Gates BC- 250T Instruction Manual

INSTACTIONS

FOR

INSTALLING

AND

OPERATING

THE

GATES MODEL

BC-

250T

250

W.

TRASMITTER

113-875

Gates

Radio

Company

tlincy,

Illinois

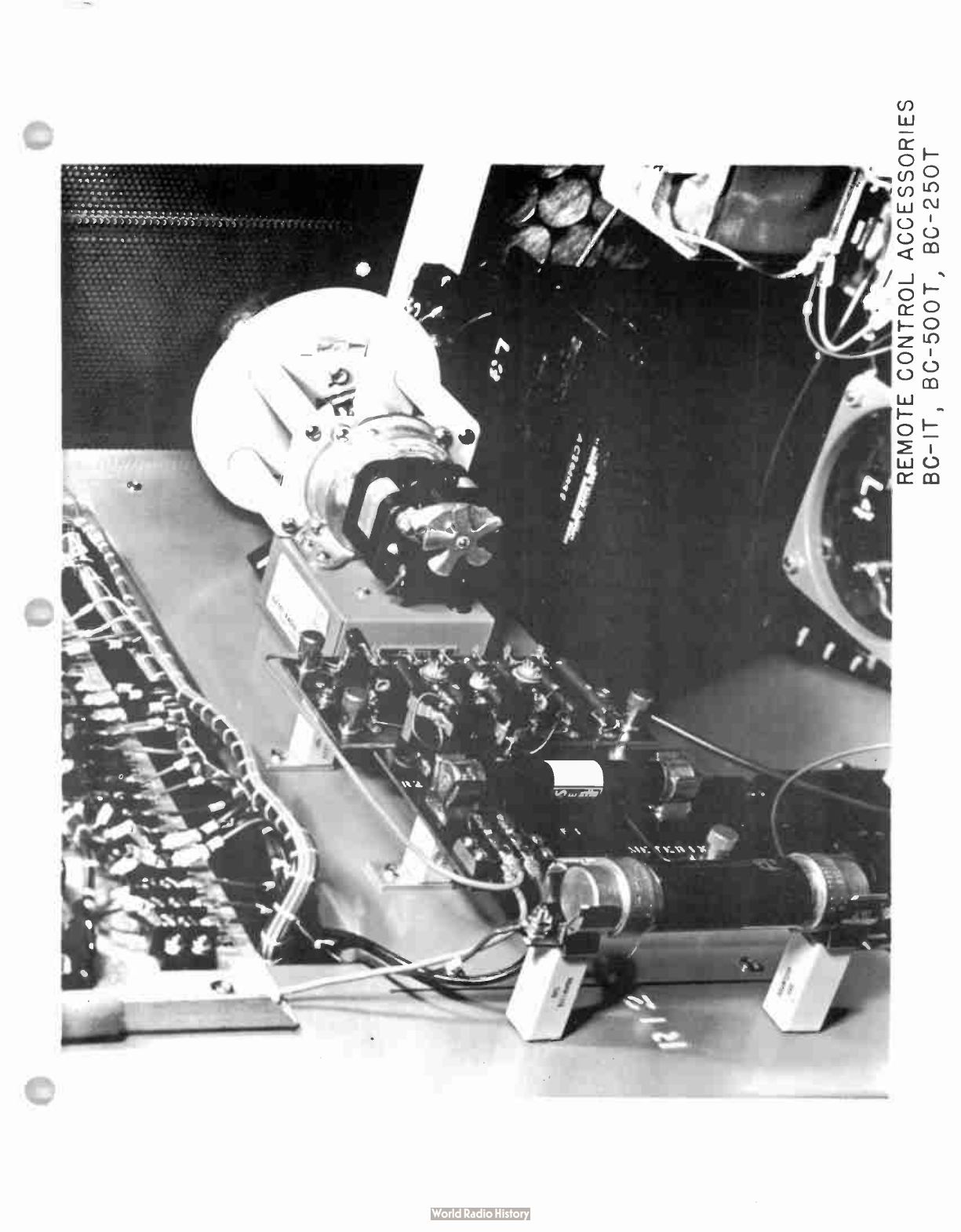

REMOTE

CONTROL

ACCESSORIES

BC-

IT,

BC-

500T,

BC-

250T

ADDENDA

SdEET

INSTALLATION

INSTRUCTIONS

FOR

R102E

CONTROL

IN

GATES

TRjINSMITTERS

BC-

1T,

BC-

500T,

BC-

250T

Refer

to

the

following

overall

transmitter

schematic

diagrams:

BC- 1T -

C-78130

BC-

500T -

E-25569

BC-

250T -

E-25582

A

steel

plate,

drilled

for

mounting

the

M-4719

Plate

Voltage

Kit,

M-4720

Plate

Current

Kit

and

M-4703

Rheostat

Assembly,

is

available

for

the

installer's

use.

Tapped

mounting

holes

for

this

plate }

lave

been

provided

in

the

cabinet

corner

supports,

directly

beneath

the

terminal

boards

and

conactors (

right

side

of

transmitter

as

viewed

from

front).

