Gates EZ ALIGN RED 7420-1000 User manual

EZ ALIGN™RED

PRECISION LASER ALIGNMENT

OPERATING INSTRUCTIONS

PART NUMBER 7420-1000

2 3

EZ ALIGN™RED PRECISION LASER ALIGNMENT OPERATING INSTRUCTIONS

Thank you for your purchase of the Gates EZ Align™

laser alignment system. These instructions will

introduce you to your new laser pulley alignment

components and their operation. We are confident

that Gates EZ Align™will bring you many years of

productive service if used properly.

The system consists of two units: the laser

transmitter and the reflector. Each unit is equipped

with powerful magnetic brackets that mount to

almost any pulley or sprocket.

Gates EZ Align™is the answer to misalignment

in belt driven machinery. It replaces older, less

accurate methods of pulley alignment such as

using a straight edge, string line, or the human eye

-- all techniques that lend themselves to error.

In today’s demanding maintenance arena where

tighter specifications and speedier results are a

must, Gates EZ Align™provides the accuracy and

reliability that traditional methods cannot. With

time and manpower at a premium, Gates EZ Align™

is your solution. Using the system requires no

training and a single operator can do the job!

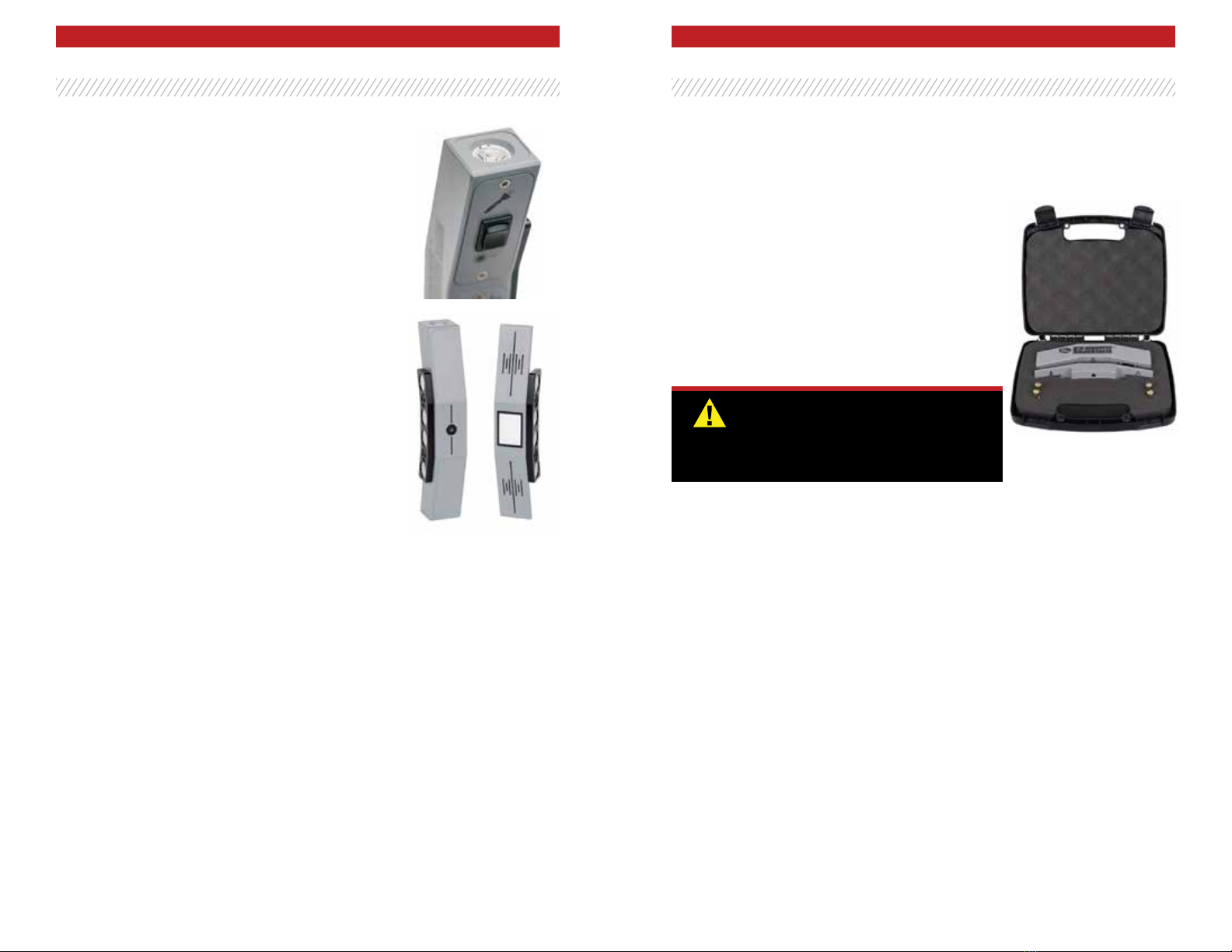

GATES EZ ALIGN™RED

7420-1000

System consists of:

• EZ Align™Laser Transmitter with AAA

alkaline batteries and class II laser diode

• EZ Align™Reflector Unit

• High density polyethylene Carrying Case with

die cut foam insert

• User Manual

7420-1000 Gates

EZ Align™Red with

carrying case and cut

foam insert

EZ Align™Laser

Transmitter (left) and

EZ Align™Reflector

(right)

4 5

EZ ALIGN™RED PRECISION LASER ALIGNMENT OPERATING INSTRUCTIONS

FOREWORD

Welcome to laser pulley alignment using Gates

EZ Align™. This patented, easy-to-use device from

Gates Corporation will enable you to perform pulley

alignment tasks with ease and precision.

This document is intended not only to guide you

on the operation of the system, but also to provide

useful and related information about belt and

pulley alignment.

An aligned pulley system reduces both pulley and

belt wear, and reduces equipment vibration, which

in turn leads to improved machine performance.

Proper pulley alignment reduces unscheduled

downtime, and improves the reliability of your

equipment.

Gates EZ Align™provides an innovative approach

to alignment, using Gates tested, proven reflected

laser beam technology.

At Gates Corporation, we strive to produce high

quality documentation, and therefore welcome your

feedback. If you have comments or suggestions to

help us improve our documentation, please let us

know by emailing PTPAsupport@gates.com.

CAUTION

Always lock-out

the electrical

power to the motor

prior to performing

any maintenance

Failure to do so

could result in

serious injury or

death to personnel

and may cause

damage to

equipment

Battery

Thumb

Screw Hole

Location

Rocker Switch

Laser / Off / Flashlight

2 AAA Alkaline Batteries

INTENDED USE

Gates EZ Align™is designed for aligning belt

drives in industrial environments. This simple

alignment system requires only one operator.

Gates Corporation assumes no liability for damage

or injury resulting from uses other than those

described in this document.

COMPLIANCE

Gates EZ Align™conforms to all relevant CE

requirements. Per Annex II.B of the Machinery

Directive (98/37/EC) IEC608-25-1 EN 60825-1

LASER SAFETY

The Gates EZ Align™system uses a Class II laser.

Class II lasers comply with the requirements

outlined in the FDA specification 21 CFR Ch. 1, Parts

1040.10 and 1040.11, as well as ANSI standards.

The Gates EZ Align™operates at a wavelength of

532nm. DO NOT look into the laser beam at any

time, including during set-up and adjustment of

operation.

CALIBRATION

The Gates EZ Align™is factory calibrated and

therefore should not require any adjustments. It is

recommended however, that the unit be returned

to the factory or an authorized service center each

year for calibration.

BATTERY OPERATION

Gates EZ Align™is powered with 2 AAA alkaline

batteries with an operating time of approximately

25 hours. To replace the depleted batteries,

simply turn and remove the two thumb screws on

the back of the transmitter to expose the battery

compartment. Remove the old batteries and

replace them with new ones.

6 7

EZ ALIGN™RED PRECISION LASER ALIGNMENT OPERATING INSTRUCTIONS

LED FLASHLIGHT

Built-in LED flashlight combined in one convenient,

compact design. Ultra-bright white LED with

100,000 hour bulb life, 150 lumens and 5000K

LED Color.

Due to the powerful magnets on the Gates EZ Align™

units, we recommend handling the assembly with

care. The units should be kept away from magnetic

materials such as watches, spectacle frames and

other items that could be damaged.

When not in use, the Gates EZ Align™magnetic

units should be stored in their durable case.

For maximum performance, ensure that the optics

on the laser transmitter, the reflecting surface

on the reflector and the outside housing of both

units are kept clean and dust free. The units may

be cleaned with a lint-free cloth or a swab using a

premium glass cleaner solution.

MAGNETIC BRACKETS

Powerful magnetic brackets hold the Gates EZ

Align™firmly in place

GETTING STARTED

Mount the units on the pulley faces to be aligned.

The reflector should be mounted onto the pulley to

be moved or adjusted, while the laser transmitter

should be mounted onto the stationary pulley. The

operator should determine which pulley is movable

and which is stationary. The movable pulley is

often the smallest one, and is often mounted to

the motor shaft. In some cases both pulleys and

shafts may need to be adjusted to achieve the

desired alignment.

