Gates BC1G Instruction Manual

GATES

INURUCTIONS

FOR

InaLLING

AND

OPERATING

TH2

GATES

TYEE

BC1G,

1000/250

WATT

BROADCAST

TRAI\UIIITTER

Gates Radio

Company

I.B. #

888

0800

001

Quincy,

Illinois

MODULATION

TRANSFORMER

INSTRUCTIONS

Please

read

these

instructions

before

attempting

to

test

the

modulation

transformer

in

this

transmitter.

The

modulation

transformer

employed

in

this

transmitter

may

be

of

a

type

which

will

indicate

unequal

resistance

in

the

primary

windings.

An

ohmmeter

check

of

the

wind-

ings

may

indicate

that

the

transformer

is

defective;

whereas

in

reality,

this

is

a

normal

reading

and the

modulation

transformer

is

performing

normally.

In

order

to

properly

check

this

transformer

outside

of

the

transmitter

circuit,

merely

apply

117

volts,

60

cycle

a.c.

to

the

secondary

winding.

Check

the

voltage

on

each

half

of

the

primary

winding.

If

the

transformer

is

oper-

ating

normally,

then

these

voltages

s'r-viicl

be

approximately

equal.

Gates Radio

Company

Quincy,

Illinois

SAFETY

NOTICE

This

equipment

employs

voltages

which

are

dangerous

and .

may

prove

fatal

if

contacted

by

operating

personnel.

Extreme

caution

should

be

exercised

when

working

with

the

equipment.

KEEP

AWAY

FROH LIVE

CIRCUITS

Observe

safety

regulations.

Do

not

change

tubes

or

make

adjustments

inside

equipment

with

hiLh

voltages

on.

Do

not

depend on

door

interlocks

or

switches

for

protection.

No

reliance

should

be

placed

on

the

interlock

switches

for

removing

high

operating

voltages.

SWITCH

TO

SAFETY

SAFETY

FIRST:

.

1hen

workind

on

the

transmitter,

disconnect

the

primary

power

at

the

building

wall

switch.

WARRANTY

The

Gates

warranty,

gladly

supplied

in

detail

on

request,

generously

covers

all

materials

when

returned

to

the

Gates

factory

for

inspection,

transportation

paid.

Certain

moving

parts

and

tubes

are

guaranteed

usually

on

an

hourly

bnsis

and

that

of

the

manufacturer's

guarante.

This

warranty

does

not

extend

to

free

service

in

the

field,

but

this

service

is

wail-

able

at

a

modest

cost,

where

required.

BC1G

TABLE

OF

CONTENTS-

Pàe

SAFETY NOTICE

WARRANTY

TABLE

OF

CONTENTS

SPECIFICATIONS

ILLUSTRATION,

BC-

1G

FRONT

VIEW -

PHOTO

800

0437

001

SECTION

I -

GENERAL

DESCRIPTION

1.1

Mechanical

Construction

1.1.1

Transmitter

Controls

1.2

Incidental

Information

1.2.1

Tube

Handling

1.2.2

Transmitter

Building

Temperatures

1.2.3

Grounding

1.2.4

Antenna

Coupling

SFCTION

II -

THEORY

OF

OPERATION

2.1

M5422

Oscillator

Unit

2.1.1

Tube

Complement,

M5422

Oscillator

Unit

2.1.2

Type

of

Oscillator

Circuit

2.1.3

Type

of

Crystal

Used

2.1.4

First

IPA,

12BY7A

2.1.5

M5422

Oscillator

Tuning

Procedure

2.2

BC-

1G

Transmitter

Description

2.2.1 -

Tute.___Lineup

2.2.2

BC-

1G

llrfayrem

.-

1-t-t-

er

- -

CIr

cu

i:

t

ry

2.3

Power

Supplies

2.3e1

Bias

Supply

2.5.2

600/625

.

yolt,

Low

Voltage

Supply

2.3.3

2800

Volt

Supply

2.3.3.1

High Voltage

Supply

Operation

at

250

Watts

Output

2.3.3.2

BC-

1G

Power

Change

Facility

2.4

Attachment

of

Remote

Control

in

BC-

1G

SECTION

III -

INSTALLATION

3.1

3.2

3

.3

3.3.1

).3.2

3.3.3

3.3.4

3.3.5

3.3.6

3.3.7

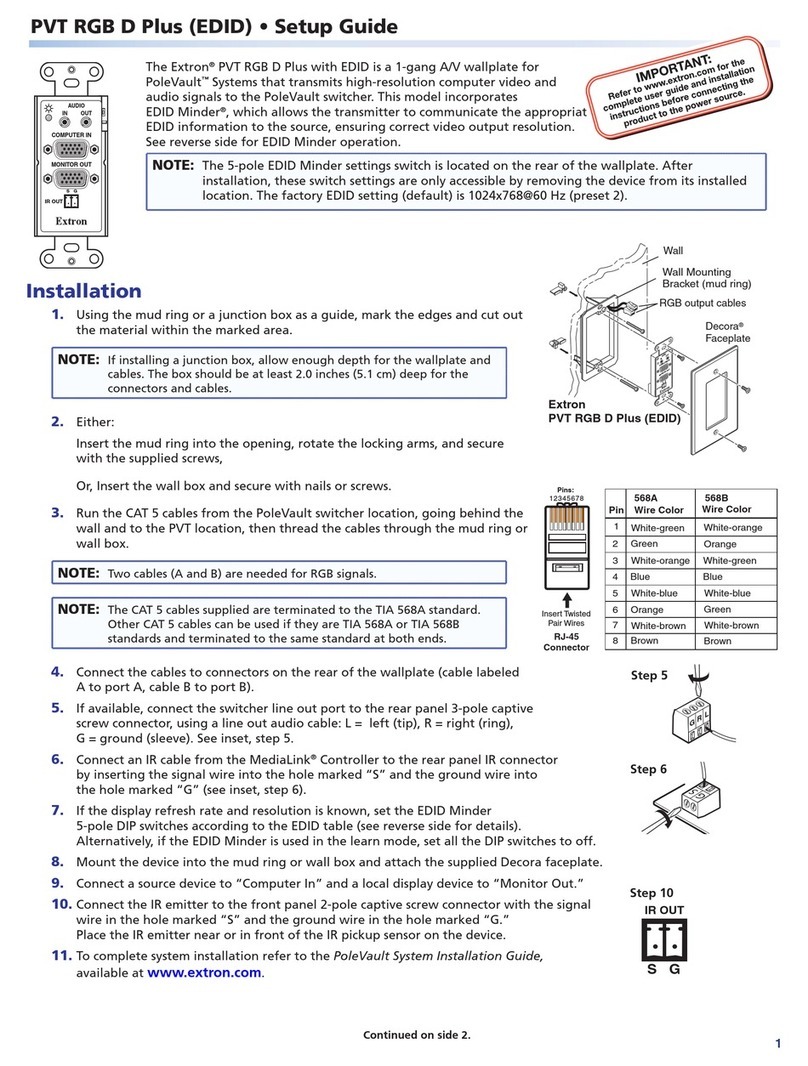

Installation

Hints

Transmitter

Inspection

Transmitter

Connections

Primary

Power

Transmitter

Ground

Audio

Input

Modulation

Monitor

Frequency

Monitor

RF

Output

Remote

Control (

if

used)

-1-

BC-

1G

3.3.7.1

3.3.7.2

3.3.7.3

3.3.7.5

3.3.7.6

3.3.7.7

3.3.7.8

3.3.8

3.4

Detailed Instructions

for

Rerrate-Control

Connections

Plate

Rheostat

Motor

Assembly

'Remote

Power

Change

Reset,

Plate

Off

Remote.