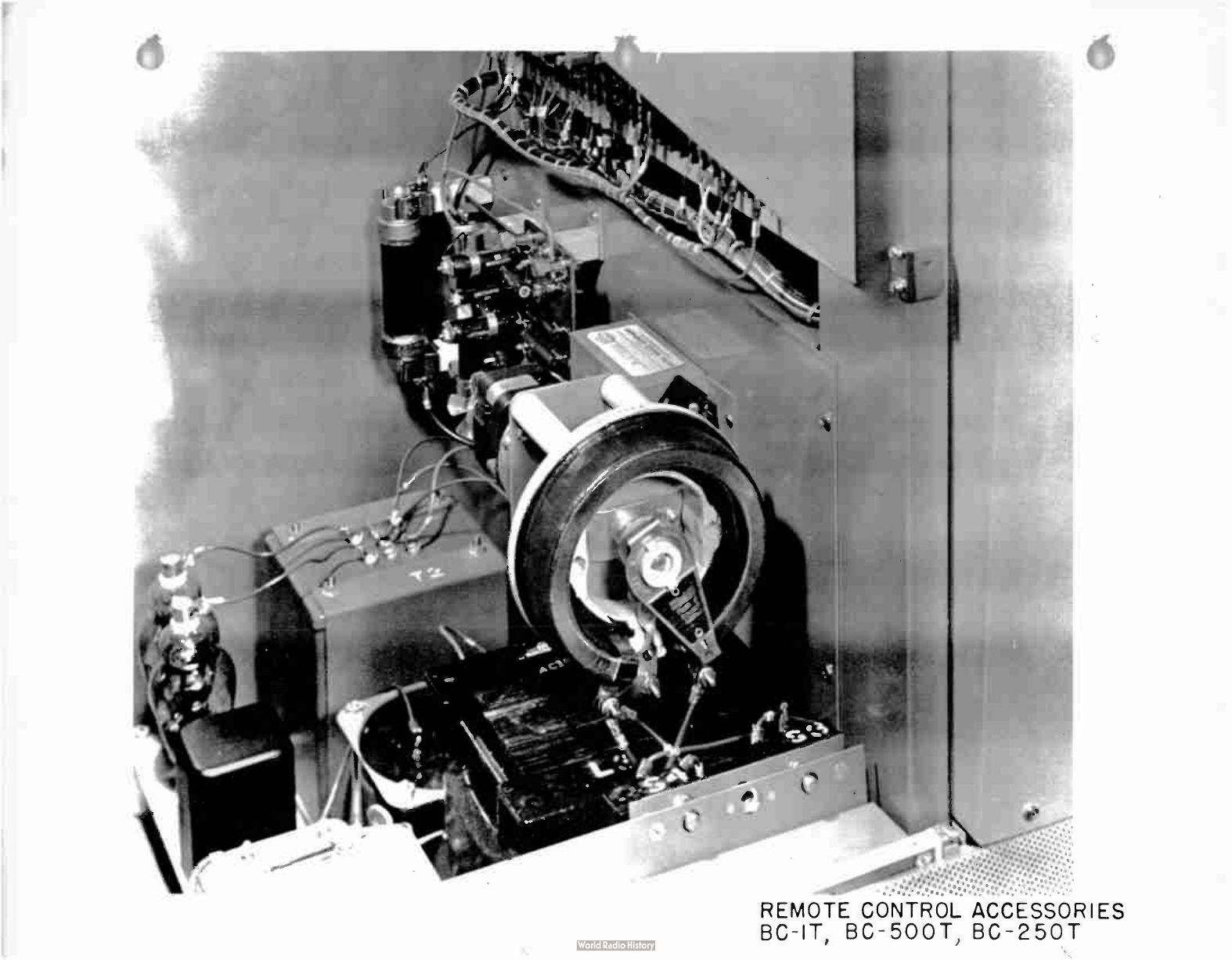

Photographs

showing

the

remote

control

kits

in

place

is

included

witn

these

instructions.

M-4703

Motor Rheostat

Assembly

As

viewed

from

the

rheostat

end

of

this

assembly,

with

the

three

rheostat

terminals

to

the

left,

strap the

center

terminal (

arm)

to

the

top terminal.

Since

application

of "

increase"

voltage

brings

about

clockwise

rotation

of

the

arm (

same view),

resistance will

decrease. ,

riti

application

of .

idecrease°

voltage,

the

resistance

will

increase.

2he

existing

plate

voltage

meters

in

the BC-

1T,

BC-

500T

and

BC-

250T

Transmitters

read

plate

to

cathode

voltage,

whereas

the

remote con-

trol

voltage

sampling

kit

will

read

plate

to

ground

voltage.

There-

fore,

in

order

for

the

two

meters

to

track

the

rheostat

must

be

wired

in

series

with

the

high

voltage

lead

feeding

the

final

amplifier.

Proceed

as

follows:

1.

Disconnect

from

modulation

reactor

L-3,

the

high

voltage

lead

which

runs

upward

to

the

final

amplifier

RF

choke

L-9.

Remove

this

wire

from

the

cable

until

sufficient

length

is

available,

thet

connect

to

one of the

motor

rheostat

terminals.

2.

Using

Packard

cable

or

a

high

voltage

equivalent,

run

a

lead

from

the

other

rheostat

terminal

to

this

same

modula-

tion

reactor

terminal

discussed

in

Step

1.

Set

the

trans-

mitter

voltage

control

R-14,

for

maximum

voltage (

minimum

resistance).

3.

The

control

circuit

hook-up between

the

M-4703

motor

and

remote .

s,ontrol

unit

is

explained

in

the

Re:lote

Control

instruction

book.

-1-

Plate

Voltage

Extension

Kit

M-4719

1.

Using

Packard

cable

or

a

high

voltage

equivalent,

connect

the

M-4719

1

1-1V' terminal

to

the

motor

rheostat

terminal

furthermost

from

the

poWer

supply.

Do

not

connect

to

the

rheostat

terminal

which

goes

to

the

modulation

reactor.

Connect

the

M-4719

kit

termiA.al -

G. to

a

good

ground

point

within

the

transJylitter.

2.

Refer

to

the

Remote

Control

Instruction

Book

for

connection

of

meter

sar.cple

voltage

to

remote

control

unit.

Plate

Current

Extension

Kit

M-4720

1.

The

plate

current

kit

is

to

be

connected between

the

lower

end

of

the

P.A.

overload

relay

K-6

and

ground.

2.

A

ground

lead

runs

from

a

chassis

ground

terminal

to

one

of

the

coil

terminals

on

K-7

modulator

overload

relay,

then

to

one

coil

terminal

of

K-6

P.A.

overload

relay.

Clip

out

the

portion

between

K-6

and

K-7.

K-7 is

to

retain

its

direct

chassis

ground

since

we

want

only

P.A.

current

to

flow

through

the

plate

current

kit.

3.

Both

K-6

and

K-7

must

retain

their

shunt

resistors

directly

across

their

respective

coils.

4.

The "

G

terminal

of

the

two-

terminal

strip

on kit

M-4720

connects

to

a

good

ground

point

within

the

transmitter.

Run

a

lead

from

the

other

terminal,

upward

to

the

K-6

te_aainal

which

was

formerly

grounded.

5.

Refer

to

the

Remote

Control

Instruction

Book

for

connection

of

sampling

voltage

to

Remote

Control

Unit.

Remote

Plate

Start-

too

Circuitry

The

BC-

1T,

BC-

500T

and

BC-

250T

overall

schematic

diagrams

plainly

in-

dicate

the

necessary

connections

for

filament

and

plate

remote

control.

The

plate

start-

stop

circuitry

consists

merely

of

shunting

the

trans-

mitter

plate-

start

switch

with

a

set

of

n)rmally

open

remote

control

contacts.

The )

late-

stop

function

is

accomplished

by

connecting

a

set

of

normally

closed

remote

contacts

in

series

with

the

transmitter

plate-

stop

switch.

Remote

Filament

Start-

Stop

Circuitry

Note

that

a

jumper

is

to

be

removed

in

the

filament

contactor

circuit.

Removal

of

this

jumper

disables

the

holding

contacts

on

the

filament

contactor.

A

set

of

remote

normally

-

opon

contacts

shunted

across

the

transmitter's

filament-

start

switch

will

then

serve

as

filament

start

-2-

and

hold,

satisfying

FCC

requirements

for

a '

fail-safe'

circuit.

If

the

telephone

line

between

studio

and

transmitter

fails,

or if

the

remote

control

equipment

becomes

defective

the

remote

holding

con-

tacts

open.

Tnis,

in turn,

causes

the

filament

contactor

to

drop

out,

removing

the

transmitter

from

the

air.

