GAYLORD Ultima Vent GX2-UV User manual

THE

GAYLORD VENTILATOR

TECHNICAL MANUAL

FORTHE Ultima VentTM “GX2-UV” SERIES

NON WATER-WASH VENTILATORS

10900 S.W. AVERY STREET • TUALATIN, OREGON 97062-1149 U.S.A.

800-547-9696 • 503-691-2010 • FAX: 503-692-6048 • email: info@gaylordusa.com

GAYLORD INDUSTRIES

EFFECTIVE DATE 4-05

2

To Our Customers. . .

Congratulations on your recent purchase of a Gaylord

kitchen exhaust hood system. We are proud to be able

to provide you with a quality product that incorporates

the latest engineering concepts and is a result of over

50 years of experience in the foodservice kitchen

exhaust industry.

If you have other Gaylord equipment such as a Gaylord

UtilityDistributionSystem,QuencherFire ProtectionSys-

tem, or Roof Top Air Handling Equipment, etc., please

refer to the corresponding supplementary equipment

manuals.

If you have further questions, please call us toll free at

1-800-547-9696oremail:info@gaylordusa.com. Weare

more than happy to help.

Sincerely,

Gaylord Industries

STREET ADDRESS: 10900 S.W. Avery Street, Tualatin, Oregon 97062-8549 U.S.A.

PHONE: 503-691-2010 • 800-547-9696 • FAX: 503-692-6048 • email: ga[email protected] • www.gaylordusa.com

GAYLORD INDUSTRIES

World Headquarters: 10900 S.W.Avery Street •Tualatin, Oregon 97062-1149 U.S.A.

“Undisputed World Leader in

Engineered Systems for

Commercial Kitchens”tm

COMMERCIAL KITCHEN EXHAUST SYSTEMS • FIRE PROTECTION • UTILITY DISTRIBUTION • ROOF TOP UNITS • POLLUTION CONTROL

3

TABLE OF CONTENTS

“GX2-UV”VENTILATORMODELDESCRIPTION“ ..............................................................4

“GX2-UV” SERIES PRINCIPLE OF OPERATION .......................................................... 5 – 7

MAINTENANCEANDCLEANINGINSTRUCTIONS .............................................................8

UVPREVENTIVEMAINTENANCE .......................................................................................9

SAFETY CONCERNS WITH UV........................................................................................10

START-UP PROCEDURES .............................................................................................. 11

MEASURINGINLET SLOTVELOCITY ....................................................................... 12 –14

TROUBLESHOOTING ...............................................................................................15 – 20

MODEL CUV-100 SERIES CONTROL CABINET .............................................................21

MODEL CUV-100 SERIES CONTROL..............................................................................22

PARTS LIST ...................................................................................................................... 23

UV MODULE PARTS .........................................................................................................24

GEMSYSTEMDIAGRAM...................................................................................................25

UVHOOD WIRING ............................................................................................................26

WIRINGDIAGRAMS................................................................................................... 27 – 28

STANDARD VENTILATORMODELS.................................................................................29

METRICCONVERSION CHART .......................................................................................30

START-UP INSPECTION REPORT ..................................................................................31

WARRANTY ...............................................................................................Inside back cover

© Copyright 2005, Gaylord Industries

ADDITIONAL COPIES $10.00

Themanufacturerreservesthe right to modify thematerialsand

specificationsresultingfrom a continuing programofproduct im-

provement or the availability of new materials.

ALL RIGHTS RESERVED. NO PART OF THIS BOOK MAY BE REPRODUCED, STORED

IN A RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY FORM BY AN ELECTRIC, ME-

CHANICAL,PHOTOCOPYING, RECORDINGMEANS OROTHERWISEWITHOUTPRIOR

WRITTEN PERMISSION OF GAYLORD INDUSTRIES COPYRIGHT 2004.

PATENT NUMBERS

U.S.A.: 4,266,529

4,281,635

4,356,870

CANADA: 1,139,151

1,155,366

GERMANY: 8,034,240

4

“GX2-UV” VENTILATOR MODEL DESCRIPTION

Thereare3differenttypesof“GX2-UV”“GrandGaylord”nonwater-washventilators.Thedifferences

involvethetypeandlocationoffiredamperandwhethertheventilatorhasafiredamper. Thefirstpart

ofthemodelnumber indicates the type of ventilator, see below:

Explanation of Prefixes:

GX2-UV-FDD Nonwater-washventilatorwithremovableextractorinsertsandafuselink

activatedfiredamperlocatedattheductcollar(

weighted

).

[NoDamper motor,No Thermostats]

GX2-UV-EDD Nonwater-washventilatorwithremovableextractorinsertsandathermo-

statically activated (

electric

) fire damper located at the duct collar. [

With Damper motor and 1 or more Thermostat(s)]

GX2-UV-ND Nonwater-washventilatorwithremovableextractorinsertsandNoFire

Damper.

[No damper motor, No Thermostats]

5

The Gaylord “GX2-UV” Series Non Water-Wash Ventilator

offers simplicity, economy and performance that no other

ventilator can offer. The unique “extractor insert” gives a

grease extraction efficiency far superior to that of a typical

bafflefilter.TheGaylord“GX2-UV”SeriesVentilatorsareUL

Listed and meet all the requirements of NFPA #96 and the

International Mechanical Code.

EXHAUSTFANOPERATION

TheexhaustfaniscontrolledbytheGaylordCUV-100Control

Cabinet. The cabinet is usually located on a wall near the

ventilator.Whenthecontrolisturnedon,theexhaustfanand

UV Lamps will come on.

GREASEEXTRACTION

TheGaylord“GX2-UV”SeriesVentilator extractsup to99%

of the grease, dust, and lint particles from the airstream

passing through it. Grease extraction is accomplished by

unique, removable stainless steel “extractor inserts” which

incorporate a series of horizontal baffles. As the air moves

through the extractor at high speed, it is forced to make a

seriesofturnsaroundthesebaffles,forcingtheheavier-than-

air particles of grease, dust, and lint to be thrown out of the

airstream by centrifugal force. The sticky grease collects in

the extractor and the liquified grease drains down into the

main grease gutter which slopes to the grease cup. Note:

“GX2-UV” SERIES PRINCIPLE OF OPERATION

Someventilatorsmaybeequippedwithoptional“CustomAir”

baffles (shown dotted) to reduce the exhaust volume over

specific light duty cooking appliances. The extractor inserts

come in two sizes15½" (5.6 lbs.) and 19½" (6.75 lbs.).

Particulate Separator

Once the largest particles of grease have been captured

throughinertialimpactionbythebaffles.Thesmallerparticles

ofgreasewillbearrestedintheparticulateseparatorusingthe

principlesofdiffusionandinertialimpaction.

UVLamps

Oncethebafflesandparticulateseparatorshavecollectedthe

grease particles larger than 1 micron. The UV lights will be

abletobreakdowntheremaininggreasebydirectexposure

to 254nm light and by the Ozone, Hydroxyl Radicals and

Anionicoxygencreatedbythe187nmUVlight.Thiswillcarry

down the ductwork and continue to break down the grease,

particulate and odor molecules keeping the ductwork much

cleaner.ThebyproductsofthisprocessareCO2,H20andthe

basemineralsfromthegreaseandparticulatemattercoming

offofthe cookingsurface.Therewillbealightgray dustthat

collects on the lamps, which will be need to wiped off. The

ductwork will need to be inspected per NFPA-96 schedules

but, will need much less frequent cleaning.

