Gate Motors MyGate myAster Series User manual

REVISION 2019-2

automation Kit for swing gates

myAster

GateMotors: +44 (0)1202 744958 • Technical support: +44 (0)1202 725489

www.gatemotors.co.uk • Sales and Accessories: +44 (0)1202 717191

ENGLISH

Installation Manual

BY

REVISION 2019-2

KG

Use and installation of the product

must comply with Machinery

Directive 2006/42/CE.

Verify that the system is EN 124445

and EN 12453 standard compliant.

Installation must be carried out by

qualified personnel who are aware of

the associated potential hazards, and

are operating in full compliance with

current regulations.

General safety precautions

This manual contains important information for the safety of consumers.

An improper installation can result in serious injury to people and/or property.

Before beginning the installation it is absolutely necessary to read this manual in its entirety.

Save this manual for future consultation.

GateMotors: +44 (0)1202 744958 • Technical support: +44 (0)1202 725489

www.gatemotors.co.uk • Sales and Accessories: +44 (0)1202 717191

The myAster motor is designed to automate swing gates. The use

of this product for purposes other than those described above

and installation executed in a manner other than instructed in this

technical manual are prohibited.

All myAster systems are irreversible, therefore an electric lock is

not essential – but an electric lock is recommended for additional

security, or for use in areas exposed to high-winds. The electric

lock must be installed on the gate leaf that opens first and must

be connected with the terminals of the control unit.

If fitting an electric lock, remove all manual locks and bolts.

In the event of a power cut the gate motor can be released by

manual operation.

Use of the product must be restricted to its intended use. Any

other use is to be considered dangerous and therefore forbidden.

Do not allow children to play with the fixed command devices, or

in the gate’s area of operation. Keep any remote control devices

(i.e. transmitters) away from children.

Keep the gate and the gate opener regularly maintained. Use only

myGate or GateMotors supplied spare parts.

Users are strictly forbidden to carry out any changes on the gate

motor.

GateMotors is not liable for any damage resulting from improper,

wrongful or unreasonable use.

The use of this equipment must observe the safety standards in

force in the country where it is installed, as well as the standards

governing proper installation.

KG

KG

KG

KG

KG

KG

KG

KG

KG

KG

KG

KG

KG

Any lawn watering devices

must not wet the gate

motor from the bottom up.

There is sufficient

space for manual

release.

The opening of the automated

gate is not an entrapment

hazard with regards to any

surrounding fixed parts.

Intended use and application

PRE-INSTALLATION

CHECKLIST

Verify that the technical features

fit your installation needs.

The gate hinges are in

good condition and

are suitably lubricated.

The gate leafs

swing freely and are

clear of obstruction

The gate has mechanical

stops in both the open

and closed positions.

Always cut off the power

during the installation or

maintenance of any parts.

The gates are NOT on

either an upward

or downward slope.

KG

KG

KG

KG

KG

KG

KG

KG

KG

KG

REVISION 2019-2

Tools and xings

RECOMMENDED FIXINGS

(not included)

REQUIRED TOOLS

Brick

Screw and wall plug

Concrete

Concrete anchor

Metal pillar

Nut and bolt

Steel

Lock nut

Steel / Aluminium

Nut and bolt

Wood

Wood screw

RECOMMENDED

GATE LEAF FIXINGS

(not included)

GateMotors: +44 (0)1202 744958 • Technical support: +44 (0)1202 725489

www.gatemotors.co.uk • Sales and Accessories: +44 (0)1202 717191

myAster dimensions

50 mm

119 mm

169 mm

myAster 3 = 665 mm

myAster 4 = 765 mm

myAster 5 = 865 mm

myAster 6 = 965 mm

myAster 3 = 980 mm

myAster 4 = 1180 mm

myAster 5 = 1380 mm

myAster 6 = 1580 mm

TOP ELEVATION

SIDE ELEVATION CLOSED SIDE ELEVATION OPEN

88 mm

REVISION 2019-2

myAster 3 myAster 4 myAster 5 myAster 6

Power supply 24 Vdc 230 V ~ 50 Hz 24 Vdc 23 0V ~ 50 Hz 24 Vdc 230 v ~ 50 Hz 230 V ~ 50 Hz