In

multiple

transmitter

installations,

the

filament-

fail

safe

opera-

tion

is

accomplished

in

a

slightly

different

manner,

so

that

indivi-

dual

filament

control

for

the

various

transmitters

is

possible.

Each

transmitter

employs

its

individual

slave

relay

associated

with

its

respective

transmitter

filament

contactor.

The

fail-safe

relay

in

the

remote

control

unit,

in

turn,

holds

energized

all

of

the

slave

relays.

The

slave

relay

contacts

are

wired

in

series

with

their

respective

filament

cont,actor

off

circuits,

providing

a

holding

circuit.

Thus,

separate

on-

off

filament

control

is

possible

for

each

transmitter.

These

circuits,

along

with

drawings,

are

preseni;ed

in

detail

in

the

Remote

Control

Instruction

Book.

INDEX

Page

Section

I

Electrical

Description

1

Section

II

Mechanical

Description •

1

Section

III

Installation

2

Section

IV

Gates

BC-

250T

Transmitter

Details

3-11

Section

V

Initial

Tune-up

of

Gates

BC-

250T

12-16

Section

VI

General

Operating

Procedure

17-18

Section

VII

Summary

19

Guarantee

1-2

Photographs

Electrical

Parts

List

1-5

Drawings

A-30957 -

Tuning

Chart,

BC-

250T

A-30958 -

Typical

Voltage

Chart

A-30584 -

Typical

Curves,

Vacuum

Ovenless

Crystals

A-30585 -

aood Base

B-13816 -

Schematic,

M-5422

Oscillator

Unit

B-65286 -

Schematic,

Driver

Unit

C-77711 -

Schematic,

Audio

Input/C.thode

Follower

C-77723 -

Simplified

Schematic,

Control

System

C-77736 -

Outline

Diagram

B-65293 -

Bias

Supply,

BC-

250T

E-25582 -

Main

Overall

Schematic

1/16/58

-1-

BC-

250T

Xmtr.

SECTION

I

ELECTRICAL

DESCRIPTION

Gates

transmitter,

type

BC-

250T,

has

been

designed

as

a

completely new

250

watt

broadcast

unit

capable

of

excellent

service

in

the

standard

broadcast

band.

Electrical

specifications

are

as

follows:

1.

Power

output,

250

watts.

The

Gates

BC-

250T

can

be

satis-

factorily

operated

at

275

watts

output,

if

necessary,

to

overcome

losses

in

transmission

lines

and/or

phasing

equipment.

2.

Frequency

Range -

1600

Kc

to

540

Kc,

3.

Power

Supply -

230 volt,

50/60

cycle,

2

wire.

4.

Power

Consumption -

Approximately

1450

watts

with

normal

program

modulation

of

85%.

5.

Frequency

Stability - +

10

cycles,

obtained

by

use

of

vacuum,

ovenless

quartz

crystal

assemblies.

6.

Type

of

modulation -

High

level

Class

modulation

capability

100%.

7.

Audio

Input - +

7

DB +

2

DB for

100%

modulation

at

1000

cycles

8.

Frequency

Response -

-+2

DB,

50 to

10,000

cycles.

9.

Audio

Input

Impedance

--

150/250/600

ohms.

10.

Distortion -

3% or

less,

50

cycles

to

7500

cycles

measured

at

95%

modulation.

11.

Noise -

Minus

60

DB

below

100%

modulatian.

12.

Carrier

Shift -

3%,

or

less,

0-100%

modulation.

13.

Output

Impedance -

To

match

50/70

ohms

at

all

frequencies

540-1600

Kc.

Coupling

unit

available

for

other

impedances.

14.

Tubes

Used -

One -

12BY7A

Oscillator

Two -

6BG6G

Cathode

Follower

One -

12BY7A

First

IPA

Audio

Drivers

Two - 6BG6G

Second

IPA

Two -

810

Class

uB.'

Modulators

(parallel

operated)

One -

5R4GY

Bias

Rectifier

Two -

810

Power

Amplifier

Two -

866A

Intermediate

Voltage

Two -

6BG6G

Input

Audio

Rectifier (

600/650)

Two -

8008

High

Voltage

Rectifier

(1300

V.)

15.

Crystals

Used -

Provision

made

for

two

vacuum

mounted

oven-

less

type

crystal

assemblies,

each

switchable

into

oscilla-

tor

circuit

from

front

panel.

16.

Printed ‘

Firing -

The

oscillator

and

first

IPA,

the

radio

frequency

driver,

the

audio

input/cathode

follower

stage

and

the

feedback

ladder

assembly

are

designed

around

printed

wiring.

SECTION

II

HEC

-

di.IÏICAL

DESCRIPTION

1.

Overall

dimensions -

78"

high,

36-1/16

wide

and

31-29/32"

deep.

Back

and

right

hand

side

are

of

bolt-

On

construction.

Front

door

swing

is

28.

2.

Floor

space

required -

8

sq.

ft.

3.

Weight,

in

operating

condition -

750

pounds.

1/16/58

-1-

BC-

250T

Xmtr.

C

C

SECTION

III

INSTALLATION

This

instruction

book

affords

valuable

information

for

persons

who

are

installing

and

operating

the

Gates

BC-

250T

transmitter.

The

following

mentioned

points

should

be

studied

so

that

the

unpacking

and

setting

up

procedure

will

be

well

in

mind

when

doing

the

actual

work.

1.

Check

all

packing

lists

for

materials

supplied.

2.

Study

the

instruction

book

before

attempting

to

set

up

the

equipment.

3.

Have

the

transmitter

location

clean

so

that

the

various

parts

can

be

safely

placed

out

of

harms

way

when

the

unit

is

unpacked.

4.

It

is

well

ta

have

a

mounting

base,

set

in

place,

upon

which

the

transmitter

can

be

set.

This base

can

be

made

from

2°

x

4°

lumber

dimensioned

as

shown

in

Gates

Dwg.

A-30585.

It

should

be

painted,

preferably

black.

This base

should

be

lagged

to

the

floor

and

measures

taken

to

insure that

the

top

side

of

the

frame

is

perfectly

level.

This

will

give

a

good,

solid,

level

base

on

which

the

transmitter

can

be

set.

This

procedure

also

allows

the

external

transmitter

wiring

to

enter

the

cabinet

from

practically

any

point

underneath

and

be

run

to

the

entry

holes

provided

in

the

base

of

the

cabinet.

5.

Use

heavy primary

wire

from

the

building

switch

box

terminals

to

the

transmitter

fuse

block.

or

M3

copper

wire

should

be

suitable

for

these

two

leads.

6.

Be

sure

the

power

company

has

installed

large

enough

service

for

all

the

equipment,

transmitter,

lights,

water

pump,

etc.,

which

will

be

used

at

the

transmitter

site.

7.

Do

a

good

job

of

installing

the

equipment.