Plate

Voltage

Indication

'Remote

Plate-

Current

Indication

Remote

Tower

Light

Indication

Remote

Antenna

Current

Metering

Studio

Procedure,

for

Remote

Control

Operation

Crystal

Installation

SECTION

IV -

TUNE-UP

PROCEDURE,

1000

WATT

CARRIER

4.

1

4.1.1

4.1.2

4.2

4.3

4.4

4.5

4.5.1

Preliminary

Tune-up

Checks

(Transmitter

locally

controlled)

Checking

Filament

Voltage,

Bias

Supply

and

Low

Voltage

Supply

Checking

Power

Amplifier

Tuning

Components

Neutralizing

the

Power

Amplifier

Power

Amplifier

Tuning

Modulator

Adjustment

Modulation

Monitor

Connections

Method

of

Adjustment,

Coil

L43

and

Resistor

R34

SECTION

V -

TUNE-UP

PROCEDURE,

250

WATTS

SECTION

VI -

HELPFUL

OPERATIONAL

INFORMATION

6.1

Frequency

Adjustment

6.

9

Transmitter

Cleanliness

6.3

Relay

Maintenance

6.4

Care

of

Printed

iring

Boards

6.5

Cabinet

Ventilating

Fan

6.6 -

Teet-quipment

revinsroeen

Esc

5.7

D.C.

Resistance-tle

-

a-ectrem

-

entallod•

AM-

30469E -

Gates

478 0084

000

6.8

Reprints

ary

a

Replacing

Components

on

the

Printed

Chassis. (

Gates

has

a

printed

sheet

furnished

on

request,

no

charge)

b)

HGlpful

General

Information

SECTION

VII - PARTS

LIST

SECTION

VIII -

TRANSMITTER

PHOTOGRAPHS

800

0437

002 -

800

0437

003 -

800

0437

004 -

800

0437

005 -

800 0437

006 -

800

0437

007 -

800 0437

008 -

800

0437

009 -

Front

Door

Open,

Screen

in

Place

Front

Door

Open,

Screen

removed

Front

Door

Open,

Screen

removed,

Panel &

Shelf

Inside

View,

Top Portion,

Transmitter

Inside

View,

Bottom

Portion,

Transmitter

Rear

View,

Back Removed,

showing

Rectifiers

Rear

View,

Back

Removed,

showing

Panel

&

Shelf

Side

View,

Side

Cover

Off

-2-

BC-

1G

SECTION

IX -

CIRCUIT

DIAGRAMS

AND

CHARTS

A-30584

Typical

Curves,

Frequency

Stability,

Vacuum

Crystal

821

3816

001

Schematic,

Oscillator

Unit,

M5422

813

7774

001

Typical Voltage

Chart

813

7711

001

Tuning

Chart

813

7626

001

Wiring

Diagram,

Modulator

Selector

Switch

813

7928

001

Supplemental

Relay

Connections,

KlA

813

7961

001

Supplemental

Relay

KlA

Location

813

7914

001

Wiring

Diagram,

Remote

Plate

Voltage

Control

837

8485

001

Wiring

Diagram,

Studio

Unit,

RDC-10C

837

9369

001

Wiring

Diagram,

Transmitter

Unit,

RDC-10C

826

9003

001

Interconnections

using

RDC-10C

Transmitter

Unit

813

7963

001

Running

Sheets,

Panel &

Shelf

813

7962

001

Running

Sheets,

Cabinet

826 8808

001

Control

Circuitry

813

7924

001

Base

Layout

813

7529

001

Diagram,

Primary

Relay

Kl

813

7628

001

Wiring

Diagram,

Multimeter

S2

Connections

813 8885

001

Contact

Identification

852

5878

001

Overall

Schematic

-3-

BC-

1G

Tranauitter

SPECIFICATIONS

BC-

1G,

1000/250 WATT

TRN.31`

,

IITTER

Talf,

FOLLOWING

SPECIFICA

.

2IONS

A.;

.E

TYPICAL -

RATED

POWER

OUTPU2:

1000/250

watts.

Capable

of

1100/275

watts,

if

necessary,

to

overcome

possible

losses

in

directional

arrays.

FREQUENCY

RANGE:

2000

Kc

to

540

Kc

PRIMARY

PUER

INPUT:

230

volts,

3

wire,

solid

neutral,

single

phase,

50

to

60

cycles.

Approximately

3850

watts

consumed

at

100%

tone

modu-J..-

tion,

at

1000

cycles.

FREQUENCY

STABILITY: +

5

cycles

within

temperature

range

of

-

50

to

122°F.

ELEVATION:

6500

feet.

VENTILATION

NECESSARY:

Provision

should

be

made

to

allow

1500

CPM

of clean,

outside

air

under

all

circumstances

AUDIO

INPUT:

INPUT

AUDIO

IMPEDANCE:

FREQUENCY

RESPONSE:

DI0TORTION:

CARRIER

SIM:

RF

OUTPUT

IMPEDANCE:

DUMMY

ANnNNA:

16

DB, +

2

7Y

1

k,

for

100%

modulation

for

both

output

powers.

As

supplied, 600

ohms,

w.ich

will

also

serve

to

match

500

ohms

satisfactorily.

Input

may

be

connected

for

150/250

ohms,

if

desired.

+1.5

DB,

30 to

12,000

cycles.

Rated

at

3%

from

50

to

10,000

cycles,

at

95%

modulation.

60

DB,

or

better,

below

100%

modulation.

37,

or

less,

between

0

and

100%

modulation.

Jill

match

resistive

loads

from

50 to

70

ohms.

51.5

ohms,

inbuilt

TUBES

USED:

2)

12BY7A,

Osc. &

let

IPA

6)

807,

Audio &

2nd IPA

4)

833A,

Power

Amp. &

Modulators

Silicon

rectifiers

are

used

in

bias,

intermediate voltage

and

high

voltage

supplies.

