GAYLORD ELXC Series User manual

10900 S.W. AVERY STREET • TUALATIN, OREGON 97062 U.S.A.

GAYLORD INDUSTRIES

EFFECTIVE DATE 06-2011

OPERATION, MAINTENANCE

& INSTALLATION MANUAL

For

“ELXC” AND “ELXC-UV” SERIES

VENTILATORS

Rev. 07

10900 S.W. AVERY STREET - TUALATIN, OREGON 97062 U.S.A.

email: info@gaylordventilation.com - 800-547-9696 - FAX: 503-692-6048

www.gaylordventilation.com

OPERATION, MAINTENANCE

& INSTALLATION MANUAL

For

“ELXC” AND “ELXC-UVi” SERIES

VENTILATORS

ii

ALL RIGHTS RESERVED. NO PART OF THIS BOOK MAY BE REPRODUCED, STORED IN A

RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY FORM BY AN ELECTRIC, MECHANICAL,

PHOTOCOPYING, RECORDING MEANS OR OTHERWISE WITHOUT PRIOR WRITTEN

PERMISSION OF GAYLORD INDUSTRIES. COPYRIGHT 2011.

© Copyright 2011, Gaylord Industries

The manufacturer reserves the right to modify the materials and

specicaons resulng from a connuing program of product

improvement or the availability of new materials.

ADDITIONAL COPIES $25.00

iii

Gaylord Industries

10900 SW Avery St.

Tualatin, OR 97062

Office: 503.691.2010

Toll Free: 800.547.9696

www.gaylordventilation.com

Gaylord Industries 10900 SW Avery Street Tualatin, OR 97062 www.gaylordventilation.com

To Our Customers:

Congratulations on your recent purchase of an ELXC or ELXC-UVi Series Ventilator. We are proud to be

able to provide you with a quality product that exemplifies our long standing dedication to quality

engineering and manufacturing.

Your ELXC or ELXC-UVi Series Ventilator is assembled from some to the very finest components

available and is designed for years of efficient, effective, and trouble-free operation. In addition, the

product has undergone rigorous quality control inspections and testing prior to shipment.

If you have any questions, please contact us at info@gaylordventilation.com or by calling us toll free

800-547-9696. We are more than happy to help.

Sincerely,

Gaylord Industries

iv

Table of Contents

Chapter 1 – Introducon Page

Introducon ..……………………………………………………………………………………………………………………. 1-1

Model Descripon …………………………………………………………………………………………………………….. 1-2

Model Number Sequence ………………………………………………………………………………………………. 1-3

Chapter 2 – Principles of Operaon

ELXC Series - Turning on the Exhaust Fan .............................................................................. 2-1

ELXC Series - Turning o the Exhaust Fan ………………….………………………………………………………… 2-3

ELXC Series - Wash Cycle ………………………………………………………………………………………………..…… 2-3

ELXC Series - Fire Protecon ……………………………………………………………………………………………..… 2-5

ELXC-UVi Series - Turning On the Exhaust Fan and UV System …............................................. 2-7

ELXC-UVi Series - Turning O the Exhaust Fan and UV System .……………………………………………. 2-10

ELXC-UVi Series - Wash Cycle .................…………………………………………………………………………….. 2-11

ELXC-UVi Series - Fire Protecon ………………………………………………………………………………………… 2-13

Wash System Overview ........................……………………………………………………………………………… 2-15

Wash System - Frequency and Length of Wash ................…………………………………………………… 2-15

Wash System - Recommended Detergent …………………………………………………………………………… 2-17

Balancer Dampers ...............………………………………………………………………………………………………. 2-19

Chapter 3 - Maintenance

Operator Preventave Maintenance ...................……………................................................... 3-1

UV System - Scheduled Prevenve Maintenance …………………………………………………………….... 3-3

Chapter 4 - Troubleshoong

Trouble Shoong ……………………………………………………………………………………………………………… 4-1

Venlator Control Matrix .………………………………………………………………………………………………… 4-5

Chapter 5 – Tesng and Repair

Measuring Airow .............................................................................................................. 5-1

Makeup Air Guidelines ……………….……………………………………………………………………………………. 5-6

Replacing UV Lamps ........................................................................................................... 5-7

Replacing UV Lamp Sockets ................................................................................................ 5-10

UV Ballast Box – Overview ................................................................................................. 5-14

UV Ballast Box – Replacing Parts ........................................................................................ 5-15

UV Ballast Box – Seng Pressure Switches ......................................................................... 5-16

Venlator Water Solenoid Valves ........................................................................................ 5-23

Venlator Spray Nozzles ..................................................................................................... 5-25

Chapter 6 - Parts

Parts - Venlator ..................................................................................................................... 6-1

Parts – UV Venlator …………………………………………………………………………………………………………. 6-4

Parts – UV Lamp Module …………………………………………………………………………………………………… 6-5

Parts – UV Ballast Box ……………………………………………………………………………………………………….. 6-7

Chapter 7 – Wiring Diagrams

Wiring Diagrams ……………………………………………………………………………………………………………….. 7-1

Appendices

Installaon Requirements …………………………………………………………………………………………………. A-1

Typical Installaon Illustraon .…………………………………………………………………………………………. A-5

Venlator Start-Up Inspecon and Tests - Overview..……………………………………………………...... B-1

Pre-Start-Up Checklist ..............................................……………………………………………………...... B-1

Start-Up Inspecon and Test Report Forms ..............……………………………………………………...... B-3

Limited Warranty .........................……………………………………………………................. Inside Back Cover

1-1

Chapter 1 - Introducon

Introducon

About this Technical Manual

The purpose of this manual is to provide the Operator, Maintenance and Service personnel instrucons for

operang, maintaining and troubleshoong the Gaylord Venlator. Venlators incorporang UV Systems,

most maintenance and all repairs must be performed by a trained and cered service company. This man-

ual also includes informaon and guidance to contractors for inial installaon of the Venlator.