Time

spent

in

making

the

installation

as

good

electric-

ally

and

mechanically

as

possible,

will

pay off

in

the

future

by

insuring

less,

off- the-

air

time.

1/16/58

-2-

BC-

250T

Xmtr.

SECTION

IV

BC-

250T

TRANJMITTER

DETAILS

The

transmitter

has

been

readied

for

shipment

by

having

all

tubes

removed

from

their

respective

sockets,

relay

contacts

have

been

blocked

and

tied

and

other

parts,

such

as

parasitic

suppressors,

tube caps

and

leads,

etc.,

tied

down

securely

to

prevent

damage

during

shipment.

Vacuum

enclosed

time

delay

relays

have

been

re-

moved

from

their

sockets.

The

power

amplifier

RP

choke,

L9,

and

the

coupling

capacitor,

C9,

also

have

been

removed.

The

connector

straps

have

been

adequately

tagged

for

easy,

correct

re-

connection.

These

components

have

been

adequately

marked

and

packed

in

cartons

that

are

in

turn

safely

secured

within

the

transmitter.

All

of

the

power

and

modulating

equipment

has

been

shipped

intact

within

the

cabinet,

thus

relieving

tile

installation

engineer

of

the

re-

instal-

lation

of

these

components.

Coil

L13

located

at

top

rear

of

cabinet

has

special

mounting

straps

provided

to

insure

safe

travel during

transit.

These,

along

with

all

other

packing

material,

string,

tape,

etc.,

should

be

removed

from

the

components.

All

relays should

be

inspected

for

free

travel

of

armatures

and

con-

tacts.

The

following

information

concerning

the

Gates

BC-

250T,

per-

tains

to

its

general

construction

and

operation.

It

is

highly

de-

sirable

to

study

the

various

sections

of

the

transmitter

in

order

to

completely

understand

and

comprehend

its

operation.

The

complete

transmitter

is

built in

a

welded

steel

cabinet

with

most

of

the

low

power

RF

and

audio

components

mounted

vertically

on

a

formed

aluminum

panel

and

shelf

assembly.

The

high

power

modu-

lators

and

power

amplifier

810's

are

located

on

a

tube

shelf

at

the

top

of

this

basic

assembly.

The

power

amplifier

tuning

and

loading

components

are

mounted

on

a

large

aluminum

panel

assembly

at

the

top

of

the

cabinet.

This

assembly

is

perforated

to

allow

the

heated

air

within

the

cabinet

to

pass

through

it

and

then

out

of

cabinet.

Located

in

the

base

of the

transmitter

are the

heavy

power

components,

such

as

power

transformer,

rectifier

filament

transformers,

filter

-omponents,

modulation

choke

and

transformer,

and

rectifier

tubes.

The

transmitter

is

completely

dead

front;

there

is

a

perforated

metal

inner

shield

extending

downward

from

the

power

amplifier

panel

to

the

air

intake

panel.

The

inner

shield

is

joined

to

the

air

filter

panel

by

means

of

two

thumb "

quick

off"

fasteners.

1,

fear

the

right

hand

fastener

are

the

interlocks

for

the

600

volt

and

1350

volt

power

sup-

plies.

All

controls

are

available

to

the

operator

through

a

cut

out

in

this

perforated

screen

panel.

If

this

panel

is

removed,

the

600

volt

and

1350

volt

power

supply

interlocks

function,

removing

these

voltages

from

the

transmitter.

This

transmitter

is

crystal

controlled

by

means

of

the

il

-

5422

oscil-

lator

unit

which

is

located

on the

panel

and

shelf

assembly.

The

crystal

change-

over

switcn,

Sl,

along

with

the

frequency

adjust

vari-

able

condensers,

Cl

and

C2,

are

cinveniently

located

on

the

front

control

panel.

The

M-5422

frequency

control

unit

uses

a

12BY7A

tube

1/1

6/58

-3-

BC-

250T

Xmtr.

connected

circuitwise

as

an

electron

coupled

oscillator,

controlled

by

a

vacuum

mounted,

ovenless

type

crystal

assembly.

Positions

for

two

crystals

is

provided

in

the

oscillator

unit.

The

untuned

plate

circuit

of

the

oscillator

is

capacity

coupled

to

the

grid

of

the

first

IiA,

another

12BY7A

physically

located

in the

small

oscillator

unit.

This

stage

operates

under

very

c)nservative

conditions

and

makes

a

fine

isolation

buffer

between

the

oscillator

and

the

R.2.

driver.

Due

to

the

conservative

operating

potentials

and

the

extremely

low

crystal

cUrrents,

the

M-5422

oscillator

unit

has

exceptional

frequen-

cy

stability.

The

crystals

are

of

a

low

teifeperature

co-

efficient

type

which

do

not

need

a

heated

oven

to

maintain

frequency

well

within

FCC

limits.

Frequency

trimmers,

Cl

and

02,

provide

a

small

deree

of

frequency

adjustment

which

may

be

required

if

the

crystals

age.

The

M-5422

oscillator

unit

is

easily

tuned

to

the

operating

frequency.

No

tuning

is

required

for

the

oscillator

itself,

just

insert

the

cry-

stal,

or

crystals,

and

set

the

crystal

selector

switch

accordingly.

The

first

IPA

stage (

12BY7A,

V2

in

unit)

must

be

tuned.

Provision

is

made

to

supply

U.F.

voltage

from

a

resistive

divider

at

the

output

of

the

M-5422

oscillator

to

a

frequency

monitor

such

as

the

Gates

M-2890.

This

monitor

drive

is

available

between

terminal #

27

on

TB1

and

ground.

See

overall

schematic

-

J'e-25582.

For

typical

voltages

occurring

in

the

oscillator

unit

see

Gates

Dwg.

A-30958.

The

total

plate

current

drawn

by

the

oscillator

and

first

nA

tubes

in

the

osc-

illator

unit

is

in

the •

neighborhood

of

20

to

25

ma.

as

measured

on

the

multimeter

when

the

multimeter

switch

is

in

the

position

marked

'Plt.

Our.

Osc/Bufl.

The

positive

plate

potential

applied

to

the

oscillator

unit

is

derived

from

the

600 volt

power

supply

through

a

20,000

ohm

dropping

resistor,

R9.

Printed

wiring

is

used

in

this

oscillator

unit.

The

second

IPA

stage

ases

two

6BG6G

beam

power

pentodes

operating

in

parallel.

These

tubes

nave

approximately

600/650

volts

applied

to

their

plates.

The

cathode

current

of

the

two

6BG6G

tubes

will

run

between

150

and

200

ma.

depending

upon

loading

and

operating

fre-

quency.

This

cathode

carrent

is

indicated

on

the

multimeter

when

the

selector

switch

is

set

to

'

RF

Driver

Cath..

The

stage

is

tuned

from

the

front

panel

by

control

knob

designated

at

Ji3.2

Driver

Tuning'.

