Gates M6108A User manual

M6108A

TRANSISTOR

MONITOR

AMPLIFIER

9

INSTRUCTION

BOOK

IB

#888

0921

001

GATES

RADIO

COMPANY

•

QUINCY,

ILLINOIS

•

62301

•

U.S.A.

A

division

of

Harris-Intertype

Corporation

.

I

■

■1

o

O

TECHNICAL

DATA

Gain:

Output

Impedance:

1.2

o ms,

approximately.

o

Maximum

Input

Level:

Frequency

Response

:

0

dbm.

Maximum

Output

Level

:

+

59

into

8

o ms

(8

watts).

Harmonic

Distortion:

Maximum

Operating

Ambient

Temperature:

F.)

C.

F.)

0.

Intermodulation

Distortion:

Power

Requirements:

117

Volts

at

50/60

cps.

,

18

watts.

Transistors

:

Noise

Level:

Rectifiers:

Source

Impedances:

(silicon)

4

X5A2

o

Finis :

C

Input

Impedances:

Mounting:

Load

Impedances:

Size

:

deep,

8-1/2

”

long.

Weig t

:

4

lbs

.,

net.

7

lbs.

,

packed.

Cubage

:

0.9

cu.

ft.,

Icmestic

pack.

DESCRIPTION

a

trails-^

o

-1-

+

1.0

db

from

20

to

20,000

cps

@

normal

output

level.

Under

1,0%

from

50

to

15,000

cps

@

+

58

dbm

output

(6

watts).

Under

1.0%

from

50

to

15,000

cps

@

+

59

dbm

output

(8

watts).

55

db

(matc ing

600

o m).

59

db

min.

(bridging

6,000

o m)

Under

1.0%

at

+

58

dbm

equivalent

sine

wave

power

output,

using

40

and

7000

cps

mixed

4:1.

-

85

db

below

rated

output

level

(+

59

dbm).

600

o ms

matc ing

input,

balanced

(transformer

input).

6,000

o ms

,

bridging

input,

balanced

(bridging

pad

and

transformer

input).

Two

key ole

slots,

rubber

bumpers

on

bottom,

permanent

or

movable

mounting,

in

any

position.

2

1

2

Lig t

grey

cover,

flat

black- eat

sink

c assis.

2N1414

2N214

2N1185

2N1225

2N5614

600

o ms

for

600

o ms

matc ing

input.

150/600

for

6000

to

10,000

o m

bridging

input.

1

2

(151°

5-1/4"

ig ,

4-5/8"

(185°

55°

Maximum

Storage

Ambient

Temperature:

85°

4

to

16

o ms

(8

o ms

nominal),

un

balanced

(transformerless

output,

isolated

from

AC

ground

by

power

transformer).

f e

M6108A

:

Monit^j?

Amplifier

is

istorized,

self-contained

amplifier

de

signed

for

use

in

broadcasting,

record

ing,

and

general

sound

reinforcement

applications.

Special

tec niques

ave

been

employed

to

obtain

reliability,

low

distortion,

and

good

temperature

sta

bility.

T e

amplifier

can

be

mounted

in

any

position

and

does

not

require

ventil

ation

w en

andling

8

watts

of

program

material.

T e

input,

power,

output

con

nections,

fuse

and

input

level

control

are

mounted

on

end

panels

of

t e

c assis.

INSTALLATION

MOUNTING

INPUT

CONNECTIONS

AMPLIFIER

PARALLELING

POWER

CONNECTIONS

I

2

3

4

5 6

7

0

GND.

Fi s.

1

NOTE

67

3

I

4

6000-n.

Fig.

2

OUTPUT

CONNECTIONS

M6108

MONITOR

AMPLIFIER

-2-

0

T e

amplifier

as

been

provided

wit

two

key ole

slots

for

#8

screws

for

fixed

or

permanent

mounting.

In

t e

event

t at

a

preamplifier

driver

is

used

requiring

a

minimum

load

of

10,000

o ms,

a

2200

o m

resistor

may

be

added

at

eac

bridging

input

terminal.

Wit

t is

c ange,

1.5

volts

input

wil]

be

required

for

full

output.

W ile

t e

amplifier

can

andle

a

contin

uous

8

watts

of

program

material,

CAUTIC

s ould

be

exercised

during

full

power

sine

wave

testing

to

avoid

exceeding

t e

t ermal

capabilities

of

t e

c assis

eat

sink.