SECTION

I

GENERAL

DESCRIPTION

It

is

the

purpose

of

this

instruction

book

to

thoroughly

explain

in

a

clear,

concise

manner,

the

workings

of

the

Gates

BC-

1G

Broad-

cast

Transmitter,

as

well

as

installation

and

operational

infor-

mation.

The

pictures

show

clearly

all

components

within

the

cabinet,

these

parts

are

adequately

marked

for

easy

reference

back

to

the

parts

list

and

to

the

written

text.

This

instruction

book

is

a

manual

for

installational

information

and for

future

reference

during

servicing

of

the

transmitter.

1.1

MECHANICAL

CONSTRUCTION

The

BC-

1G

Transmitter

is

completely

self-contained

in

one

attrac-

tive

steel

cabinet,

measuring

78

n

high,

37°

wide

and

29"

deep,

with

a

full

front

door

with

its "

shadow

moulding'

covering

practi-

cally

the

complete

front.

This door

is

hinged

from

the

left

side,

it

requires

33"

floor

space

to

swing.

Four

large

meters

are

loca-

ted

on

a

panel

mounted

across

the

top

of

the

cabinet.

Most

of

the

controls

are

mounted

behind

and

hidden

by

this

door,

the

exception

being

the

filament

start/stop,

reset,

plate

off,

low

power

and

high

power

combination

switch

and

neon

indicators.

These

switches

are

mounted

on

the

right

hand

cabinet

corner

post,

protruding

through

an

opening

in

the

door,

when

it

is

closed.

The

heavy

power

components

are

mounted

on

the

base

of

the

cabinet.

The

low

powered

audio

and

radio

frequency

stages

are

built

upon

a

"panel

and

shelf"

assembly,

along

with

the

control

circuitry

and

the

bias

supply.

Mounted

on

the

shelf

portion

of

this

assembly

is

the

multi-

winding

filament

transformer

used

to

energize

all

tube

filaments

in

the

silicon

powered

transmitter. (

If

tube

rectifiers

are

used,

two

additional

rectifier

filament

trans-

formers

must

be

used).

At

the

top

of

this

panel

assembly

is

the

four

sets

of

filament

connectors

which

secure

the

P.A.

and

modulator

833A

tubes.

The two

tubes

to

the

front

of

the trans-

mitter,

V40

and

V41,

are

the

RF

amplifiers,

the

two

toward

the

rear,

V42 and

11

1

1.3,

are

the

modulators.

This

complete "

panel

and

shelf"

assembly

is

hinged

to

the

right

rear

cabinet

corner

post,

and

held

securely

by

three

captive,

slotted

head

screws

at

the

front

corner

post.

This

feature

allows

this

panel

to

be

loosened,

then

swung

inward

on

its

hinges,

to

provide

access

to

the

complete

panel without removing

the

right

hand

side

of

the

cabinet.

This

is

of

great

advantage

if

the

transmitter

is

located

in

a

position

necessitating

other

equip-

ment

to

be

placed

directly

against

the

right

hand

side

of

the

-transmitter.

All

tuning

controls

are

available

from

the

front

of

the

trans-

mitter. (

Large

front

cabinet

door

must,

of

course,

be

opened).

An

interlocked

perforated metal

screen

is

mounted

over

the

front

opening

of

the

transmitter,

which

gives

the

utmost

physical

pro-

tection

to

the

operating

personnel.

This

screen

is

easily

re-

movable

from

the

cabinet,

allowing

full

access

to

the

inside

of

-1-

BC-

1G

dUle

cabinet

from

the front.

One

exhaust

fan

is

located

above

the

833A

power

tubes,

in

the top

of

the

cabinet,

to

draw

the

heated

air

up

and

out

during

operatior...

Two

disposable

air

filters

are

located

in

the

lower

portion

of

the

back

cabinet

cover,

through

which

cool

air

is

drawn

into

the

transmitter.

The

dummy

antenna

asselnbly

is

mounted

on

the

left

cabinet

wall,

toward

the

top,

as

viewed

from

the

front.

Both

the

back

and

right

hand

side of

this

transmitter

cabinet

is

removable

for

servicing,

if

required.

1.1.1

TRANSMITTER

COUTROLS

All

transmitter

tuning

controls

are

available

from

the

front

of

the

transmitter.

The

small

vertical

panel,

which

is

an

integral

part

of

the " panel

and

shelf"

assembly

located

on

the

right

side

of

the

cabinet,

behind

the

front

door,

has

the

following

controls:

1.

The

crystal

selector

switch,

Sl,

and the

two

crystal

trimmer

capaoitors,

Cl

and

02. (

The

M5422

Crystal

Oscillator

Unit

is

mounted

directly

behind

this

panel.

Its

controls,

Sl,

Cl

and

02,

protrude

through

a

small

aperture

in

this

panel,

and

thus,

are

available

from

the

front).

2.

The

R2

driver

tank

tuning

ca

-

oacitor,

04.

3.

Multimeter

switch,

32,

4.

Modulator

cathode

current

selector

sitch,

Si.

5.

Modulator

bias

controls,

R1

and

R2.

The

following

controls

are

located

on

the

right

hand

corner

post

section

of

the

cabinet:

1.

Filament

rheostat,

R43.

2.

Plate

rheostat,

R41.

3,

Filament

On/Off,

341. (

Red pushbutton).

4.

Reset,

342. (

Red

pushbutton),

5.

i'late

stop,

343. (

White

pushbutton).

66

250

latt

carrier, $

44

6

(

Amber

pushbutton).

7.

1000 ',

Iatt

carrier,

345. (

lhite

pushbutton).

8.

Local/Remote

toggle

switch,

340.

-2-

BC-

1G

A

complemeet

of

four-

large

ineters-are_mounted

on -

a

panAl

at

-

the

top

of

the

cabinet.

From

left

to

right,

they

are:

1.

Multimeter,

M40

2.

Modulator

cathode

current,

M43.

3.

P.A.

plate

current,

M42.

4.

P.A.

plate

volts,

M41.

The

line

meter,

M44,

is

mounted

on

the

power

amplifier

panel,

and

is

visible

when

the

front

cabinet

door

is

open.

Also,

on

this

I.A.

panel

we

find

the

power amplifier

tuning

control,

L40,

the

power

amplifier

load

control,

L42,

and

the

neutralizing

adjustment,

C40.

This

latter facility

is

a

screw

driver

adjust-

ment

made

through

a

small

opening

in

the

panel,

it

is,

of

course,

a

seldom

manipulated

control.

1.2

INCIDENTAL

INFORMATION (

TUBE

HANDLING,

TRANSMITTER

MIDING

TEMPERATURE,

ETC.

It

is

well

to

mention

several

areas

that

make

for

better

and

more

profitable

operation.

1.2.1

TUBE

HANDLING

The

Gates BC-

1G

Transmitter

uses

833A

power

tubes

in

the

power

amplifier

and

modulator

stages.