Check to see if the offset distance from the pulley

mounting face to the groove is the same for both

pulleys. If not, the optional Offset Bracket Kit may

be very helpful.

GATES EZ ALIGN™SET-UP

Pulley alignment has never been so simple. Open

the Gates EZ Align™case and remove the two

compact and durable units that comprise the

alignment system. Turn the laser unit on using

the rocker switch located on the back of the

transmitter.

Do not look into the laser beam at

any time! Ensure that the machinery

or equipment to be aligned has been

locked out and tagged out.

8 9

EZ ALIGN™RED PRECISION LASER ALIGNMENT OPERATING INSTRUCTIONS

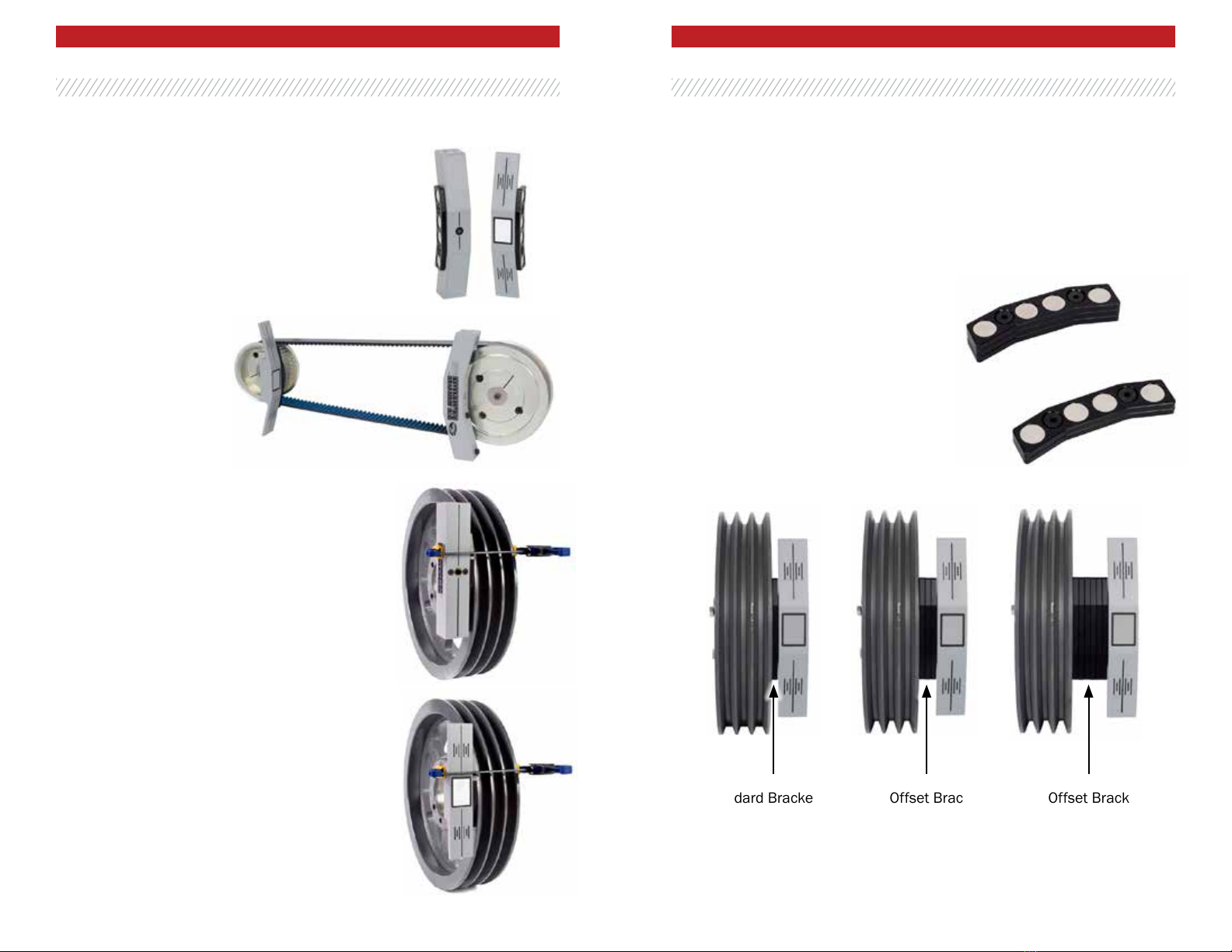

OFFSET BRACKET KIT (OPTIONAL)STANDARD MAGNETIC

MOUNTING

The Gates EZ Align™is equipped with a powerful

magnet bracket assembly, allowing the operator

to mount the system on almost any pulley face,

quickly and easily.

