Gazomat Inspectra User manual

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 1/48

Portable gas leak detector

Operating manual

11, Rue de l’Atome-B.P. 50081

F-67802 BISCHHEIM –France

Phone +33 (0)3 88 19 72 30 –Fax +33 (0)3 88 19 72 19

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 2/48

WARNINGS

GAZOMAT reserves its right to update the contents of this manual, in

line with the evolution of the product.

Text and pictures in the manual are not binding on GAZOMAT.

Copyright Gazomat © 2009

All rights to translation, adaptation and reproduction by any process

reserved in all countries. No part of this document may be copied,

reproduced or transcribed without the written consent of Gazomat.

No part of this document may be circulated outside Gazomat in this form.

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 3/48

EC DECLARATION OF CONFORMITY

GAZOMAT

11, Rue de l’Atome

67802 Bischheim –France

hereby declares that the product designed for use in explosive atmospheres and here

designated as:: Inspectra Laser version 100%gaz - Atex

Is in conformity:

With the 94/9/EC Directive of 23 March 1994

With the 89/336/EC CEM Directive of 3 May 1989.

With the explosion-proof standards relative to use in explosive atmospheres:

EN 60079-0 of 2006:

Electrical apparatus for explosive gas atmospheres: - General

requirements.

EN 60079-11 of January 2007:

Explosive atmospheres –Equipment protection by intrinsic safety « i ».

With the type of apparatus that have been examined and fully approved by the

INERIS certifying institute, rue J. Taffanel, 60550 Verneuil en Halatte, France,

organization registered under the number 0080 –and for which INERIS has

issued a Type EC examination certificate under the number

INERIS05ATEX0051 with its addenda under numbers 05 ATEX 0051 X/01 and 05

ATEX 0051 X/02.

The manufacturing unit in Bischheim has been registered under the number N° 03

ATEX Q 416 by the l’INERIS certifying Institute, rue J. Taffanel, 60550 Verneuil

en Halatte, Institute itself registered under the number 0080.

Bischheim, 14th March 2007 Vincent GHIRCOIAS

Proxy for Gazomat

T.D. WILLIAMSON France General Manager

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 4/48

CONTENTS

1Warnings ........................................................................................................................ 6

1.1 Reading obligation.......................................................................................................6

1.2 InspectraLaser device version ..................................................................................6

1.3 Equipment generating invisible laser radiation...........................................................7

2Marking.......................................................................................................................... 8

3First starting up...............................................................................................................8

4Introduction.................................................................................................................... 9

5User interface ............................................................................................................... 11

5.1 Description.................................................................................................................11

5.2 Keypad.......................................................................................................................12

5.3 Display.......................................................................................................................13

5.3.1 Measurement area ..............................................................................................13

5.3.2 Indicator area......................................................................................................14

5.3.3 Dialogue area......................................................................................................14

5.4 Alarm indicators ........................................................................................................15

5.5 Wired communication port (optional).......................................................................16

6Mechanical aspects.......................................................................................................17

6.1 Battery compartment .................................................................................................17

6.2 Gas inlet and outlet....................................................................................................17

6.3 Hydrophobic filter housing........................................................................................18

6.4 Carrying strap grooves...............................................................................................19

6.5 Sampling circuit.........................................................................................................19

7Operation...................................................................................................................... 22

7.1 Device On/Off ...........................................................................................................22

7.2 Starting up..................................................................................................................22

7.3 Preliminary inspection with the gas check kit...........................................................23

7.3.1 Composition and use of the gas check kit..........................................................23

7.4 Standard functions.....................................................................................................25

7.4.1 Backlighting on/off ............................................................................................25

7.4.2 Pump on/off........................................................................................................25

7.4.3 User alarm on/off ...............................................................................................26

7.5 Advanced functions...................................................................................................26

7.5.1 Access to menu...................................................................................................26

7.5.2 Menu structure and browsing.............................................................................27

7.5.3 Resetting the configurable options.....................................................................28

7.5.4 Selecting the language........................................................................................29

7.5.5 Selecting the measurement mode.......................................................................29

7.5.6 Selecting the minimum and maximum bar levels..............................................30

7.5.7 Displaying the measured maximum value.........................................................31

7.5.8 Selecting the user alarm .....................................................................................31

7.6 Conditions of use –Range of temperature. ...............................................................32

8Audio alarms ................................................................................................................ 32