During

t ese

tests

it

is

recommer

ded

t at

a

duty

cycle

of

30

seconds

on

t

5

minutes

off

be

used

to

allow

eat

buil

up

to

dissipate.

Provisions

are

made

for

c anging

from

600

o m

matc ing

to

6,000

o m

bridging

on

t e

input

terminal

strip.

Fig.

1

s ows

t e

connection

for

600

o ms.

Fig.

2

s ows

t e

connection

for

6,000

o m

bridging.

It

is

not

recommended

t at

amplifiers

of

t is

type

be

paralleled

at

t eir

outputs

to

obtain

ig er

power.

W ere

more

pow

er

is

required

t an

can

be

supplied

by

one

amplifier,

t e

speaker

load

s ould

be

divided

between

several

amplifiers

w ic

ave

t eir

inputs

bridged

across

t e

common

signal

source.

Output

connections

are

made

to

t e

two

lug

terminal

strip

on

t e

end

plate

of

t e

c assis.

Groups

of

speakers

may

be

driven

wit

t is

amplifier;

connected

in

series,

parallel,

or

series

parallel;

but

t e

combined

impedance

s ould

not

be

less

t an

4

o ms.

Wit

an

impedance

of

more

t an

12

o ms,

t e

amplifier

will

not

be

able

to

deliver

full

output

power.

Speaker

matc ing

transformers

permit

t e

paralleling

of

a

number

.of

speakers

,

de

pending

on

t e

unit

required.

Gates-

.'

Part

No.

480

0005

000

transformer.-:

is.x"

available,

aving

a

primary

of.

48

.

o ms

and

a

secondary

of

8

o ms

for

matc ing

purposes

.

In

wiring

speaker

loads

it

s ould

be

re

membered

t at

8

watts

at

8

o ms

repre

sents

1

ampere

of

audio

current.

T e

recommended

use

of

No.

16

gauge

twisted

and

s ielded

wire

will

prevent

power

losses

and

possible

interaction

of

cir

cuits.

4

5

.JUMPER

4

a

y

f

I

117

volts

A.C.,

50/60

cycles

is

supplied

t ru

t e

power

cord

and

power

plug

on

t

c assis

end

plate.

A

power

switc

is

no

required

due

to

t e

low

power

consumptic

and

eat

dissipation.

THEORY

OF

OPERATION

When,

he

Q5

L

I

02

Q6

Q4

Q7

•

'1

T2

FI

OS

C9

-3-

CIO

R2

PARTS

LOCATION

M6I08

TRANSISTOR

MONITOR

AMPLIFIER

.1

General

feedback

loops

are

employed

in

t e

amplifier

including

R5,

R19,

02,

04,

and

05•

02

and

04

provide

ig

frequency

feedback

w ile

05

supplies

positive

feed

back

from

t e

output

to

t e

collector

circuit

of

Q2

to

increase

t e

signal

andling

capacity

of

t is

stage.

