Function introduction

Controller function introduction

F-01 Address, Range1-200

F-02 Low point alarm

F-03 High point alarm

F-04 Zero calibration

F-05 4mA offset correction

F-06 ADC check

F-07 Standard gas concentration

F-08 Calibration switch

F-09 Production date

F-10 Reserved function

F-11 Serial communication check. 0 no check, 1 odd check, 2 even check

F-12 Arrangement mode of the floating-point data

0:DCBA

1:ABCD

2:CDAB

Need to press OK to save after all the above parameters are modified, which can take effect

immediately, power outage restart also valid.

MENU

RESET

OK

+

BACK

-

MENU button, from the measurement state into the functional state

alarm reset to eliminate alarm function

confirm button

plus

return

minus

Remote controller function

Installation Instruction

1. Location Selection

The location selection of the gas detection transmitter is essential to achieve the best detection

results. In the selection of location, we need to consider the following factors: the density of gas in a

leaking point, proportion of target gas, the impact of surrounding buildings, condition of production

equipment, wind direction and annual meteorological conditions and even the location of windows

and doors in an indoor environment.

We provide the following suggestions for your reference:

A. Maintain a proper distance between the detector and the possible gas leaking point. It would

react too fast or too frequent if the distance is not enough, which may paralyze people's mind.

B. The detector must be located in the downwind of the possible leaking point.

C. If installed indoor, but the source of the leak is outdoor, the detector must be installed at the air

inlet.

D. Determine the height according to proportion of target gas in air.

E. Determine the quantity of detectors according to the condition of possible leaking point,

frequency of staff attendance and time of stay as well as the economic effect.

F. Consider to increase quantity of inspection point if the equipment is old.

G. Protect the detector from radiation of high temperature heart source. Environments of both

very high temperature and very low temperature will affect the result and lifespan of the detector.

118.00

φ8.00

140.00

φ8.00 φ8.00

102.30

206.00

89.00

Method of Calibration

To guarantee the measurement accuracy of the transmitter, regular calibration and maintaining

rigorous record is necessary.

Devices needed for calibration: a bottle of sample gas used for range calibration (60%F.S standard

gas in normal site),relief valve, flow meter of 0~1000ml/min, transparent and smooth conduit for

gas, standard gas housing, digital multimeter, stopwatch and etc.

Note: The value of transmitter WB (4mA) , WC (20mA) , Wz (zero potentiometer), WA (range

potentiometer, also known as calibration potentiometer) and host alarm has been set right before it

leaves the factory. User should not adjust casually. It is the value of zero potentiometer (Z) and

calibration potentiometer (S) needed to be set on spot.

1. Zero Point Calibration

Open the detector in clean air, if there is readings after counting down.

Press the button "MENU" of the remote controller, the detector displays "F-01", press"+" or"-",

change the function to "F-04", and click "OK". The detector value will be displayed as 0.

In the zero calibration of oxygen detection transmitter, we must use nitrogen of purity over

99.99%.