The manual is divided into chapters for easy reference to a parcular subject. The pages in the chapters

are numbered with the chapter number, then a dash, and then the page number. So for example pages in

Chapter 2 are numbered 2-1, 2-2, 2-3 etc. Figures and Tables are numbered in a similar manor. For example

Figure 5-3-2 is on page 5-3 and is the second gure. Please keep your manual in a convenient locaon so it

can be accessed easily.

If you have any quesons or concerns with the installaon, operaon, maintenance or service of your Gay-

lord Venlator, please contact Gaylord Industries;

Web: www.gaylordvenlaon.com

E-Mail: info@gaylordvenlaon.com

Main Phone: 503-691-2010 Toll Free: 800-547-9696

Safety

It is important that the operator read Chapter 2, Principle of Operaon, and Chapter 3, Maintenance, before

operang the Venlator for the rst me. Parcular aenon should be given to all the Cauon and Warn-

ing statements.

Related Technical Manuals

1. ELXC and ELXC-UVi Series Venlators are controlled by a Gaylord Command Center. The specic

manual for this control is tled Operaon and Maintenance Manual for the Gaylord Command

Center.

2. ELX and ELX-UVi Venlators may include a Gaylord “Capture Wall” opon. The specic manual for

installaon of this is tled Installaon Manual – ELX Venlators with Capture Wall.

Operaon and Maintenance Manuals may be downloaded from the Gaylord website:

www.gaylordvenlaon.com or be obtained by calling Gaylord Industries.

1-2

Chapter 1 - Introducon

Model Descripon Overview

The Gaylord Model ELXC Series Venlator is a high grease extracon eciency Venlator that incorporates

a hot water Wash Cycle that automacally washes the accumulated grease out of the Venlator and into

the building drain system. The Model ELXC-UVi Series includes the addional feature of an Ultraviolet Light

System that dramacally reduces grease accumulaon in the exhaust plenum, ductwork and fans.

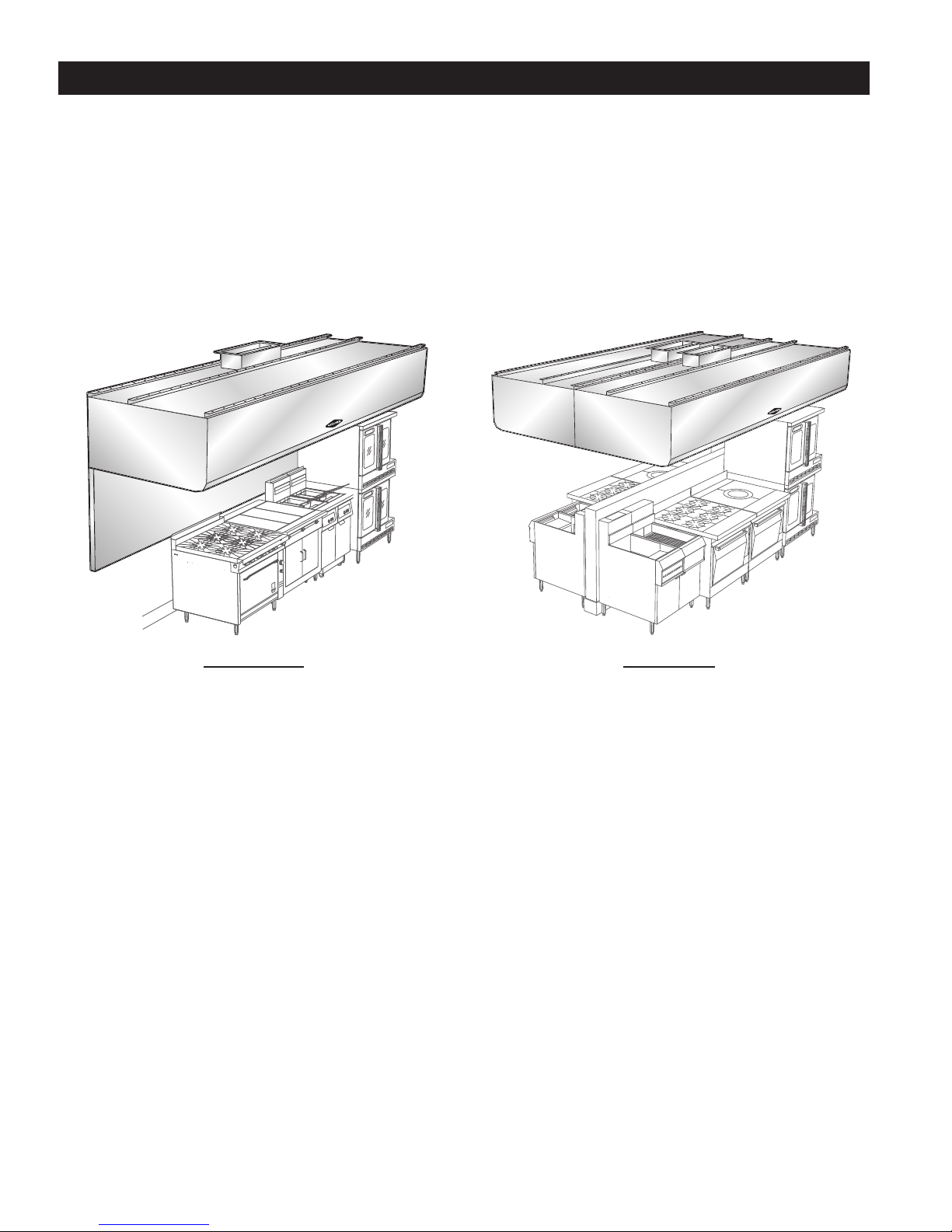

Both the ELXC and ELXC-UVi Venlators come in many dierent models as illustrated below. Your Venlator

may appear slightly dierent as they may have been custom designed to t the space and applicaon.

Figure 1-2-1

Model ELXC Series

Wall Mounted Canopy Shown With

Oponal Capture Wall

Figure 1-2-2

Model ELXC-BB Series

Island Style for all Double Island Arrangement

1-3

Chapter 1 - Introducon

Model Number Sequence

Gaylord Venlator model numbers are made up of an alphabec prex followed by a series of alphabec

and/or numeric suxes to designate the style of venlator and various opons. Sequence of model num-

bers is as follows.