This

stage

will

tune

from

1600

Kc

to

1050

ic

with

no

padding

conden-

ser

required.

Jee

frequency

determining

component

chart,

Gates

Dwg.

A-30957.

Thee

is

meter

indication

of

the

112

drive

supplied

to

the

two

6BG6G's

by

setting

the

selector

switch

to

position

marked

.

1i1J'

Driver

Grid'.

In

normal

operation

the

grid

current

indication

of

this

stage

will

be

on

the

order

of

.3

to .

5

ma.

lith

normal

voltages

applied

and

adequate

grid

drive

the

6BG6G's

in

this

RF

driver

stage

will

supply

between

100

and

120

grid

mils

to

the

power

amplifier.

This

current

will

vary

according

to

tuning

and

operating

frequency,

but

should

never

run

less

than

100

ma.

This

F.A.

grid

current

is

also

measured

by the

multimeter,

being

indicated

on

the

meter

when

the

selector

switch

is

placed

in

the "

Power

Amp.

Grid"

position.

The

plate

dissipation

of

the

two

6BG6G tubes

is

kept

within

accept-

able

limits

by the

use

of

a

cathode

resistor,

1i2,

used

for

develop-

ing

some

cathode

bias.

If

the

drive

to

this stage

is

lost,

the

cath-

ode

developed

bias

will

tend

to

hold

the

plate

current

within

reason-

able bounds. Most

of

the

circuitry

of

this

2nd

IPA

stage

is

made

1/16/58

-4- BC-

250T

Xtr.

up

of

printed

wiring,

only

the

plate

coil,

L8,

tuning

capacitors,

07

and

015,

and

plate

choke,

L7,

are

mounted

external

to

the

printed

wiring

board.

The

plate

voltage

which

energizes

the

two

6BG6G

RF

drivers

is

develop-

ed

in

a

600/650

volt

power

supply

using

two

866A

tubes

as

rectifiers.

Typical

voltages

appearing

within

this stage

are

shown

on Gates

Dwg.

A-30958

and

also

on

Schematic

B-65286.

Neutralization

of

the

power

amplifier

is

accomplished

by

the

"

Ricen

method,

the

out

of

phase

voltage

being

obtained

from

the

6BG6G

tank

coil,

L8.

There

are

several

taps

brought

out

adjacent

to

the

elec-

trical

center

of

this

coil,

these

taps

affording

rough

neutraliza-

tion.

By

means

of

the

variable

neutralizing

condenser,

010

and

these

taps,

it

is

possible

to

completely

neutralize

the

810

tubes

in the

power

amplifier.

The

neutralizing

condenser,

C10,

can

be

adjusted

from

the

front

of

the

transmitter,

by

use

of

a

screw

driver

working

through

the

small

aperture

in

the

lower

right

side

of

the

upper

front

panel.

The

neutralizing

condenser,

010, is

located

directly

behind

this

front

panel,

its

shaft

being

insulated

by

means

of

a

slotted

bakelite

shaft

bushing.

The

power

amplifier

makes

use

of

two

810

tubes.

Most

of

the

power

amplifi'úr

and

output

circuitry

is

mounted

on

an

aluminum

panel

and

chassis,

assembly

at

the

top

of

the

cabinet.

The

heated

air

4)asses

through

the

P.A.

assembly

through

numerous

openings.

This

P.A.

assembly

is

,.

lade

up

of

PA

tank

coil,

L12,

PA

tank

condensers,

Cil

and

012, (

always

operating

in

parallel)

outpuL,

coils, L13

and

L14,

loading

condensers,

C13

and

C14,

modulation

pick-

up

coil,

L15,

plate

blocking

condenser,

C9,

and

plate

bypass

conden-

ser,

C8.

The

amplifier

circuit

consists

of

an °

L.'

and

two .'

f°

sec-

tions,

a

circuit

proved

over

the

years

as

one

which

is

flexible

and

also

very

effective

in

attenuation

of

undesirable

harmonics.

The

coil

and

capacitor

values

as

supplied

with

the

transmitter,

are

ef-

fective

in

loading

into

a

51.5

ohm

load. 3ee

tuning

chart,

Dwg.

A-30958.

The output

circuit

of

the

BC-

250T

includes

a

pickup

coil,

L15,

which

supplies

sufficient

RF

voltage

to

operate

a

modulation

monitor

such

as the

Gates

MO-

3629.

This

voltage

is

available

at

a

small

terminal

board,

TB2,

located

on

the

front

panel,

at

the

left,

ins'

This

amplifier

makes

use

of

no

variable, air

dielectric

condensers

(except

the

neutralizing

condenser,

010).

The

P.A.

tank

circuit

is

tuned

by

means

cf

a

rolling

contact

induc-

tor,

L12.

This

method

of

tuning

is

helpful

in

preventing

arcs

or

flash-overs

that

may

occur

in

variable

air

dielectric

condensers,

especially

if

the

transmitter

is

used

in

locations

where

the

dust

problem

is

bad.

The

P.A.

tank

condensers

are

two

type

G1

Sangamo

mica's,

always

connected

in

parallel.

The

combined

total

value

will

range

from .

0004

mfd.

at

1600

Kc

to .

001

mfd.

at

540

Kc.

The

load-

ing

condensers,

013

and

014,

also

vary

according

to

frequency.

For

information

concerning

these

variable

frequency

determining

compen-r

4-

see

Gates

Dwg.

A-30957 included

in

this

instruction

book.

1/1

6/59

-5-

BC-

250T

Xmtr.

The

power

amplifier

plate

current

is

read

on

M2,

a

0-500

MA

DC

meter.

This

current

will

generally

run

from

260

ma.

to

280

ma.

depending

upon

the

efficiency

and

the

applied

plate

voltage.

The

normal

plate

voltage,

as

read

on

plate

voltmeter,

113,

will

be

around

1350

volts,

As

mentioned

previously,

the

P.A.

grid

current,

as

indicated

on

the

multimeter,

will

be

100 to 120

ma.

depending

upon

frequency,

tuning,

etc.

Two

F.A.

tuning

control

knobs

are

located

on

the

power

ampli-

fier

panel,

the

left

hand

one

controls

the

variable

output

coil,

L14,

and

is

marked '

Loading.

The

right

hand knob

allows

rotation

of

the

variable

P.A.

tank

coil

tuning

the

power

aMplifier.

This

control

is

marked '

P.A.

Tune.

The

power

amplifier

is

protected

from severe over-

load

by

a

cathode

overload

relay.

This

relay,

K6,

is

located

on

the

aluminum

shelf

adjacent

to

the

multiple

810

filament

transformer,

T9.

Its

coil

is

shunted

by

a

semi-

variable

resistor,

R21,

this

resistor

allows

the

trip

out

point

to be

varied

considerably

above

and

below

the

normal

cathode current

drawn

by

the

810

power

amplifier

under

normal

conditions.