Common Malfunction, Repair and Maintenance

Product component

Fixed Gas Detector

Instruction Manual

Qualification Certificate

Remote Control

one

one

one

one

2. Steps of Installation

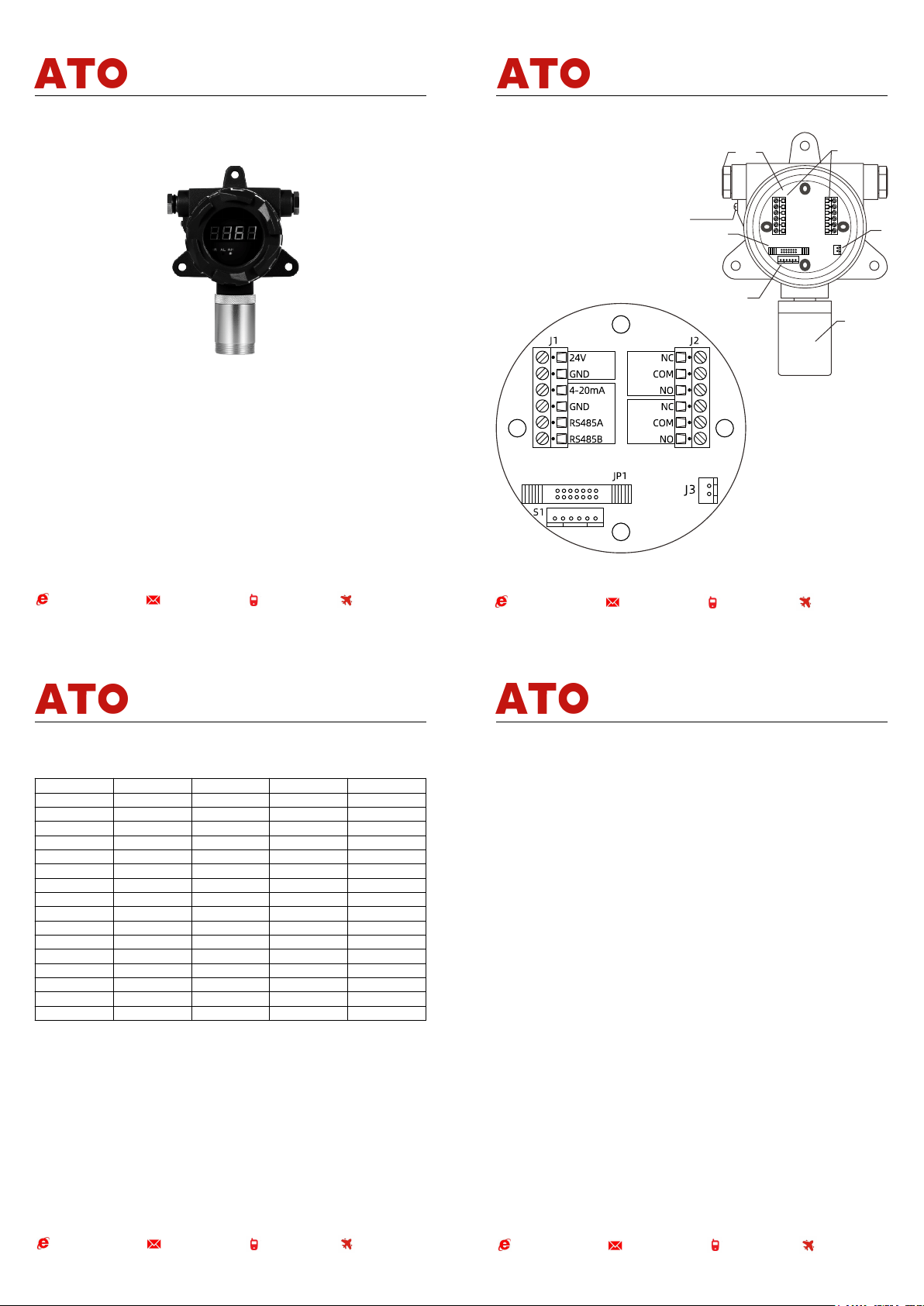

Connect wire to correspondent terminals. Don't work with power on. The arrangement of

terminals differs according to the type of transmitter. The definition of different wires:

Red: positive-input of power (12 to 24V)/24V+

Black: ground wire of power/24V

Yellow:4-20mA output.

Orange: RS485A

Blue: RS485B

Brown: Free

Fix the detector on the wall with expansion bolt, make sure the transmitter is downward, or the

detector cannot work property. Users can also separate the bracket and transmitter according to the

condition on spot, fix the bracket before connection.

For the sake of safety and interference reduction, please connect the housing with reliable ground

wire. For the wire between the transmitter and the main engine, the shorter, the better. And protect

the wire with iron pipe.

potential in reference point is

not correct

Adjust zero point gradually and then adjust potentiometer (4mA)

Return to Yuante for repair

Value of S potentiometer

setting is too small

Value of S potentiometer

setting is too large

Heat settling time is not

enough

Return to Yuante for repair

PRV

PTFE PIPE

Empty

Gas detector

Standard gas

Flowmeter

2. Range Calibration

1. Enter into "F-07"as the same way above . The

"F-07" value is the concentration of the standard

gas, initialized to half of the measure range. This

value can be modified through the"+" and"-" keys to

make it consistent with the standard gas

concentration which need to be calibrated. Press

"OK" to exit.

2. Enter into"F-08"to change 0 into 1,then back to

detection interface.

3. Connect the 200-400mL/min standard gas in

detection interface, when the detector value is

stable, press "OK" for 3 seconds, then the

instrument will be calibrated automatically. The

measured concentration value is consistent with the

value set in "F-07".

4. After calibration, left the detector in the air for a

while. Shut off the power when the detector value is

close to zero.