1._____ 2._____ 3._____ 4._____ 5.______ 6._____ 7._____ 8.______ 9._____

Series Damper

Type

Style Front Lip

Design

(Opon)

Apron

Design (If

Applicable)

Canopy

Front

Height

(Opon)

Solid fuel AutoStart Hood

Depth

Denion of Prexes and Suxes

1. Series

ELXC ……………………… High Efficiency Water Wash Ventilator incorporating XGS Extractors.

ELXC-UVi ................. High Efficiency Water Wash Ventilator incorporating XGS Extractors and UV

treatment.

2. Damper Type

GFBD.........................Gaylord Fire Balancing Damper. Has an electric, thermostatically activated Fire/

Balancing damper located at the duct collar with back draft feature. 250°F N.C.

Thermostat standard.

GEBD …………………… Gaylord Electric Balancing Damper. Has an electric balancing damper located at

the duct collar with back draft feature.

GBD …………………….. Gaylord Balancing Damper. Mechanical balancing damper located at the duct

collar with internal set.

GBD-ES ………………… Gaylord Balancing Damper. Mechanical balancing damper located at the duct

collar with external set.

ND ………………………. No Damper.

3. Style

Blank ……………… Wall mounted canopy style.

CL …………………… Island style for single line of cooking equipment using one extraction chamber

(Light to Medium Duty only).

BBC-CL …………… Island style for single line of equipment using one extraction chamber with one

common exhaust duct.

BBC ………………… Island style for double line of cooking equipment using on one extracon chamber and

one common exhaust duct.

BB …………………… Island style for double line of equipment using two extraction chambers and two

separate exhaust ducts

4. Front Lip Design (Front lower edge of the hood)

Blank ..................... Facetted front design with 6 inch return flange. (3 Break or greater at front lip)

(CL models to have a maximum of 9”).

S............................ Square front with 6 inch “Super Capture” lip.

1-4

5. Apron Design Designation

Blank ...................... Capture wall to be added below hood. (Note: Water Wash drain to run out bottom

of capture wall. Access to drain connections to go into capture wall.)

A............................. Hood to have an apron, which will terminate at the bottom lower edge of the

canopy. (No interconnecting drains).

UW......................... Gaylord UDS to be incorporated into capture wall. (Mixed Intertek and UL listing

required).

Chapter 1 - Introducon

Denion of Prexes and Suxes – Cont.

6. Front Canopy Profile Option

Blank ..................... 30 inch or greater canopy height.

MP......................... Medium Profile – Any hood with a front height between 24 inches to 30 inches.

LP .......................... Low Profile - 12 inch to 23 inch front height.(Considerations for proper capture

and contain need to be considered with this option).

7. Solid Fuel Equipment (If Applicable – 700°F Applications only)

Blank………………...... Cooking equipment powered by sources other than the burning of wood.

SPA……………………… Hood use “XGS-SPA” Spark Arrestor Extractors – Intended applications that utilize

the burning of wood as a heat source.

8. AutoStart Opon

Blank ...................... Indicates the hood section does not have Autostart system as required by IMC.

AS ………………………. Indicates the hood section has Autostart conforming with the IMC requirement.

DCV-F …………………… Indicates the hood is equipped with an AutoStart system conforming with the IMC

requirement complying with IMC IECC, Calif. Title 24, IGCC, and ASHRAE Std. 90.1 /

189.

DCV-FH……………….... Indicates the hood is equipped with a DCV system for a single fan mul-hood

applicaon.

9. Hood Depth (Outside of Structural wall to front of hood canopy)

(##)......................... Value in inches to indicate the hood depth.

Chapter 1 - Introducon

Model Number Sequence

2-1

Chapter 2 - Principles of Operaon

ELXC Series

ELXC Series

Turning On the Exhaust Fan

Cauon: Always turn on the exhaust fan before turning on the cooking equipment.

Cauon: The chemical re exnguishing system may discharge if the exhaust fan is not on while the cook-

ing equipment is on or sll hot.

Cauon: Never operate your Venlator without the XGS Extractors in place or the Extractor Access Doors

open (Refer to Figure 2-2-2).

Operaon of the exhaust fan is controlled by the Gaylord Command Center, which is mounted in the Wash

Control Cabinet (refer to Figure 2-2-1). To start the exhaust fan push “START FAN” on the Command Center.

The Command Center control may be programmed to automacally start at a specic me. Refer to the

Operaon and Maintenance Manual for the Gaylord Command Center for complete operang instrucons.

Note 1: The ELXC Series Venlator may be equipped with a Gaylord Electric Balancing Damper, designat-

ed “GEBD” in the Venlator model number, or a Gaylord combinaon Fire/Balancing Damper, designated

“GFBD” in the model number. The Venlator model number can be found on the Venlator Nameplate (Refer

to page 2-19 for informaon on Balancing Dampers and page 5-11 for a sample of the Nameplate). If the

Venlator includes one of these dampers, when the fan is started the damper moves from the closed to open

posion, and it will take approximately 45 seconds for the exhaust to come up to 100%.

Note 2: Typically ELXC Series Venlators installed in the United States are equipped with a Gaylord Auto-

start Controller that automacally turns on the exhaust fan if the temperature at the sensors mounted in

the canopy exceeds 90°F. (Refer to Figure 2-2-2). In some instances Venlators installed outside the United

States will include an Autostart Control. Inclusion of an Autostart Control is designated by the sux “AS” or

“DCA” in the model number. The Venlator model number can be found on the Venlator Nameplate (refer

page 5-11 for a sample of the Nameplate). Refer to the Operaon and Maintenance Manual for the Gaylord

Command Center for complete informaon on the Autostart Control.