8.1 User alarms................................................................................................................32

8.1.1 Threshold alarm..................................................................................................32

8.1.2 Geiger alarm.......................................................................................................33

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 5/48

8.2 Explosive risk alarm..................................................................................................33

8.3 Malfunctioning of the measuring element.................................................................33

8.4 10,000-ppm measuring range overrun.......................................................................33

9Audio indicators........................................................................................................... 34

9.1 Calibration indicator..................................................................................................34

9.2 Pump indicator...........................................................................................................34

9.3 Battery indicator ........................................................................................................ 35

10 Maintenance ................................................................................................................. 35

10.1 Filter replacement ..................................................................................................35

10.1.1 Replacing the filter integrated into the device ...................................................36

10.1.2 Replacing the filter in the telescopic rod............................................................38

10.2 Charging and replacing the batteries......................................................................41

10.2.1 Charging the batteries.........................................................................................42

10.2.2 Replacing the batteries .......................................................................................42

10.3 Storage and environment .......................................................................................44

11 technical specifications ................................................................................................ 45

12 Parts and accessories for the InspectraLaser............................................................. 46

13 List of equipment for the gas check kit........................................................................ 46

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 6/48

1 WARNINGS

1.1 READING OBLIGATION

All users must imperatively read this manual for their own safety, the safety of those around

them and the safety of the device. Users are required to use the device as instructed by the

manufacturer in order to get the most out of the device and keep it protected from damage.

Gazomat shall not be liable if the device is used other than as instructed.

The manufacturer shall not be liable in the event of any abnormal use of the product or any

malicious tampering with the product.

1.2 INSPECTRALASER DEVICE VERSION

The InspectraLaser detector is marketed in three versions:

- 100% gas version without Atex certification, which is not to be used in explosive

atmospheres.

- 100% gas version with Atex certification, which may be used in explosive atmospheres.

- 10,000 ppm version without Atex certification, which is not to be used in explosive

atmospheres.

This manual informs the user of the conditions of use of each of the three versions of the

Inspectradetector. The user is responsible for identifying the device version being used and

for following and implementing the corresponding safety measures. The user can identify the

type of device from the marking on the front of the device (see paragraph 3.1), showing if the

device is approved for use in areas with explosive atmospheres.

Never use the INSPECTRA

portable 100% gas version and the INSPECTRA

portable

10000 PPM VERSION with no marking in atmospheres that are or are suspected to be

hazardous. The device is not designed for use in explosive atmospheres.

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 7/48

1.3 EQUIPMENT GENERATING INVISIBLE LASER RADIATION

The Inspectradetector contains a laser source. It is strictly forbidden to open the plastic

housing of the device and to remove components from the inside of the housing, because of

the risk of laser radiation exposure.

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 8/48

2 MARKING

The different device versions are marked with adhesive aluminium labels bearing the

following information, depending on the version:

100% gas version without Atex certification. Not for use in explosive atmospheres.

INSPECTRALASER

Serial no.: Year of manufacture –device no. in 3 digits

GAZOMAT

11, Rue de l’Atome

67802 Bischheim –France

100% version with Atex certification. May be used in explosive atmospheres.

INSPECTRALASER

GAZOMAT

11, Rue de l’Atome

67802 Bischheim –FRANCE

0080 -N° 05 ATEX 0051

Serial no. Year of manufacture –device no. in 3 digits

II2G Ex ib IIB T4

INERIS N° 05 ATEX 0051

The target gas detected by the INSPECTRALASER detector is stated on the label on the

side of the device.

3 FIRST STARTING UP

The Inspectradetector is first started up by:

GAZOMAT

11 Rue de l’Atome

67802 Bischheim - France

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 9/48

4 INTRODUCTION

Inspectra Laser is a portable gas detector that is designed to enable an operator moving on

foot to locate leaks in methane gas distribution systems.

The device uses the principle of infrared laser light absorption by methane molecules. That

detection principle makes the detector highly selective, and sensitive to a single ppm of

methane gas.