This

relay

shunt

resistor

is

adjusted

to

allow

the

relay,

K6,

to

pull

in

at

about

325

ma.

As

normal

cathode

current

will

be

around

260

to

280

ma.

this

gives

considerable

operational

latitude

before

the

transmitter

will

kick

off the

air.

Of

course,

this

adjustment

can

be

made

to

suit

the

individual

who

operates

the

equi:)ment.

Ihen

F.A.

overload

relay,

JÇ:6,

pulls

in,

its

contacts

close,

completing

a

230

volt

AC

circuit

through

the

coil

of

master

overload

relay,

K3.

K3

energizes

and

its

contacts

open,

causing

the

holding

circuit

of

the

plate

contactor,

K2,

to

open

and

drop

out

the

plate

relay.

This

de-

energizes

the

main

power

transformer,

Tl.

Audio

wise,

the

Gates

BC-

250I

transmitter

is

novel

in

many

respects.

The

audio

input

and

audio

driver

portion

is

made

up

of

printed

wir-

ing.

A

small

bakelite

printed

board

located

on

the

panel and

shelf

assembly

mounts

the

two

6BG6G audio

input

tubes,

the

two

6BG6G

cath-

ode

follower

tubes,

along

with

balance

control,

condensers

and

resistors

for

these

two

stages.

The

audio

input

connections

are

made

to

TB1-29

and

TB1-30,

with

a

convenient

ground

termination

on

TB1-28.

Provisions

have

been

made

on

audio

input

transformer,

T6,

to

allow

the

input

impedance

to

be

either

125,

250 or

600

ohms.

The

input

transformer

is

connected

for

600

ohm

operation

when

the

transmitter

leaves

the

factory.

This

will

take

care

of

most

audio

iruut

requirements.

A

balance

control,

.

13,

is

located

on

the

printed

circuit

board

near

the

right

hand

lower

cor-

ner.

This

control

is

in

the

cathode

circuit

of

the two

6BG6G

audio

input

tubes,

V1

and

V2.

By

use

of

this

control,

low

frequency

audio

distortion

can

be

mini-

mizes.

This

is

best

accomplished,

when

test

equipment

is

available

to

show

the

actual

distortion

present.

If

no

such

equipment

is

handy,

it

would

be

reasonable

to

adjust

this

balance

control

to

mid-

value

and

so

operate

the

transmitter.

The

second

audio

stage,

a

pair

of

6BG6G

tubes,

V3

and

V4,

aro

operated

as

cathode

followers,

these

tubes

provide

a

low

impedance

driving

source

for

the

grids

of

the

two 810

modulators.

1/16/58

-6-

BC-

250T

Xmtr.

Plate

potential

for

the

audio

input

and

cathode

followers

is

provi-

ded by

the

600/650

volt

power

supply,

mentioned

previously

as

sup-

plying

voltage

to

the

M-5422

oscillator

unit

and

the

RF

driver

stage.

Normal

voltages

to

be

expected

at

various

points

in

the

audio

input

circuits

are

given

in Gates

Dwg.

A-30958

9

typical

voltages.

The

cathode

current

of

the

two

audio

input

tubes,

V1

and

V2,

is

measured

by

multi-

meter,

the

selector

switch

being

set

at "

Input

Audio

Cathode.

This

current

will

normally

run

from

5

to

10

ma.

The

cathode

follower

tubes,

V3

and

V4,

are

biased

by

voltage

con-

trolled

by

potentiometers,

112

and

R1,

located

on

the

small

aluminum

front

panel.

These

controls

indirectly

adjust

the

operating

bias

on

the

modulators

by

varying

the

operating

constants

of the

cathode

fol-

lowers,

this

causes

a

bias

voltage

change

on the

modulators

by

having

a

voltage

drop

occur

across

the

high

resistance

cathode

resistors,

Rll

and

1112,

of

the

cathode

followers.

A

very

smooth

modulator

bias

change

can

be

attained

in

this manner,

making

it

possible

to

adjust

the

modulators

for

correct

operating

conditions.

There

is

no

meter

plate

current

indication

for

the

cathode

follower

tubes,

V3

and

V4,

it is

believed

that

if

proper

modulator

operation

is

had,

then

the

6BG6G

cathode

followers

are

operating

satisfactorily.

All

external

connections

to

the

audio

printed

wiring

is

made

to

numbered

terminals, this

is

shown

clearly

on

small

individual

draw-

ing

C-77711

of

this

section,

and

in

the

overall

schematic

E-25582.

High

level

Class "

JP

modulation

is

used

in

the BC-

250T,

a

pair

of

810

tubes

providing

the

means.

The

modulation

transformer, £

3,

working

with

these tubes

is

located

in

the

base

of

the

cabinet,

on

the

right

hand

side,

toward

the

rear.

The

grids

of

the

modulators

are

excited

by

the

two

6BG6G

cathode

followers.

The

modulators

operate

with

approximately

30

na,

static

plate

current

per

tube,

this

operating

parameter

being

set

up

from

the

front

panel

by

use

of

the

two ' bias"

controls,

R1

and

112.

To

enable

the

operator

to

individually

adjust

each

modulator

tube,

a

meter

switching

circuit

has

been

designed.

A

three

position

switch,

31,

is

located

on

the

aluminum

front

panel,

just

below

the two

bias

controls.

This

switch

has

markings

as

follows;

in

the

left

position

Modulator

1,

1, (

V8)

is

metered,

in

the

right

hand

positi.rn

Modulator /,

4

2 (

V9) is

metered

and

when

the

switch

is

in

the

center

position

marked "

Total,

both

tube

currents

are

combined

and

read.

These

currents

are

indicated

on

the

modulator

front

panel

meter,

114.

The

total

plate

current

will

be

from

250

to

300

ma.

during

times

of

heavy

modulation.

Each

modulator

has

its

filament

energized

by

a

separate filament

winding

on

multiple

filament

transformer,

T9.

The

third

winding

on

this

transformer, £

9,

is

10V,

9

ampere

capacity

and

energizes

the

filament

of

the

power

amplifier

tubes,

V6

and

V7.

The

modulators

are

protected

from

severe

overload

by

relay,

K7.

This

relay,

K7,

is

also

provided

with

a

coil

shunt

resistor,

1122,

making

it

possible

to

adjust

the

pull-

in

point

of

the

relay.

For

normal program

modulation

the

modulator

plate

current

should

not

exceed

perhaps

300

ma.

Under

sine

wave

audio

conditions

this cur-

rent

may

rise

to

400

ma.

at

the

higher audio

frequencies.

A

1/16/58

-7-

BC-

250T

Xmtr.

satisfactory

setting

for the

overload relay

would

be

around

450

ma.

This

will

take

care

of

accidental

audio

peaks

that

might

go

through.

This

overload

relay,

K7,

has

its

normally

open

contacts

connected

in parallel

with

the

normally

open contacts

of P.A.

overload

relay,

K6.