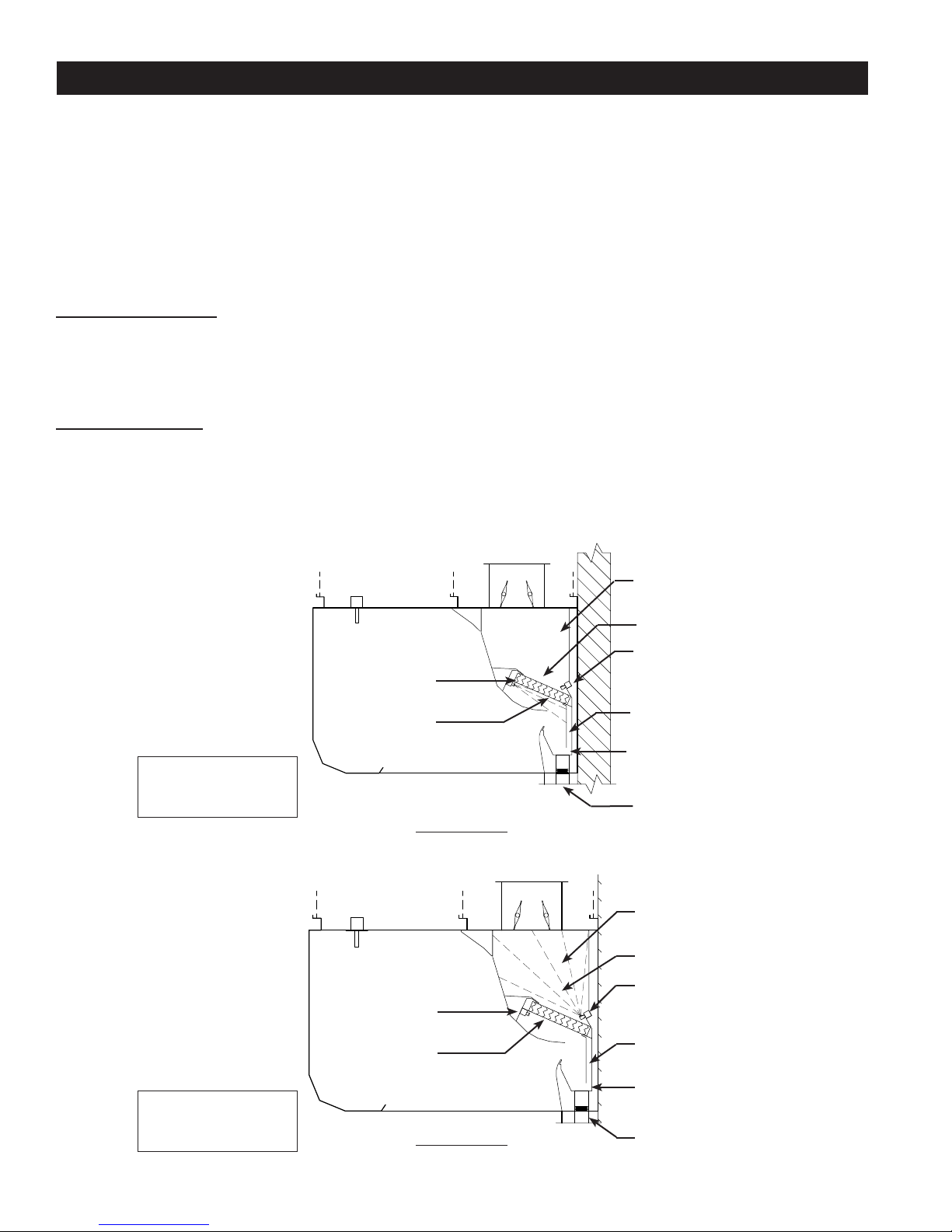

Grease Extracon

Grease is extracted by the use of Gaylord Model XGS Extractors located behind the Extractor Access Doors

(Refer to Figure 2-2-2). The hot contaminate-laden air rising from the cooking surface enters the inlet slot,

turns and is drawn through the Extractors where a high percentage of the grease and other parculate are

extracted from the air stream. The extracted liquid grease will drain down the Extractors and into the Grease

Canal which then drains into the Grease Guer. The scky grease will remain in the Extractor. The Extractors,

Grease Canal and Grease Guer are washed periodically by the automac Wash Cycle, while the fan is on.

The Gaylord Industries Model XGS Extractor is designed to deliver the absolute opmum in collecon e-

ciency at the lowest possible pressure drop. The Extractors are ETL Recognized as part of the ELXC Venlator.

They are constructed of corrosion resistant stainless steel.

2-2

Chapter 2 - Principles of Operaon

ELXC Series - Cont.

Figure 2-2-1

Wash Control Cabinet

Figure 2-2-2

Grease Extracon

Autostart Sensor

Extractor Access Door

Inlet Slot

Grease Laden Air

Balancing Damper

Gaylord Model

XGS Extractors

Grease Canal

Grease Gutter

Drain

Command Center

2-3

Chapter 2 - Principles of Operaon

ELXC Series - Cont.

Turning O the Exhaust Fan

Cauon: Always turn o the cooking equipment and allow to cool before turning o the exhaust fan. The

chemical re exnguishing system may discharge if the cooking equipment is on or hot when the exhaust

fan is o.

At the end of the cooking day, turn o the cooking equipment and allow to cool before turning o the ex-

haust fan. To turn o the exhaust fan push “STOP FAN” on the Gaylord Command Center (Refer to Figure

2-2-1). The Command Center control may be programmed to automacally turn o the exhaust fan at a spe-

cic me. Refer to the Operaon and Maintenance Manual for the Gaylord Command Center for complete

operang instrucons.

Note 1: If the Venlator is equipped with a Gaylord Autostart Controller, the exhaust fan will stay on if the

temperature at the sensor mounted in the canopy exceeds 90°F. (Refer to Figure 2-2-2). Once the tempera-

ture drops below 90°F., the fan will connue to run for 15 minutes and then shut o.