The system comes in three versions:

100% gas version : covers the measurement range from 1 ppm to 100% gas volume,

without Atex certification, not for use in explosive atmospheres.

100% gas version: covers the measurement range from 1 ppm to 100% gas volume,

with Atex certification, for use in explosive atmospheres.

10,0000 ppm version: covers the measurement range from 1 ppm to 10,000 ppm,

without Atex certification, not for use in explosive atmospheres

The features of InspectraLaser make it extremely easy to use:

Compact and lightweight

Digital display

User-friendly keypad: direct shortcut keys for fast and simple access to standard

functions and menu keys for access to advanced functions;

Carrying system that is easy to adapt to each personal build and the requirements

relating to the use of the device in the field

Use in all positions

The detector is easy to use and maintenance is limited to battery replacement and checking the

condition of the dust filter. The system and accessories adapt to all work situations, from

laboratory measurements to field gas leak detection.

Laser technology is intrinsically safe, as it does not generate hot points. It does not affect the

sample gas and is not sensitive to flow fluctuations.

The INSPECTRALASER detector is not designed for use in a contaminated environment.

No identified substances can deteriorate the INSPECTRALASER detector in its usual

working environment. However, for use in a chemical environment that is liable to damage

the sensor, please contact GAZOMAT for advice.

Inspectra Laser is the only portable gas detector in the world to offer the best technology for

detecting traces of gas and to put infrared laser technology at the service of the gas industry.

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 10/48

Safety requirements for the use of the Inspectra

Laser (94/9/CE)

CAUTION –It is strictly forbidden:

To open the detector, particularly, in a hazardous or supposedly hazardous atmosphere.

To change, to modify or to adapt external or internal parts or componants of the

detector.

Dry cells authorized for use are as follows:

Make

Varta

Duracell

Reference

4920

Procell MN 1300

Type

Alcaline Pile High Energy

Alcaline Pile High Energy

Size

LR20 D

LR20 D

Voltage

1.5V

1.5V

Any other make or type of dry cells will be considered as not in conformity and

even dangerous for the operator.

Rechargeable batteries authorized for use are as follows:

Make

SAFT

Reference

VTD 70 (VTD137) –4000mAh

Type

NiCd

Size

LR20 - D

Voltage

1.2V

Any other make or type of rechargeable batteries will be considered as not in

conformity and even dangerous for the operator.

It is imperative:

To comply with the technical specifications.

It is recommended

To carefully read the instruction notice prior to using the detector.

In case of malfunction, please contact :

ETABLI PAR:

VERIFIE PAR :

APPROUVE PAR:

Technical department

Qualité Manager

ATEX Manager

GAZOMAT After-Sales Departement

11, rue de l’atome – 67802 Bischheim Cedex - France

Phone : +33 (0)3 88 19 72 30

Fax : +33 (0)3 88 19 72 19

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 11/48

5 USER INTERFACE

5.1 DESCRIPTION

The user interface includes the following:

Keypad

Display

Alarm indicators

The ATEX marking is provided on the front of the device, for the Atex version units.

Front

*Marking specific to the Inspectra 100% gas volume version with ATEX

CERTIFICATION

Display

Buzzer

Keypad

Alarm

indicators

ATEX marking*

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 12/48

5.2 KEYPAD

The keypad has five keys:

On/Off key to switch the device on and off

Four configuration keys with a dual function

The Direct function (symbol on a blue background) is used to access a standard function (e.g.

backlighting of the display).

The Menu function (symbol on a grey background) is used to browse the menu and access

advanced functions.

Key

Direct function

Menu function

1

Device On/Off

-

2

Backlighting On/Off

Up

3

Entry into a menu

(switch key to Menu

function)

Confirm

4

Pump On/Off

Down

5

Mute selected alarm

Cancel

Key functions

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 13/48

5.3 DISPLAY

The display is made up of three areas:

Measurement area

Indicator area

Dialogue area

Display

5.3.1 MEASUREMENT AREA

This area has two display scales for the measured CH4(methane) concentration.

The upper scale displays measurements in ppm ranging from 0 to 19,999 ppm (below 20,000

ppm).

The lower scale display measurements in % gas volume above 20,000 ppm.

