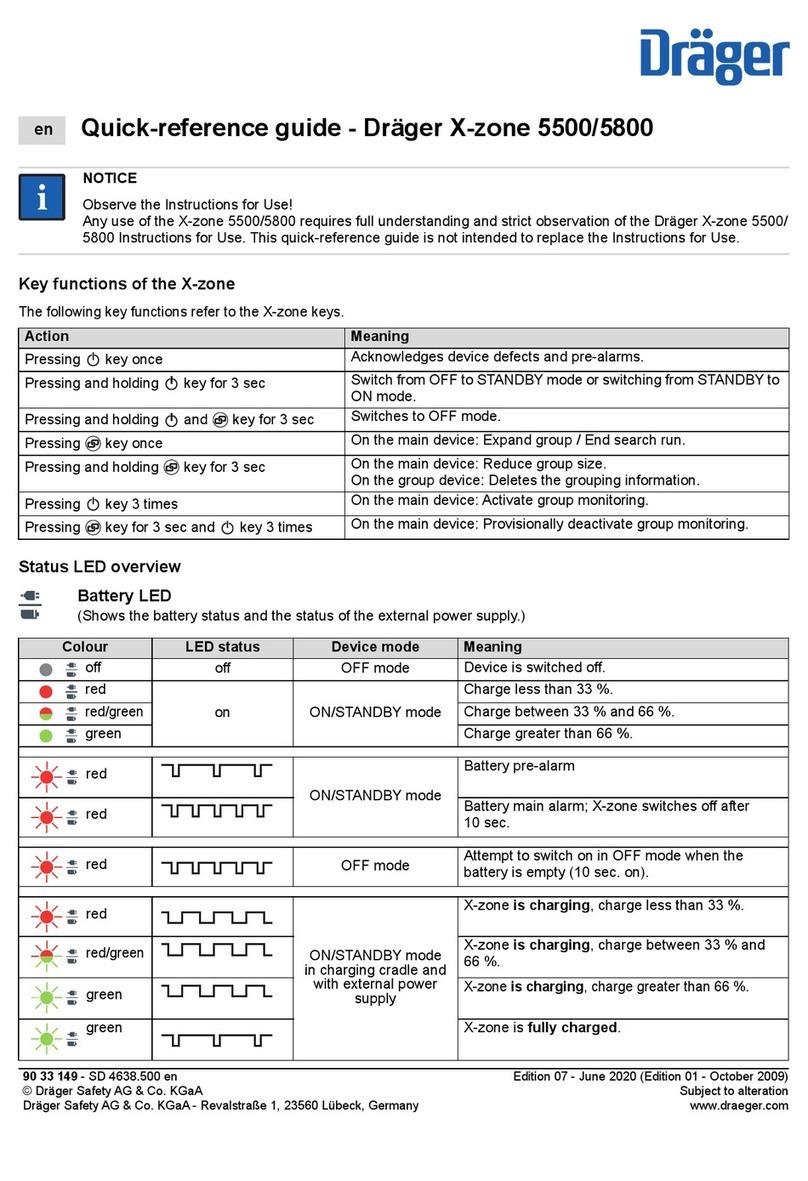

Figure . Keywords and symbols used in this manual.