Note 2: If the Venlator is equipped with a Gaylord Electric Balancing Damper, designated “GEBD” or a

Gaylord combinaon Fire/Balancing Damper, designated “GFBD”, when the fan is turned o the damper will

move from the open to closed posion and remain closed unl the exhaust fan is re-started. Closing the

damper saves building energy by not allowing condioned air from draing up the exhaust duct, or in cold

climates prevents cold air from coming down the duct and into the kitchen.

Wash Cycle

Wash Cycle - Overview

The ELXC Series is referred to as a clean in place Venlator as it has automac Wash Cycles that washes away

the extracted grease within the Extractors, Plenum and surrounding areas, with hot, detergent injected wa-

ter. The grease is ushed down into the Grease Guer which slopes to a drain line which leads to the build-

ing drain system.

The Venlator has two wash manifolds, the Extractor Wash Manifold, to wash accumulated grease out of the

Extractors, and the Plenum Wash Manifold to wash the accumulated grease out of the Plenum area (Refer

to Figure 2-4-1 and 2-4-2). The two manifolds are independently connected to the Wash Control Cabinet,

Figure 2-2-1, typically located in, or near the kitchen (Refer to Figure A-5-1 in the Appendix on page A-5 for

a typical arrangement of the Wash Control Cabinet and Venlator). The Wash Control Cabinet houses the

Command Center, valves, detergent pump, detergent tank and other plumbing components needed to op-

erate the Wash Cycles. (Refer to Figure 2-15-1 on page 2-15 for a detailed illustraon of the Wash Control

Cabinet). Two electric solenoid valves are located on the top of or near the top of each Venlator secon

(Refer to Figure A-5-1).

Wash Cycle Sequence

The two wash manifolds, Extractor Wash and Plenum Wash, operate independently of each other as the

Extractor, Grease Canal and Grease Guer typically need washing more frequently than the Plenum area.

Timers in the Command Center are programmed to iniate either the Extractor Wash or Plenum Wash based

on the number of hours the exhaust fan has been on.

2-4

Chapter 2 - Principles of Operaon

ELXC Series - Cont.

Wash Cycle Sequence – Cont.

The frequency and the length of the Wash Cycle is determined by the type of cooking equipment involved;

Light Duty, Light/Medium Duty, Medium Duty, Heavy Duty, and Extra Heavy Duty. Refer to Table T-2-16-1,

Typical Example of Frequency and Length of Wash Cycles, on page 2-16 for typical applicaon. Washing the

Venlator based on hours of operaon for specic Dues of equipment provides the opmum in cleaning

performance with the lowest possible water and detergent consumpon.

Wash Cycle Example

Extractor Wash Cycle – The Extractor Wash Cycle only comes on while the exhaust fan is on, typically dur-

ing cooking (Refer to Figure 2-4-1). Using Table T-2-16-1 on page 2-16, if the cooking equipment under the

Venlator is Heavy Duty then the Extractor Wash would come on every 4 hours of fan operaon, stay on for

3 minutes and then shut o. Refer to page 2-15 for addional details on the wash cycles.

Plenum Wash Cycle - The Plenum Wash Cycle only comes on while the exhaust fan is o (Refer to Figure 2-4-

2). Using Table T-2-16-1 on page 2-16, if the cooking equipment under the Venlator is Heavy Duty then the

Plenum Wash would come on every 16 hours of exhaust fan operaon, stay on for 3 minutes and then shut

o. Typically the Plenum Wash Cycle will begin, if the number of fan on hours has been sased, immedi-

ately aer the exhaust fan has been shut o. Refer to page 2-15 for addional details on the Wash Cycles.

Figure 2-4-1

Extractor Wash On

Figure 2-4-2

Plenum Wash On

Plenum Area

Plenum Area

Extractors

Plenum Wash Sprays

Plenum Wash

Manifold

Plenum Wash

Manifold

Grease Canal

Grease Canal

Grease Gutter

Grease Gutter

Extractor Wash

Sprays

Extractors

Drain

Drain

Extractor Wash

Manifold

Extractor Wash

Manifold

Note: Extractor Wash

comes on only when the

Exhaust Fan is On.

Note: Plenum Wash

comes on only when the

Exhaust Fan is O.

2-5

Chapter 2 - Principles of Operaon

ELXC Series - Cont.

Fire Protecon

Fire Damper

The ELXC Series Venlator may be equipped with a combinaon Gaylord Fire/Balancing Damper, designated

“GFBD” in the Venlator model number. If equipped, a 250°F. thermostat will be mounted at the entrance

of the exhaust duct collar (Refer to Figure 2-6-1). In the event of a re and if the thermostat reaches 250 °

F., the following will occur:

1. The re damper will close prevenng re from extending into the exhaust duct and fan.

2. The exhaust and supply fans will shut o.

3. If the Venlator was in a Wash Cycle it would shut o.

4. If the Command Center is wired to a building re alarm system the alarm will acvate.

5. If the Command Center is wired to a building management system it will nofy of a re condion.

6. Once the thermostat cools below its set point, the exhaust and supply fans can be re-started by

pushing “START FAN” on the Command Center.

Fire Exnguishing Systems

The Naonal Fire Protecon Associaon Standard 96 (NFPA-96) and the Internaonal Fire Code (IFC) requires

the use of a Fire Exnguishing System to cover the cooking surfaces, Venlator exhaust plenums (the area

behind the grease extractors), and the exhaust duct (Refer to Figure 2-6-1). Upon acvaon of the Fire Ex-

nguishing System the follow will occur:

1. Fire exnguishing agent will discharge through the cooking equipment nozzles, the plenum nozzles

and the duct nozzle(s).

2. The protected cooking equipment and possibly other cooking equipment will shut o. Refer to the

above referenced codes for specic equipment that must shut o.

3. If the Fire Exnguishing System is wired to a building re alarm system the alarm will acvate.

4. If the Fire Exnguishing System is wired to a building management system it will nofy of a re con-

dion.