IMPORTANTNOTE:Neveroperateventilatorwithoutextrac-

tor inserts in place.

GREASE EXTRACTION

FIG. 1

6

“GX2-UV” SERIES PRINCIPLE OF OPERATION

FIG. 2

CLEANING

Atthe endof thecookingday theexhaust fanisturned offat

the CUV-100 control. After the fan has been turned off, the

extractorinsertsandparticulateseparatorsareremovedand

can be washed either in a dishwasher or soaked and rinsed

off.Thegreasecupisalsoremovedandemptiedatthistime.

Toeaseintheremovaloftheextractorinserts,an“Extractor

Removal Tool” is available which eliminates the need for

kitchen personnel to climb up on the cooking equipment, or

upa ladder.

TheUVlampswilldevelopacoatingofdust.Thiscoatingmust

beremovedforoptimumperformance.Therefore,onceaweek

whilethecartridgesareremoved,inspectthelampsandclean

asneeded.Useacleandryclothandifnecessarywashwith

milddetergentandwaterfirst.

7

“GX2-UV” SERIES PRINCIPLE OF OPERATION

FIREPROTECTION

NFPA-96 requires the use of Surface Fire Protection (Duct,

Plenum,Surface/Appliance)onallhoods.Itisthesesystems

that are the first line of defense against equipment fires.

The“GX2-UV-FDD”Seriesventilatorincorporatesafuselink

damper at the duct collar. In the event of a fire, should the

fuse link at the duct collar reach 280°F, the fuse link melts

allowing the damper to close. (See Fig. 3) After the fire is

extinguished the fuse link(s) in the duct collar needs to be

replacedandthedamperreset.

The“GX2-UV-EDD”SeriesventilatorincorporatesanElectric

Damper at the Duct collar and thermostat(s), which are

located at the point where the ductwork joins the ventilator.

FIG. 3

When the temperature of the conveying airstream, which

must pass over the thermostat(s), reaches 250°F, the

ElectricDamperattheDuctcollarclosesandtheExhaust

andSupplyfansandUVLampsshutoff,whentheventilator

andfansarewiredaccordingtoGaylord’swiringdiagram.

After the thermostat(s) cool below 250°F the damper will

resetautomatically, and theExhaust and Supplyfans will

restart,iftheCUV-100control is turned “ON”.

The“GX2-UV-ND”SeriesventilatordoesNOThaveadamper.

Thedamperinthe“GX2-UV-FDD”andthe“GX2-UV-EDD”

preventtheflamesfromenteringtheductworkandspread-

ingtootherpartsofthebuilding.Thefireiscontainedinthe

kitchenareawhere it can beproperlyfought.

8

MAINGREASE

GUTTER

DURING CLEAN-UP PROCEDURES AT

THE END OF THE COOKING PERIOD

SPECIAL ATTENTION SHOULD BE

GIVEN TO WIPING CLEAN THE AIR

INLET OF THE VENITLATOR

EXTRACTORINSERTS

DURING CLEAN-UP PROCEDURES

AT THE END OF THE COOKING

PERIODTHESE AREASSHOULD

NORMALLY BE WIPED DOWN.

CLEANING

At the end of each cooking day, the exposed interior

surfaces of the ventilator should be wiped down and the

greasecupemptied. Duringthecourseofoperation,grease

particlesaregraduallycollectinginsidetheextractorinserts

and particulate separator. Daily, or at periodic intervals,

dependingonthetypeofcooking,theextractorinsertsand

particulate separators, must be removed and cleaned. To

clean,proceedas follows:

1. Remove extractor inserts by hand or by using the

extractor removal tool. CAUTION: Care should be

takenwhenremovingextractors,especiallyoverfryers.

It is recommended that the cooking equipment be

cooleddownandthefryersbecoveredpriortoremoving

extractors. Toremove,liftupslightlyonextractorinsert

and pull straight out.

2. Extractor inserts may be cleaned either by using a

dishwasherorbywashinginasinkusinghotwaterand

a degreasing detergent. Formula G-510 is highly

recommended for this application. For information

contact:

20/10ProductsInc.

P.O. Box 7609

Salem,OR97303

Phone:800-286-2010

Fax:503-363-4296

E-mail:twentyte[email protected]

3. With the extractor inserts and particulate separators

removed,wipeandcleanthebackwallandthegrease

gutterwithhotdetergentwater. NOTE:Ifasteamorhot

waterpressurewasherisusedforperiodiccleaningof

theinterior,connectahosetothegutterdrainandlead

it to a floor sink or large bucket to drain off the water.

4. Toreplacetheextractorinserts, caremustbetakento

insure that point “A” rests in the rear clip as illustrated

in Fig. 4.

5. Iftheventilator(s)hasafuselinkoperatedsupplyduct

firedamperNFPA-96requiresinspectionofthefuselink

every6monthsandreplacementannually.

6. UVlampsmustbewipeddown

on a regular basis. This

may need to be done

asoftenasweekly

onsomesystems.

INSPECTION AND CLEANING REQUIREMENTS

The2001editionofNFPA-96(StandardforVentilationControl

and Fire Protection of Commercial Cooking Operations)

requirethathoods,ductsandexhaustfans beinspected by

aproperlytrained,qualifiedandcertifiedcompanyorperson(s)

inaccordance withthe followingtable.

Uponinspection,iffoundtobecontaminatedwithdepositsfrom

grease-laden vapors, the entire exhaust system shall be

cleanedbyaproperlytrained,qualified,andcertifiedcompany

orperson(s)acceptabletotheauthorityhavingjurisdiction.

Whenaventcleaningserviceisused,acertificateshowing

date of inspection or cleaning shall be maintained on the

premises. Aftercleaningiscompleted,thevent cleaning

contractor shall place or display within the kitchen area a

label indicating the date cleaned and the name of the

servicingcompany. Itshallalsoindicateareasnotcleaned.

Factory trained service agencies are certified by Gaylord

Industries,Inc.toperformtheseinspections.Forthename

andphonenumberofyournearestagentcall 800-547-9696

orwww.gaylordusa.comandgotoservice.

MAINTENANCE AND CLEANING INSTRUCTIONS

CAUTION: Care should be taken when removing extractors,

especially over fryers. It is recommended that the cooking

equipment be cooled down and the fryers be covered prior to

removing extractors.

FIG. 4

ELUDEHCSNOITCEPSNIMETSYSTSUAHXE

gnikooCfoemuloVroepyTycneuqerF

snoitarepognikoocemulov-hgihgnivressmetsyS gnikoockowrogniliorbrahc,gnikoocruoh-42sahcus ylretrauQ

gnikoocemulov-etaredomgnivressmetsyS snoitarepo yllaunnaimeS

hcus,snoitarepognikoocemulov-wolgnivressmetsyS ro,sessenisublanosaes,spmacyad,sehcruhcsa sretnecroines yllaunnA

9

UV PREVENTIVE MAINTENANCE

Theseitemswillneedtobeperformedbyatrainedandqualified

Certified Service Agency (CSA) on the same schedule as the

exhaustsysteminspection scheduledescribedin NFPA-96and

on the previous page in this tech manual. These tasks involve

potential exposure to high doses of UV light and live electrical

components.Thereisriskofinjurytoskinandeyesandinthecase

of electrical shock, injury or death! For a list of CSAs go to

www.gaylordusa.com and go to "Service Agencies" for a list of

companiesnearestyou.