NONFERROUS PULLEYS AND

SPROCKETS MOUNTING

When mounting Gates EZ Align™to a nonferrous

pulley or sprocket, use the optional QUICK-GRIP

Micro One-Handed Bar Clamp.

Standard Bracket ½ Offset Bracket ¾ Offset Bracket

Use the optional Offset Bracket Kit with pulleys

when a large offset is required. The kit includes a

1/2-inch and a 3/4-inch offset bracket. Combine

both offset brackets to achieve a 1 1/4-inch offset.

10 11

EZ ALIGN™RED PRECISION LASER ALIGNMENT OPERATING INSTRUCTIONS

ALIGNMENT

CONDITION CHECK

Vertical Angularity Axial Offset Horizontal Angularity

MISALIGNMENT CONDITIONS AS

DISPLAYED ON THE GATES EZ ALIGN™

Vertical Angularity Axial Offset Horizontal Angularity

Offset

marks

Alignment Reference Lines

For different pulley edge thicknesses, use the

offset marks on the face of the reflector to establish

the amount of offset. The marks are in 1/8-inch

increments.

Alignment processes should be carried out in

an area protected from bright sunlight, or in

a shaded area, to allow easy viewing of the

laser line on the Gates EZ Align™units.

Misalignment conditions include vertical angularity,

horizontal angularity and axial offset. The position

of the transmitted laser line on the reflector

indicates vertical angularity and axial offset.

Horizontal angularity is indicated by the position of

the reflected laser line on the transmitter.

TYPICAL MACHINE

MISALIGNMENT CONDITIONS

12 13

EZ ALIGN™RED PRECISION LASER ALIGNMENT OPERATING INSTRUCTIONS

CORRECTING PULLEY

MISALIGNMENT

1. Correct vertical angularity by shimming

the movable machine using precut 304

stainless steel shims. Correction of this

angular misalignment can be observed on the

reflector.

2. Correct axial offset by adjusting the movable

pulley or machine axially. This correction can

also be observed on the reflector unit.

3. Correct horizontal angularity by adjusting the

movable machine laterally. The correction

can be viewed on the laser transmitter during

adjustment.

By following the three steps above, aligning the

belt drive should be completed quickly. However,

one alignment correction may affect other

alignment conditions, so these steps may need to

be repeated until the system is completely aligned.

Good alignment is achieved when the transmitter

laser line and the corresponding reflected laser line

coincide with the reference lines on the reflector

and laser transmitter respectively.

Good Alignment

IMPORTANCE OF GOOD

PULLEY ALIGNMENT

Good pulley alignment increases belt drive

reliability and efficiency by reducing premature

wear or failure of pulleys, belts and bearings.

Pulleys can be aligned using conventional string

and straight-edge methods, but this is often time

consuming and prone to error.

Gates EZ Align™is a laser system specifically

designed for the alignment of belt driven

equipment. Patented and proven reflected laser

beam technology significantly helps to reduce drive

installation time, manpower and potential errors

associated with pulley alignment and installation.

The Gates EZ Align™system uses a return beam

angle that is twice the angle of incidence, so

the reflected beam travels twice the distance,

dramatically enhancing accuracy. Alignment is

indicated with great precision, resulting in labor

savings and increased production uptime.

Straight-Edge Method

String Line Method

14 15

EZ ALIGN™RED PRECISION LASER ALIGNMENT OPERATING INSTRUCTIONS

MACHINE PREPARATION

Before commencing any work ensure basic safety

rules are adhered to.

CAUSES OF BELT FAILURE

Before beginning pulley alignment, examine

potential causes of belt or pulley failure and correct

them to prevent recurrence. Some causes of failure

could include poor drive maintenance (wrong

belt tension, pulley misalignment), environmental

factors (sunlight, harsh temperature fluctuations),

improper installation (wrong belts/sheaves,

belts forced onto grooves), or operating factors

(overload, shock load).

INSPECTION

Perform a visual inspection of the belts and of

each pulley and its grooves. Look and feel for

cracks, chips, or excessive groove wear. Proper

contact between the belts and the pulleys must be

ensured.

SOFT FOOT

Inspect the movable machine for “soft foot.”

Feeler gauges can be used under a loosened foot

to measure the gap. Shim the machine foot with

the largest amount of gap (the amount indicated

with the feeler gauges) until no reading is larger

than 0.05mm (0.002” or 2 mils). Use precut 304

stainless steel shims. Severe “soft foot” distorts

the machine frame when bolted down, causing

damage to seals and bearings. It could also lead to

high vibration levels on the machine bearings.

Loose

clothing or long

hair must never be

allowed anywhere

near belt-driven

machinery. All

equipment MUST

be locked out and

tagged out.