_These_are

of

the

single

wire

or

thread

filament

type,

as

com-

pared

to

other

tubes

which _

may

have

the

filament (

heater)

con-

tained

in

a

tube,

which

is

commonly

called

the

cathode

assembly.

Tubes

having

single

wire,

or

thread

type

filaments,

supported

by

springs (

such

as

the 833A)

require

more

than

normal

care

in

handling.

These

filament

wires

are

easily

broken

by

sudden,

heavy

vibration.

At

all

times

handle

the

tubes

with

care,

until

they

are

safely

inserted

in

the

tube

sockets

of the

transmitter.

At

this

point,

more

care

must

be

exercised

in

this type

of

power

tube,

as

the

filament

prongs

are

also

the

means

by

which

the

tubes

are

secured.

Make

sure

the

filament

connections

have

some

"give"

so

that

no

undue

strain

is

placed

on

the

glass-

to-

metal

filament

prongs.

As

the

glass

envelope will

expand

a

bit

during

operation,

the

two

securing

filament

connectors

must

be

free

to

move

themselves.

Take

care

when

making

the

grid

and

plate

connections

to

the

tube,

do

not

put

any

undue

strain

on

these

connections during

tube

in-

stallation.

Of

course,

the

connections

to

the

grid

and

plate

should

be

flexible

to

allow

for

expansion

of

the

tube.

For

shipping

or

storing

it

is

advisable

to

use

the

packing

material

and

carton

that

the

tube was

shipped

in

from

the

tube

manufacturer.

Following

these

reasonable

precautions,

there

should

be

no

trouble

in

handling

these

tubes.

-3-

BC- 1G

1.2.2

TRANSMITTER

BUILDING

TiMPIATURES,

If

this

transmitter

is

to

be

unattended (

operated

by

remote

con-

trol)

care

should

be

taken

that

winter

temperatures

inside

the

transmitter

building

do

not

go

below

50°F.

Mercury

vapor

tubes.

(if

used)

will

arc

back

at

low

temperatures,

often

causing

severe

damage

either

to

themselves

or

other

expensive

components.

Pro-

tective

relays

and

fan

motors

may

also

become

sluggish

under

extremely

cold

conditions.

Failure

to

provide

adequate

winter

minimum

building

temperatures

will void

the

guarantee.

1.2.3

GROUYDriG

The

grounding

of

the

transmitter

installation

is

of

major

import-

ance.

Remember,

it

is

a

part

of

your

radiating

system.

It

can

be

safely

assumed

that

the

better

the

complete

ground

system,

the

more

efficient

will

be

the

radiating

system.

A

lack

of

complete

grounding

of

the

transmitting

and

audio

equipment

may

cause

trouble

from

stray

RF

getting

into

the

audio,

and

may

cause

unstable

trans-

mitter

performance,

etc.

It

is

wise

to

bond

all

electrical

con-

duit,

water

piping,

metal

building

framework

to

the

overall

ground

system.

If

these

suggestions

aie

followed,

there

will

be

less

trouble

over

the

years,

as

the

ground

system

ages.

1.2.4

ANT_NNA

COUPLING

Antenna

coupling

equipment

not

involved

in

these

instructions

is

a

very

important

part

of

the

entire

successful

operation.

The

instructions

supplied

with

the

antenna coupler will

aid

in

its

adjustment.

As

all

radiating

towers

must

be

measure&

electric-

ally

by

an

approved -

engineer,

he

could

check

and

advise

on

the

tune-up

of

the

antenna

coupler.

If

your operation

is

directional

the

engineer

will,

of

course,

tune

the

entire

directional

system,

which

includes

the

antenna

coupling

equipment.

SECTION

II

THEORY

OF

OPERATIE

This

section

of

the

instruction

book

will

include

the

theory

of

operation

of

the

M5422

Oscillator

Unit

when

combined

as

an

in-

tegral

part

of

this

1000/250

watt

Transmitter.

A

general

des-

cription

of

the

complete,

overall

transmitter

operation

will

be

given.

2.1

M5422

OSCILLA

.

20à

UNIT

This

oscillator

unit

physically

is

inches

wide,

including

mounting

flanges,

6

inches

high,

and

6g

inches

deep,

including

connector

plug.

The

unit

is

mounted

by

means

of

its

flanged

bottom

on

the

aluminum

vertical

portion

of

the °

panel

and

shelf",

Its

controls

extend

out

through

a

cutout

in the

front

vertical

panel.

The

oscillator

shield

cover

held

in

place

by one

thumb

screw,

can

be

re,.loved

by

unfastening

and

sliding

horizontally

away

from

the

oscillator

chassis.

Connections

to

the

M5422

oscillator

unit

are

made

by

a 8

position

female

plug,

Pl,

at

the

rear.

2.1.1

TUBE

COMPL2hENT

OP

TH2

M5422

OSCILLATOR

UNIT

This

oscillator

unit

uses

a

12BY7A

oscillator

tube,

V1,

driving

another

12BY7A,

V2,

the

first

IPA.

2.1.2

TYPE

OF

OSCILLit20.'i

CIRCUIT

The

12BY7A

oscillator

tube

operates

in

a

crystal

controlled

grid

plate

circuit,

also

often

referred

to

as

a

grounded

plate Colpitts

circuit.

Excitation

is

controlled

by

the

proper

ratio

of

tl/é

two

capacitor

values

of

C3

and

04.

2.1.3

TYPE

OP

CRYSTAL

UD

This

oscillator

unit

has

facilities

for

two

vadulim

and

glass

enclosed

crystal

assemblies,

each

crystal

car{be

selected

for

use

by

means

of

the

rotary

switch,

Si. (

One

crystal

is

needed

for

operation,

the

second, if used,

would

be

a

spare).

These

crystals

are

mounted

in

octal

based,

glass

envelopes

which

have

been

pumped

to

a

high

vacuum.

These

plug

into

octal

sockets

in

the

oscillator

unit.

The

crystals

are

of

the

low

temperature

co-

efficient

type,

there

is

no

need

for

crystal

heater

ovens

for

normal

operation.

Frequency

trimmer

capacitors,

Cl

and

02,

are

tunable

from

the

front -

these

capacitors

are

connected

in

shunt

with

the

crystals

and afford

a

slight

frequency

adjustment

which

can

be

used

during

initial

tune-up.

Also,

ageing

of

the

crjstals

could

cause

a

slight

frequency

change

during

day

to

day

operation.

This

change

can

be

compensated

for

by

re-

adjustment

of

these

capacitors.

-5-

BC- 1G

2.1,4

12BY7A

FIRST

IPA

This

tuned

first

IPA stage

is

lightly

capacitively

coupled

to

the

oscillator.

Its

output

circuit

L3

and

09,

is

used

on

frequencies

from

1600

Kc

to

800

Kc;

from

800

Kc

to

540

Kc

a

padder

capacitor,

Cll,

100

mmfd.

mica

is

connected

in

parallel

with

capacitor,

C9,

The

output

of

this

stage

is

capacitively

coupled

to

the

grid

cir-

cuit

of the

two

807

second

IPA

tubes,

through

C10

in

the

oscilla-

tor

unit

and

C8

in

the

807

stage.

