Gates BC-1E User manual

TRANSMITTI`VGAQ U I PME NT

--

MODEL BC-1E

BROADCAST TRANSMITTER

1000 WATTS HIGH LEVEL MODULATION

Here is a 1000 watt transmitter that is better than has

heretofore been offered. Outstanding among its many

features are style, accessib,lity, good workmanship, the very

best components, economical operation and a pressure type

cabinet.

GATES R13/104 COMPANY

MANUFACTURERS. tNGINEERS, SINCE 1922

QUIN CY, ILLINOIS, U.S.A.

www.americanradiohistory.com

t

L/4

TRANSMITTÌRNG; ÉQUI PMENT

Vhen the front door is open all low po,er radio

frequency tuning adjustments and metering are

available. No interlocks are required on the front

door as the inside panel Is of dead front con-

struction. Final and modulator tubes are easily

viewed thru the -glass In the front panel and

the door even if the door Is closed.

GENERAL CONSTRUCTION

Both appearance and reliability are stressed

in the design of the BC-1E transmitter. Modern

lines are evident in the cabinet construction

and the arrangement of the manual controls

and meters is such that they are most conven-

ient for the operator and pleasing to the eye.

The cabinet is enhanced by using a multi-coat

synthetic enamel, baked and hand rubbed to

produce a smooth, lustrous finish. It is excep-

tionally easy to clean and will retain its original

sheen for many years.

Internal framework chassis and panels are

copper plated and masked in appropriate places

from the enamel finish to secure a good elec-

trical bond throughout the transmitter. Weld-

ed joints throughout the angular framework

assure maximum strength.

Considerable advantage in making tuning

adjustments is obtained because the panel be-

hind the front door is electrically dead and con-

sequently the front door does not require inter-

locks. The back doors are, of course, interlocked

to prevent access to harmful votages when

they are open.

Another major advantage is the pressure

type cabinet. Dirt and dust are kept out of the

equipment by building up a slight air pressure

inside. Ths is accomplished by drawing air into

the cabinet by a fan mounted inside the left

back door and exhausting it thru the filtered

opening in the top. The inlet is also filtered to

prevent the entrance of dirt and foreign mat-

ter. These filters are easily cleaned and can be

used indefinitely.

Tube life of the 833-A tube is lengthened

for over normal expectancy by the small blow-

ers located beneath them.

MAINTENANCE ACCESSIBILITY

All of the normal functions of maintenance

may be accomplished thru the back doors of

the BC-1E as the major circuits and compon-

ents are easily reached from the back. The fre-

quency control unit is easily removed by slip-

ping off the style strips, taking out the few

screws that hold it to the panel and sliding it

out on its runners. The components on either

side of the transmitter are exposed by taking

off the panels on either side. Inspection is re-

quired in these sections very infrequently.

FREQUENCY CONTROL UNIT

The radio frequency signal in the BC-1E is

started in the frequency control unit, separate-

ly designated as the Model 25-A. It contains

the oscillator circuit, using a type 802 tube,

GATES RAD}IO COMPANY

MANUFACTURERSjNIN)EERS, SINCE 1922

QUIN CY, letI-NOIS, U.S.A. www.americanradiohistory.com

TRANSMITT Nt1\16,4(QUIPMENT

The audio amplifier deck at the top. control panel below and

modulation transformer and reactor on the bottom are shown

here. Notice the neat arrangement of the components and wiring

-not crowded. Boar to find your way around. Each electrical

part here as well us in other sections of the transmitter is

coded to aorreepond with symbols on the schematic diagram

and parts lists In the instruction book.

THE R.F. DRIVER STAGE

Just above the 25-A frequency control unit

is the driver chassis which contains one 813

tube and the grid and plate components neces-

sary for its proper functioning. The R.F. from

the 25-A is fed to the grid circuit of the driver

thru a low capacity flexible shielded cable.

Power for the tube elements is brought in on

the rear of the chassis. Two meters for in-

dicating grid and plate current in this stage

are located on the front panel.

THE FINAL R.F. AMPLIFIER

The upper portion of the cabinet contains

the final radio frequency amplifier. Shunt feed

is used to supply the two parallel connected

type 833-A tubes in this stage. Particular at-

tention has been given to the mechanical de-

sign to obtain sturdiness and enhance the elec-

trical characteristics. Every component op-

erates substantially under its rating. Support-

ing members are made of copper plated steel

angle or heavy gauge sheet accurately formed.

The final plate inductor is made of edgewise

wound silver plated copper ribbon mounted on

mycalex spacer bars. Final tuning is ac-

complished by an oversize capacitor having

cast aluminum plates with a rounded polished

bead on all edges to reduce corona discharge.

Overmodulation tests show that it is virtually

impossible to induce breakdown or component

heating even though applied over long periods

of time.