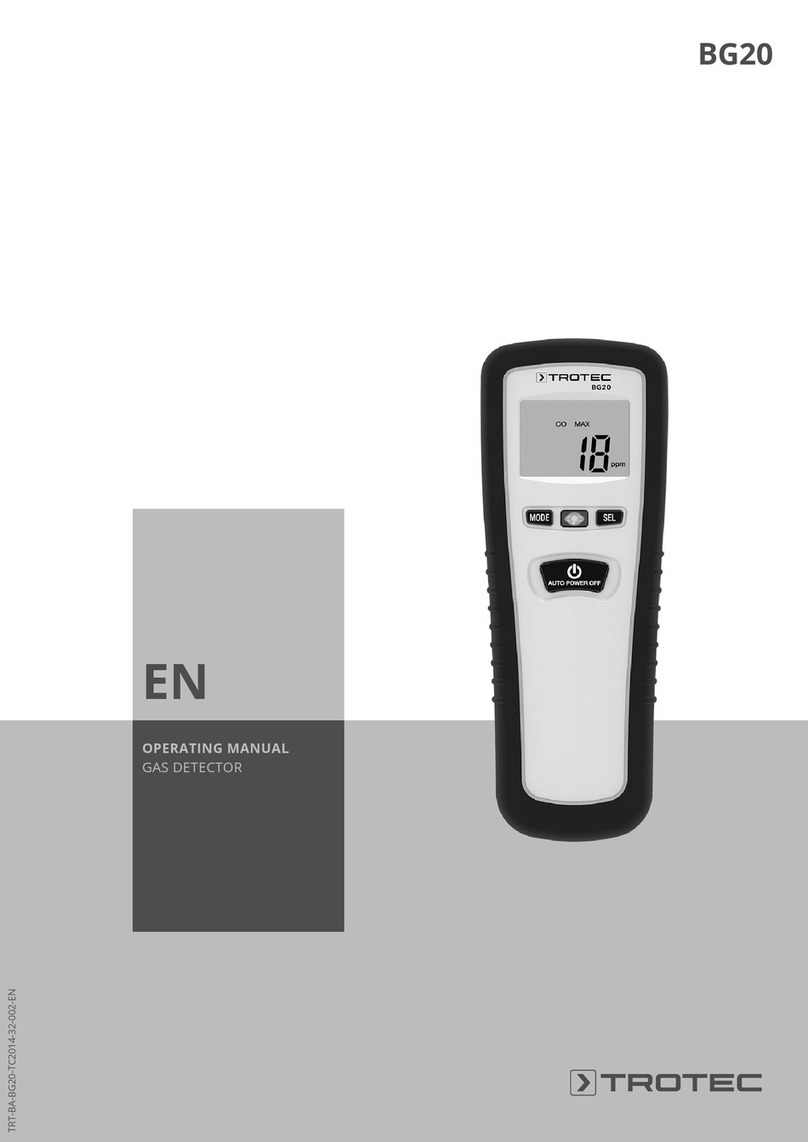

Figure . The G-Shield Fire HMI.

Figure . The G-Shield Fire HMI fitted to its optional enclosure.

Figure . Sensor Platform with G-Pod fitted.

Figure . The G-Pod has electrical connections and an alignment key.

Figure . G-Shield HMI dashboard cutout.

Figure . G-Shield Fire HMI enclosure rear view showing VESA mounts.

Figure . Sensor platform exploded view.

Figure . Splash Guard.

Figure . G-Pod key and Sensor Platform keyway.

Figure . Bushing Nut with Grub screw.

Figure . HMI electrical connections.

Figure . Input power connection details.

Figure . Sensor Platform connection details.

Figure . SW set to the ON position on Sensor Platform .

Figure . Relay connection details.

Figure . Relay connection details.

Figure . G-Shield Fire system wiring diagram.

Figure . HMI user interface icons.

Figure . HMI home screen user interface.

Figure . HMI Power on.

Figure . HMI Power on after power interruption.

Figure . Alarm levels.

Figure . Home screen - no gas detected.

Figure . HCN Warning Alarm On.

Figure . CO Warning Alarm On.

Figure . HCN Danger Alarm On.

Figure . Push to mute Danger Alarm.

Figure . CO Danger Alarm On

Figure . Co Danger Alarm muted.

Figure . Calibration equipment.

Figure . Calibration reminder.

Figure . Calibrate now.

Figure . Response test gas requirements and pass criteria.

Figure . HCN response test too high.

Figure . HCN response test too low.

Figure . CO response test too high.

Figure . CO response test too low.

Figure . Sensor calibration due.

Figure . Error messages.

Figure . Sensor communication error.

Figure . G-Pod dimensions.