Adequate

drive

of

from

2

to

5

ma.,

depending

upon

operating

frequency

is

provided

for

the

two

807's.

Approximately

180

to

210

volts

DC

is

applied

to

the

oscil-

lator

unit,

being

supplied

by

the

625

volt

power

supply

through

dropping

resistor,

R5.

Drive

voltage

for

operation

of

a

Frequency

Monitor,

such

as

the

Gates

114990,

is

provided.

The

monitor

drive

output

is

obtained

from

the

plate

circuit

of

the

1st

IPA

stage.

A

small

coupling

capacitor,

012,

is

used.

2.1.5

M5422

OSCILLATOR

TUNING ±

ROCEDURE

The

following

tuning

instructions

should

be

followed

when

placing

the

M5422

oscillator

in operation.

If

this

procedure

is

not

followed,

it

is

possible

to

tune

the

oscillator

to

the

second

harmonic

of

the

crystal

rather

than

the

fundamental.

Information

that

follows

was

obtained

with

the

M5422

oscillator

connected

to

its

proper

UP

load and

30

feet

of

RG62/U

cable

con-

nected

to

the

monitor

terminal

6

with

shield

to

ground,

or

terminal

P.

RG62/U

cable

runs

13.5

mmfd.

per

foot,

or

a

total

of

approximately

400

mmfd.

effective

capacity

on

the

30

foot

lengths.

Shorter

lengths

of

cable

on

frequencies

above

600

Kc

will

effect

the

tuning

of

the

unit.

More

tuning

capacity (

09)

or

more

turns

of

the

slug

in

L3

may

be

required

for

resonance.

Shorter

lengths

of

monitor

cable

on

frequencies

from

600

Kc

to

540

Kc

may

prevent

the

unit from

tuning

to

resonance.

If

this

is

the

case,

capacity should

be

added

across

the

cable

to

make

up

the

difference

in

effective

capacity.

Longer

lengths

of

cable

would

mean

less

capacity

or

less

inductance

needed

for

resonance

in this

frequency

range.

It

is

recomended

tnat

the

proper

length

of

RG62/U

be

used

whenever

possible.

Frequencies

from

1600

Kc

to

800

Kc

1.

NO

.

ADDING

needed

in

this

frequency

range,'

2.

Make

sure

that

slug

of

L3 is

screwed

all

the

way

out.

From

1600

Kc to

approximately

1100

Kc,

tune

09

for

dip

in

plate

curr

nt

or

peak

in

grid

current

of

following

stage.

If

C9

does

not

tune

through

resonance,

screw

in slug

on

L3

a

turn

at

a

time,

until

resonance

is

obtained

with

C9.

800

Mc

is

tuned

with

09

near

maximum

capacity

and

slug

of

L3

screwed

in

7

turns.

-6- BC-

1G

If

above

procedure

is

not

followed,

it

will

be

posatble

for

crystals

from

approximately

900

hO

to

800

4Qtia---turie

to

their

second

harmonic,

if

slug

in

L3

has

not

-

been

screwed

dawn

to'

approximately

7

turns

for

800

Kc.

Frequencies

from

540

Kc to

800

Kc

1.

The

padder

capacitor

Cil,

100

mmfd.

located

on

bottom

of

L3

must

be

connected

in

the

circuit.

2.

The

slug

of

L3

should

be

screwed

down 14

turns.

Frequencies

from

540

Kc

to

approximately

600

Kc

can

be

resonated

with

capacitor

09.

If

complete

resonance

cannot

be

obtained

on

09,

screw

the

slug

of

L3

back

out

a

turn

at

a

time

until

reso-

nance

is

obtained

by

turning

09.

At

800

Zc

resonance

will

be

with

09

near

minimum

capacity

and

the

slug

of

L3

screwed

out

approximately

7

turns

from

the

starting

point,

14

turns

down.

CAUTION

-

If

above

procedure

is

not

followed

and

padder

not

connected,

it

will

be

possible

to

tune

crystals

from

540

Kc

to

800

Kc to

their

second

harmonic.

!‘fter

resonance

has

been

obtained, the

crystal

may

be

set

to

oxact

frequency

by

using

the

frequency

monitor.

Set

the

slots

of

the

trimmer

capacitors,

Cl

and

02,

located

on the

front

of

the

unit,

at

right

an

G

les

to

the

plane

of the

trimmer

mounting

screws.

qith

the

crystal

selector

switch

turned

to

W1

crystal,

the

frequency

should

be

very

close

to

zero;

if

not,

adjust

the

trimmer

FREQ.

j1

until

frequency

is

zero

or

to

point

desired

for

operation.

Turn

crystal

selector

switch

to

2

position

and

re-

peat

above.aperation

with

trimmer

FREQ.

7,2.

The

tuning

of

these

condensers

will

not

effect

tile

resonate

tuning

of

the

unit

and

capacitor

09

will

have

very

little,

if

any,

effect

on

the

trimmer

adjustments.

2.2

BC-

1G

TRANSMITTR

DEJCRIPTION

The

following

information

will

briefly

describe

this

transmitter,

giving

tube

line-up

and

circuitry

of

the

audio

and

RP

sections

along

with

the

various

power

supplies

used.

2.2.1

TUBE

LINE-UP

As

mentioned

previously

the

M5422 Oscillator

Unit

uses

a

12BY7A

oscillator

and

a

12BY7A

first

IPA.

This

stage

drives

a

pair

of

807's

second

IPA,

which

in

turn

supplies

tile

driving

power

for

a

pair

of

833A

tubes

operating

in

parallel

as

the

modulated

Class "

C"

power

amplifier.

The

audio

system uses

a

pair

of

push-pull

807's.

as

the

audio

input

amplifier,

these

driving

another

pair

of

807's

operating

as

a

cathode

follower

stage

which

in

turn

drives

the

two

Class "

B"

833A

modulator

tubes,

these

tubes

in

turn

high-level

plate

modu-

late

the

833A's

in

the

2,i7

power

aniplifier.

-7-

BC-

1G

The

bias

supply

-

uses

si

1

trcm

-

rectifiers.

The

intermediate

voltage

supply

makes

use

of

silicon

rectifiers

in-

a-

full-

wave

center

tapped

configuration.

Silicon

units

are

used

in

the

high

voltage,

full-

wave

center

tapped

rectifier.

2.2.2

BC-

1G

TRAN,JMITTER

CIRCUITRY

The

BC- 1G

transmitter

uses

the

M5422

oscillator

unit

to

drive

the

two

807's

operating

in

parallel

as

the

RF

driver

stage.--

This

stage

operates

with

approximately

600/625

volts

on

the

plate

of

the tubes,

400

volts

on

the

screens,

and

60

to

65

volts

negative

on the

grids.