1. Inspection of the Lamps and Ballasts

a. Checkthelampsforproperoperation

1. Turn on the fan and look for the green "UV System

On" light on each hood section

a. If it is not on refer to "UV Troubleshooting",

pages 17, 18 and 20.

2. Open the UV Access door with the key

3. Turnonfan

4. Verify all of the Extractor Inserts are installed.

5. Depress the UV Access door safety switch

6. Check all indicator LEDs, 6 green and 3 red, to

ensure that they are all on. If they are not all on go

to "UV Troubleshooting", pages 17, 18 and 20.

2. Inspect the Plenum (around the UV lamps)

a. DisconnecttheUV modulepower cord

b. RemovethenutsholdingtheUVmoduletotheventila-

torwitha nutdriver

c. RemovetheUVmodulefromtheventilator

d. Checkforbuild-upofdepositsofgrease,dustand/or lint.

e. Clean as necessary with a mild detergent, water and

arag

f. ReinstalltheUV module.

3. Test the Safety Interlock switches

a. RemoveoneExtractorInsertwiththefanon

• The UV lamps should shut off

• An audible alarm on the CUV-100 should come on

• TheRed“UVSafetyInterlockActivated”lightonthe

ventilator and CUV-100 control should come on

b. Open the UV Access door with the fan on

• The UV lamps should shut off

• An audible alarm on the CUV-100 should come on

• TheRed“UVSafetyInterlockActivated”lightonthe

ventilator and CUV-100 control should come on

c. Turn off the breaker to the Exhaust Fan. Press the

“StartFan” button on theCUV-100 control

• The UV lamps should shut off (stay off)

• An audible alarm on the CUV-100 should come on

• TheRed“UVSafetyInterlockActivated”lightonthe

ventilator and CUV-100 control should come on

4. Check all gaskets for damage

a. Replaceany gaskets that arewornor damaged

5. Check the Hour Meter

a. Recordthehours

b. Determinetheapproximatehoursbetweeninspection

intervals.

c. Determinewhenthe8000-hourlifeofthelampswill

occurandinformtheoperatoroftheapproximatedate

when the lamps will need to be replaced

Replacing UV Lamps

Danger!

Theseitemswillneedtobeperformedbyatrainedandqualified

CertifiedServiceAgency(CSA).Thesetasksinvolvepotential

exposure to high doses of UV light and live electrical compo-

nents.ThereisariskofseriousinjurytoskinandeyesfromUV

light.Thereisriskofshock,injury,and/ordeathfromelectrical.

For a list of CSA’s go to www.gaylordusa.com and go to the

“ServiceAgencies”foralistofcertifiedcompaniesnearestyou.

1. SecureallpowertotheCUV-100 control

2. Secure all circuits that provide power to the UV lamps

3. Open the UV Access door with the key

4. DisconnecttheUV modulepower cord

5. RemovethenutsholdingtheUVmoduletotheventilator

withanutdriver

6. RemovetheUVmodulefromtheventilator

7. Remove the bolts on each end of the UV module (2 on

each end) that hold the end caps on

8. Disconnect the lamp connector(s) on the UV lamp(s) to

bereplaced

• Eachlampconnectorshouldbelabeledfrom1to6on

bothends

• Lamp#1isattheFrontoftheventilatorwhentheUV

module is installed

• Lamp#6isattheBackoftheventilatorwhentheUV

module is installed

• Besuretore-labelthelampconnectorsifnecessary

9. Lubricatethelampsaroundthegrommetsoneachendofthe

UVlamp withasmallamountofG-510orsimilardetergent

10. Slide the UV lamp out one end, CAREFULLY!

11. Inspectthegrommets aroundthelamps

• Replace any grommets that show cracks, checking,

or any other damage

12. Checkallwires fordamage

• Replace any wires showing damage

13. Lubricate each of the new UV lamp(s) before installing

with a small amount of G-510 or similar detergent

14. Re-connectthelampconnectorsonbothendsof theUVlamps

• Eachlampconnectorshouldbelabeledfrom1to6)on

both ends

• Lamp #1 is at the Front of the ventilator when the UV

module is installed

• Lamp #6 is at the Back of the ventilator when the UV

module is installed

15. Re-install the UV module end caps and torque the bolts

to 7-10 in-lbs.

16. Re-installtheUVmodule in theventilator

17. Tighten all nuts holding the UV module to the ventilator

18. Re-connecttheUVmodulepowercord

19. CheckforproperoperationofUVlamps

Warning: DoNOTdefeatthepurposeoftheinterlocks duringcleaningand maintenance!

CERTIFIEDSERVICEAGENTMAINTENACEWARNING!

10

Aswithmanytypesoftechnologyifitisnotusedproperlyand/

orproper precautionsare nottaken thereis thepotential for

injury or harm. This is especially true with UVC light due to

thefactthatitdoesnotphysicallyhurtatthetimeofexposure.

While UVC is very effective at breaking down grease mol-

ecules, direct exposure to large amounts is harmful to skin

and eyes. The amount of UVC generated in these hoods is

greaterthanthatwhatresultsfromdirectexposuretothesun.

Under no circumstances is it acceptable to view the lighted

lamps without proper eye protection or expose bare skin

directly to the light. All interlocks and safety precautions

calledforinthismanualmustbefollowedtoavoidthepotential

for harm to service personnel and/or operators. In addition,

only trained and authorized personnel may perform some

maintenanceSeepreviouspagefordetails.

Personal Protective Equipment

1. Eyeprotectionthatprevents100%ofUVC beingtrans-

mitted through the lens must be worn at all times when

performing service work on any Ultima Vent that is

energized and/or has the potential to be energized and

expose personnel to UVC light.

2. Wheneverserviceworkisperformeditisrecommended

thatlongsleevepantsandshirtsbeworntominimizethe

potentialforinadvertentexposureoftheskin toUVC.

SafetyInterlocks

This product comes equipped with the following sensors to

verifythatallaccessdoorsareinplaceandthattheexhaust

fanisrunning:

1. MechanicaldoorswitchontheUVAccessdoortoensure

that the door is closed

2. GaylordExtractorMonitor(GEM) thatensuresall ofthe

Extractor Inserts are installed.

3. Air Pressure switch to verify air flow and exhaust fan

operation

Allofthesedevicesmustbeworkingand/oradjustedproperly

in order for the system to operate properly.

SAFETY CONCERNS WITH UVC

11

Beforeusing the Ultima Ventacomplete and thoroughstart-up ofthe Ultima Vent systemmustbe performed byaqualified, and

authorized service technician. Because of this the UV modules will be shipped separate from the hood to an Certified Service

Agent(CSA). Contact GaylordIndustries toarrange forthis service. It isnormally includedin thepurchase priceof thehoods.