If

a

modulator

overload

does

occur,

the

K7

modulator

overload

relay

pulls

in

causing

230

volts

a.c.

to

be

applied

to

the

coil

of

master

overload

relay,

K3,

which

in

turn

energizes

and

pulls

in

to

open

the

holding

circuit

of

plate contactor,

K2.

This

removes

the

high

voltage

from

the

modulators

and

the

power

amplifier.

Feedback

from

the

plates

of

the

modulators

back

to

the

audio

input

tube

grids

has

been

provided.

A

small

bakelite

priated

wiring

board

is

located

on

the

panel

and

shelf

assembly,

directly

above

the

modulation

transformer,

T3.

By

means

of

a

resistor/capacitor

divider

network

out

of

phase

voltage

is

fed

bac!:

to

the

audio

in-

put.

The BC-

250T

transmitter

makes

use

of

approximately

9

DB

of

feedback

measured

at

1000

cycles and

90c/;

modulation.

This

feedback

helps

to

reduce

the

hum

and

also

improves

the

distortion

figures. •

All

relays

for

the

operation

of

the

transmitter

are

mounted

on

the

panel

and

shelf

a

ssembly,

the

previously

mentioned

P.A.

and

the

modulator

overload

relays,

K6

and

K7,

being

on

the

top

shelf

ad-

jacent

to

the

multiple

filament

transformer, .

29.

All

other

relays

are

mounted

at

the

bottom

of

the

panel

and

shelf

assembly

along

with

necessary

fuses,

time

delay

relays,

etc.

The

main

line

fuses,

Fl

and

F2,

are

located

at

the

left

bottom

section

of the

inside

panel

asseilbly,

directly

over

TB-

1.

This fuse

receptacle

is

the

terminal

location

for

the two

230

volt

primary

input

wires.

Fifteen

ampere

cartridge

fuses

are

used.

Next

in

line

is

the

filament

con-

tactor,

Kl.

Filament

contactor,

Kl,

is

energized

by

depressing

the

filament

start

switch,

S5,

located

on

the

front

column

directly

beneath

the

multimeter.

This

operation

causes

the

primary

input

voltage

to be

connected

directly

to

the

primaries

of

all

filament

transformer

(T4,

8008

fil.

trans.,

T5,

866A

fil.

trans.,

1

28,

dual

6.3

volt

fil.

trans.

for

audio,

RF

driver

and

osc.

unit

and

T9,

the

10

volt

mul-

tiple

fil.

trans.

for

the

modulators

and

power

amdlifier).

At

the

same

time

the

heater

for

time

delay

relay,

K5,

is

energized.

After

30

seconds

the

contacts

of

K5 (

low

voltage

time

delay)

close

and

this

action

energizes

the

primary

of

T2,

the

600/650

volt

power

transformer. (

If

the

interlock

switch,

33,

is

depressed.)

Along

with

tlis

sequence

of

events,

the

primary

of

the

bias

transformer,

T7,

is

energized

and

as

the

bias

rectifier,

V5,

heats,

bias

voltage

is

developed.

This

will

be

approximately

neg.

280

volts.

Listing

the

functions

performed

when

35,

the

filament

start

button, has

been

depressed,

we

have --

1.

All filaments

energized,

filament

pilot

light

on,

low

volt-

age

time

delay relay

heating.

2.

Bias

supply

energized,

neg.

280

volts,

developed

setting

up

bias

for

cathode

follower

and

modulators.

3.

600/650

power

supply

energized (

if

low

voltage

door

inter-

lock

S3

is

depressed).

This

has

energized

the

plate

circuits

of

the

crystal

oscillator,

first IPA

and

hF

driver and

if

they

are

correctly

tuned,

there

will

be

grid

drive

to

the

1/16/58

-8-

BC-

250T

Xmtr.

'power

amplifier.

Also

the

600/650

volts

has

been

applied

to

the

input

audio

and

cathode

follower

stage.

4.

High

voltage

time

delay

relay,

K4,

heated

and

its

control

contacts

closed. (

After

primary

of 12

is

energized.)

Plate

contactor,

K2,

is

located

next

to

the

filament

contactor,

near

the

lower

part

of

the

panel

and

shelf

assembly.

If

the

high

voltage

door

interlock

switch,

34,

is

closed

and

high

voltage

time

delay

re-

lay,

K4,

is

heated

and

its

contacts

closed,

it

would

be

possible

to

energize

this

plate

contactor,

K2,

by

depressing

the

plate

start

but-

ton

located

just

beneath

the

meter

column.

When

plate

contactor,

K2,

closes,

several

operations

occur.

1.

The

high

voltage

plate

transformer,

11

primary,

is

energized,

developing

high

voltage (

1350/1400

approx.)

for

and

modulator

plates.

2.

Plate

nilot light energizes.

This

would

place

the

transmitter

on

the

air.

The

Gates

BC-

250T

transmitter

makes

use

of

3

separate

power

supplies.

1.

Bias

Power

Supply.

It

is

made

up

of

a

combined

filament

and

plate

transformer

T7,

working

in

conjunction

with

bias

rectifier,

V5,

a

5R4GY,

filter

choke

L6,

filter

condenser

06

and

associated

resis-

tors

and

potentiometers.

The

bias

potentiometers,

R1

and

R2,

indirectly

vary

the

modulator

bias,

by

controlling

the

cathode

follower

bias

and

thus

the

current

flow,

through

the

cathode

follower

resistors,

Rh

l

and

R12.

There

is

ap-

plied

a

negative

280

volts

between

these

resistors

and

ground.

An opposing

voltage

of

approximately

240

volts

is

developed

by

current

flow

trough

Rll

and

R12,

thus

putting

the

difference (

about

30/40

volts)

on

the

grids

of

the

modulators.

This

supply

energizes

when

the

filament

start

button

is

depressed.

2.

600/650

Volt

Power

Supply

This

supply

makes

use

of

a

pair

of

866A

rectifiers,

the

filaments

of

which

are

heated

by

transformer,

T5.

The

primary

of

T5

is

energied

at

the time

the

fila-

ment

start

switch

is

operated.

Approximately

30

seconds

after

the

filaments

are

energized,

and

low

voltage

time

delay

relay,

K5,

has

heated

and

closed

its

contacts,

this

causing

the

primary

of

T2,

the

600/650

volt

power

transformer

to

energize (

if

the

low

voltage

door inter-

lock

switch

33

is

closed)

develop

approximately

600

volts

d.c.

after

being

rectified

by

V4

and

V3,

the

two

866A

rectifiers.

This

voltage

is

applied

to

the

M-5422

oscillator

unit

through

a

dropping

resistor,

E9,

which

reduces

it

to

approximately

195V.

The

600

volts

is

ap-

plied

to

the

RF

driver.

Also,

this

same

voltage

is

ap-

plied

to

the

audio

input/cathode

follower

stages.