5. The Fire Exnguishing System should be wired to the Gaylord Command Center. If it is, the following

will occur:

a) If the exhaust and supply fan were on the exhaust fan would stay on and the supply fan would

shut o. If the exhaust and supply fans were o, the exhaust fan would come on and the supply

fan would stay o.

b) If the Venlator Wash Cycle was on it would shut o.

c) If the Venlator is equipped with a Gaylord Electric Balancing Damper (model GEBD) or a Gay-

lord Fire/Balancing Damper (model GFBD) the damper will open.

6. Aer discharge, the Fire Exnguishing System must be recharged and cered by a re system con-

tractor and all exnguishing agent cleaned up before the cooking equipment can be turned back on.

For Operaon and Maintenance of the Fire Exnguishing System, refer to the system manufacture’s Owner’s

Manual.

Important: NFPA-96 requires inspecon and cercaon of re systems every 6 months.

2-6

Chapter 2 - Principles of Operaon

ELXC Series - Cont.

Figure 2-6-1

Fire Exnguishing System Discharge

Fire Extnguishing System

Duct Detector

250°F Thermostat

Used only when a Gaylord Fire

Balancing Damper (Model GFBD)

is used.

Fire Extinguishing System

Plenum Nozzle(s)

Fire Extinguishing System

Cooking Equipment Nozzles

*Illustration shows Fire Extinguishing System discharging.

Fire Extinguishing System

Cooking Equipment

Detectors

Fire Extinguishing System

Duct Nozzle

When a Fire Extinguishing System discharges, the

Balancing Damper remains open or opens if it was

closed. If equipped with a Model GFBD Damper

and the thermostat activates, the damper closes.

2-7

Chapter 2 - Principles of Operaon

ELXC-UVi Series

Ultraviolet Systems (UV)

Overview

Venlators incorporang UV Lamps are designated Model ELXC-UVi Series Venlators. UV Systems are used

to remove a high percentage of grease that the Extractors cannot remove, oering many benets to the

owner/operator. The UV Lamps are mounted in a UV Module which slide into a track downstream (aer)

the XGS Extractors (refer to Figure 2-10-1). The electronics and ballasts for UV System are mounted in a UV

Ballast Box which is located on the top of the Venlator (refer to Figure 2-10-1). The ELXC-UVi Venlator

is equipped with UV Status Lights to monitor the status of the UV System, and Safety Interlocks to protect

operators from exposure to UV light (refer to Figure 2-8-1).

For proper UV operaon, the Venlators must be maintained in good working order. The UV system must be

inspected periodically and the lamps replaced as necessary. The Venlator, ductwork and exhaust fan must

be inspected in accordance with NFPA-96 or local guidelines, though frequency of duct cleanings should be

signicantly reduced.

UV Safety

Cauon: Exposure to UV light is harmful to skin and eyes.

The ELXC-UVi Venlator is equipped with panels and Safety Interlocks to protect operators from direct expo-

sure to UV light. All safety precauons called for in this manual must be followed to avoid the potenal for

harm to operators or service personnel. Refer to Page 3-3 for complete descripon of safety precauons.

Turning On the Exhausng Fan and UV System

Cauon: Always turn on the exhaust fan before turning on the cooking equipment.

Cauon: The chemical re exnguishing system may discharge if the exhaust fan is not on while the cook-

ing equipment is on or sll hot.

Cauon: Never operate the Venlator without the XGS Extractors in place or the Extractor Access Doors

open (Refer to Figure 2-10-1).

Operaon of the exhaust fan and UV Lamps is controlled by the Gaylord Command Center (refer to Figure

2-9-1). To start the exhaust fan and turn on the UV Lamps push the “START FAN” buon on the Command

Center. The Command Center control may be programmed to automacally start the exhaust fan at a spe-

cic me. Refer to the Operaon and Maintenance Manual for the Gaylord Command Center for complete

operang instrucons of the Command Center.

Note 1: The ELXC-UVi Series Venlator may be equipped with a Gaylord Electric Balancing Damper, desig-

nated “GEBD” in the Venlator model number, or a Gaylord combinaon Fire/Balancing Damper, designated

“GFBD” in the model number. The Venlator model number can be found on the Venlator Nameplate (Refer

to page 2-19 for informaon on Balancing Dampers and page 5-11 for a sample of the Nameplate). If the

Venlator includes one of these dampers, when the fan is started the damper moves from the closed to open

posion, and it will take approximately 45 seconds for the exhaust to come up to 100%.

2-8

Chapter 2 - Principles of Operaon

ELXC-UVi Series - Cont.

Turning On the Exhausng Fan and UV System – Cont.

Note 2: Typically ELXC-UVi Series Venlators installed in the United States are equipped with a Gaylord Au-

tostart Controller that automacally turns on the exhaust fan if the temperature at the sensors mounted in

the canopy exceeds 90°F. (Refer to Figure 2-10-1). In some instances Venlators installed outside the United

States will include an Autostart Control. Inclusion of an Autostart Control is designated by the sux “AS” or

“DCA” in the model number. The Venlator model number can be found on the Venlator Nameplate (Refer

to page 5-11 for a sample of the Nameplate). Refer to the Operaon and Maintenance Manual for the Gay-

lord Command Center for complete informaon on the Autostart Control.

Note 3: The UV Lamps will not come on unless all the XGS Extractors are in place and the Extractor Access

Doors are closed as shown in Figure 2-10-1 and 2-10-2.

Note 4: The UV Lamps will not come on unless all the UV Module Access Doors are closed and latched as

shown in Figure 2-10-2.

Note 5: The UV Lamps will not come on unless the exhaust fan is running.

UV Status Lights

Each Venlator secon contains a bank of UV Status Lights to monitor the UV System (refer to Figure 2-8-1).

There are three colored lights, Blue, Yellow and Green. They indicate the system status as follows:

1. Green On: The UV system is operang properly.

2. Yellow On: One or more UV Lamps are not operang. If the yellow is on, less UV is being generated,

however it does not prevent the operaon of the Venlator or indicate an unsafe condion.

3. Blue On: One or more XGS Extractors are not in place and/or one or more UV Module Access Doors are

not closed properly, or the internal temperature of the Ballast Box has exceeded 118° F. which acvates

the High Temperature Shutdown Controller. During this mode the UV System is not operang and is in a

UVi System Standby mode unl the cause has been corrected.