Figure . Sensor Platform dimensions.

Figure . HMI dimensions.

Figure . HMI enclosure dimensions.

Figure . List of spare parts.

Figure . HMI enclosure assembly.

Figure . Sensor Platform assembly.

Figure . Dummy Plug fitted to Sensor Platform.

G-Shield Instruction Manual

Version 16

6 Keywords and Symbols Used in This Manual

Symbol Keyword Description

Warning WARNING: Do not (warning text). Can cause injury or

death to personnel.

No

Symbol Caution CAUTION: Do not (caution text). Can cause damage

to parts or equipment.

HMI Human Machine Interface

(Shown with optional stainless steel enclosure).

Sensor Platform Sensor Platform with Splash Guard attached.

G-Pod G-Pod sensor module.

Splash Guard The Splash Guard gives protection to the G-Pod

from changes in environmental conditions.

Dummy Plug The Dummy Plug gives protection to the Sensor

Platform when a G-Pod is not fitted.

MODBUS MODBUS® is a data communications protocol

developed by Modicon now Schneider Electric.

7 Intended use

The G-Shield Fire detects HCN and CO outside the vehicle and displays the results on

the HMI.

WARNING: The G-Shield Fire detects HCN and CO. These gases can cause injury or

death to personnel.

WARNING: The G-Shield Fire is not a personal gas detector. If you do not use a

personal gas detector this can cause injury or death to personnel.

Figure 2. Keywords and symbols used in this manual.

WARNING: Do not use the G-Shield Fire in an explosive or oxygen rich atmosphere.

An explosion can cause injury or death to personnel.

G-Shield Instruction Manual

Version 17

8 Safety Precautions

Read all safety warnings before you install or operate this equipment.

9 What is in the Box?

The HMI has a touch panel display with connections for power, communications, and

external alarms. An RS-485 data port connects the HMI to the Sensor Platforms. Refer

to section 11, Electrical Installation.

Figure 3. The G-Shield Fire HMI.

The G-Shield Fire is available with an enclosure. Use the enclosure when it is not

possible to install the HMI directly into the dashboard. The enclosure is compliant with

the VESA 75 requirements.

9.1 HMI

Figure 4. The G-Shield Fire HMI fitted to its optional enclosure.

G-Shield Instruction Manual

Version 18

9.2 Sensor Platform

The Sensor Platform supplies the electrical connections for the G-Pods. The Sensor

Platform uses RS-485 and MODBUS RTU.

Figure 5. Sensor Platform with G-Pod fitted.

9.3 G-Pod

The G-Pod is a smart, hot-swappable gas detector that contains calibration

information and sensor data.

Calibrate the G-Pod in the workshop or maintenance section for fast deployment.

The G-Shield Fire is supplied with one HCN G-Pod, and one CO G-Pod.

Figure 6. The G-Pod has electrical connections and an alignment key.

G-Shield Instruction Manual

Version 19

10 Installation Information

WARNING: The G-Shield must be installed by an approved person. Incorrect

installation can cause injury or death to personnel.

10.1 HMI Installation

Install the HMI into the vehicle cab. You can install it directly into the dashboard or use

the optional stainless steel enclosure. The enclosure has an industry standard VESA

75 attachment on its rear cover.

WARNING: The HMI can distract the driver and cause an accident. An accident can

cause injury or death to personnel.

Figure 7. G-Shield HMI dashboard cutout.

Figure 8. G-Shield Fire HMI enclosure rear view showing VESA 75 mounts.

G-Shield Instruction Manual

Version 110

Figure 9. Sensor platform exploded view.