8. Check the air velocity at the inlet slot

9. Record the data on the start up form. Determine the

correct inlet slot velocity and record that in the design

velocitylocation. Then determinethepercentage of de-

sign that the actual air velocity represents

11. RemoveanExtractorInsert

a. Thered“SafetyInterlock Activated”lampshouldcomeon

andan audible alarm sound.

12. Check the UV Access door interlock

a. Open the UV Access door with the fan on.The red

“SafetyInterlockActivated”lampshouldcomeon and

anaudiblealarmsound.

Caution:BeforeanyFiretestsareperformed,checkwith

the building superintendent to see if the Surface Fire

Protectionsystemiswiredtothebuildingalarm,monitor-

ingsystem, and/orfire department.

13. If the FP contractor is there have them trip the micro

switches on the FP system to verify that the Exhaust

Fan(s) starts and supply Fan(s) shut off.

14. Onceallisworkingcorrectlydemonstratethefollowingto

the end user

a. IfthehoodisinterlockedwiththeFPsystem.Havethe

FP contractor test it and confirm that the External fire

modeworksproperly.

b. InstructthemthatifforanyreasontheycanseetheUV

light directly they must shut off the hood immediately

and call a CSA.

c. Check for proper damper operation if this hood has a

damper

d. Howtoremove,cleanandreplacetheExtractorInserts

e. Thattheyneedtoperformtherequiredendusermain-

tenancedescribedin thetechmanualandhireCSAto

perform the UV maintenance as described in the tech

manualandhavetheductsysteminspected/orcleaned

pertherequirementsofNFPA-96.

f. Thefrequencywill need tobeadjusted based onthe

type,amountanddurationofcookingdoneatthissite.

q. Fill out the start up form completely with comments

r. NotifytheDealer/customeriftheairvolumesaremore

than 5% low or 10% high and give the dealer and GC

a copy of the Start-up report.

g. SendacopyoftheStart-upreporttoGaylordandkeep

a copy for your records.

START-UP PROCEDURES

Start-up requirements and activities

AtthetimeofshipmentaCertifiedServiceAgent(CSA)willbe

selectedtoperformtheinstallationoftheUVmodulesandthe

start-up for the Ultima Vent system.

TheServiceagentshouldconfirmthefollowingpriortogoing

to the job site:

1. The Exhaust and Supply fan(s) are connected to the

ductwork

2. Thefans have electricityandwill run

3. The CUV-100 control panel is mounted and has the

following:

a. PowertotheCUV-100

b. All necessary electrical connections between the CUV-

100 and the hood, surface fire protection system, and

fans.

4. All lighting wiring is connected to the hoods and light

switch

5. There is a 120 Volt, 20 Amp power circuit going to each

hood section, for UV lamps

6. Any personnel (Fire Marshal, owners rep., GC, FP

contractor,airbalancer,etc)requiredtowitnessthestart

upwouldneedtobenotifiedoftimeanddateforstart-up.

Field Start up directions

Allow about 1 hour per hood section, at the job site, for the

activitiesdescribedbelow:

1. CheckforpowertotheCUV-100andwiringbetweenthe

CUV-100andthehoods

2. Check that all Extractor Inserts are properly installed

3. StarttheexhaustfanbyturningtheCUV-100controlon.

Bothsupplyandexhaustfansshouldstart.Thegreen“UV

SystemOn”lightshouldbeon.Ifthisdoesnotoccurrefer

to"UV Troubleshooting"on pages17, 18 and 20.

4. TurnCUV-100controloff.Thiswillshutoff thefans.

5. Open the UV Access door and remove the blank plate

from the UV light opening.

6. InstalltheUVlightmodulesinthehood.Connecttheplug

on the UV module to the hood.

7. Start the exhaust fan and check for the green “UV

SystemOn”lightatthehood(s)andcontrolpanel.Make

sure that all access doors are closed.

12

MEASURINGINLETSLOTVELOCITY

Smoke capture and grease extraction efficiency are de-

pendentupontheproperairvelocityattheinletslotofthe

ventilator.Therequiredaverageslotvelocitiesareshown

on the “Air Velocity Chart” below. If the slot velocity is

below the required average, the exhaust fan must be

adjustedaccordingly.

NOTE: The height of the inlet slot can vary depending

uponthedesignoftheventilator. Itis,therefore,important

to first measure the inlet slot and compare it to the chart

below to determine the required average inlet slot veloc-

ity. The designed CFM per lineal foot is related to the

velocity as shown on the chart below. The total CFM for

the ventilator can be found on the ventilator nameplate.

(See Figure 6).

Airvelocityreadingslessthanwhatisspecifiedonthe“Air

Velocity Chart” may allow smoke and grease to escape

theconfinesoftheventilatorand/orreducegreaseextrac-

tion efficiency. This can result in grease deposits which

lead to sanitation problems or fire hazards if left uncor-

rected. If air velocity readings are higher than those

specified, it will require more energy to operate the

exhaustfanandexcessivenoiselevelswillresult. Higher

orlowervelocitiesthantherequiredaveragewillnormally

put the entire heating and ventilating system out of bal-

ance.Whenmeasuringtheairvelocityitisveryimportant

to take an average reading across the inlet slot plane as

described on Page 13. Positioning the sensing head

incorrectlywillgivevelocityreadingsthatcannotbecom-

pared to the “Air Velocity Chart”.

