Chapter 2 - Principle of Operation, Page 2-2__________________________________________________

Grease Extraction/Smoke Removal

Overview

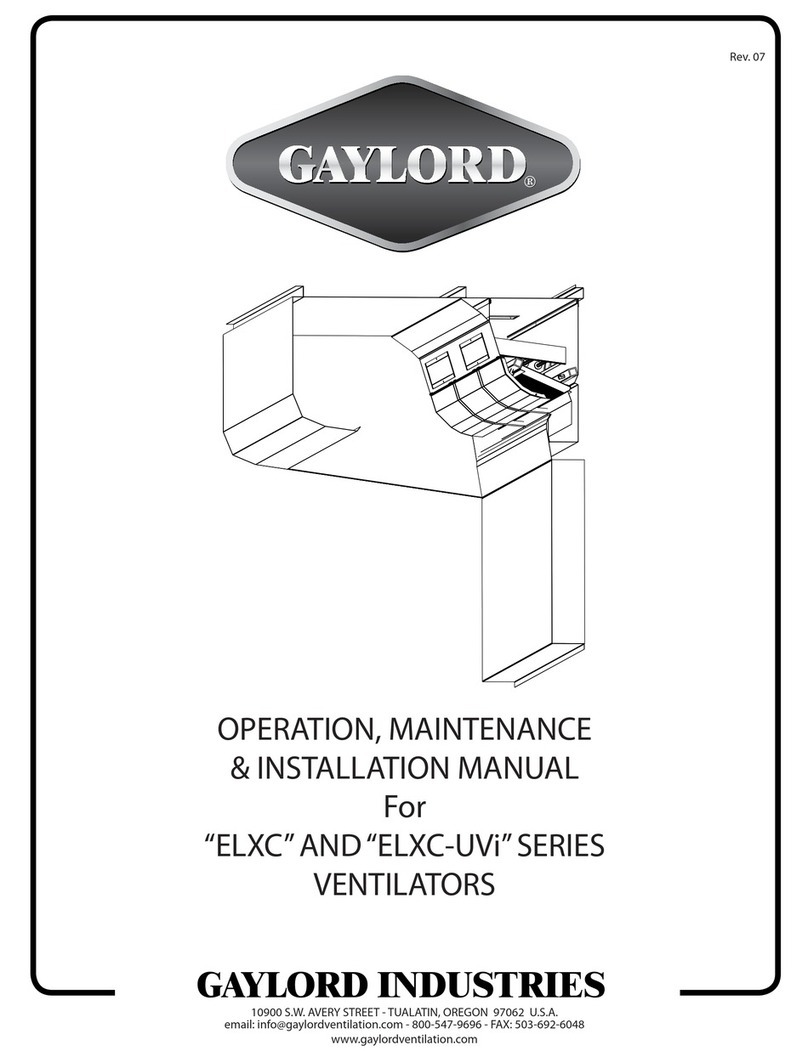

The Gaylord “CG3-UVi-SPC” Series Ventilator extracts up to 95% of

the grease, dust and lint particles

from the airstream passing

through it, when operated and maintained in accordance with

design

specifications. This high rate of grease extraction is accomplished by the use of grease extraction

baffles, Particulate Separators and UV lamps and ESP Cells. The following describes the function of each.

Grease Extraction Baffles

When the exhaust fan is started the hot, grease-laden air rising from the cooking

surface merges with

the higher velocity air that wipes the front

of the cooking equipment and extends, like an air blanket, from

the front edge of the cooking equipment to the air inlet slot of the

V

entilator. As the air moves

through the V entilator’s extraction chamber at a high

speed, it is forced to make a series of turns

around three

baffles. As this high velocity air turns around each baffle, the

larger

particles of grease are

thrown out

of the airstream by centrifugal force and collected on the baffles. The extracted grease,

dust and lint are collected in the interior of the ventilator,

remaining out of the airstream until

removed daily by the Wash

C

ycle.

Baffle #1

Important Note: The following description of Baffle #1 is for the standard CG3-UVi-SPC series

Ventilator. For operation of Baffle #1 for series FDL, FDT, FDD, and ND refer to TableT-2-15-1).

This baffle, located at the air entrance of the ventilator, is a

three position damper. Position #1

is the Exhaust Mode as

shown in Figure 2-3-1 , position #2 is the Wash Cycle Mode as shown

in Figure 2-9-1, and

position #3 is the F ire Mode as shown in Figure 2-15-1. When the START

FAN button is

pushed on the Command Center, the damper opens to the

exhaust mode position

#1 to become the preliminary grease

extraction baffle. There is a small sloped grease

collecting

gutter on the back side of the damper which drains off liquefied

grease to one end of the

Ventilator, preventing it from re-entraining into the airstream.

Baffle #2

This baffle is located on the interior back wall of the ventilator

and is a stainless steel pipe,

equipped with brass spray

nozzles on 8" to 10" centers (Refer to Figure 2-3-1). During the

wash

cycle, hot detergent water is released through the

nozzles.

Baffle #3

This baffle is located on the back of the inspection doors (Refer to Figure 2-3-1). This baffle is also a

grease collecting gutter, collecting the grease extracted by the ventilator preventing the contaminants

from dropping back into the high velocity airstream.

Optional Custom Air Baffles

Some Ventilators may be equipped with optional Custom Air baffles, shown dotted, which reduces

the exhaust volume where the baffles occur (Refer to Figure 2-3-1).

Particulate Separator

Once the larger particles of grease have been captured

through inertial impaction by the baffles, the

smaller particles will be arrested in the Particulate Separator using the

principles of diffusion and inertial

impaction (Refer to Figure 2-3-1). These collected

particles will be washed away each day by the Wash

Cycle.