Worn belts or

pulleys and other

components should

be replaced before

proceeding with

pulley alignment.

DRIVE BELTS

The condition of the worn belt is a good indication

of the type of misalignment or other problems that

may be present. Belts must be changed as soon as

undue wear is detected. For a multiple-belt drive,

all belts must be replaced together. Only belts

from the same manufacturer should be combined

together in order for the belts to share the load

equally.

In order to replace the belts on a belt drive

system, they must first be loosened. This is often

accomplished by simply loosening the driver or

driven unit and reducing the center distance.

In other cases, an idler pulley may need to be

loosened and moved. Belts must never be forced

or rolled onto a pulley as this can damage the

pulley as well as the belt tensile cord.

New belts must be properly stored. They should be

kept in a cool, dry place with no exposure to direct

sunlight or heat. They also should not be hung

from single pegs. For further information, refer to

Gates Belt Drive Preventive Maintenance & Safety

Manual.

PULLEYS

If installing new pulleys and belts, ensure that the

correct belt/pulley combination and the correct size

belts have been selected. Existing pulleys should

be inspected carefully for wear and replaced if

necessary. Consult Gates Belt Drive Preventive

Maintenance & Safety Manual.

PULLEY RUN-OUT

Axial pulley run-out will influence alignment

readings. Axial run-out should be confirmed to be

within recommended limits.

16 17

EZ ALIGN™RED PRECISION LASER ALIGNMENT OPERATING INSTRUCTIONS

PULLEY ALIGNMENT

There are three basic parameters that describe

pulley misalignment. These include vertical

angularity, horizontal angularity, and axial offset,

and may occur in any combination.

There are several pulley alignment methods. The

most common include the straightedge or string

methods, in which the straightedge or strings

must touch the two edges of each pulley face

simultaneously (four-point contact for drives with

two pulleys). The pulleys should be rotated half a

turn and checked again. Since a string can bend

around corners, it is not easy differentiating

between axial offset and horizontal angularity when

only three-point contact is made. A straightedge or

string also cannot always detect twist angle.

Vertical Angularity Axial Offset Horizontal Angularity

Straight-Edge Method

By contrast, the Gates EZ Align™units mount

magnetically to the face of most pulleys. The

transmitter unit projects a laser line onto the

reflector unit, which is magnetically attached to the

other pulley face. Alignment involves ensuring that

the transmitted and reflected laser lines match

with the respective reference lines.