Below 20,000 ppm, measurements are displayed as follows :

Display below 20,000 PPM

Display above 20,000 PPM

X X X X X

PPM

(5 digits)

_ _ _ _ _

PPM

X.X %

GAS

(2 digits)

XXX.X %

GAS

( 4 digits)

The two scales are separated by a status bar. The minimum and maximum levels of the bar are

configurable from the menu.

Indicator area

Concentration measurement

display

Dialogue box

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 14/48

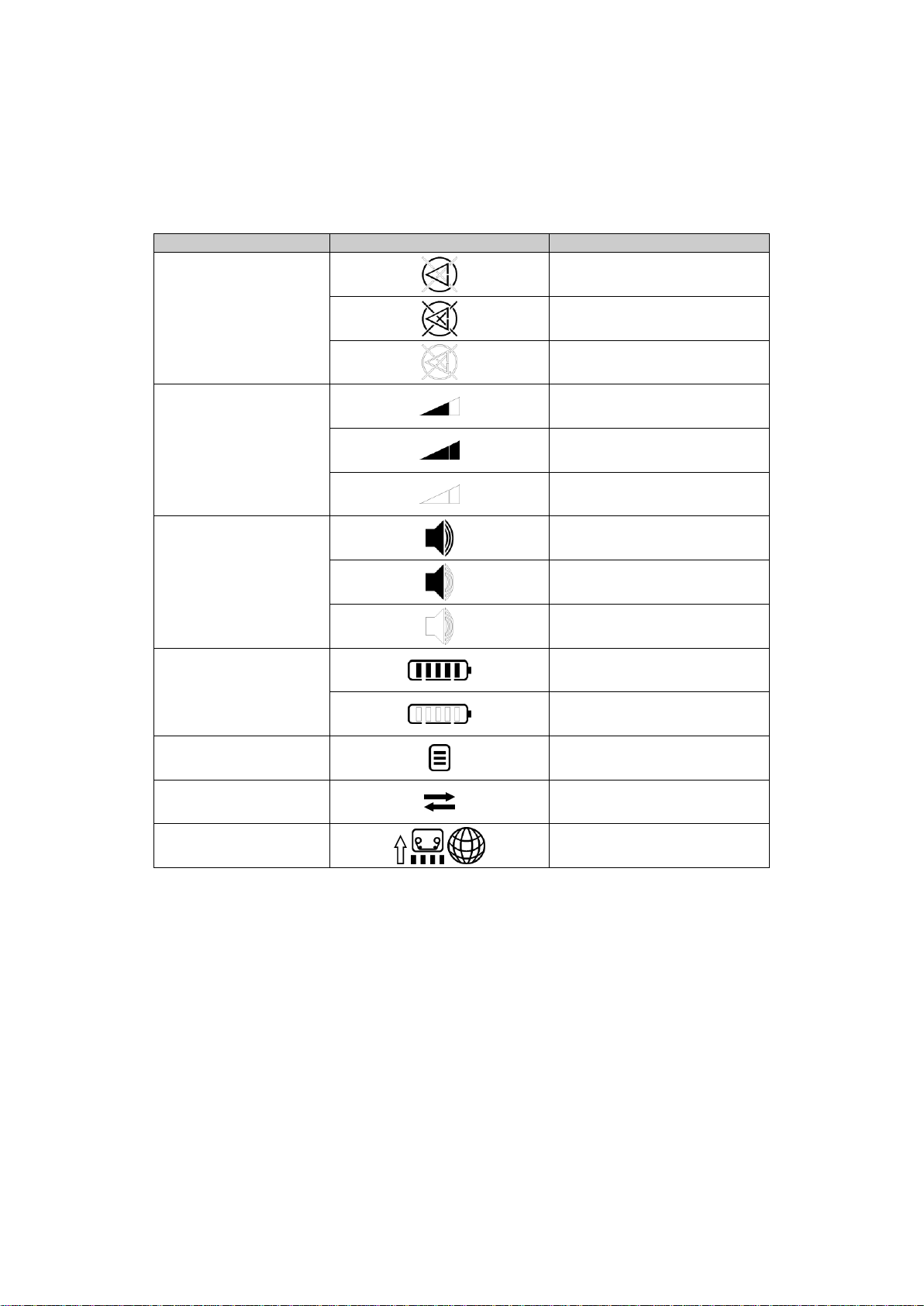

5.3.2 INDICATOR AREA

Indicators are symbols that provide information to the operator about the status of the device

and its working configuration.