Absorption 0,5-0,75 A 1.2 - 1.7 A 0,5-0,75 A 1.2 - 1.7 A 0,5-0,75 A 1.2 - 1.7 A 1.2 - 1.7 A

Motor power 50 W 280 W 50 W 280 W 50 W 280 W 280 W

Capacitor -- 8 µF -- 8 µF -- 8 µF 8 µF

Thermic protection -- 150° -- 150° -- 150° 150°

Maximum thrust 2500 2800 N 2500 2800 N 2500 N 2800 N 2800 N

IP level 44 44 44 44 44 44 44

Revolutions speed 1600 rpm 1400 rpm 1600 rpm 1400 rpm 1600 rpm 1400 rpm 1400 rpm

Leaf’s maximum length 2000 mm 2000 mm 2500 mm 2750 mm 3000 mm 3500 mm 4000 mm

Leaf’s maximum weight 275 Kg 350 Kg 250 Kg 350 Kg 150 Kg 250 Kg 250 Kg

Maximum opening 110º 110º 110º 110º 110º 110º 110º

90º opening time 15” 17” 20” 22” 25” 27” 32”

Duty cycle 80 % 40 % 80 % 40 % 80 % 40 % 40 %

GateMotors: +44 (0)1202 744958 • Technical support: +44 (0)1202 725489

www.gatemotors.co.uk • Sales and Accessories: +44 (0)1202 717191

Technical features

INWARD FACING

A

B

C

ED F G H

myAster Kit Contents (included)

2 x Motors

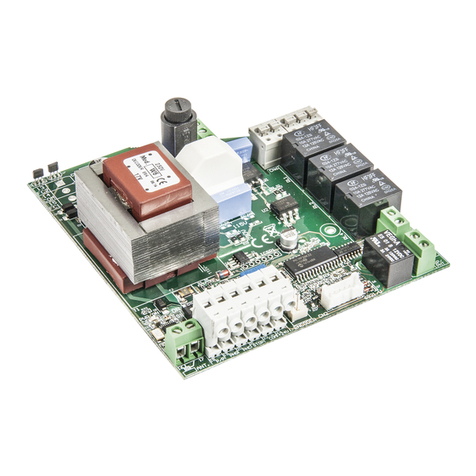

1 x Control Board (with in-built aerial)

2 x Wired Safety Photocells

2 x Radio Remotes

2 x Gate Fixing Brackets S3

2 x Pillar Fixing Brackets T1

2 x Manual Release Keys

2 x Fixing pins

A

B

C

D

E

G

F

H

REVISION 2019-2

GateMotors: +44 (0)1202 744958 • Technical support: +44 (0)1202 725489

www.gatemotors.co.uk • Sales and Accessories: +44 (0)1202 717191

Installing the motor

Motor positioning

Make sure there are mechanical stops (B) for opening and closing.

The motor has to be fitted keeping a height above ground of between 400 mm and 500 mm. If the gate

is particularly light, fit the motor as close as possible to the gate centerline. The motor should not be fitted

lower than 150 mm from ground level. And no more than 600 mm higher than ground level.

Centreline

min height = 150 mm

max height = 600 mm

Left motor Right motor

INWARD FACING

Check that the open position of the automated gate is not an entrapment hazard with regards

to any surrounding buildings or fixed objects and there is sufficient space for manual release.

INSTALLATION INSTRUCTION

SEQUENCE

1Thoroughly read sections: General safety

precautions, and Intended use and application.

2Check all the components.

3Identify the fixing points on the pillar and on

the gate.

4Verify measurement D.

5Adjust bracket T1 as needed.

6Fix the motor to the bracket T1

7Release the motor.

8Fix bracket S3 to the gate.

9Fix the motor ram to the bracket S3.

10 Position the cables as per the Wiring

installation overview.

11 Connect the control unit and all accessories.

12 Program the radio receiver.

13 Program the working times.

REVISION 2019-2

GateMotors: +44 (0)1202 744958 • Technical support: +44 (0)1202 725489

www.gatemotors.co.uk • Sales and Accessories: +44 (0)1202 717191

If the ideal scenario of

measurements Aand B(above)

is unachievable then refer to

the below tables to determine

the position and mounting hole

selection for bracket T1.