TRAHCYTICOLEVRIA

SEIRES"SD"TPECXESEIRES"2XG"LLAROF

lanimoN thgieH fo tolStelnI

motsuCtuohtiW selffaBriA motsuChtiW selffaBriA

dengiseD repMFC .tFlaeniL

telnIegarevA )MPF(yticoleVtolS

.niM mumitpO .xaM

dengiseD repMFC .tFlaeniL

telnIegarevA )MPF(yticoleVtolS

.niM mumitpO .xaM

"3 )dtS(

"4 )lnE(

052 072 582 003 004

0031 0631 5241 5641 0961

0831

5341

0051

5451

0871

0541 0051 5751 5261 0781

051 061 071 081 052

067 097 018 548 0401

008

038

558

088

5901

088 078 009 539 0511

MEASURING INLET SLOT VELOCITY

*SROTALITNEVSEIRES"SD"ROF

rePMFCdengiseD .tFlaeniL telnIegarevAderiuqeR )MPF(yticoleVtolS

latoT htoB stolS

tnorF tolS raeR tolS tolStnorF

.niM mumitpO .xaM

tolSraeR

.niM mumitpO .xaM

003 004 051 052 051 051 067 5731 008

0541 088 0251 595 595 526 526 556 556

13

MEASURING INLET SLOT VELOCITY

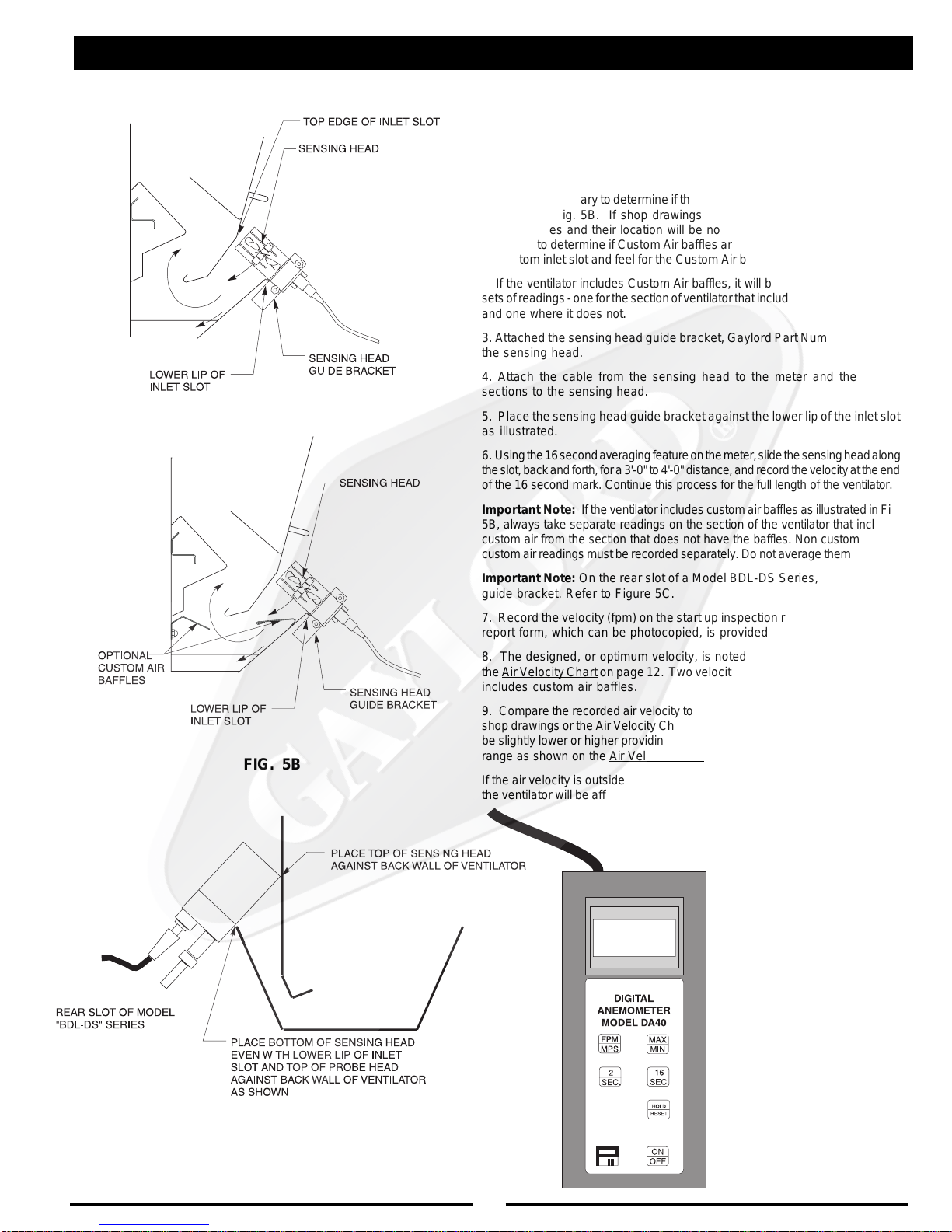

FIG. 5A

FIG. 5B

FIG. 5C

CROSS SECTION OF TYPICAL

VENTILATOR INLET SLOTS

Thestandard instrumentused for measuring the inletvelocities ona Gaylord

Ventilator is a Pacer, Model DA40 or DA4000 Digital Anemometer. This

instrument is the easiest, most accurate and the best suited for measuring

ventilator inlet slot velocities. To take accurate air velocity readings, follow

the instructions below.

Instructions

1. It is first necessary to determine ifthe ventilatorincludes CustomAir baffles

as shown in Fig. 5B. If shop drawings are available, and if equipped, the

custom baffles and their location will be noted on the front elevation. If not

available, to determine if Custom Air baffles are provided run your hand along

the bottom inlet slot and feel for the Custom Air baffle as illustrated in Fig. 5B.

2. If the ventilator includes Custom Air baffles, it will be necessary to take two

setsofreadings-oneforthesectionofventilatorthatincludesCustomAirbaffles

and one where it does not.

3. Attached the sensing head guide bracket, Gaylord Part Number 18408, to

the sensing head.

4. Attach the cable from the sensing head to the meter and the handle

sections to the sensing head.

5. Place the sensing head guide bracket against the lower lip of the inlet slot

as illustrated.

6. Usingthe16secondaveragingfeatureonthemeter,slidethesensingheadalong

theslot,backandforth,fora3'-0"to4'-0"distance,andrecordthevelocityattheend

of the 16 second mark. Continue this process for the full length of the ventilator.

Important Note: If theventilator includes custom air baffles as illustrated in Fig.

5B, always take separate readings on the section of the ventilator that includes

custom air from the section that does not have the baffles. Non custom air and

customair readingsmust berecorded separately. Do not average them together.

Important Note: On the rear slot of a Model BDL-DS Series, do not use the

guide bracket. Refer to Figure 5C.

7. Record the velocity (fpm) on the start up inspection report form. A sample

report form, which can be photocopied, is provided on page 16.

8. The designed, or optimum velocity, is noted on the shop drawings and

theAirVelocityChartonpage12. Twovelocitieswillbenotediftheventilator

includes custom air baffles.

9. Compare the recorded air velocity to the designed air velocity shown on the

shop drawings or the Air Velocity Chart on page 12. The recorded velocity may

be slightly lower or higher providing that it is within the minimum and maximum

range as shown on the Air Velocity Chart .

If the air velocity is outside the minimum/maximum range, the performance of

the ventilator will be affected and therefore the exhaust fan must be adjusted.

14

1. MINIMUM TOTAL EXHAUST

VOLUMEFOR THIS HOOD SECTION

2. MAXIMUMTOTALSUPPLY

VOLUMEFOR THIS HOOD SECTION

3. EXHAUSTSTATICPRESSUREAT

DUCT COLLAR

4. SUPPLYSTATICPRESSUREAT

DUCT COLLAR

5. THIS HOOD SECTION SUITABLE FOR APPLIANCES WITH MAXIMUM COOKING

SURFACETEMPERATUREOF:

˚F FOR LINEAL FT. OF HOOD

˚F FOR LINEAL FT. OF HOOD

6. REFER TO GAYLORD VENTILATOR TECHNICAL MANUAL FOR INLET

VELOCITYREQUIREMENTSANDMETHOD OF CHECKINGVELOCITY

7. ELECTRICAL RATING OF LIGHT FIXTURES: 120 VOLT, 60 HZ. OR 220 VOLT,

50HZ.OVERALL RATING -12AMPSOR LESS

8. ON "GX2" and "PG" SERIES VENTILATORS EQUIPPED WITH FUSE LINK

OPERATEDEXHAUST FIREDAMPER USEONLY 280˚ F,RATED 30LBS. MIN. UL

LISTEDFUSIBLELINKFORREPLACEMENT

9

. IF HOOD IS EQUIPPED WITH INTEGRAL MAKE-UP AIR WITH FUSE LINK OPER-

ATEDFIREDAMPER USEONLY165˚ F, RATED30LBS. MIN. ULLISTED FUSIBLE

LINKSFORREPLACEMENT

10.DUCTWORKANDEXHAUSTFAN

A. STATIC PRESSURE OF DUCT SYSTEM MUST BE ADDED TO VENTILATOR

STATICFORTOTAL SYSTEMSTATIC

B. ALL DUCTWORK MUST BE WELDED LIQUIDTIGHT

HOOD MOUNTING REQUIREMENTS

MINIMUM DISTANCE FROM COOKING SURFACE TO FRONT

LOWEREDGEOFHOOD

MAXIMUM DISTANCE FROM COOKING SURFACE TO FRONT

LOWEREDGEOFHOOD

MINIMUM OVERHANG FROM FRONT OF HOOD CAVITY TO

FRONT OF COOKING SURFACE

MAXIMUM SETBACK FROM FRONT OF HOOD CAVITY TO

FRONT OF COOKING SURFACE

MINIMUM OVERHANG FROM SIDE OF HOOD TO EDGE OF

COOKINGSURFACE

SERIAL NO:

MODEL NO:

W.G.