C7

--------

UNDERSIDE

~~~

-------

PRINTED

BOARD

03

T ermistor

R4

compensates

for

variations

in

t e

amplifier

bias

due

to

temperature

c anges.

C oke

LI

renders

t e

amplifier

insensitive

to

c anges

in

capacity

across

t e

output

leads.

T e

power

supply

is

a

conventional

full

wave

bridge

rectifier

wit

filter

capacitor

circuit.

>

T e

amplifier

is

driven

by

an

input

transformer

w ic

provides

for

isolation

W

and

matc ing

functions

in

t e

primary

by

means

of

split

windings

and

resistive

pads.

T e

input

level

control

provides

a

constant

load

to

t e

input

transformer

secondary

w ile

furnis ing

a

gain

con-

.

trol

function.

Transistor

QI

operates

as

an

emitter

follower

and

provides

im-

oedance

matc ing

from

t e

input

to

t e

oltage

amplifier,

Q2.

Note

t at

Q2

is

t e

only

stage

w ic

as

voltage

gain.

A

ig

frequency

transistor

is

used

at

t is

point

to

improve

stability.

T e

output

stages

of

t e

amplifier

operate

Class

B,

and

are

arranged

in

t e

circuit

configuration

known

as

"single

ended

pus -pull"

or

a

'followed

emitter

follow

er".

T e

upper

and

lower

units

are

in

series

across

t e

power

supply,

and

t e

load

is

connected

at

t eir

junction.

W en

t e

signal

at

t e

collector

of

Q2

goes

negative;

Q5,

Q5,

and

Q7

conduct;

since

t ey

are

all

PNP

types.

signal

goes

positive;

Q4,

Q6,

and

Q8

all

conduct;

since

Q4

is

an

NPN

type.

T us,

t e

full

signal

appears

at

t e

junction

.point.

Q3,

Q5?

Q7»

and

Q6,

Q8

are

con

nected

in

a

compound

or

"Darlington"

configuration,

a

connection

w ic

provi

r

des

extremely

ig

current

gain,

and

im

proves

linearity

at

ig

signal

levels.

’

-J

-A

|

J

_

-

!

--

■'

•

■

>

W<r

a

__

it

■.

■4

16

‘

T7

17

C2

XQI

’

INPUT

OUTPUT

T

B

'

I

,

(7.0

4

16

BLU

+

[20/50

<r

T0i

0.9

1.0

YEL

4,

o

RED

5

GROUND

8RNZ

0.7

1.0

0.9

ui

4

4

co

I

I

I

II

Q

CBI

D

—

*

IA

-33V.

DC

•■•

‘

‘

Si

•

+

o

2

3

EXTERNAL

CONTROL

CONNECTS

TO

TERMINALS

6,I(ARM)B7

x

o

<

R5

56K

R4

T

50K

y

25°C

R6

390

R7

I0K

C5

25/25

4:

+

CRI

X5A2

CR3

QC5A;

C4

.0005

C3

X02

'

^r2NI225'

CR2-

w

X5Ai

CR4

X5A2.

RII

390

►

RIO

•

100

R8

IK

R9

7.5

K

C9

1000/50

X03

2NI4I4

XQ4

2N2I4

RI2

470

R

15

470

XQ5

?NH6i

RI3

51

RI6

51

XQ7

2N36I4

XQ8

2N36I4

SCHEMATIC

M6I08

A

TRANSISTOR

MONITOR

AMPLIFIER

RI7

l,IW

UJ

o

z

<

a:

o

R2

,560

R3

I30K-L-

2NI4I4

x

70

------

C6

-rlOO/3

+

RI9

47K

LI

5uh

+

T

T8

3

28

V.

AC

XQ6

2NII83

T1

478-0187-000

GRN.

<

RI4

S

IJW

“

C7

1000/

85

r£HH

C|

5P/j

5

A

>

RI8

e

22

I

C8

-r

25

200V

I.

ALL

CAPACITORS

IN

MFD,

WITH

D.C.W.-V

,

EXCEPT

WHERE

NOTED.

2

ALL

RESISTORS

I/2W.,

5%

EXCEPT*

I

%

,

AND

WHERE

NOTED.

3.0

DESIGNATES

BOARD

LUG

CONNECTIONS.

4

D

C

VOLTAGES

MEASURED

AGAINST

B+,

WITH