Forty-five (

45)

volts

of

this bias

is

fixed,

being

supplied

from

the small

bias

power

supply,

this

voltage

is

suffi-

cient

to

limit

the

plate

dissipation

to

an

allowable

value

in

the

event

that

grid

excitation

is

lost.

In

normal

operation,

the

cathode

current

of

this

807

RF

driver

stage

will

run

from

150

to

200

ma

total

for

-

both

tubes,

varyng

so7levihat

with

operating

fre-

quency

and

loading.

This

current

is

indicated

on

the

multimeter

when

the

multimeter

switch

is

set

in

the

° RF

Driver

Cath."

posi-

tion.

With

this

same

selector

switch

set

in

the

"

RF

Driver

Grid"

position,

grid

current

to

the

807

ill'

driver

stage

will

be

indi-

cated.

This

will

be

on

the

order

of

2

to

5

mils.

The

plate

and

screen

voltages

of

the

807

RF

driver

are

modulated

slightly, this

feature

tends

to

increase

the

UF

drive

to

the

modu-

lated power

amplifier

on

peaks

of

the

modulation

cycle,

this

improves

the

distortion

figure

of

the

transmitter.

The

RF

driver

stage

is

capacitively

tuned

by

the

250

imfd.

vari-

able

capacity,

04.

Below

1150

Kc

a

padding

capacitor

must

be

connected

in

parallel

with

C4.

The

power

amplifier

of

the

transmitter uses

two

833A

tubes

con-

nected

in

parallel.

The

output

circuit

of

this

PA

stage

can

be

said

to

be

made

up of

an "

L.'

and

two

itTn

networks,

which

effec-

tively

transform

the

operating

tube

impedance

down

to

the

50/70

ohms

found

at

the

line

terminal

of

the

transmitter.

This

network

also

does

a

commendable.

job

in

reducing

to

a

minimum

the

trans-

mission

of

harmonics

which

might

be

generated

in

the

transmitter.

Power

amplifier

coils

140 and

142 are

of

the

continuously

variable

type

and

are

used

to

tune

the

power

amplifier

to

resonance,

in the

case

of

1,40,

and

to

vary

the

loading

by

means

of

L42.

Other

than

the

neutralizing

capacitor

040,

there

are

no

variable

air

dielec-

tric

capacitors

used

in

the

power

amplifier

of

this transmitter.

This

adds

greatly

to

its

Grid

drive

to

the

amplifier

should

be at

least

100

ma.

for

good

operation.

This

will

be

indicated

by

the

multimeter

when

the

multimeter

selector

switch

is

in

the "

Power

Amp.

Grid"

position.

Higher grid

drive

up

to

150

ma. is

acceptable,

but

this

drive

will

vary

slightly,

depending

upon

the

transmitter

frequency.

-8-

BC-

1G

The-tranmitter

-

wfll

match

50/70-chm-nhyl

need

loads,

delivering

full

power

ou

-

4ut

with

power

amplifier

plate

efficiency

of

70»

or

better.

Other

load

impedances

are

available

on

special

order.

Audio

wise,

the

Gates

BC- 1G

transmitter

is

novel

in

many

respects.

The

audio

input/audio

driver

assembly

is

made

up

basically

of

components

mounted

on

a

printed

wiring

board.

Tais

assembly

is

.

located

on

the

panel

and shelf

section

of

the

transmitter

and in-

cludes

the

two 807

audio

input

tubes,

the

two 807

cathode

follower

audio

driver

tubes,

along

with

the

balance

coatrol,

113,

condensers

and

resistors

for

these

two

stages.

The

audio system

is

push-

pull

in

operation

for

all

stages.

The

cathode

follower

audio

driver

tubes,

V3

and

V4,

are

biased

by

voltage

controlled

by

tàe

potentiometers,

R2

and

R1,

located

on

the

small

aluminum

front

panel.

These

controls

indirectly

adjust

the

operating

bias

on

the

modulators

by

varying

the

operating

constants

of

the

cathode

followers,

this

causes

a

bias

voltage

change

on

the

modulators

by

having

a

voltage

drop

occur

across

the

high

resistance

cathode

resistors,

1111

and

1112,

of

the

cathode

followers.

A

very

smooth

modulator

bias

change

can

be

attained

in

this

manner,

making

it

possible

to

adjust

the

modulators

for

correct

operating

conditions.

There

is

no

metering

of

the

plate

current

of

the

807

cathode

followers,

V3

and

V4,

it

is

believed

that

if

proper

modulator

operation

is

had,

then

the

807

cathode

followers

are

operating

satisfactorily.

High

level

Class "

B"

modulation

is

used

in

the BC-

1G,

a

pair

of

833A

tubes

providing

the

means. The

grids

of

the

modulators

are

excited

by

the two

807

cathode

follower

audio

driver.

The

output

of the

modulators

is

coupled

to

the

Class °

C"

amplifier

by

means

of

the

capacitor

045,

and

the

reactor

L47.

The

secondary

of

the

modulation

transformer

T41

does

not

curry

any

power

amplifier

DC.

Feedback

from

the plates

of the

modulators

back

to

the

audio input

tube

grids

has

been

provided.

A

small

feedback

ladder

printed

wiring

board

is

located

on

the

panel

and

shelf

assembly

direct1y

above

the

modulation

transformer,

T41.

By

means

of

a

resistor/

capacitor

divider

network

out-

of-

phase

voltage

is

fed

back

to

the

audio

input.

The

transmitter

makes

use

of

approximately

12

to

14

DB

of

feedback

measured

at

1000

cycles

and 90%

modulation.

This

feedback

helps

to

reduce

the

noise

and

also

improves

tae

distortion

figures.

The

power

amplifier

and

the

modulator

plate

circuits

are

protected

against

abnormally

high

overload

currents

by

means

of

relays,

K6

and

K7.

These

are

located

on

the

top

shelf

of

the "

panel

and

shelf"

assembly,

adjacent

to

the

multi-

winding

filament

trans-

former,

T3.

The

overload

relays,

K6

and

K7,

have

their

coils

shunted

by 20

ohm semi-

variable

resistors.

By

adjustment

of

the

slider

tap.,

the

relay pull-

in

point

can

be

selected.

These

resistors

have

been

set

at

the

factory

for

normal

operation.

K6,

the

modulator

overload

will

pull

in

at

a

modulator

total

-

plate

current

of

approximately

600

Ma. (

Normal

plate

current

for

voice

and

music

programming,

hitting

100

will

be

around

400

ma

total).

-9-

BC-

1G

PA

overload

K7

is

set

for

approximately

700

1.1a

pull-

in (

normal

PA

plate

current

will

range

from

525

to

600

1,

1a,

dependin

g

on

PA

transmitter .efficiency).