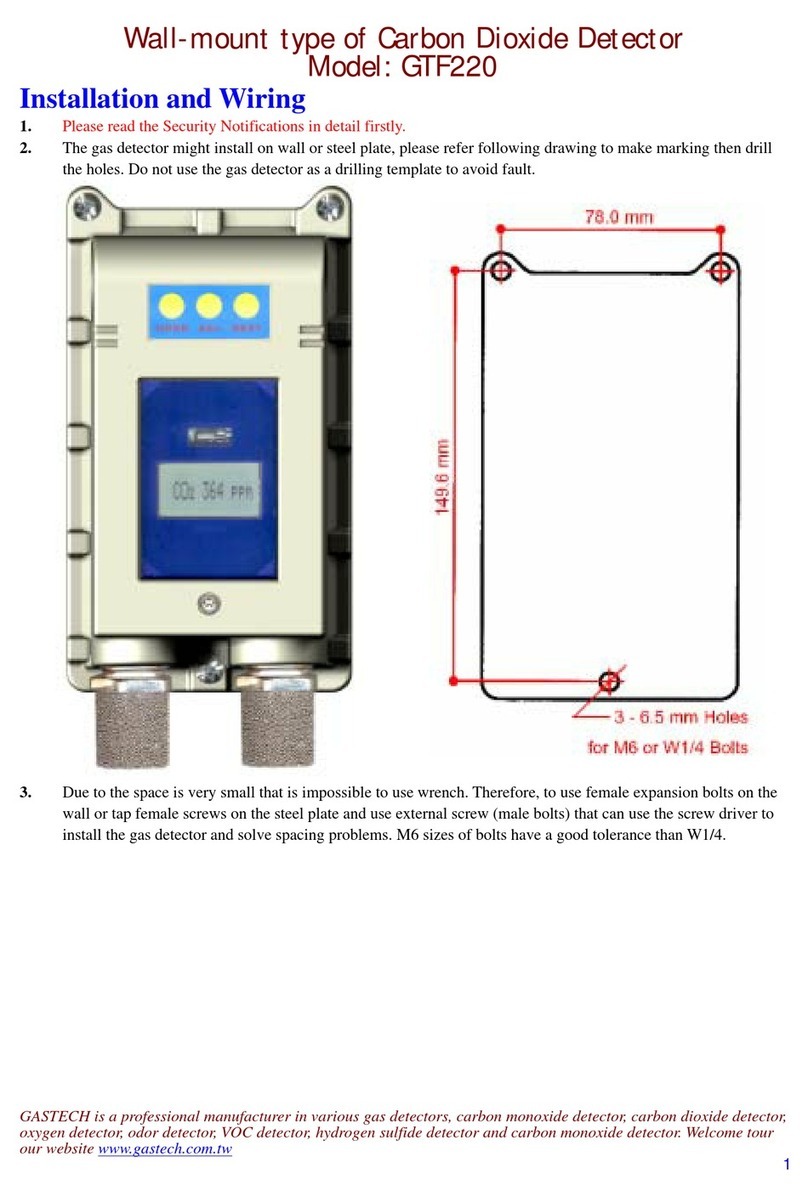

Install the Sensor Platforms vertically at the rear of the vehicle. Make sure the G-Pod

sinter faces the ground. Use the M25 x 1.5P thread to attach the Sensor Platform to the

vehicle. Torque the Mounting Nut to between 12Nm and 20Nm. Gastech recommends

finger tight and ⁄ of one turn. You can use Loctite® 243™ Threadlocker to make sure

the nut does not loosen because of vibration.

CAUTION: The G-Pod sinter must face towards the ground. Sudden pressure changes can

cause a loss of accuracy.

Replace the G-Pod with a Dummy Plug (P/N 65-2000-00) during maintenance. Refer to

section 17.2.

CAUTION: Do not try to attach the Splash Guard when a Dummy Plug is installed as it will not

fit.

10.2 Sensor Platform Installation

Make sure a Splash Guard is used when a G-Pod is attached to the Sensor Platform.

The Splash Guard provides protection to the G-Pod from wind and water.

Figure 10. Splash Guard.

CAUTION: Do not exceed 20Nm when the Mounting Nut is tightened. Damage can be caused

to the gasket.