POWER SECTION

The bottom portion of the transmitter con-

tains the power supply components, the mod-

ulation transformer and reactor and associated

parts. Type 575-A tubes are used to provide

high voltage to the R.F. final amplifier and

modulator. Medium voltages are supplied to

all other stages except the frequency control

unit by a pair of 8008 tubes.

GATES RÁDÍO COMPANY

MANUFACTURERkéIti1G:INERS, SINCE 1922

QUIN CY, IL°LLfNOIS, U.S.A.

www.americanradiohistory.com

TRANSMITTING ÉQdJIPMENT

and two buffer stages which use a type 45

tube and a type 802 tube in that sequence. A

carefully selected crystal is used to secure

accurate control of the oscillator frequency.

The two lightly loaded buffer stages effect-

ively isolate the oscillator from the power

amplifiers. The crystals used in the 25-A have

exceptionally low drift and are mounted in

Bliley BC46T temperature controlled ovens.

Two may be installed and a switch is provided

so that instant change may be made from one

to the other.

The 802 oscillator is of the un-

tuned plate type, very stable in

operation. Average deviation over

long periods of time in the field

shows experience of only a few

cycles variation. The first buffer,

a type 45, is also untuned and

lightly coupled to obtain utmost

stability. The third stage, an 802

is terminated in a high impedance

circuit from which the output is

fed directly to the grid of the

radio frequency driver stage.

Power for all tube elements is ob-

tained from a self-contained power

supply on the 25-A chassis. A sep-

arate AC power line to the 25-A

is terminated at the back of the

transmitter and is left connected

to the source at all times to per-

mit the crystal ovens to heat at

all times.

In addition to front panel

switching of crystals controls are

provided for making minor fre-

quency adjustments on the oscil-

lator and tuning the second buffer

plate circuit, individual switches

for application of plate power to

the oscillator and buffer stages

and pilot lights to show heating

cycles of the crystals and power

application. Three inch meters in-

dicate oscillator plate current, sec-

ond buffer grid current and second

buffer plate current. The temperature of the

crystals can be easily read on the thermometers

viewed through apertures on the front panel.

Particular attention has been given to

maintenance of the 25-A. All terminations, in-

cluding "take off" for a frequency monitor are

on terminals in the rear and may be easily

reached from the back of the transmitter. To

make removal of the entire 25-A easy the

chassis is mounted on slides and is held firmly

in place by four screws in the front panel.

The entire rear of the transmitter nuiras up sa that maintenance and Instw'bion is

GATES RAtDi10. COMPANY

MANUFACTURERSÉkaINEERS, SINCE I922

t.,r *4-.0nc www.americanradiohistory.com

TRANSMITTÌ IG EQUIPMENT

CONTROL SECTION

This portion of the circuit is incorporated

on a single panel on the right side of the trans-

mitter. The control circuits consist of the

power application relays for high voltage and

filament voltage and overload and timing re-

lays. The incoming AC power line fuses and

main power switch of the thermal overload

type are also located on this panel. Manual

control of the plate voltage and filament volt-

age for the final R.F. amplifier is accomplish-

ed by two rheostats which are operated by

knobs on the left side on the front of the

BC-1E transmitter. Push button stations on

the right side operate the filament start relay

which also applies bias voltages. Push button

stations on the left side on the front of the

cabinet operate the high voltage relay. Direct-

ly adjacent are controls for tuning the final

amplifier.

At the top of the control section is the bias

supply which provides a fixed negative voltage

for the modulator grids. This consists of a

power transformer, dual selenium rectifiers

and filter. The use of selenium rectifiers as-

sures an efficient and well regulated bias sup-

ply with the inherent long life obtainable from

selenium units. Balancing the bias voltages is

easily done by means of two potentiometers

located just inside the front door. Bias may be

adjusted while full power is applied.

AUDIO SECTION

Directly above the control section is a

chassis containing the first audio amplifier and

the driver stages. Two type 6B4G tubes are

used in the first stage and two 845's in the

driver. All low voltage terminations are

brought out on a sturdy barrier type phenolic

terminal strip. Three ceramic insulated posts

accommodate the high voltage connections.

The 833A moduator tubes are near the top

of the transmitter in line with the R.F. power

amplifier tubes. Associated components are

located on the bottom of the cabinet.