20K-n.

VOLT

METER

,

AT

4

38

08M

OUTPUT.

5.

(

R.M.S.SIGNAL

VOLTAGES

AT

IKC»-

15

DBM

WPUT,

(600^x.

+

38DBM

OUTPUT

*•.05

MAINTENANCE

PREVENTIVE

MAINTENANCE

2.

1.

2.

4.

5.

5.

6.

o

7.

8.

1.

PRINTED

CHASSIS

COMPONENT

REPLACEMENT

CHECKING

COMPONENTS

1.

-5-

T e

condition

of

t e

power

supply

can,

be

most

readily

c ecked

by

measuring

Voltages

may

be

c ecked

wit

Q5,

Q6,

Q?

and

Q8

removed,

provided

t at

t e

speaker

load

is

disconnected.

Do

not

remove

or

insert

transistors

wit

t e

power

on.

W en

servicing

t e

amplifier,

t e

follow

ing

points

s ould

be

observed:

C eck

t e

power

amplifier

supply

voltage

at

t e

collector

of

Q5

or

Q7-

On

t e

power

transistors,

suc

as

t e

2N1183

and

2N?614

,

t e

collector

is

con

nected

to

t e

case.

T e

components

s ould

be

carefully

c eck

ed

by

measuring

circuit

voltages

and

res

istances

before

attempting

to

remove

one

of

t e

leads

from

t e

printed

c assis.

Extreme

care

must

be

exercised

in

remov

ing

t e

lead

to

prevent

damage

to

t e

board

or

conductors.

T is

operation

s ould

not

be

considered

unless

it

is

t e

only

way

t e

component

can

be

c ecked.

Circuit

voltages

are

reversed

from

standard

vacuum

tube

practice,

as

is

t e

polarity

of

all

electrolytic

capacitors.

Do

not

probe

t e

printed

board

wit

a

metal

probe

wit

t e

power

on.

T e

location

of

t e

positive

end

of

eac

electrolytic

capacitor

is

indicated

by

t e

w ite

dot

marked

on

top

of

t e

circuit

board.

T e

M6108

Monitor

Amplifier

is

designed

for

long,

trouble-free

service..

However,

as

wit

all

ig

quality

electronic

equip

ment,

a

regular

program

of

inspection

s ould

be

followed.

T ese

points

s ould

be

covered:

W en

replacing

eit er

Q7

or

Q8»

and

before

turning

on

t e

power,

c eck

wit

an

o m-meter

between

transistor

case

and

c assis

to

make

certain

t at

a

s ort

circuit

does

not

exist.

Note

t at

insulating

was ers

are

placed

under

t e

transistors

to

provide

insulation.

Remove

dust

w ic

collects

on

t e

printed

board

or

in

t e

ousing,

wit

a

soft

brus .

It

is

recommended

t at

w en

t e

ampli

fier

is

first

placed

in

operation,

t at

D.C.

voltages

be

measured

wit

t e

same

voltmeter

t at

will

be

used

for

mainten

ance

and

troubles ooting,

and

t an

t ese

readings

be

recorded

on

t e

amplifier

sc ematic.

T e

speaker

bus

and

B-

volt

ages

s ould

be

recorded

wit

an

wit out

signal,

SERVICING

t e

D.C.

voltage

between

t e

c assis

and

t e

case

of

output

transistor

Q8.

(One

/-x

of

t e

two

power

transistors

mounted

on

'

—

'

t e

end

of

t e

c assis).

T is

voltage

will

be

muc

ig er

or

lower

t an

nor

mal

if

trouble

is

present

in

t e

power

amplifier.

If

one

lead

must

be

removed

wit out

dam

age

to

t e

component,

apply

a

well