G-Shield Instruction Manual

Version 111

10.3 G-Pod Installation

Align the key on the G-Pod with the keyway on the Sensor Platform. Push the G-Pod

into the Sensor Platform.

CAUTION: Sensor Platforms are supplied without a G-Pod installed. Make sure you install a

G-Pod.

The Bushing Nut attaches the G-Pod to the Sensor Platform. Hold the Bushing Nut in

position with the Grub screw. Tighten the Grub screw with the supplied 1.3 mm hex

wrench. Do not use thread lock.

NOTE: You will notice some resistance as air is expelled from between the G-Pod and

the Sensor Platform. This is normal.

CAUTION: Do not overtighten the Grub screw. The Grub screw can damage the threads on

the Sensor Platform.

Figure 11. G-Pod key and Sensor Platform keyway.

Figure 12. Bushing Nut with Grub screw.

G-Shield Instruction Manual

Version 112

11 Electrical Installation

Connect the G-Shield Fire to a DC supply voltage of 9 to 30V. The G-Shield Fire can

be installed into vehicles with a 12V DC or 24V DC electrical system.

Figure 13. HMI electrical connections.

The HMI has 2 inputs for power.

VBAT supplies constant power to the Sensor Platforms. VBAT connects internally

to VOUT+ on the sensor RS-485 connection. Constant power is necessary for the

G-Pods. Connect the vehicle battery input to VBAT.

ACC supplies power to the HMI. Connect the vehicle accessories circuit to ACC. The

HMI will turn on and o with the vehicle ignition.

11.1 HMI Power Inputs

Label Connection Description Rating

VBAT Positive supply from vehicle battery 9 - 30 VDC

GND GND connection

ACC Positive supply from vehicle accessories circuit 9 - 30 VDC

Figure 14. Input power connection details.

WARNING: The G-Shield must be installed by an approved person. Incorrect

installation can cause injury or death to personnel.

G-Shield Instruction Manual

Version 113

Label Connection Description

VOUT+ Positive supply voltage to Sensor Platform

A+ Signal A

B- Signal B

GND GND supply voltage to Sensor Platform

Figure 15. Sensor Platform connection details.

Label Connection description

NO Normally open relay contact

COM Common relay contact

NC Normally closed relay contact

Label Connector description

NO Normally open relay contact

COM Common relay contact

NC Normally closed relay contact

Figure 16. SW1 set to the ON position on Sensor Platform 2.

Figure 17. Relay 1 connection details.

11.2 Sensor Platform Connections

The HMI has 2 relay outputs to connect external equipment. The relays are activated

when the gas detected reaches the danger alarm level. See section 12.6 Test Relays.

RS-485 is a balanced transmission standard. The end of the electrical transmission

line must have a termination resistor. Set the switch SW1 to the ON position to use the

built-in termination resistor for Sensor Platform 2.

Figure 18. Relay 2 connection details.

11.3 Sensor Platform Termination Resistor

11.4 Relay Connections

G-Shield Instruction Manual

Version 114

11.5 Wiring Diagram

Figure 19. G-Shield Fire system wiring diagram.

11.6 Cable Information

Use four core sheathed cable between the HMI and the Sensor Platforms. The

maximum cable length permitted is 20m.

Use stranded tinned copper conductors in a PVC jacket. Cable size of 16 AWG to

22 AWG is suitable. The maximum allowable outside diameter (OD) is 6.5mm. Use

insulated bootlace ferrules to avoid damage to the copper conductors.

NOTE: You can use equivalent alternatives for this item.

The G-Shield Fire has two Sensor Platforms. Use a suitable cable to connect the HMI

to the first Sensor Platform and use the same specification cable to connect to the

second Sensor Platform. Refer to section 11.6 Cable Information.

Gastech recommends inline fuses for both power feeds. Refer to figure 19 for the fuse

values.

NOTE: The vehicle may already have adequate fuse protection.

G-Shield Instruction Manual

Version 115

12 HMI Operation

The HMI controls the G-Shield. It shows gas level, Sensor Platform status, and alarm

indication. The HMI has a capacitive touchscreen interface and uses custom icons and

text to give information to the user.