R.F. OUTPUT COUPLING

The R.F. power amplifier of the BC-1E

radio transmitter is connected single ended

and couples to the transmission line or antenna

through a combination harmonic filter and im-

This view shows the output coupling section, large resistors

and main power transformer. Notice the Intake air filters at

the lower left. If desired coaxial line ma.v he brought up thru

the bottom of the cabinet for consentent termination ta the

K. F. output.

GATES RAD__Q COMPANY

MAN UFACTURERS.e LIVERS, SINCE 1922

QUINCY, IL`LI'NOIS, U.S.A.

www.americanradiohistory.com

TRANSMITTNG EQUIPMENT

É

pedance matching section. The capacity tuning

in the power amplifier forms a radio frequency

potentiometer, thereby adjusting by selection

of components the impedance match between

the modulated plate circuit and the load. The

coupling adjustment consists of an L section

circuit of parallel capacitance and series induct-

ance. The loading inductance may be tapped at

any point along its length and in conjunction

with adjustments of the variable capacitor may

be arranged to match a wide range of line im-

pedances. The variable loading capacity is

adjusted by a knob on the left side of the front

of the cabinet. Directly above is the final plate

tuning knob. Positive action gear reduction

and shaft assemblies assure quick easy adjust-

ments in both the final plate tuning and load-

ing operations.

Below the loading components are found

the high voltage bleeder and bias resistors,

meter multiplier and audio monitoring circuits.

This latter circuit is a capacitor resistor ar-

rangement connected to give true monitoring

of carrier output.

no. "Wadi(led sciteamt lc of the R(' -iE transmitter shows the fundamental electrical arrangement.

GATES RIAD/104 COMPANY

MANUFACTURERS;tklNEERS, SINCE 1922

QUIN CY, 1L'14NO1S, U.S.A.

www.americanradiohistory.com

TRANSMITTING, ËQUIPMENT

METERING

The meter complement for the BC-1E trans-

mitter is complete in every way. Along the top

of the cabinet are located large four inch

meters for indicating R.F. line current, power

amplifier grid current, power amplifier plate

current, modulator plate current, power ampli-

fier plate votage and filament voltage for the

modulator and power amplifier filaments.

Just inside the front door is found a panel

containing a single meter and four switches.

Two of these switches are used to connect the

modulator plate current meter so that it will

indicate the plate current of either or both

modulator tubes. The other two connect the

small meter on this panel to indicate plate cur-

rent in either the first audio or driver stages..

The functions of the meters found on the

radio requency driver and frequency control

panels are described in the sections concerning

these panels.

Metering is available for indicating plate

current in every stage and grid current for

the radio frequency driver and final stages.

NEUTRALIZING

The final R.F. amplifier is the only stage

requiring neutralization. This adjustment is

made by a screwdriver slot adjustment located

next to the meter used for indicating plate cur-

rent in the audio stages.

POWER CHANGING

Provision may be made for operating the

BC-1E transmitter at 500 or 250 watts output

by means of a series of voltage dropping re-

sistors for the final R.F. amplifier plate volt-

age and an attenuator circuit to reduce the

audio input to the proper level. A switch locat-

ed on the front panel inside the door actuates

a relay that makes the proper connections.

ACCESSORY EQUIPMENT

The normal meter complement includes an

RF line current meter on the left end of the

row of large meters at the top. This meter is

of the external thermocouple type. If desirable

a remote reading antenna current meter may

be installed in place of the line current meter.

It may be of the external thermocouple type or

the remote diode rectifier type. The MO-2765-A

diode rectifier remote antenna current meter

consists of a meter having a one milliampere

movement with a scale calibrated in R.F.

amperes and a small unit containing a current

transformer and rectifier. The rectifier and

current transformer unit are generally located

inside the antenna tuning unit at the antenna.

Negligible power is required by the current

transformer to operat this device.

A complete line of antenna tuning units

are available for use with the BC-1E transmit-

ters. Detailed information on them will be

found in catalog sheets devoted to the subject.

The MO-2786-A series of antenna tuning units

incorporate the MO-2765-A diode type remote

antenna current meter and also two or three

coil lighting chokes.

Remote antenna current diode unit. MO-:785-A. The meter pro-

vided matches those along the top of the BC-IE transmitter.

GATES RAEl0 COMPANY

MANUFACTURERSMÇIjERS, SINCE 1922

QUIN CY, IL`LI'NOIS, U.S.A.

www.americanradiohistory.com

TRANSMITTIIVG EQUIPMENT

SPECIFICATIONS

POWER OUTPUT-1000 watts. May be operated as 1000/500 watt, 1000/250 watt,

500/250 watt, or as a 500 watt transmitter. Power reduction may be in-

corporated to suit requirements.

FREQUENCY RANGE-Any frequency from 530 to 1600 KC. (To be specified by

customer.)

FREQUENCY STABILITY-Phis or minus 10 cycles maximum.

POWER INPUT-Average program modulation, 1000 watts output, approximately

5.6 KW; 500 watts output, approximately 4.0 KW.

POWER SUPPLY-230 volts, 50/60 cycles, single phase. Variation not to exceed plus

or minus 10%.