D200 mm 175 mm 150 mm 125 mm 100 mm 75 mm 50 mm 25 mm 0 mm

A140 mm 170 mm 200 mm 195 mm 190 mm 185 mm 210 mm 235 mm 260 mm

B150 mm 225 mm 200 mm 205 mm 210 mm 215 mm 190 mm 165 mm 140 mm

Bracket quota 50 mm 50 mm 50 mm 80 mm 110 mm 140 mm 140 mm 140 mm 140 mm

Minimum leaf length 1030 mm 1000 mm 980 mm 990 mm 990 mm 970 mm 970 mm 950 mm 930 mm

myAster 4

D225 mm 200 mm 175 mm 150 mm 125 mm 100 mm 75 mm 50 mm 25 mm

A225 mm 250 mm 245 mm 240 mm 235 mm 260 mm 285 mm 310 mm 335 mm

B275 mm 250 mm 255 mm 260 mm 265 mm 240 mm 215 mm 190 mm 165 mm

Bracket quota 50 mm 50 mm 80 mm 110 mm 140 mm 140 mm 140 mm 140 mm 140 mm

Minimum leaf length 1150 mm 1130 mm 1130 mm 1130 mm 1140 mm 1120 mm 1100 mm 1070 mm 1050 mm

myAster 5

D275 mm 250 mm 225 mm 200 mm 175 mm 150 mm 125 mm 100 mm 75 mm

A275 mm 300 mm 295 mm 290 mm 315 mm 310 mm 335 mm 360 mm 385 mm

B325 mm 300 mm 305 mm 310 mm 285 mm 290 mm 265 mm 240 mm 215 mm

Bracket quota 50 mm 50 mm 80 mm 110 mm 110 mm 140 mm 140 mm 140 mm 140 mm

Minimum leaf length 1300 mm 1240 mm 1280 mm 1260 mm 1260 mm 1270 mm 1240 mm 1220 mm 1200 mm

myAster 6

D150 mm 125 mm 100 mm 75 mm 50 mm 25 mm 0 mm

A100 mm 125 mm 150 mm 145 mm 140 mm 135 mm 160 mm

B200 mm 175 mm 150 mm 155 mm 160 mm 165 mm 140 mm

Bracket quota 50 mm 50 mm 50 mm 80 mm 110 mm 140 mm 140 mm

Minimum leaf length 880 mm 860 mm 840 mm 840 mm 850 mm 850 mm 830 mm

myAster 3

90º

Pillar bracket T1

How to determine xing dimensions

Position the bracket T1 using the measurement Aand Bas indicated

in the below table for an inward opening angle of 90° (pic E).

(pic E)

myAster 3 myAster 4 myAster 5 myAster 6

A150 mm 200 mm 250 mm 300 mm

B150 mm 200 mm 250 mm 300 mm

D125 mm (max.) 175 mm (max.) 225 mm (max.) 275 mm (max.)

(Table A)

REVISION 2019-2

GateMotors: +44 (0)1202 744958 • Technical support: +44 (0)1202 725489

www.gatemotors.co.uk • Sales and Accessories: +44 (0)1202 717191

Fix the pivot bracket T1 onto the pillar by welding or bolting (O

/13 mm bolts), making sure the measurements shown

in the previous table are met. Ensure to keep a minimum distance of 30 mm from the pillar edge as shown (pic H).

In cases of masonry pillars, use chemical or resin to secure the bolts into position. Brackets T1 are supplied in two

versions, left hand and right hand and match the according motor (see picture I). Fix the motor to bracket T1 and place

the pivot pin PR1 through the holes. Keep the pivot pin PR1 oriented downward (pic J).

Fixing pillar bracket T1

Gates xed on the edge/corner of a pillar

In this case the gate can be opened up to 120°. To achieve this, measurement Amust

be equal to or greater than measurement B(pic F).

Based on the figures shown on the previous page (Table A) – Ideally measurement B

(Pic F) will be decreased by the same amount as the Ameasurement is increased.

For example: If installing the myAster 3Ti – measurement A increasing 20 mm (now

170 mm) means measurement B ideally decreases 20 mm (now 130 mm).