Stationary Pulley

Laser Transmitter Reflector

Movable Pulley

String Line Method

18 19

EZ ALIGN™RED PRECISION LASER ALIGNMENT OPERATING INSTRUCTIONS

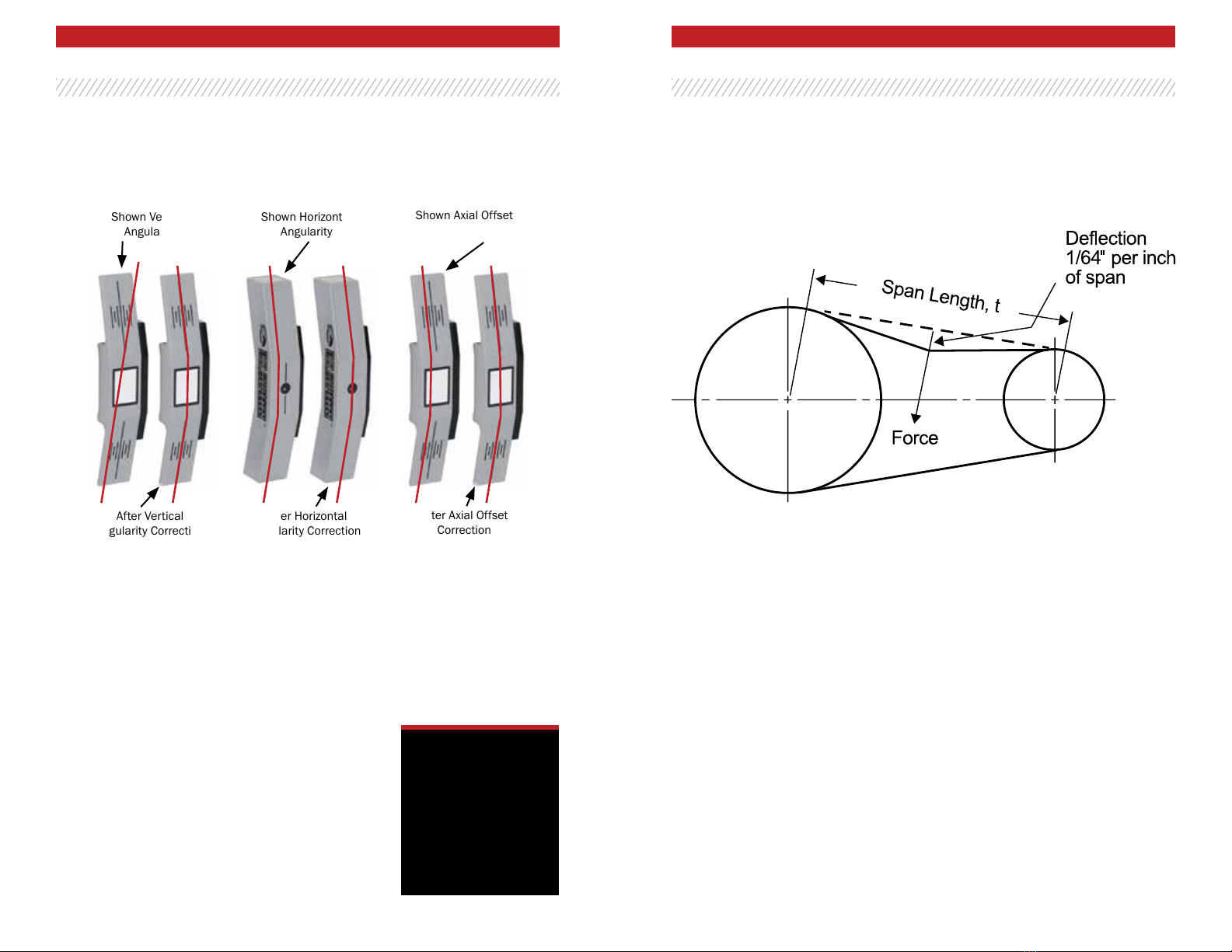

Shown Vertical

Angularity

After Vertical

Angularity Correction

Shown Horizontal

Angularity

After Horizontal

Angularity Correction

Shown Axial Offset

After Axial Offset

Correction

The sequence

in which the

misalignment

correction is

carried out may

vary from one

situation to the

next.

FORCE–DEFLECTION METHOD

OF BELT TENSIONING:

1. Measure the belt span length and calculate

the desired deflection distance (1/64" per

inch of span length).

2. Using a spring scale, press down on the belt

in the approximate center of the span, and

deflect the belt to the desired level. When

the desired deflection distance has been

reached, note the force registered on the

spring scale.

3. Adjust belt tension until the force required

to achieve the desired deflection distance is

within the belt manufacturer’s recommended

force values for the type of belts being used.

New belts generally require higher tension

levels than used belts because they have not

been run in.

Incorrect belt tension (as well as pulley

misalignment) adversely affects belt drive

reliability and efficiency. After the pulleys have

been aligned, it is very important to tension the

belts to manufacturer’s recommendations.

The following diagrams depict misalignment

conditions using the Gates EZ Align™and the

corresponding corrections as observed on the units.

Vertical angularity should be corrected first. This

is done by shimming the unit that the movable

pulley is mounted to. The next step is to correct

horizontal angularity. This is accomplished by

shifting or twisting the position of the unit that

the movable pulley is mounted to. Use lateral

jackscrews if available, otherwise the unit will need

to be loosened and re-positioned. Finally, correct

axial offset by moving the unit that the movable

pulley is mounted to axially or reposition one of

the pulleys on its shaft. Since performing one

alignment correction almost invariably affects the

other alignment conditions, this process may have

to be repeated several times.

Gates EZ Align™enables all three alignment

conditions to be monitored simultaneously. The

accuracy of the alignment is greatly increased and

the process can be completed quickly and easily.

20 21

EZ ALIGN™RED PRECISION LASER ALIGNMENT OPERATING INSTRUCTIONS

It is possible for belt tension adjustments to

alter pulley alignment, and for pulley alignment

adjustments to alter belt tension levels. The Gates

EZ Align™tool will help monitor the pulley alignment

condition as belts are adjusted for the correct

tension level.