In addion to the Status Lights on the Venlator, the Gaylord Command Center displays text indicang a simi-

lar message as the Status Lights. Refer to the Operaon and Maintenance Manual for the Gaylord Command

Center for complete operaonal instrucons.

Note: If either the Yellow or Blue light are on refer the Troubleshoong secon of this manual beginning on

page 4-1 for correcve acon.

Figure 2-8-1

UV Status Lights

UVi

SYSTEM

ON

UVi

LAMP

FAILURE

UVi

SYSTEM

STANDBY

20385

SYSTEM STATUS

UVi Ventilator

Integrated DCV

2-9

Chapter 2 - Principles of Operaon

ELXC-UVi Series - Cont.

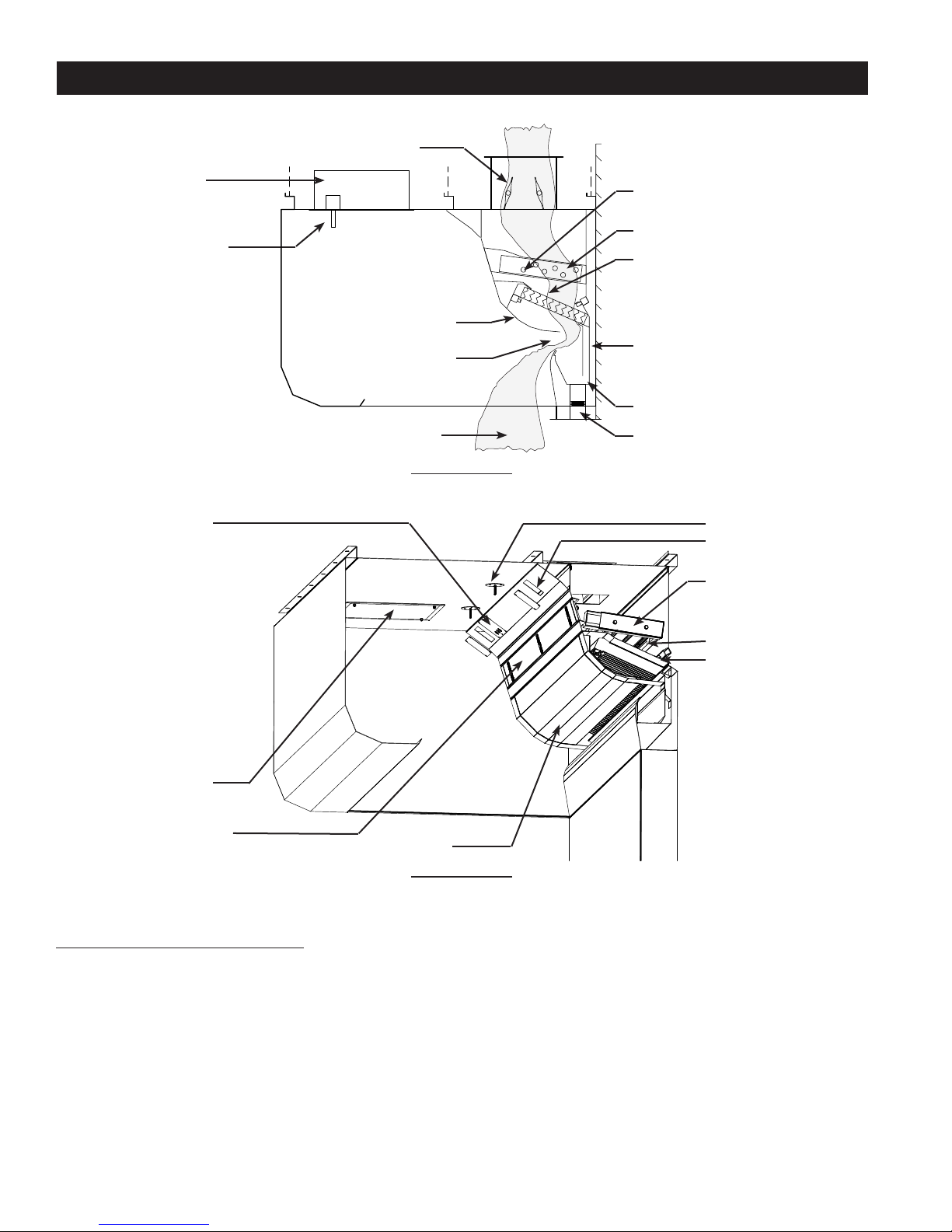

Grease Extracon

Grease is removed from the exhaust air by combinaon of the Gaylord Model XGS Extractors and the UV

Lamps (Refer to Figure 2-10-1). The hot contaminate-laden air rising from the cooking surface enters the

inlet slot, turns and is drawn through the Extractors where a high percentage of the grease and other par-

culate are extracted from the airstream. As the air enters the Plenum chamber, the grease parcles are

exposed to the ultraviolet light which oxidizes the parcles into a light gray powder which are deposited on

the Lamps, the Plenum chamber and in the exhaust duct. Some powder may exhaust out the exhaust fan.

The extracted liquid grease will drain down the Extractors and into the Grease Canal which then drains down

into the Grease Guer. The scky grease will remain in the Extractors. The Extractors, Grease Canal and

Grease Guer are power washed periodically, while the exhaust fan is on, by the automac Extractor Wash

Cycle. The UV Lamps are also washed periodically during a Plenum Wash Cycle. Refer to page 2-11 for de-

tails on the Wash Cycles.

The Gaylord Industries Model XGS Extractor is designed to deliver the absolute opmum in collecon ef-

ciency at the lowest possible pressure drop. The Extractors are ETL Recognized as part of the ELXC-UVi

Venlator. They are constructed of corrosion resistant stainless steel.

Figure 2-9-1

Wash Control Cabinet

Command Center

2-10

Chapter 2 - Principles of Operaon

ELXC-UVi Series - Cont.