clean

ed

and

tinned

25

to

60

watt

iron

to

t e

fillet

adjacent

to

t e

lead.

Wit

small

long

nose

pliers

or

t in

screwdriver,

pry

t e

folded

portion

of

t e

lead

in

line

C eck

t e

speaker

bus

voltage

,

w ic

appears

at

t e

collectors,

or

cases

of

Q6

and

Q8.

3.

Circuit

resistances

s ould

be

meas

ured

only

after

removing

t e

associated

transistor

or

transistors,

to

prevent

damage

due

to

o m-meter

battery

voltage.

s arp

cutters.

pliers

B

A

RESOLDERING

THE

COMPONENT

LEAD

2.

I

FdLg.

6

-

Installing

New

Component

Fig.

3

-

Cleaning

Holes

pliers

Fig.

4

-

Removing

Lead

REPLACING

COMPONENTS

3<

-6-

£

■M

fold

&

clip

ere

F

<

/

3

iron

tip

clip

leads

i<

i

bottom

view

of

c assis

iron

tip

Fig.

5

“

Removing

Components

After

removing

t e

leads

,

prepare

t e

c assis

for

t e

new

component

as

explain

ed

in

paragrap

2

and

Fig.

3«

Wit

t e

iron

applied

to

t e

fillet,

pull

t e

wire

gently

out

of

t e

component

side

of

t e

c assis:

Be

sure

t e

component

lead

is

straig t

and

free

of

solder.

Pus

it

gently

back

t ru

t e

ole

until

some

of

it

s ows

on

t e

ot er

side.

Solder

carefully

but

rapidly

to

prevent

c assis

damage.

To

replace

t e

component,

fold

t e

leads

on

t e

new

part

to

t e

same

spacing

as

t e

mounting

oles.

Insert

t e

part

and

fold

t e

leads

under

t e

c assis

to

old

t e

component

firmly

against

it:

Components

can

be

replaced

wit

less

c ance

of

damage

to

t e

c assis

t an

t e

removal

and

rewiring

of

one

of

t e

leads.

Remove

as

follows:

Clip

t e

leads

close

to

t e

body

of

t e

component.

Heat

t e

fillet

and

gently

pus

t e

wire

t ru

un-

;il

t e

ook

may

be

clipped

off.

Clip

t e

ook

off

(on

t e

soldered

side)

wit

T e

base

material

used

on

t e

printed

c assis

is

t e

best

available

for

t is

service.

T e

two

ounce

copper

is

twice

as

eavy

as

used

in

average

applications

of

t is

type

of

equipment.

T is

assures

reliable

service

and

repair.

wit

t e

ole.

Applying

t e

iron

for

more

t an

four

seconds

at

a

time

may

dam-

.^age

t e

c assis

base

material.

VX

Remove

as

muc

solder

from

t e

lead

as

possible.

Remove

all

t e

kinks

in

t e

wire.

Wit

eat

applied,

gently

pull

t e

wire

t roug

t e

ole.

If

t e

component

is

good,

replace

as

fol

lows:

Use

a

metal

twist

drill

(1/8

”

dia.

or

less)

to

clear

t e

ole

only

in

t e

fillet

of

solder.

Turn

wit

t e

fingers

only.

Remove

solder

slowly

to

prevent

t e

drill

from

tearing

t e

fillet.

Clip

off

t e

excess

wire.

Place

t e

iron

on

bot

t e

component

lead

and

fillet.

Solder

carefully

and

rapidly

to

prevent

damage

to

t e

c assis

base.

If

one

of

t e

conductors

is

damaged,

it

is

seldom

necessary

to

scrap

t e

printed

c assis.

Lay

a

small

piece

of

wire

(#18

to