W.G.

ENGINEERING DATA

THIS EXHAUST HOOD HAS BEEN TESTED

TO STANDARD UL 710 "EXHAUST HOODS

FOR COMMERCIAL COOKING

EQUIPMENT"

THISEXHAUST HOOD IS LISTEDUNDER UL

FILE NUMBER 11403

THISEXHAUSTHOODMEETSALLREQUIRE-

MENTSOF THE LATESTEDITION OF NFPA-

96ANDTHEIMC(INTERNATIONALMECHANI-

CAL CODE)

oSUPPLIEDWITHFACTORY INSTALLED ULLISTED

GRINNELL CORP. EA-1, 1/4" ORIFICE, 65 DEGREE

DEFLECTOR SPRINKLER(S) FOR THE PROTEC-

TION OF UNLIMITED LENGTH OF GREASE DUCT

HAVING A MAXIMUM DUCT PERIMETER OF 50

INCHES PER SPRINKLER. CONNECT TO NFPA 13

SPRINKLERSYSTEMWATERSUPPLYONLY.

PATENT PENDING

EXHAUST HOOD WITH

EXHAUST DAMPER

UL-GX2/PG1000

WORLDHEADQUARTERS

GAYLORDINDUSTRIES,INC.

10900 S.W. AVERY STREET

TUALATIN, OR 97062-8549 USA

PHONE: 1-503-691-2010

FAX: 1-503-692-6048

LISTED

370Y

C.F.M.

C.F.M.

MAINTENANCE INSTRUCTIONS

1. REMOVE, INSPECT AND CLEAN FILTERS OR GAYLORD EXTRACTOR

CARTRIDGES AS REQUIRED

2. REMOVE AND EMPTY GREASE CUP AS REQUIRED

3. CAUTION-DONOTOPERATEVENTILATORWITHOUTFILTERSOREXTRACTOR

CARTRIDGESINPLACE

4. REPLACEFILTERSIN"PG"SERIESONLYWITHULCLASSIFIEDGREASEFILTERS.

IN "PGX" AND "GX2" SERIES REPLACE WITH GAYLORD INDUSTRIES

EXTRACTORCARTRIDGES.

5. IF THE VENTILATOR(S) HAS A FUSE LINK OPERATED EXHAUST OR SUPPLY

DUCT FIRE DAMPER THE NATIONAL FIRE PROTECTION ASSOCIATION'S

PAMPHLET NFPA-96 REQUIRES INSPECTION OF THE FUSE LINK EVERY 6

MONTHS AND REPLACED ANNUALLY. REFER TO THE GAYLORD VENTILATOR

TECHNICALMANUAL FORDETAILS.

The total required exhaust volume can be

found stamped on the UL nameplate located

on each hood section.

FIGURE 6

MEASURING INLET SLOT VELOCITY

TOTAL EXHAUST CFM HERE

TOTAL SUPPLY CFM HERE

15

TROUBLE-SHOOTING

MOTPMYSMELBORPELBISSOPNOITCAEVITCERROC

SSOLEKOMS

.1tonsirotalitneV-ssoLekomS .ylreporpgnitsuahxe .A

.B

.C

.D

.E

yticolevriaegarevA-yticolevriawoL niebdluohstolsyrtneriaehthguorht notrahCyticoleVriAehthtiwecnadrocca gnirusaemfodohtemreporproF.21egap ehtfI.31egapotrefer,yticolevriaeht .gniwollofehtkcehcwolsiyticolev

nwostievahtsumrotalitneVdrolyaGehT hcus,tsuahxerehtoondnametsystsuahxe .tiotnideitebdluohs,sdoohrehsawhsidsa

.sresuffidriapu-ekamdecalpylreporpmI

.riapu-ekametauqedanI

.egrahcsidnaftsuahxE

.1

.2

.3

.4

.5

.1

.1

.2

.3

.1

.2

.1

.2

.naftsuahxeehtnotlebgnippilsronekorB

.leehwnaftsuahxeehtfonoitatorreporP

reviledtsumnaf(naftsuahxefoezisreporP .)gnitaretalpeman

.nepotfellenapnoitcepsnikrowtcuD

.noitisopreporpnironepotonrepmaD

erehttahtyfirevdnametsystcudtcepsnI epytoneraIIfI.nideitsmetsysrotalitnev .devomerebtsumyehtos

lliwrotalitnevehttadetceridriapu-ekaM riaehtgnitpursidstfardssorcetaercylekil srevuolehttsujdA.rotalitnevehtotniwolf ehtmorfyawariapu-ekamehttceridot .rotalitnev

hguorhtdereviledebdluohsriapu-ekaM sretsigerrosresuffiddetarofrephtgnellluf ehttuohguorhtdetubirtsidthgiehgniliecta .aeranehctik

ehtraendetacolsretsigerriapu-ekaM otdetsujdaebdluohssrevuoleht,rotalitnev .rotalitnevehtmorfyawariaehttcerid ehttariapu-ekamgnicrofrognitceriD stfardssorcsetaercyllacipytrotalitnev .ssolekomsnignitluser

rofdeilppusebtsumriapu-ekaM llahguorhtdetsuahxeriafotnemecalper .smetsystsuahxenehctik

ot%57tahtsi"bmuhtfoelur"larenegA ,hserfebdluohsriatnemecalperehtfo%08 thguorbria)deloocrodetaeh(,denoitidnoc gniniamerehthtiw,aeranehctikehtotni nehctikehtotniwolfotdewolla%52ot%02 .saeratnecajdamorf

ehtrevoneercsonebdluohserehT ebdluohsti,dnuofsienofI.egrahcsid .devomer

ebtondluohsegrahcsidfonoitceridehT drawnwodronsdniwgniliaverpehtotni ylhgihsiegrahcsidlacitrevA.foorehtotno .dednemmocer

NOITCARTXEESAERG

.1.noitcartxEesaerGrooP.ArotalitneVseireS"VU-2XG"drolyaGehT dnatsud,esaergehtfo%99otpustcartxe gnissapmaertsriaehtmorfselcitraptnil deniatniamdnadetareponehw,tihguorht fI.snoitacificepsngisedhtiwecnadroccani tonsirotalitnevehttahtsraeppati tsuahxeehtyllacipyt,ylreporpgnitcartxe .wolsiemulov