Figure 2-10-1

Grease Extracon

Figure 2-10-2

Model ELXC-UVi Series Cutaway

Turning O the Exhaust Fan

Cauon: Always turn o the cooking equipment and allow to cool before turning o the exhaust fan. The

chemical re exnguishing system may discharge if the cooking equipment is on or hot when the exhaust

fan is o.

At the end of the cooking day, turn o the cooking equipment and allow to cool before turning o the ex-

haust fan. To turn o the exhaust fan and UV Lamps push the “STOP FAN” buon on the Gaylord Command

Center (Refer to Figure 2-9-1). The Command Center control may be programmed to automacally turn o

the exhaust fan at a specic me. Refer to the Operaon and Maintenance Manual for the Gaylord Com-

mand Center for complete operang instrucons.

UV Module Access Door

Access to Ballast Box

UV Status Lights Autostart Sensor

Static Tap Opening

UV Lamp Module

UV Lamps

Extractor

Autostart Sensor

Grease Laden Air

Balancing Damper

Gaylord Model

EXG Extractors

UV Lamps

UV Module

Ballast Box

Accessable from

Underside

Grease Canal

Grease Gutter

Drain

Extractor Access Doors

Extractor Access Door

Inlet Slot

2-11

Chapter 2 - Principles of Operaon

ELXC-UVi Series - Cont.

Turning O the Exhaust Fan - Cont.

Note 1: If the Venlator is equipped with a Gaylord Autostart Controller, the exhaust fan will stay on if the

temperature at the sensor mounted in the canopy exceeds 90°F. (Refer to Figure 2-10-1). Once the tempera-

ture drops below 90°F., the fan will connue to run for 15 minutes and then shut o.

Note 2: If the Venlator is equipped with a Gaylord Electric Balancing Damper, designated “GEBD” or a

Gaylord combinaon Fire/Balancing Damper, designated “GFBD”, when the fan is turned o the damper will

move from the open to closed posion and remain closed unl the exhaust fan is re-started. Closing the

damper saves building energy by not allowing condioned air from draing up the exhaust duct, or in cold

climates prevents cold air from coming down the duct and into the kitchen.

Wash Cycle

Overview

The ELXC-UVi Series is referred to as a clean in place Venlator as it has automac Wash Cycles that washes

away the extracted grease within the Extractors, UV Lamps, Plenum and surrounding areas, with hot, deter-

gent injected water. The grease is ushed down into the Grease Guer which slopes to a drain line which

leads to the building drain system.

The Venlator has two wash manifolds, the Extractor Wash Manifold, to wash accumulated grease out of the

Extractors, and the Plenum Wash Manifold to wash the accumulated gray powder, created by oxidaon of

the grease by the UV Lamps, out of the Plenum area (Refer to Figure 2-12-1 and 2-12-2). The two manifolds

are independently connected to the Wash Control Cabinet typically located in, or near the kitchen (Refer to

Figure A-5-1 in the Appendix on page A-5 for a typical arrangement of the Wash Control Cabinet and Venla-

tor). The Wash Control Cabinet houses the Command Center, valves, detergent pump, detergent tank and

other plumbing components needed to operate the Wash Cycles (Refer to Figure 2-15-1 on page 2-15 for a

detailed illustraon of the Wash Control Cabinet). Two electric solenoid valves are located on the top of or

near the top of the Venlator (Refer to Figure A-5-1).

Wash Cycle Sequence

The two wash manifolds, Extractor Wash and Plenum Wash, operate independently of each other as the

Extractor, Grease Canal and Grease Guer typically need washing more frequently than the UV Lamps and

Plenum area.

Timers in the Command Center are programmed to iniate either the Extractor Wash or Plenum Wash based

on the number of hours the exhaust fan has been on. The frequency and the length of the Wash Cycle is de-

termined by the type of cooking equipment involved; Light Duty, Light/Medium Duty, Medium Duty, Heavy

Duty, and Extra Heavy Duty. Refer to Table T-2-16-1, Typical Example of Frequency and Length of Wash

Cycles, on page 2-16 for typical applicaon. Washing the Venlator based on hours of operaon for specic

Dues of equipment provides the opmum in cleaning performance with the lowest possible water and

detergent consumpon.

2-12

Chapter 2 - Principles of Operaon

ELXC-UVi Series - Cont.

Wash Cycle Sequence – Cont.

Wash Cycle Example

Extractor Wash Cycle – The Extractor Wash Cycle only comes on while the exhaust fan is on, typically dur-

ing cooking (Refer to Figure 2-12-1). Using Table T-2-16-1 on page 2-16, if the cooking equipment under the

Venlator is Heavy Duty then the Extractor Wash would come on every 4 hours of fan operaon, stay on for

3 minutes and then shut o. Refer to page 2-15 for addional details on the wash cycles.

Plenum Wash Cycle - The Plenum Wash Cycle only comes on while the exhaust fan is o (Refer to Figure 2-12-

2). Using Table T-2-16-1 on page 2-16, if the cooking equipment under the Venlator is Heavy Duty then the

Plenum Wash would come on every 16 hours of exhaust fan operaon, stay on for 3 minutes and then shut

o. Typically the Plenum Wash Cycle will begin, if the number of fan on hours has been sased, immedi-

ately aer the exhaust fan has been shut o. Refer to page 2-15 for addional details on the Wash Cycles.

Figure 2-12-1

Extractor Wash On

Figure 2-12-2

Plenum Wash On

UV Lamps

Plenum Area

Extractors

Plenum Wash

Manifold

Grease Canal

Grease Gutter

Extractor Wash

Sprays

Drain

Extractor Wash

Manifold

Note: Extractor Wash

comes on only when the

Exhaust Fan is On.

Plenum Area

Plenum Wash Sprays

UV Lamps

Plenum Wash

Manifold

Grease Canal

Grease Gutter

Extractors

Drain

Extractor Wash

Manifold

Note: Plenum Wash

comes on only when the

Exhaust Fan is O.

This manual suits for next models

1

Table of contents

Other GAYLORD Fan manuals