Typical gate mounting for swing gates

Gate hinged in the centre of the pillar Gate hinged on the corner of the pillar

Pillar

Gate leaf

Gate leaf

Pillar

Fig. A Fig. B

Min. 30 mm T1 Left

T1 Right

PR1

G1

(pic H) (pic I) (pic J)

Outward opening

• In the case of an outward opening gate, the gate

motor must be positioned on the inside face of

the gate pillar (pic G).

• In this case the measurement A(distance between

the axis of the hinges and the rotation axis of the

motor) has to be measured towards the centre of

the gate, and it is necessary to modify the bracket

T1 to adapt it to the new fixing position (pic G).

• In order to not reduce the size of the passage, the

motor can be positioned in the upper part of the

gate, at a height no less than 2000 mm.

• You can find the position of the front bracket with

the method indicated above, but with the leaf of

the gate open.

• The preferred measurements are the same as

those shown on the previous page (Table A).

• All fastenings must be strong and secure.

(pic G)

(pic F)

OUTWARD FACING

INWARD FACING

INSIDE

FACE

INSIDE FACE

REVISION 2019-2

GateMotors: +44 (0)1202 744958 • Technical support: +44 (0)1202 725489

www.gatemotors.co.uk • Sales and Accessories: +44 (0)1202 717191

• Insert the hexagonal release key (included in the fixing pack) and turn clockwise (pic O).

• The right hand motor will require an anti-clockwise turn (pic P)

• You will now be able to manually open and close your gate.

• If you wish to lock back your system, insert and turn the key in the oppostite direction.

• The gates can be at in any position – since after the first start command the system will return to its default settings.

Manual release

NB: Check the manual opening of the gate leaf before definitively fixing the

bracket S3 to make sure the gate can open fully to your required angle.

To determine the position of bracket S3:

• Put the gate in the closed position.

• Manually release the motor (see below).

• Extend the ram to maximum opening.

• Push back the ram 20 mm. This stops the motor from ‘leaping forward’ (pic K).

• Affix the bracket S3 to the motor ram slot as illustrated (pic L). Place the pivot pin PR1 into the locating hole (pic L).

• Secure the bracket S3 to the gate leaf. Ensure the ram is perfectly straight. Use a spirit level for accuracy.

20 mm

Gate brackets S3

(pic K) (pic L)

(pic O) (pic P)

PR1

S3

Left motor Right motor

REVISION 2019-2

GateMotors: +44 (0)1202 744958 • Technical support: +44 (0)1202 725489

www.gatemotors.co.uk • Sales and Accessories: +44 (0)1202 717191

• Cut off the power before starting the wiring.

• See the control panel instruction manual (separate documentation) and

refer to the Control Board section for guidance.

• A circuit breaker should be fitted close to the gate (3 mm wires) to

protect both the gate control panel and the property’s main fuse box.

A 6Aautomatic breaker or a 16 A single phase breaker complete with

fuses shall be suitable.

• Make sure you have suitable tubing and conduits for the electrical

cables: feed the motors, control panel and accessories separately, in

order to prevent interferences that may result in bad operation.

• Fit the power cable keeping a curve as shown (pic Q) in order to avoid

water backflow inside the motor.

• The power supply lines – to the motors, to the control unit and to the

accessories, must be separated to avoid interferences which could

generate problems to the system.

• Any equipment (either of control or safety) connected to the control

unit must be tension free.