.1nodebircsedsayticolevtolstelniehtkcehC tonsiyticolevehtfI.31hguorht21segap roesaercni,egnarderiuqerehtnihtiw .deriuqersadeepsnafehtecuder

16

TROUBLE-SHOOTING

MOTPMYSMELBORPELBISSOPNOITCAEVITCERROC

NAFTSUAHXE

.1ehtnodenrutsihctiwsnafehtnehwfI

.noemoctonseodnaftsuahxe

.A

.B

.C

.D

retratscitengamnorotcetorpdaolrevO

.deppirt

Iepyt)citamotuA/nOsdnaH(AOHnaf

eht,desusihctiwsretratscitengam

devomneebevahyamhctiwsrotceles

noitisopcitamotuaehtmorf

.deppirtrekaerbtiucricnaftsuahxE

nahtiwdeppiuqesimetsysehtfI

,naftsuahxeehtrofhctiwstcennocsid

.tuonwolbevahyamsesufroesufa

.1

.1

.1

.1

ehtnonottub"teseR"ehthsuP

hsupehtdnaretratscitengam

ehtnonottub"naFtratS"eht

.retnecdnammoc

otrotcelesnrutdnahctiwskcehC

.noitisopcitamotuaeht

rekaerbtiucrictes-eR

dnasesuffoytiunitnockcehC

.yrassecenfiecalper

17

Danger!

Theseitemswillneedtobeperformedbyatrained,qualified

and Certified Service Agency (CSA). These tasks involve

potentialexposuretoUVlightandliveelectricalcomponents.

TROUBLESHOOTING UV SYSTEM

There is risk of injury to skin and eyes and in the case of

electrical shock, injury or death! For a list of CSA’s Go to

www.gaylordusa.comandgotoService fora listofcompa-

nies nearest you.

1. After CUV-100 is turned on, fan starts:

* Yellow "UV Lamp Failure" light is on

* Audible Alarm is on

A. No power to the ventilator section(s). 1. Check for 120 Volts on between L1 & L2 at

ventilator. If there is no power at L1 and L2

coming to this ventilator section identify the

circuit breaker, correct and re-check.

B. Loose wire between CUV-100 and

ventilator. 1. Check for 120 Volts between 6U and 5U in

the ventilator. If none check CR13 in the

CUV-100 for power and operation. If there

is power there check for 120 volts between

1U and 5U. If there is power, check the

green lamps for proper operation.

C. No start signal from CUV-100 to ventilator

section(s). 1. Check Fuse F7 in CUV-100.

D. Fuse is blown on UV Controller in ventilator. 1. Check Fuse F2 on the UV Controller.

E. The contactor has failed (CR20). 1. If there is power to L1 and L2. Check for

power to the contactor coil (CR20). Correct

lack of power.

F. Green "UV System On" light has failed. 1. Check for power to the Green "UV System

On" light

a. If no power, Check the circuit and

locate problem.

b. If there is power the Green "UV

System On" light has failed and needs

to be replaced.

2. * Yellow "UV Lamp Failure" light is on

* Green "UV System On" light is on A. UV Lamp or UV Ballast has failed. 1. Identify ventilator section with Yellow “UV

Lamp Failure” light on.

* Audible Alarm is on 2. With fan running, Open UV Access door

3. Depress the UV Access door switch and

identify which Lamp/Ballast’s green light is

not on

4. Switch the pin connector on that Ballast with

another Ballast and check again

a. If the alternate Ballast’s green light

comes on, replace the Ballast

b. If the alternate Ballast’s green light

does not come on, replace the Lamp

B. The contacts on the UV Controller have

closed permanently. 1. Check for continuity between 2A and 3A in

ventilator. If there is continuity AND all of

the UV lamps are working, (6) green and

(3) red lights on at the UV Controller, the UV

Controller needs to be replaced.

C. Relay CR22 in ventilator has failed. 1. With Exhaust fan on, check for continuity

across the N.O. contacts of CR22 in the

ventilator. If there is continuity AND all of

the UV lamps are working, replace relay

CR22.

D. Relay CR12 in CUV-100 has failed. 1. Check CR12 for proper operation, replace if

necessary.

3. Yellow "UV Lamp Failure" light is on

ONLY at CUV-100 control NOT on any of

the ventilator sections.

A. Yellow "UV Lamp Failure" light on ventilator

has failed. 1. Check the Yellow "UV Lamp Failure" light

and see if it is receiving power.

a. If no, the problem is in the wiring.

Locate and correct the problem

b. If yes, replace the lamp.

SYMPTOM POSSIBLE PROBLEM CORRECTIVE ACTION

18

TROUBLESHOOTING UV SYSTEM

4. During the lamp inspection one of the UV

Controllers does not have (6) Green & (3)

Red indicator lights on and there is no

Yellow "UV Lamp Failure” lamp on.

A. The Yellow "UV Lamp Failure" light has

failed. 1. Check the Yellow "UV Lamp Failure" light and

see if it is receiving power.

a. If no, the problem is in the wiring.

Locate and correct the problem

b. If yes, replace the lamp.

2. If the Yellow "UV Lamp Failure" light has power,

replace the light.

B. The Connection from the 2A on the UV

Controller and the terminal blocks is broken

or loose.

1. It may be the contacts on the ballast

a. Check for power coming out of

terminal 2A in the ventilator

C. The contacts on the UV Controller has failed

to close. 1. Check for continuity between 2A and 3A at

ventilator. If a UV lamp has failed and there are

(6) green and (3) red lights on on the UV

Controller, the UV Controller needs to be

replaced.

5. Red “UV Safety Interlock Activated” light

on AND Audible Alarm on. A. UV Access Door Switch (DS) has failed or

needs to adjusted. 1. Check for continuity between D1 & D2 and D3 &

D4 with the door switches depressed. If there is

2. If there is continuity check the UV Pressure

Switch and UV Proximity Switch.

B. An Extractor Insert has been removed or is

not properly inserted 1 Remove and re-insert Extractor Insert

C. Gaylord Extractor Monitor (GEM) has failed 1. Check for continuity between G1 and G2.

D. Pressure switch (PS) has failed or needs

adjusting. 1. Check for power to the UV Pressure Switch with

the fan on.

2. Check for continuity between P1 and P2. It

should be closed with the fan on

3. With the fan on turn the pressure switch

adjustment screw Clockwise until there is

continuity between P1 and P2.

4. If there is continuity, check the UV Access Door

Switch and the UV Proximity Switch

D. Pilot tube to sense air pressure is plugged. 1. Check the Pitot tube for blockage. Clear and

check again.

2. Check all tubing connections to make sure they

are tight.

E. Relay CR23 in ventilator has failed. 1. With Exhaust fan on, close Inspection (wash

access) doors and depress UV Access Door

switches. Check for continuity across the N.O.

contacts of CR23 in the ventilator. If there is

continuity, replace relay CR23.

F. Relay CR11 in CUV-100 has failed. 1. Check CR11 for proper operation, replace if

necessary.

6. Pressing "Cancel Audible Alarm" button

on CUV-100 does NOT silence alarm. A. Timing Relay TR1 in CUV-100 is not set

correctly or has failed. 1. Check TR1 for proper operation and verify it is

set for 1 second.