Figure 20. HMI user interface icons.

Figure 21. HMI home screen user interface.

Icon Description Icon Description

Back button Enter button

Home button Information button

Save button Settings button

Undo button

G-Shield Instruction Manual

Version 116

12.1 HMI Power On

The vehicles accessory circuit provides power to the HMI. When the vehicles ignition

is switched to ACC the HMI will turn on.

NOTE: Constant power is supplied to the Sensor Platforms through the VBAT

connection on the HMI.

Power applied to

HMI

Splash screen

G-Shield power

up completed

NOTE: The G-Shield is ready for use within one minute.

G-Shield is

ready for use

Power interruptions to the G-Pods require an additional warm up period. Interruptions

can be caused by routine maintenance to the vehicles electrical system or from failure

of the electrical system.

G-Pod power interruptions occur when VBAT is disconnected or when a G-Pod is

replaced.

Figure 22. HMI Power on.

G-Shield Instruction Manual

Version 117

The G-Shield follows an extended power up sequence when power is first applied to

the G-Pods.

Power applied to

HMI

G-Shield waits

for G-Pods to

stabilize

Sensor

Platforms

detected

Splash screen

G-Shield is

ready for use

G-Shield power

up completed

The G-Shield is prepared for use when the G-Pods complete their five minute

warm-up.

Figure 23. HMI Power on after power interruption.

G-Shield Instruction Manual

Version 118

12.2 Information

The information screen shows details of the installed sensors, the HMI firmware

version, and the telephone number for tech support.

The HMI home screen provides access to important system information.

Step 1. Push for three seconds. Step 2. Push to return to the home screen.

12.3 Settings

The settings menu is protected by a Personal Identification Number (PIN) code and is

accessed from the home screen.

Step 1. Push for three seconds. Step 2. Default PIN code is four zeros.

Step 3. Type in the PIN code. Push Step 4. Push to return to the home screen.

If the PIN code is not recognized please refer to section 12.4 Incorrect PIN.

NOTE: PIN codes can be four to six digits long. Each character is masked for security

purposes.

G-Shield Instruction Manual

Version 119

12.4 Incorrect PIN

The user has typed an incorrect PIN code. This example shows seven digits have

been entered. PIN codes must be four to six digits in length.

The HMI gives instant feedback if an incorrect PIN is entered. The input field is

automatically cleared and a message is displayed.

NOTE: There is no limit to the amount of times an incorrect PIN can be entered.

Contact Gastech if you have forgotten the PIN code.

Step 1. Push to continue Step 2. Type in PIN again.

12.5 Change PIN

Step 2. Type in the current PIN code.Step 1. Push to continue

Step 3. Push to continue. Step 4. Type in a new PIN code.

G-Shield Instruction Manual

Version 120

Step 5. Push to continue. Step 6. Type in the same new PIN code.

Step 7. Push to continue. Step 8. The PIN code has been changed.

If the PIN codes do not match, the HMI will display this screen.

NOTE: There are no limits to the number of times you can attempt to key in the new

PIN code.

If you cannot recall the new PIN code chosen, then push to start the change PIN

code operation again.

To stop the PIN code change, push until the Settings screen is shown. Push

to return to the home screen.

Step 9. Type in the same new PIN code.

Table of contents

Other GasTech Gas Detector manuals

GasTech

GasTech D-Guard2S User manual

GasTech

GasTech F-GUARD UVIR User manual

GasTech

GasTech Cannonball 3 User manual

GasTech

GasTech F-Guard-IR3-H2-HD User manual

GasTech

GasTech F-Guard-UV-IR-HD User manual

GasTech

GasTech D-Guard2 User manual

GasTech

GasTech GTF220 User manual

GasTech

GasTech F-Guard-IR3-H2 User manual

GasTech

GasTech D-Guard User manual

GasTech

GasTech GTD2000-Tx User manual