230V

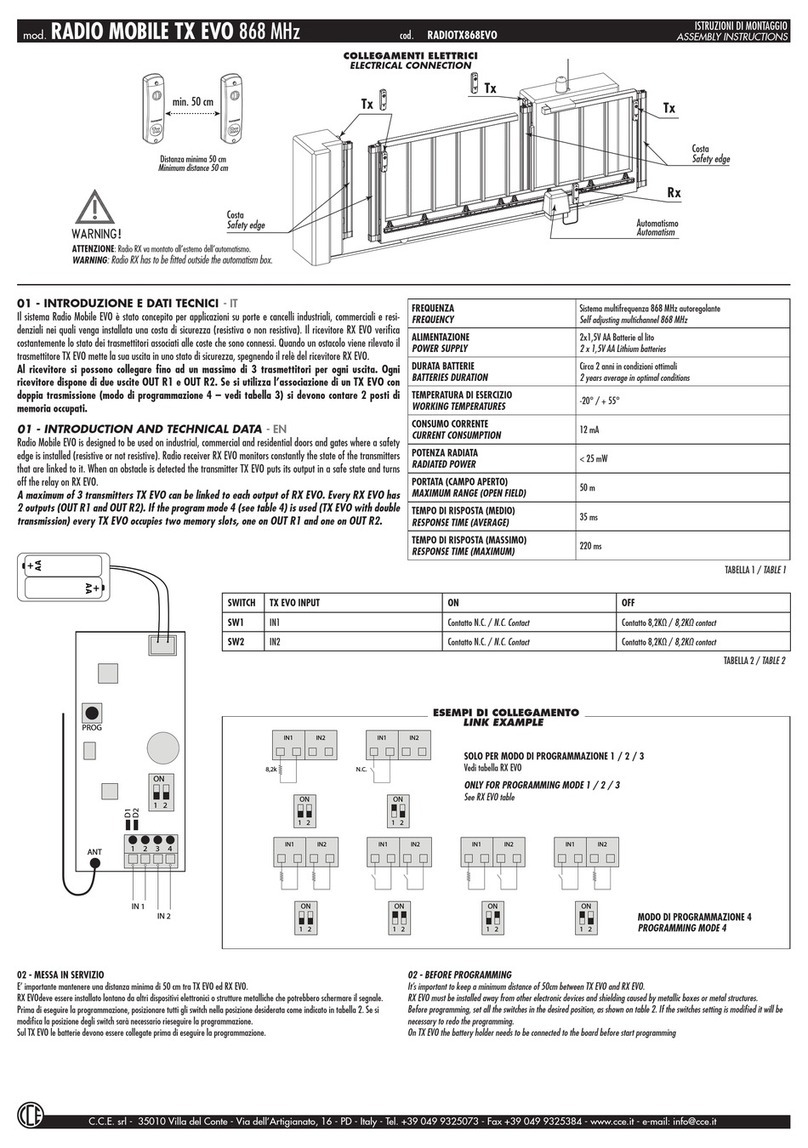

AMotor 3 x l,5 + T

BControl panel 2 X l,5 + T

C

C1

Photocells

Photocells

rx 4 x 0,50 mm2

tx 2 x 0,50 mm2

DKey-switch 2 X 0,50 mm2

EAerial RG58

FRadio receiver 2 X 0,50 mm2

Wiring installation overview

INWARD FACING

(pic Q)

A A

B

D

E

F

C

C1

C

C1

REVISION 2019-2

GateMotors: +44 (0)1202 744958 • Technical support: +44 (0)1202 725489

www.gatemotors.co.uk • Sales and Accessories: +44 (0)1202 717191

Warranty

GateMotors warrants to you that the supplied goods will be free from

defects in workmanship and materials under normal use for a period

of 3 years on mechanical and 1 year on electrical parts from the date

the goods were invoiced.

Any form of warranty provided here is strictly conditional upon

compliance with the instructions for use and maintenance. The

Installation and any maintenance works are the responsibility of who

installs the system.

The warranty is on a ‘return to base’ basis. This means goods must be

returned to us for testing before any further action can be taken.

If a defect arises and a valid claim is received by GateMotors within

the warranty period, the goods should be returned as per instructions

below. Shipping costs will be paid by the customer in the first

instance. If the goods are deemed faulty then shipping costs will be

reimbursed upon proof of purchase.

All goods returned to us for repair or warranty claim will be inspected

and repaired/replaced as necessary.

GateMotors will not be liable for costs incurred relating to removal or

re-installation of goods found to have a manufacturing defect.

The limited warranty does not apply in the event of:

• Opening or repair by someone not authorised by GateMotors.

• Repair or replacement of any goods or part thereof damaged by:

misuse, moisture, liquids, proximity or exposure to heat, abuse,

non-compliance with the installation and/or usage instructions

supplied with the goods, neglect or misapplication.

• Any disfigurement / removal / tampering of any labels attached to

the product will invalidate the warranty.

• Transferring the warranty to any other person. The warranty is

only applicable to the original purchaser.

Under no circumstances and in no way will GateMotors be liable for

damages, including any loss of profits, savings, or other incidental or

consequential damages, resulting from the use or inability to use the

myGate products.

The limited warranty does not affect any legal rights under the

national legislation governing the Consumer Rights Act 2015.