These

relays

may

pull-in-prmatave

during

sine

wave

audio

modulation

at

the

100»

level.

In

this

event

the

adjustments

can

be

made

to

allow

for

this

type

of

operation.

If

the

current

in

either

circuit

exceeds

the

value for

which

its

relay

was

set,

the

relay

will

energize,

causing

its

normally

closed

contacts

to

open,

which

in

turn

opens

the

coil circuit

of

auxiliary

relay,

K9.

This

causes

the

contacts

of

relay

K9

to.

eat-

urn

to

their

normally

open

position;

thus,

opening

the

coil

circuit

of

the

high

or

low

power

contactor (

whichever

had

been

in

use),

this

reoves

primary

voltage

from

240,

the

high

voltage

power

transformer.

2.3

POWER

3UPPIinS

The

Gates

BC-

1G,

1000/250

watt,

Transmitter

makes

use

of

three

separate

power

supplies.

These

use

full

wave,

C.T.

rectifier

and

filter

assemblies.

Each

of

the

three

silicon

supplies used

in

the

transmitter

will

be

fully

described

in

the

following

paragraphs.

2.3.1

BL'5

JUPPLY

This

supply

is

made

up

of

a

plate

transformer,

Ti,

working

in

conjunction

with

the

bias

rectifier,

a

silicon

rectifier

consist-

ing

of

10

diodes,

400

volts,

PDT,

filter

choke

Li,

filter

capaci-

tor,

C3,

and

associated

resistors

and

potentiometers.

The

bias

potentiometers,

R1

and

112,

indirectly

vary

the

modulator

bias

by

controlling

the

cathode

follower

bias

and,

thus,

the

current

flow

through

the

cathode

follower

resistors,

Rll

and

2.12.

There

is

applied

a

negative

280

volts

between

these

resistors

and

ground.

An

opposing

voltage

of

approximately

210

volts

is

developed

by

current

flow

through

Rll

and

1112;

thus,

putting

the

difference

(about

60 to

70

volts)

on

the

grifa3

of

the

modulators.

This

bias

supply

also supplies

45

volts

of

fixed

bias

to

the

two 807's

in

the

RF

driver

stage. "

This

voltage

is

obtained

by

a

tap

on

bias

resistor,

R12.

This

bias

supply

is

energized

at

tue

time

that

the

filament

start

button,

41,

is

depressed.

2.3.2

600/625

VOLT

LOI

VOL2,GE :

3UPILY

This

supply

uses

14

diode

units

of

600

volt

PIV

rating

working

as

a

full

wave

C.2.

rectifier,

with

a

choke

input

filter

system.

Choke

1,46

is

rated

at

10

hy.,

capacitor

C47

is

a

10

mfd

unit.

This

supply

develops

aparoximaely

600/625

volts

which

is

applied

to

the

two 807

HF

driver

tubes.

The

same

voltage

is

dropped

to

around

575

volts

through

series

resistor,

114,

and

applied

to

the

two

audio

stages.

The

115422

oscillator

unit

derives

its

plate

potential

from

this

same

power

supply,

the

voltage

being

dropped

to

approximately

195

volts

by

means

of

series

resistor,

R5.

This

supply

has

a

time

delay

relay,

K8,

connected

in

its

primary,

which

delays

the

application

of

this

low

voltage

for

approximately

10

seconds

after

the

filament

voltage

has

been

applied.

This

-10-

BC-

1G

supply

also has

its

primary in

series

-

with

door

interlock

-

switches

346 -

and

348.

If

either

the

front

protective

screen

or

the

buck

cabinet

cover

is

not

securely

in

place

this

supply

will

be

in-

operative.

2.3.3

2800

VOLT

3-

UPPLY

High

voltage

for

the

power

amplifier

and

modulator

is

developed

by

two

silicon

rectifier

assemblies,

each

consisting

of

30

diode

units

of

600

volt

PIV

rating,

working

as

a

full

wave

C.T.

recti-

fier.

This

supply

is

capable

of

delivering

slightly

over

one

ampere

DC.

The

main

power

transformer,

T40,

the

filter

choke,

L45,

and

filter

capacitor,

048,

are

located

in

the

bottom

section

of

the

transmitter

cabinet.

This

high

voltage

supply

is

inter-

locked

with

the

front

panel

grill

and

the

interlock

switch,

347.

As

mentioned

previously,

this

transmitter

has

a

metal

grill

work

covering

the

front of

the

unit,

this

protects

the

operating

per-

sonnel

from

the

dangerous

high

voltages

which

are

present

inside

the

transmitter

cabinet.

The

lower

edge

of

the

protective

grill

is

secured

by

two

quick

operating

ON/OFF

fasteners.

when

this

grill

is

in

place,

its

lower

edge

operates

the

safety

door

inter-

lock

switches,

S46

and

347.

2.3.3.1

HIGH

VOLTAGE

SUPPLY

OPERATION

AT

250

UTT3

OUTPUT

The

BC-

1G

1000/250

watt

Transmitter

can

operate

at

250

watts,

this

is

made

possible

by

reducing

the

primary

voltage

applied

to

the

high

voltage

transformer,

T40.

For

1000

watt

operation

this

primary voltage

is

approximately

230

volts,

for

250

watt

carrier

output

this

primary

voltage

is

dropped

to

115

volts,

this

develops

around

1350

volts

through

the

supply

which

is

applied

to

the

power

amplifier

and

modulators.

2.3.3.2

BC-

1G

POLER

CdA7GE

FACILITY

The

operation

of

the

BC-

1G

Transmitter

at

either

1000

watt

or

250

watt carrier

level

is

accomplished

by

the

operation

of

two

power

contactors, (

K2

or

k3)

and

one

auxiliary

relay,

K9.

The

relay

and

contactor

operating

sequence

is

as

follows:

For

250

watt

carrier -

Filament

OFF/OH

pushbutton

switch,

341,

is

depressed.

All

filaments

are

energized,

and

after

another

10

seconds,

time

delay

relay,

K8

has

closed.

gith

both

front

screen

and

rear

cabinet

cover

in

place,

the

neon

indicating

lamps

of

"Pilamentn

switch

341,

the

red "

Reset'

button

342

and

the

white

"Plate

Off"

button

343

will

be

illuminated.

A

check

of

the

multi.

meter

switch

positions

will

show

all

multimetered

circuits

indi-

cating

correctly,

the

multimeter

switch

can

be

left

in

the

P.A.

grid

current

position.

Relaj,

K9,

must

now

be

locked

in,

this

action

will

provide

a

230

volt

AC

source

for

either

high

power

contactor,

K2,

or

low

power

contactor,

K3.

Press

the

red " Reset

button

342;

this

operation

will

comiJ.ete

the

auxiliary

relay,

K9,

coil

circuit,

causing

it

to

lock

in.