TYPE OF MODULATION-High level Class "B".

A.F. INPUT LEVEL-For 100% modulation, plus 6 vu.; at average program level

plus 3 vu.

FREQUENCY RESPONSE-Within 11: db. from 30 to 10,000 cycles.

DISTORTION-Approximately 3% from 50 to 7500 cycles. 0-95% mod.

NOISE LEVEL-60 db. below 100% modulation unweighted.

R.F. HARMONICS-Less than .03%.

TUBE COMPLEMENT-

1 -802 Oscillator

1-45 Buffer

II

In 25-A Frequency Control Unit

1-802 I.P.A.

1-813 I.P.A.

2-833-A Power Amplifiers

2-6B4-G Speech Amplifiers

2 -845 Audio Drivers

2-833-A Modulators

2-575-A Rectifiers

2-8008 Rectifiers

1-5Z3 Rectifier

SALES OFFICES

123 Hampshire 40 Exchange Place

Quincy, Illinois New York 5, N. Y.

Distributors are conveniently located

in other sections of the United States

GATES RAD/I0 COMPANY

MANUFACTURERS. ENGINEERS, SINCE 1922

QUIN CY, 1LIL1'ÑOIS, U.S.A. www.americanradiohistory.com

Table of contents

Other Gates Transmitter manuals

Popular Transmitter manuals by other brands

Powercast

Powercast Powercaster TX91501B user manual

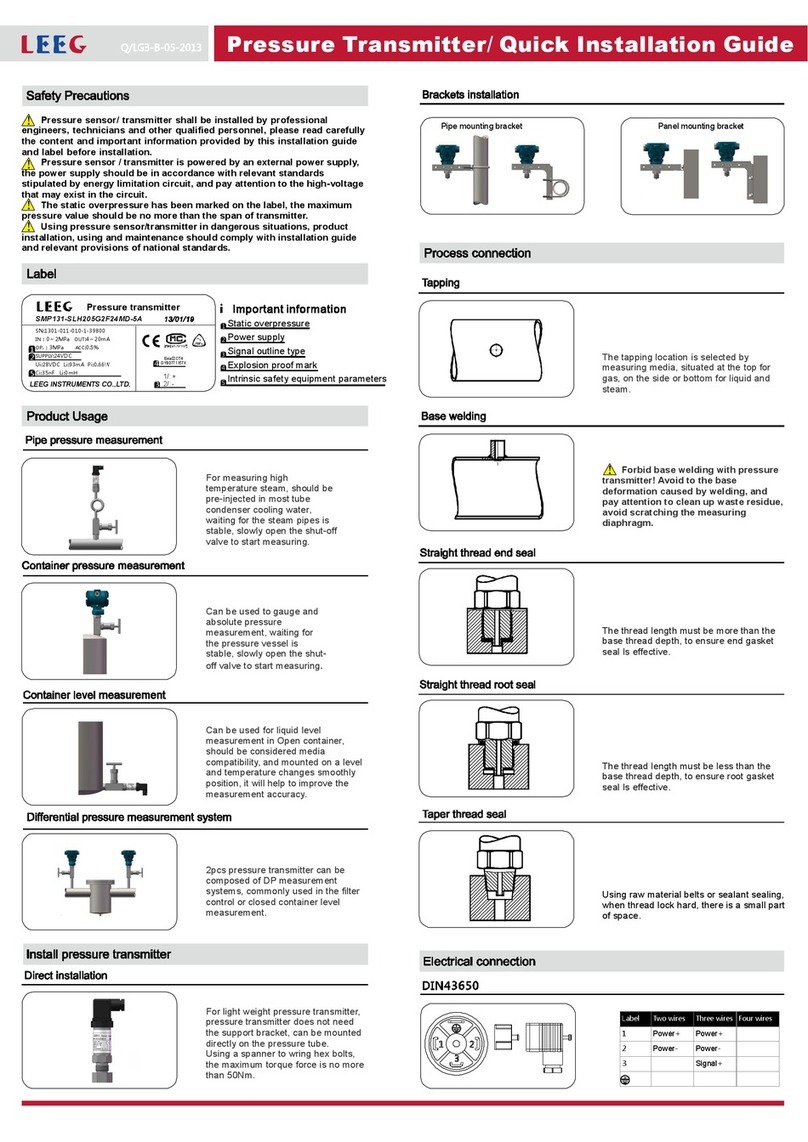

LEEC

LEEC SMP131-SLH205G2F24MD-5A Quick installation guide

MTT

MTT MS3763B user manual

Evikon

Evikon PluraSens E2670-PID user manual

Cardin Elettronica

Cardin Elettronica TXQPRO486 quick start guide

Superior Broadcast

Superior Broadcast SBFM1000SS user manual