24

ga.)

across

t e

break

and

solder

eac

end

to

t e

conductor.

If

t e

fillet

is

pulled

loose,

break

it

off

to

get

rid

of

t e

loose

end.

Fold

t e

new

component

lead

to

lay

on

t e

con

ductor

and

solder.

If

.t e

component

lead

is

too

s ort,

solder

in

anot er

piece

of

wire

to

bridge

t e

gap.

Printed

c assis

construction

places

no

mec anical

strain

on

repairs

of

t is

nature,

t us,

solder

ing

alone

will

provide

sufficient

mec an

ical

strengt

even

wit

eavy

s ock

and

vibration

in

almost

every

case.

PARTS

LIST

o

Symbol

No.

»

Ga es

Par

No.

Descrip ion

606

0116

000

CB1

Circui

Breaker,

1

Amp.

i

384

0062

000

,

Silicon

Rec ifier

494

0135

000

LI

Choke,

RF,

5

uh.

$

478

0187

000

Transformer,

Inpu

T1

Socke

Socke

Socke

Terminal

S rip,

7

erminal

Terminal

S rip,

2

erminal

Terminal

S rip,

2

erminal

Transis or,

2N1414

Transis or,

2N1225

Transis or,

2N214

Transis or,

2N1183

Transis or,

2N3614

XQ1,

XQ2,

XQ3,

XQ4

XQ7,

XQ8

XQ5,

XQ6

CR1,

CR2,

CR3,

CR4

TB1

TB2

TB3

Cl

C2

C3

C4

C5

C6

C7

C8

C9

CIO

Cll

540

0043

000

540

0100

000

559

0002

000

540

0091

000

540

0039

000

540

0073

000

540

0049

000

540

0070

000

540

0025

000

•

540

0039

000

540

0041

000

540

0018

000

542

1074

000

540

0009

000

540

0089

000

614

0218

000

614

0024

000

614

0213

000

380

0014

000

380

0013

000

380

0011

000

380

0012

000

380

0035

000

522

0227

000

500

0818

000

522

0256

000

516

0045

000

522

0242

000

522

0160

000

522

0306

000

506

0006

000

524

0104

000

508

0076

000

516

0087

000

404

0066

000

404

0294

000

913

8826

001

QI,

Q3

Q2

Q4

Q5,

Q6

Q7,

Q8

R2

R3

R4

R5

R6

R7

R8

R9

R10

Rll

R12,

R15

R13,

R16

R14,

R17

R18

R19

Cap.,

50

ufd.,

15

V.

Cap.,

50

uufd.,

500

V.

Cap.,

20

ufd.,

50

V.

Cap.,

.0005

uf.

,

1KV.

±10%

Cap.,

25

ufd.,

25

V.

Cap.,

100

ufd.,

3

V.

Cap.,

1000

ufd.,

25

V.

Cap.,

.25

ufd.,

200

V.

Cap.,

1000

ufd.,

50

V.

Cap.,

.005

ufd.,

100

V.

Cap..

.05

ufd.,

600

V.

Resis or,

560

ohm,

1/2W.

5%

Res.,

130K

ohm,

1/2W.,

5%

Thermis or,

50K

ohm

Res.,

56K

ohm,

1/2W.,

5%

Res.,

390

ohm,

1/2W.,

5%

Res.,

10K

ohm,

1/2W.,

5%

Res.,

IK

ohm,

1/2W.,

5%

Res.,

7.5K

ohm,

1/2W.,

5%

Res.,

100

ohm,

1/2W.,

5%

Res.,

390

ohm,

1/2W.,

5%

Res.,

470

ohm,

1/2W.,

5%

Res.,

51

ohm,

1/2W.,

5%

Res.,

1

ohm,

2W.,

5%

Res.,

22

ohm,

1/2W.,

5%

Res.,

47K

ohm,

1/2W.,

5%

Other Gates Amplifier manuals

Popular Amplifier manuals by other brands

CARVIN

CARVIN Belair212 manual

MTX

MTX thunder X504 owner's manual

Premier Hazard

Premier Hazard ShockWave 9005 installation instructions

Rose electronics

Rose electronics RA180 owner's manual

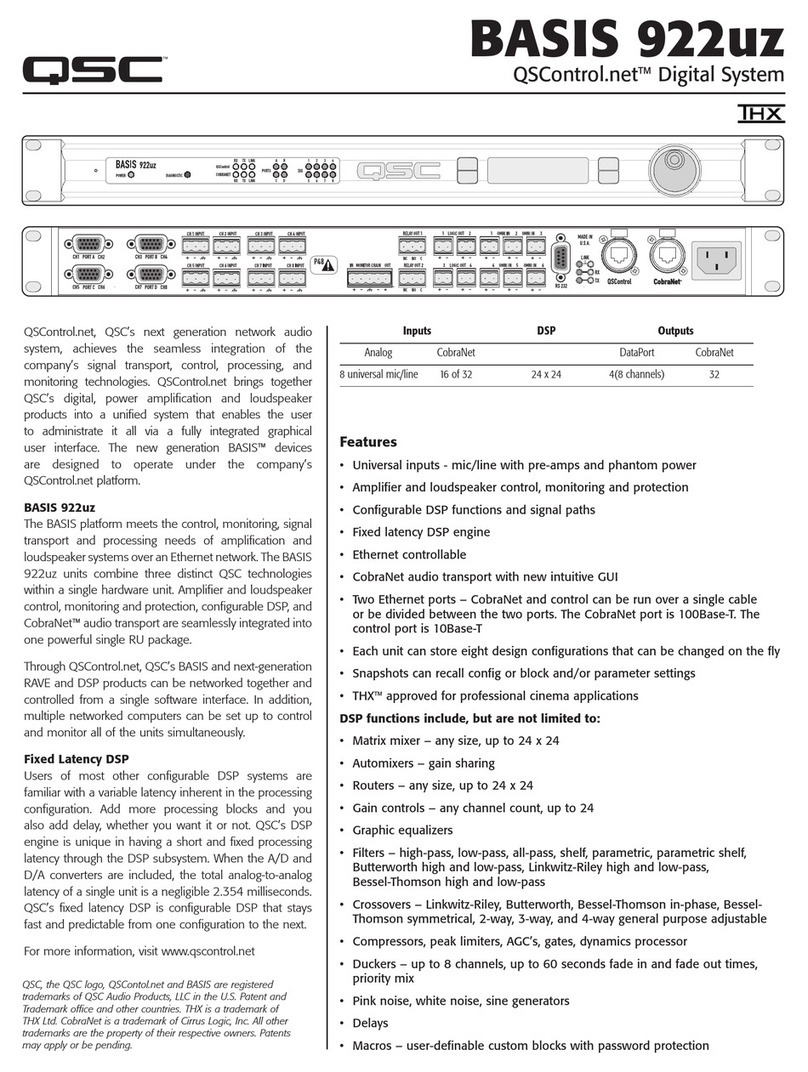

QSC

QSC BASIS 922uz Specification sheet

LY International Electronics

LY International Electronics M-9000 Series user manual