Warranty Repair Guide

Maintenance

Please dispose of responsibly.

Some components may contain hazarrdous waste. They

should be removed and processed by a licensed company.

Before acting always check the local laws on the matter.

Phasing out

and disposal

Periodic maintenance is needed. We suggest checking the state of lubrication and tightness of the

anchoring screws on the motor as well as the good operation of all safety devices and accessories.

You will be required to prove that you purchased

the items directly from us. Please have your

invoice to hand so we can trace your transaction.

Contact technichal support: 01202 725489

If our experts are unable to resolve your

problem proceed to Step 03.

Complete the Customer Returns Request Form:

www.gatemotors.co.uk/returns/

On completion of the form you will be issued

with an SRN number.

Return the item with the SRN clearly

marked on the outside of the box. The SRN will

expire after 21 days and the return will be closed.

• In the event of no fault found a £30 +VAT charge will

be incurred and the item/s will not be returned to

you until receipt of payment. Delivery costs will also

be applicable.

• All items returned that are outside the limited

warranty will incur a testing fee of £30 +VAT before

a quotation is provided for potential repairs.

1

2

3

4

5

REVISION 2019-2

GateMotors: +44 (0)1202 744958 • Technical support: +44 (0)1202 725489

www.gatemotors.co.uk • Sales and Accessories: +44 (0)1202 717191

myGate is a trademark of Proteco S.r.l.

declares that the products listed below:

myAster 3, myAster 4, myAster 5 and myAster 6 – electromechanical gear motor for swing gates

comply with the following Essential Requirements of Directive 2006/42/CE Annex I (Machinery directive):

1.1.2 1.1.3 1.1.S 1.2.1 1.2.2 1 .2.3 1.2.6 1.3.2 1.3.4 1.3.9 1.4.1 1.4.2.1 1.5.1 1.5.4 1.5.6 1.5.8 1.5.13 1.6.1 1.6.4 1.7.1 1.7.3 1.7.4

are in conformity with the following directives:

2004/108/CE (electromagnetic compatibility)

1999/5/CE (R&TTE)

2011 /65/CE (directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment)

The above listed products are delivered, limitedly to the applicable parts, according to the following standards:

- EN 12453 Industrial, commercial and garage doors and gates.

Safety in use of power operated doors. Requirements

- EN 12445 Industrial, commercial and garage doors and gates.

Safety in use of power operated doors. Test methods

- EN60335-1 Safety of household and similar electrical appliances -

Part I: General requirements

- EN60335-2-103 Household and similar electrical appliances -

Part 2-103: Particular requirements for drives for gates, doors and windows

They also state that:

- the relevant technical documentation is compiled in accordance with part B of Annex VII of directive 2006/42/CE

- the relevant technical documentation is compiled and preserved by PROTECO SRL which undertakes to transmit it by mail in

response to a reasoned request by the national authorities.

- the partly completed machinery must not be put into service until th final machinery into which it is to be incorporated has

been declared in conformity with the provisions of the directive 2006/42/CE

EU DECLARATION OF CONFORMITY

This compliance declaration combines the content of separate compliance declarations for any product

mentioned; a copy of the original compliance declaration of each product can be obtained from PROTECO Sri.

Marco Gallo

Managing Director

January 19th 2016

REVISION 2019-2

Screwjack Ltd T/A GateMotors

Pre-Sales Support: +44 (0)1202 717191 • sales@gatemotors.co.uk

Technical Support: +44 (0)1202 725489 • support@gatemotors.co.uk

PRODUCT DETAILS

Gate kit make and model ...............................................................................................................

Serial number .................................................................................................................................

INSTALLER DETAILS

Company name .............................................................................................................................

Installer ..........................................................................................................................................

Telephone number .........................................................................................................................

Signature ....................................................................... Date .....................................................

COMMISIONER DETAILS

Name .............................................................................................................................................

Signature ....................................................................... Date .....................................................

GateMotors: +44 (0)1202 744958 • Technical support: +44 (0)1202 725489

www.gatemotors.co.uk • Sales and Accessories: +44 (0)1202 717191

IMPORTANT: Please ensure the above is filled out at time of installation,

failure to do so may invalidate a warranty claim

This manual suits for next models

4

Table of contents