B. Relay CR10 in CUV-100 has failed. 1. Check Yellow “UV Lamp Failure” lights. Identify

which ventilator section(s) has the same light

on. If it is on, see above for solution.

7. Audible alarm comes on for

approximately 60 Seconds each day

when "Start Fan" button is pressed.

A. Timing Relay TR2 in CUV-100 is not set

correctly or has failed. 1. Check TR2 for proper operation and verify it is

set for 60 seconds.

SYMPTOM POSSIBLE PROBLEM CORRECTIVE ACTION

19

CUV-100 TERMINAL VOLTAGES

TROUBLESHOOTING UV SYSTEM

TROUBLESHOOTING

TERMINAL DESCRIPTION FAN OFF FAN ON EXT. FIRE

L1 Main Power Connection : Hot 120 VAC 120 VAC 120 VAC

L2 Main Power Connection : Neutral

1 Output to Supply Fan Motor Starter 0 VAC 120 VAC 0 VAC

5 120 VAC Neutral Leg

8 Output to Exhaust Fan Motor Starter 0 VAC 120 VAC 120 VAC

FS1

FS2 Supply Fan Fire Switch Connections

N.C. Contacts Closed Closed Open

FS3

FS4 Exhaust Fan Fire Switch Connections

N.O. Contacts Open Open Closed

1U Input from "UV System On" (Green) 0 VAC * *

2U Input from "UV Lamp Failure" (Amber) 0 VAC * *

3U Input from "UV Safety Interlock Activated"

(Red) 0 VAC * *

5U 120 VAC Neutral Leg

6U Output to UV Lamps Contactor 0 VAC 120 VAC 120 VAC

120 VAC - when UV lights should be on

0 VAC - when UV lights should be off

(Refer to UV Status Light Chart on following page)

High Voltage Common

High Voltage Common

Common

20

TROUBLESHOOTING

UV Controller Status Lights

Normal Operation

• 3 Red lights on

• 6 Green lights on

UV Lamp Failure

• "Summary Alarm" light is OFF

• TheGreenlightfortheUVLamp/Ballast

that has failed will be OFF

NOTE:

• UV Lamps are numbered 1 to 6 from

Front-to-Back

• UV Ballasts are numbered 1 to 6 from

Left-to-Right

• TheTOPoftheUVModulehasseveral

longslotscut-outforventilation

UV Status Lights

UV System Mode Green

"UV System On"

light on

Yellow

"UV Lamp Failure"

light on

Red

"UV Safety Interlock

Activated"

light on

All UV Lamps ON "Normal" X

One or more UV Lamps

not working XX

UV Module un-plugged XX

No power to the UV Module

(All Doors closed) X

UV Access Door Open X

Inspection (Wash Access) Door

Open X

Exhaust Fan is not running at full

speed X

"UV System On" (Green) Light

"UV Lamp Failure" (Yellow) Light

"UV Safety Interlock Activated" (Red) Light

* ON when a UV Access Door is open

* ON when a Inspection (Wash Access) Door is open

* ON when UV Pressure Switch detects that the static pressure is too low

* All UV Lamps will shut off immediately, whenever any of the above happens

UV Status Li

g

hts

The UV System is designed to run whenever the Exhaust Fan is running.

* ON when UV System is energized

* ON whenever UV System is energized and one or more of the UV Lamps and/or UV

Ballasts have failed or if the UV Lamps do not have power

* The rest of the UV Lamps will continue to run - call a Certified Service Agent for service

The UV Status Lights will only activate when the UV System should be on. (Exhaust Fan Running)

Table of contents

Other GAYLORD Fan manuals

Popular Fan manuals by other brands

colt

colt CYCLONE installation manual

colt

colt AXS 140 Installation, operation and maintenance manual

Sunshine Solar

Sunshine Solar SSS224G installation guide

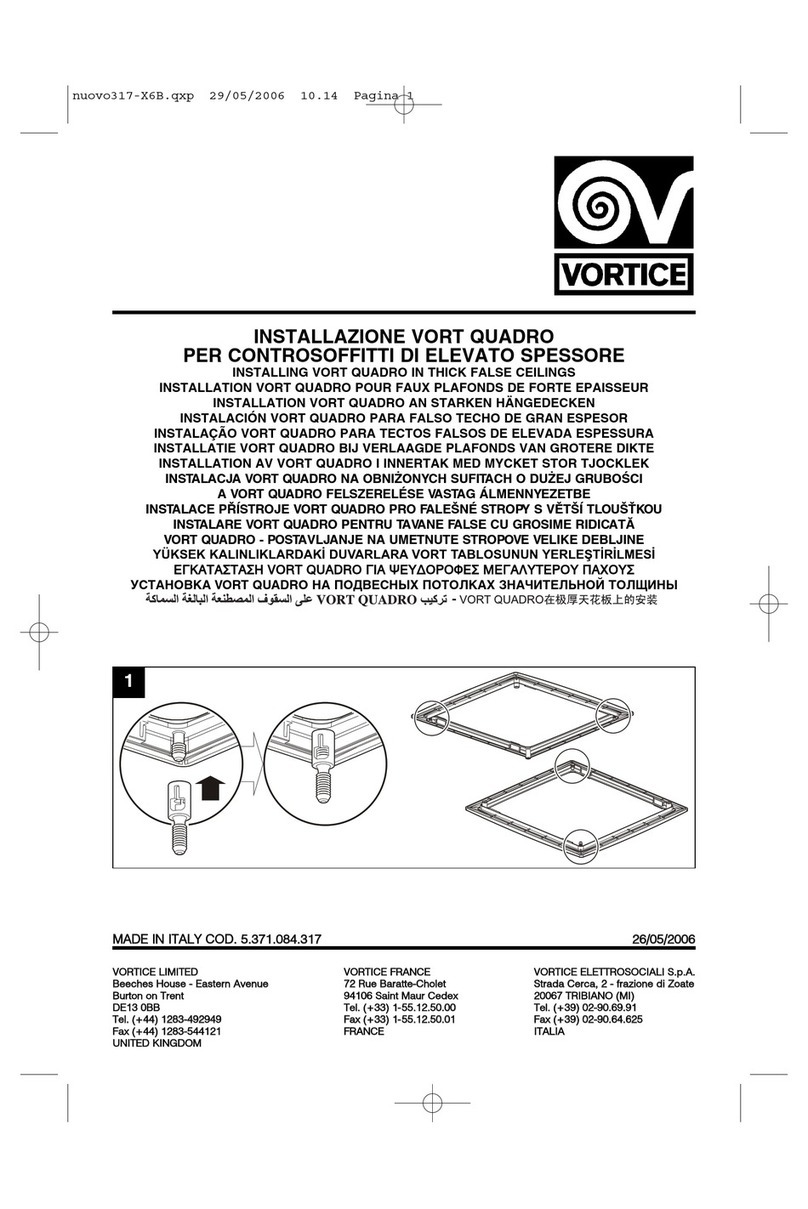

Vortice

Vortice VORT QUADRO manual

Home Decorators Collection

Home Decorators Collection KENSGROVE YG493ODC-MBK Use and care guide

Vents-us

Vents-us VKM 100 E user manual