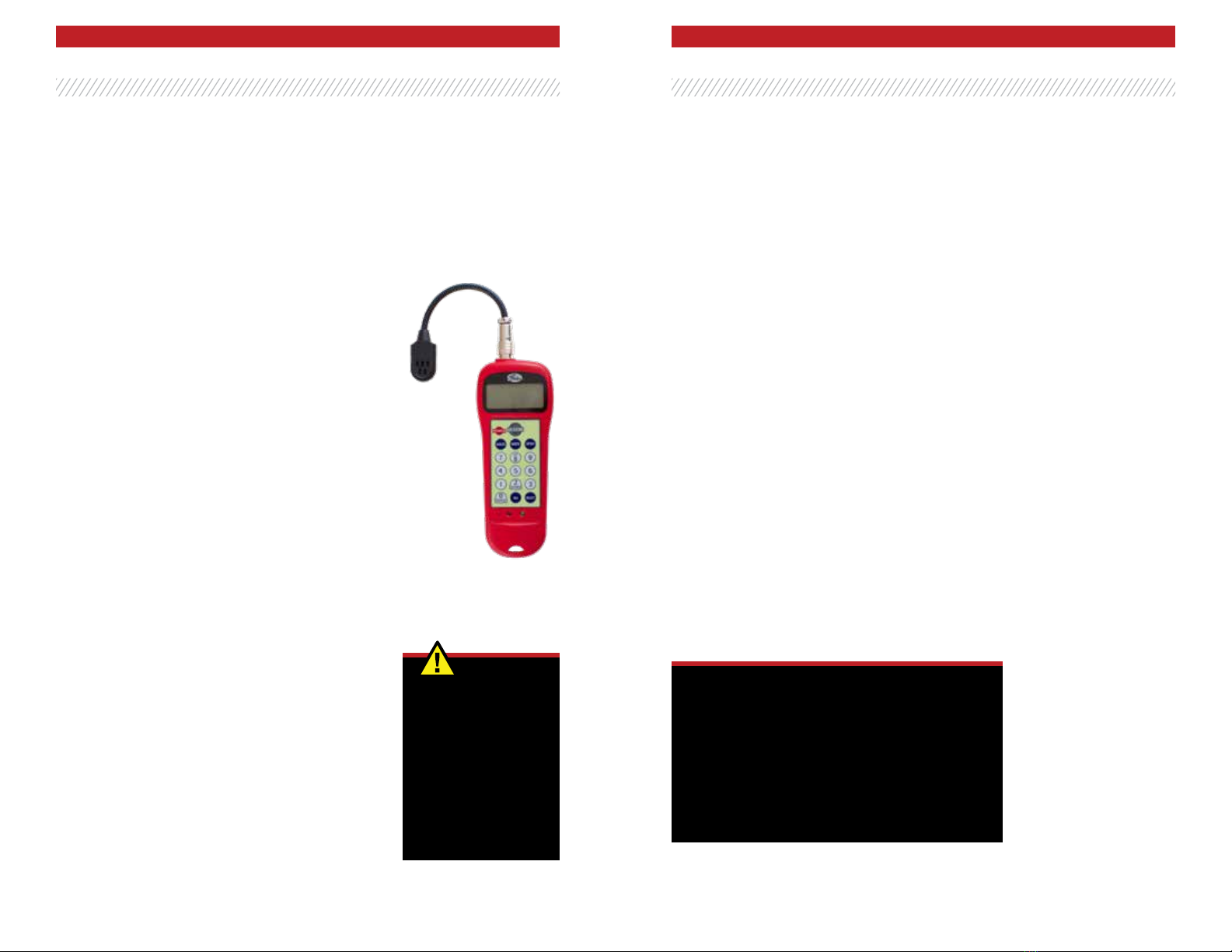

MEASURING BELT TENSION

WITH THE GATES SONIC

TENSION METER:

The Gates Sonic Tension Meter measures belt

span tension easily and accurately. Belt tension is

measured by plucking the belt span while holding

a sensor close by. Belt tension is adjusted until the

belt span frequency, or measured tension level, is

within manufacturer’s recommendations.

The final step is to operate the belt drive system for

a few hours, allowing the belts to stretch and seat

properly in the pulley grooves. The belt tension

level should then be checked to make sure it is

within manufacturer’s recommendations for new

belts. Now operate the belt drive for at least 72

hours. The belt tension level should be checked

again to make sure it is within manufacturer’s

recommendations for used belts.

Before

operating the

machinery check

to make sure

all tools and

equipment have

been properly

stowed and all

guards have been

securely replaced.

MAINTENANCE

Gates EZ Align™is designed with durable aluminum

housing designed to withhold harsh environments.

However, as with any precision instrument, care

should be taken to avoid unnecessary abuse.

1. The lenses of the transmitter and reflector

windows are coated with high performance

film. To clean, use a lint-free cloth or swab

using a premium glass cleaner solution.

2. The outside aluminum housing may be

cleaned with a clean damp cloth.

REPAIR / SERVICE

INSTRUCTIONS

1. Pack the equipment securely for shipment in

the original carrying case.

2. Enclose a note or letter including contact

information and the nature of the request or

problem. If the unit is under warranty, provide

confirmation of the purchase date.

3. If requested, estimates for non-warranty

repairs will be provided, otherwise work will

begin as soon as possible.