Indicator

Symbol

Status

Pump status

Pump on

Pump blocked

Pump off

Pump speed

Speed 1

Speed 2

Off

Alarm

Selected alarm active

Selected alarm muted

No alarm selected

Battery level

Batteries charged

Batteries down

Menu

Menu mode

Communication

Communication in progress

(infrared)

Unused symbols

-

Indicators

5.3.3 DIALOGUE AREA

The dialogue area is a graphical area that can contain up to four alphanumeric lines. It

displays the following:

Menu (Menu mode)

Selected advanced functions (Direct mode)

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 15/48

Dialogue area (Direct mode)

Dialogue area (Menu mode)

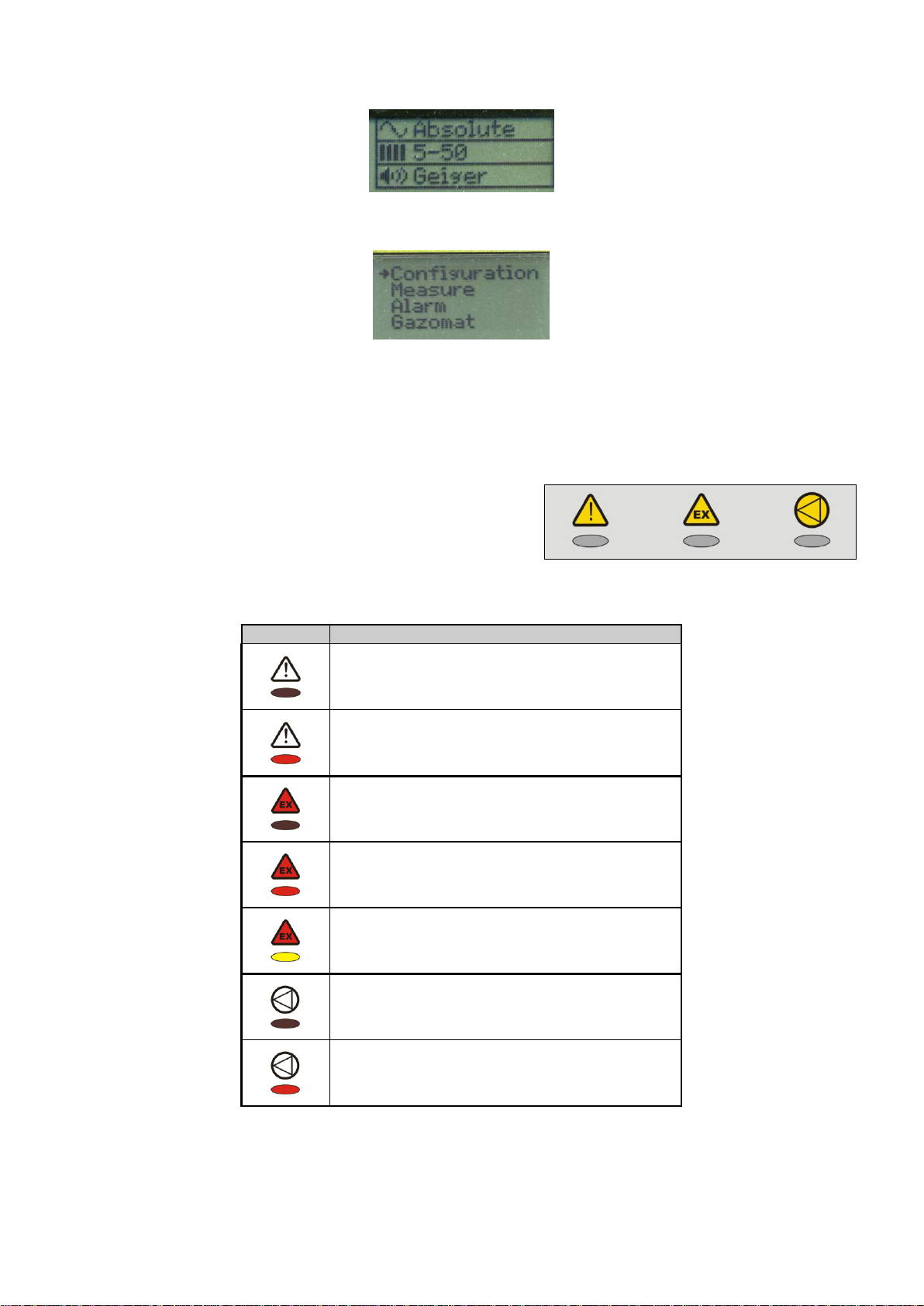

5.4 ALARM INDICATORS

Three alarm indicators are included in the display:

Threshold alarm indicator

Measured gas explosiveness risk indicator

Pump status indicator

Symbol

Indication

Threshold alarm not selected OR

programmed limit not reached

Threshold alarm selected AND

programmed limit reached

Gas concentration below LEL

Gas concentration between LEL and UEL

Gas concentration above UEL

Pump on, speed 1 or 2

Pump halted OR line blocked

Alarm indicators

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 16/48

5.5 WIRED COMMUNICATION PORT (OPTIONAL)

The communication interface is used for calibration, data saving and data retrieval operations

in non-hazardous areas.

The communication interface is located under the device (see figure below).

Access to the communication port is protected by a cap, which may only be removed in non-

hazardous areas.

Important: the connector is foolproof and the cable connector must be brought correctly

before the communication port before it is plugged in gently. The connecting ring must then

be screwed in.

Communication port components

THE COMMUNICATION PORT MAY ONLY BE USED OUTSIDE ANY

POTENTIALLY EXPLOSIVE ATMOSPHERES (IN A NON-

HAZARDOUS AREA)

Communication port

Connector cable

Cap for the

communication port

de l’embase

CAUTION : do not use the

communication cable in

explosive atmospheres

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 17/48

6 MECHANICAL ASPECTS

6.1 BATTERY COMPARTMENT

The battery compartment is located on the underside of the device and is accessible by raising

the cover that is fixed by four screws.