The

1/16/58

-9-

BC-

250

.2

Xmtr.

primary

of

this

power

transformer (

T2)

is

fused

by

a

small

fuse,

F4,

of

3

ampere

size.

High voltage

for

the

modulators

and

power

amplifier

approximately

1350

volts

is

developed

by

a

power

supply

consisting

of

main

power

transformer,

Tl,

8008

filament

transformer,

T4,

swinging

choke,

Ll,

smoothing

choke,

L2,

and

filter

capacitor,

C2

and

C3.

These

components

are

located

in

the

base

of

the

transmitter

along

the

left

hand

side

and

to-

ward

the

front.

This

high

voltage

supply

is

inter-

locked

with

the

front

panel

grill

and

interlock

switch,

S4.

Provisions

have

been

made

to

operate

the

Gates

BC-

250T

transmitter

be

remote

control. The

connections

are

clearly

shown

on

Gates

over-

all

schematic

E-25582.

It

is

necessary

to

remove

the

jumper

wire

that

normally

connects

between

contact #

1

and #

3

on

a

filament

start

contactor,

Kl,

and

wire

normally

connected

between

TB1-10

and

TB1-22.

For

shipping

purposes,

some

components

have

either

been

removed

or

mechanically

made

secure

within

the

cabinet

proper.

All

of

the

re-

moved

items

are

boxed

and

th.e

carton

containing

them

is

shipped

with-

in

the

cabinet.

The

following

items

have

been

removed -

C

e

1.

All

Vacuum

Tubes.

2.

Time

Delay

Relays,

K4

and

K5.

Contacts

of

the

filament

and

start

relays have

been held

firm

by

use

of

paper

and

tape.

Tube

caps

and

parasitic

suppressors

have

been

taped

down

to

prevent

damage

by

vibration

during

shipment.

Certain

components

have been

supported

by

wooden

braces.

All

of

this

material

should

be

removed

from

the

transitter,

care

snould

be

taken

to

see

that

all

relays

are

free

of

foreign

material

that

wJuld

prevent

them

to

operate

normally.

The

connections

to

the

various components

that

have

been

removed

are

clearly

tagged

for

easy

and

correct

replace-

ment.

Remove

extra

coil

bracing

from

L13

which

is

located

in

the

top,

at

rear.

Check

all

mechanical

connections

for

tightness.

Replace

all

vacuum

tubes,

crystals

and

time

delay

ralays

in

their

correct

sockets,

check

locations

by

reference

to

overall

schematic

E-25582

and

the

various

pictures

that

are

supplied

as

a

part

of

this

instruction

book.

At

this

time

do

not

place

the

plate

caps

on

the

866A

rectifier,

V3,

and

V4,

and

the

808

rectifiers,

V1

and

V2.

The

external

connections

are

few and

these

are

easily

made

to

the

BC-

250T

transmitter.

The

230

volt,

50/60 cycle

AC

enters

the

cabi-

net

base

at

the

right

hand

side,

near

the

rear

corner.

The

two

primary

wires

connect

directly

to

the

fuse

block,

XF1.

The

shielded

audio

input

pair

enters

the

cabinet

at

the

right

hand

side

near

the

front.

These

connections

arc

made

to

the

terminals #

29

and #

30

on

TB1.

A

ground

is

close

by

on

terminal #

28.

1/16/58

-10-

BC-

250T

Xmtr.

The

modulation

monitor

connects

to

TB2-1 &

2.

This

terminal

board

is

located

on the

back

side

of

the

tuning

and

loading

panel,

at

the

left

front

side.

This

connection

can

be

made

with

shielded

twisted

pair,

such

as

is

used

in

audio

wiring.

The

frequency

monitor

connects

to

TB1-27

and

28,

the

ground

being

terminal #

28.

This

connection

can

be

made

of

shielded

single

con-

ductor

wire,

or

low

impedance

line

such

as

RG/62U.

A

ground

stud

is

provided

on

the

cabinet

frame

for

a

transmitter

ground

connection.

Located near

the

modulation

transformer,

T3,

this

connection

facilitates

the

grounding

of

the

transmitter

to

the

overall

station

ground

system.

A

copper

strap

can

be

brought

in

through

the

access

hole

in

the

right

rear

base

section

of

the

trans-

mitter. (

The

AC

primary

wires

were

brought

in

through

this

opening

also.)

This

internal

ground

follows

up the

cabinet

support

and

fin-

ally

connects

to

the

aluminum

PA

tuning

assembly

at

the

top

of

the

cabinet.

The

RF

output

termination

is

a

ceramic

feedthrough

insulator

located

close

to

the

output

coil,

L14.

Connection

can

be

either

made

from

the

top

of

the

cabinet

through

an

access

opening,

or

the low

impedance

line

can

be

brought

in

through

the

base

of

the

transmitter

and

con-

nected

to

the

out

-

put

circuit.

A

word

of

comment

here,

concerning

the

station

ground

system.

It

should

be

constructed

as

good

as

can

be,

all

connections

well

made

and

soldered,

or

preferably

brazed.

It

is

wise

to

bond

all

electri-

cal

conduit,

metal

frame

work

of

building,

water

piping,

etc.,

to

the

overall

ground

system.

If

these

suggestions

are followed,

there

will

be

less

trouble

over

the

years

as

the

ground

system

ages.

1/1

6/58

-11-

BC-

250T

Xmtr.

z

C.:

SECTION

V

INITIAL

TUNE-UP

OF

TIE

GATES

BC-

250T

Before

proceeding

with

the

initial

tune-up

of

this

transmitter,

it

would

be

well

to

re-

check

the

necessary

things

to be

done,

before

any

voltage

is

supplied.

Briefly,

check

the

following

list.

1.

Proper

primary

line

voltage

connected

to

fuse

bloCk,

XFl

e

two

15

ampere

fuses

should

be

in

the

clips

of

this

fuse

block.

2.

Proper locatipn

of

all tubes

in

sockets.

These

tube

locations

can

be

checked

by

reference

to

the

stencil-

ling

in

the

transmitter

and

to

information

furnished

in

this

instruction

book.

Also,

make

sure

the

crystal,

or

crystals,

are

in

the

oscillator

crystal

sockets.

If

only

one

crystal

is

used,

be

sure

the

crystal

selector

switch,

Sl,

is

in

the

correct

position

to

operate

with

the one

crystal.

36

Check

to

see

that

all

tie-

down

twine

and

other

material

used

in

shipping

the

transmitter,

has

been

removed

from

the

various

components,

especially

the

relays.

4.

de-

check

all

components

that

were

installed.

Be

sure

they

are

connected

correctly.

The

parts

and

the

connec-

tors

have

been

tagged

to

insure

correct

replacement.

5.

Go

over

the

complete

transmitter,

checking

the

tightness

of

all

nuts

and

bolts,

terminal

connections,

etc.

6.

Give

all

soldered

connections

a

brief

lookinc

over.