4. Return the equipment prepaid and insured

to the Gates Corporation Service Center.

For quick turn around, “2nd Day Air” or air

shipment is recommended.

5. There will be no charge for repairs within the

warranty period due to defective materials

and/or workmanship after the unit has been

received.

FOR REPAIRS SEND UNITS TO:

GATES CORPORATION

c/o Seiffert Industrial, Inc.

Attn: Service Department

1323 Columbia Drive, Suite 305

Richardson, TX 75081 USA

800-777-6363

22 23

EZ ALIGN™RED PRECISION LASER ALIGNMENT OPERATING INSTRUCTIONS

RECOMMENDED PULLEY

ALIGNMENT VALUES

The standard limit for V-belt drive alignment is 0.5

degrees, and 0.25 degrees for synchronous drives.

Most major belt and pulley manufacturers specify

these values. Pulley alignment can be set closer

than this if the alignment procedure is carefully

followed. The following table converts degrees of

misalignment to mils/inch and mm/100 (of pulley

diameter) of misalignment between the projected

planes of the pulley faces.

ANGLE OF

MISALIGNMENT

(DEGREES) MM / 100MM MM / INCH

0.1 0.18 1.75

0.2 0.35 3.49

0.3 0.52 5.24

0.4 0.70 6.98

0.5 0.87 8.73

0.6 1.05 10.47

0.7 1.22 12.22

0.8 1.40 13.96

0.9 1.57 15.71

1.0 1.74 17.45

Bold = within recommended limits for V-belt drives

Note that the values between 0.1 and 0.5 fall within

recommended misalignment limits for V-belt drives.

STATEMENT OF LIMITED WARRANTY

Gates Corporation warrants the Gates EZ Align™to be free of defects in

material and workmanship for a period of two (2) years. This twenty four (24)

month warranty period begins when the unit is received by the purchaser.

Gates Corporation will repair or replace, at its option, any defective part of

components of which notice has been given during the warranty period. Travel

and per diem expenses, if required, to and from the place where repairs are

made, will be charged to the purchaser at the prevailing rates.

Customers should send units to Gates Corporation (use address on previous

page) for warranty repairs; freight prepaid.

Any evidence of negligent, abnormal use, or accident with exception of the

previously stated warranty or an attempt to repair equipment by other factory

authorized personnel using Gates Corporation certified or recommended

parts, automatically voids the warranty.

Special precautions have been taken to assure proper calibration; however,

calibration is not covered by this warranty. Calibration maintenance is the

responsibility of the user.

The foregoing states the entire liability of Gates Corporation regarding the

purchase and use of its equipment. Gates Corporation will not be held

responsible for any consequential loss or damage of any kind.

This warranty is in lieu of all other warranties, except as set forth above,

including any implied warranty merchantability or fitness for a particular

purpose, are hereby disclaimed. This warranty is in lieu of all other warranties,

expressed or implied.

SEE MORE POWER TRANSMISSION SOLUTIONS AT GATES.COM/PT

EZ ALIGN is a registered trademark of Gates Corporation

Gates EZ Align™7420-1000 TECHNICAL DATA

EZ ALIGN™RED LASER TRANSMITTER

Operating Distance: 8 Ft. or Better

Accuracy: 1/16” At 6 Ft.

Laser Type: 635nm Visible Red Laser Diode

Laser Power: <1 mW, Class 2

Laser Line Length: 28” At 6 Ft. (711mm at 1.9m)

Controls: Laser ON/OFF/ON

Flashlight Rocker Switch

Operating Time: 25 Hours Continuous at 72° F

Battery Type: 2 AAA Alkaline Batteries

Operating Temp: 15° F (9° C) To 110° F (43° C)

Storage Temp: -4° F (-20° C) To 140° F (60° C)

Mounting: Magnetic

Weight: 17.0 Oz. (483 g)

Dimensions: 1.3” (33mm) W x 1.3” (33mm) D

x 8” (203mm) H

Housing: Aluminum, Powder Coat Finish

EZ ALIGN™RED REFLECTOR

Reflector Size: 1” (25mm) W x 1.4” (36mm) H

Mounting: Magnetic

Weight: 9.4 Oz. (266 g)

Dimensions: 1.3” (33mm) W x 0.9” (23mm) D

x 8” (203mm) H

Housing: Aluminum, Powder Coat Finish

CARRYING CASE

Material: Black, High Density Polyethylene

Dimensions: 10.25” (260mm) W x 8” (203mm) D

x 3” (76mm) H

Insert: Die Cut Foam

Total Package Weight: 2.6 Lbs. (1.2 kg)

© 2010 - 2018 Gates Corporation. All rights reserved.

17535-M-G 6/18

Table of contents