6.2 GAS INLET AND OUTLET

The gas inlet is located on the underside of the device, in a protected recess. The gas outlet is

also located on the underside of the device, in a protected recess.

THE BATTERY COMPARTMENT MAY ONLY BE OPENED OUTSIDE

ANY POTENTIALLY EXPLOSIVE ATMOSPHERES (IN A NON-

HAZARDOUS AREA)

Gas outlet

Gas inlet

Battery compartment

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 18/48

1

The connector is used to rapidly connect the suction rod.

Just insert the end of the rod in the connector.

2

The suction rod is connected.

3

The end of the suction rod can only be released by

pressing the release button.

6.3 HYDROPHOBIC FILTER HOUSING

The dust filter housing is located on the underside of the device and is accessible by

unscrewing a cap with a pin wrench. The filter is kept sealed by an o-ring seal on the cap.

The housing contains a hydrophobic dust filter and an o-ring seal placed between the bottom

of the housing and the filter.

Sealing cap of filter housing

Cap and hydrophobic dust filter

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 19/48

6.4 CARRYING STRAP GROOVES

The carrying strap is fed into two side grooves that are designed so that the device can be

carried on the front or the side of the body or held in a hand.

6.5 SAMPLING CIRCUIT

The gas sample is brought to the sensor by means of the suction effect of the pump. A

sampling rod can be connected to the device by means of the female quick coupler.

The telescopic rod has a suction cup for detecting gas on the ground, in natural holes or in the

atmosphere.

The rigid rod is used to detect gas in areas that are uneven, narrow or hard to reach.

The operator can select from two suction speeds (speed 1 (35 l/h) and speed 2 (70 l/h)) in

order to adapt the sampling speed to the requirements and reduce the dilution of the gas

sample.

02_340_001_AJ_BE(Rev 11/05/11)

(from French version : 02_340_000_AJ_BE (Rev 11/05/11) Portable Inspectra Laser

©Copyright Gazomat 20/48

A new model of the telescopic rod is available since June 2010. With this new model, the

rigid rod simply fits into the small inlet located inside the suction cup.

Pressing the black ring will free the rigid rod.

Table of contents

Other Gazomat Gas Detector manuals