A

pair

of

normally

open

contacts

A

and

B

close,

this

makes

230

volts

AC

available

for

contactors

K2

or

K3.

rhen

the

red "

Reset"

button was

pressed,

the

neon

lamp

indication

of

both

the "

Reset"

and

the "

Plate

Off'

-11-

BC-

1G

Table of contents

Other Gates Transmitter manuals

Popular Transmitter manuals by other brands

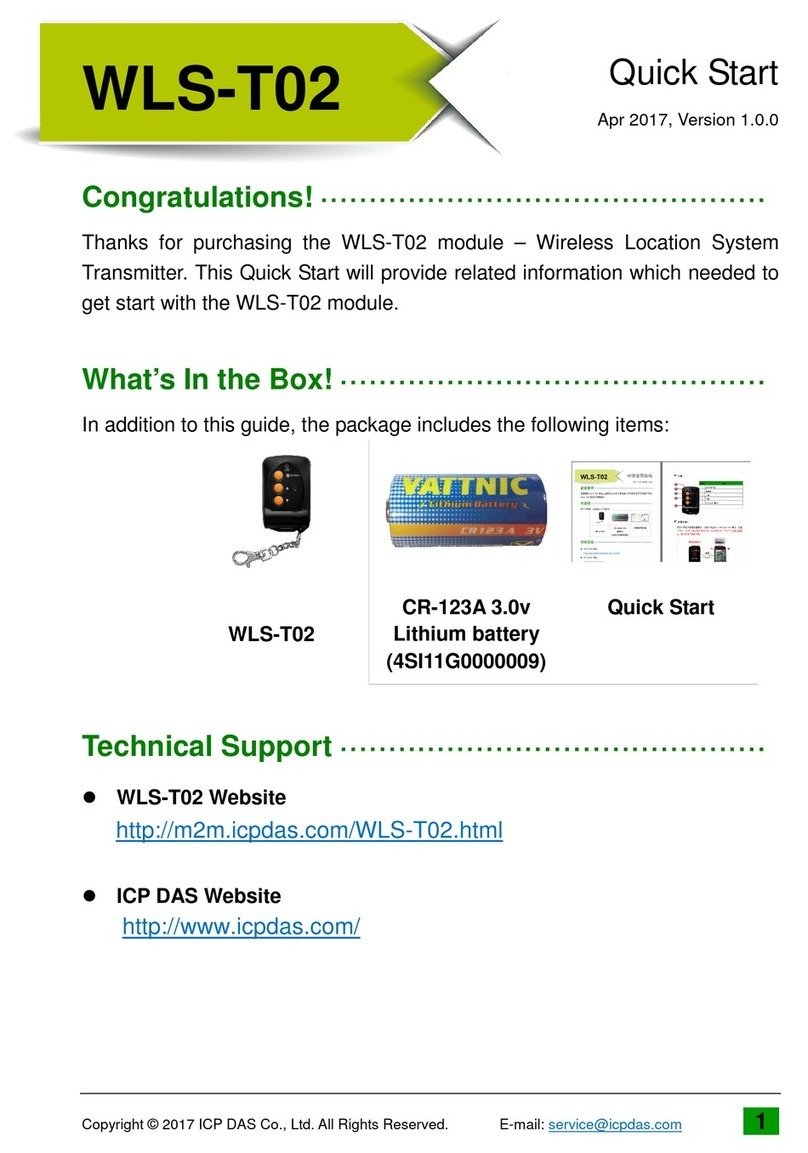

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS ALPHA PH1000 PHORP CONTROLLERTRANSMITTER Instructions d'utilisation

SMAR

SMAR TP301 Operation, maintenance and instructions manual

Stobag

Stobag SKIMY SRCH/WX Instructions for the fitter

RKI Instruments

RKI Instruments 65-2445 05 Series Operator's manual

ASTEL

ASTEL TTP 101 operating instructions

M-system

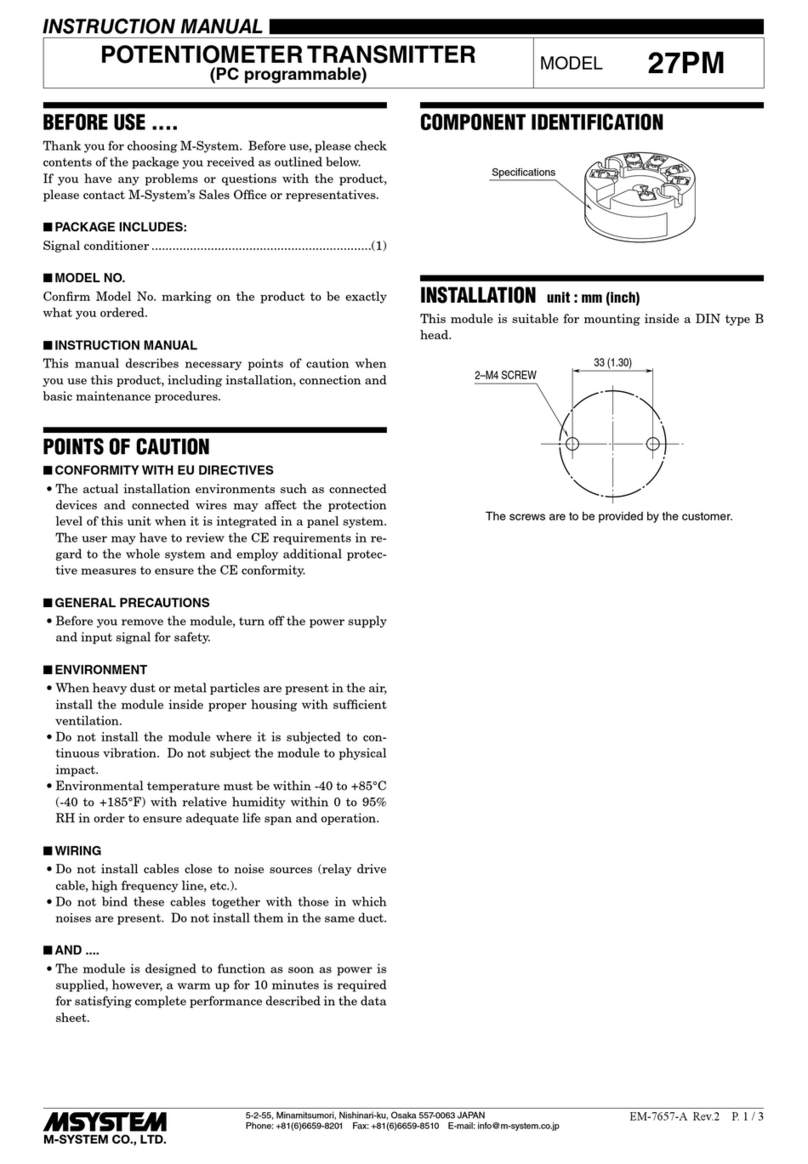

M-system 27PM instruction manual