GCE druva MPLH0XS0 User manual

GCE CENTRAL GAS SYSTEMS

IMPORTANT!

Read carefully before use! Keep the manual for future consultation!

WICHTIG!

Vor Gebrauch sorgfältig lesen!

Bewahren Sie die Gebrauchsanweisung für späteres Nachschlagen auf!

INSTRUCTION FOR USE

GEBRAUCHSANLEITUNG

MANIFOLD

ENTSPANNUNGSSTATION

EN

DE

M MANIFOLD | PPUR | L LOW FLOW | H0 HIGH PRESSURE |

HEHIGH PRESSURE WITH EPDM RELIEF VALVE

X SINGLE SOURCE | S SINGLE STAGE

M MANIFOLD | SSST | L LOW FLOW | H0 HIGH PRESSURE |

X SINGLE SOURCE | S SINGLE STAGE |

HEHIGH PRESSURE WITH EPDM RELIEF VALVE

2/68

EN

CONTENT

1 General ......................................................................................................................................................................................... 4

1.1 information about this instructions manual ...................................................................................................................... 4

1.2 Information about this manifold ......................................................................................................................................... 4

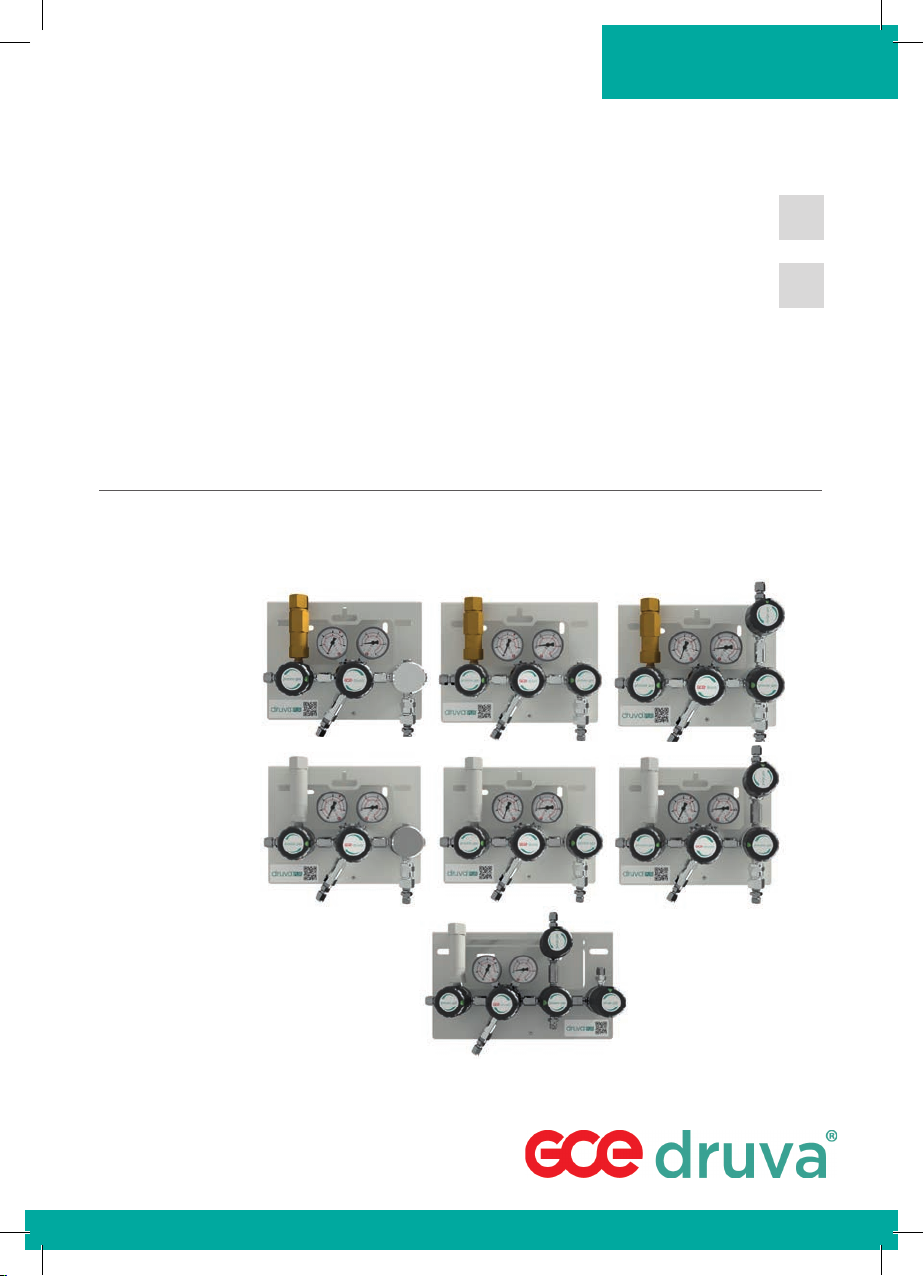

1.2.1 MPLH0XS0 / MSLH0XS0, MPLHEXS0 / MSLHEXS0 ............................................................................................ 6

1.2.2 MPLH0XSS / MSLH0XSS, MPLHEXSS / MSLHEXSS .......................................................................................... 6

1.2.3 MPLH0XSP / MSLH0XSP, MPLHEXSP / MSLHEXSP ........................................................................................... 6

1.2.4 MSLH0XSE, MSLHEXSE ............................................................................................................................................. 6

1.3 explanation of symbols ......................................................................................................................................................... 6

1.4 Limitations of liability ..............................................................................................................................................................7

1.5 Copyright ..................................................................................................................................................................................7

1.6 Spare parts .............................................................................................................................................................................. 8

1.7 Warranty provision ................................................................................................................................................................. 8

1.8 Customer service ................................................................................................................................................................... 8

2 Safety ........................................................................................................................................................................................... 8

2.1 Intended use ........................................................................................................................................................................... 8

2.1.1 Structural changes at the manifold ............................................................................................................................ 8

2.2 Fundamental risks ................................................................................................................................................................ 9

2.3 Operator’s responsibility ....................................................................................................................................................10

2.4 Personnel requirements .....................................................................................................................................................10

2.4.1 Qualifications ................................................................................................................................................................10

2.4.2 Unauthorized personnel............................................................................................................................................11

2.4.3 Training ..........................................................................................................................................................................11

2.5 Personal protective equipment .........................................................................................................................................11

2.6 Behavior in case of fi re or accident . . ..............................................................................................................................12

2.7 Environmental protection ...................................................................................................................................................12

2.8 Signage ..................................................................................................................................................................................12

2.8.1 Signs that give orders ................................................................................................................................................12

2.8.2 Signs indicating bans ................................................................................................................................................12

2.8.3 Warning signs ..............................................................................................................................................................12

3 Technical specifi cations ................................................................................................................................................13

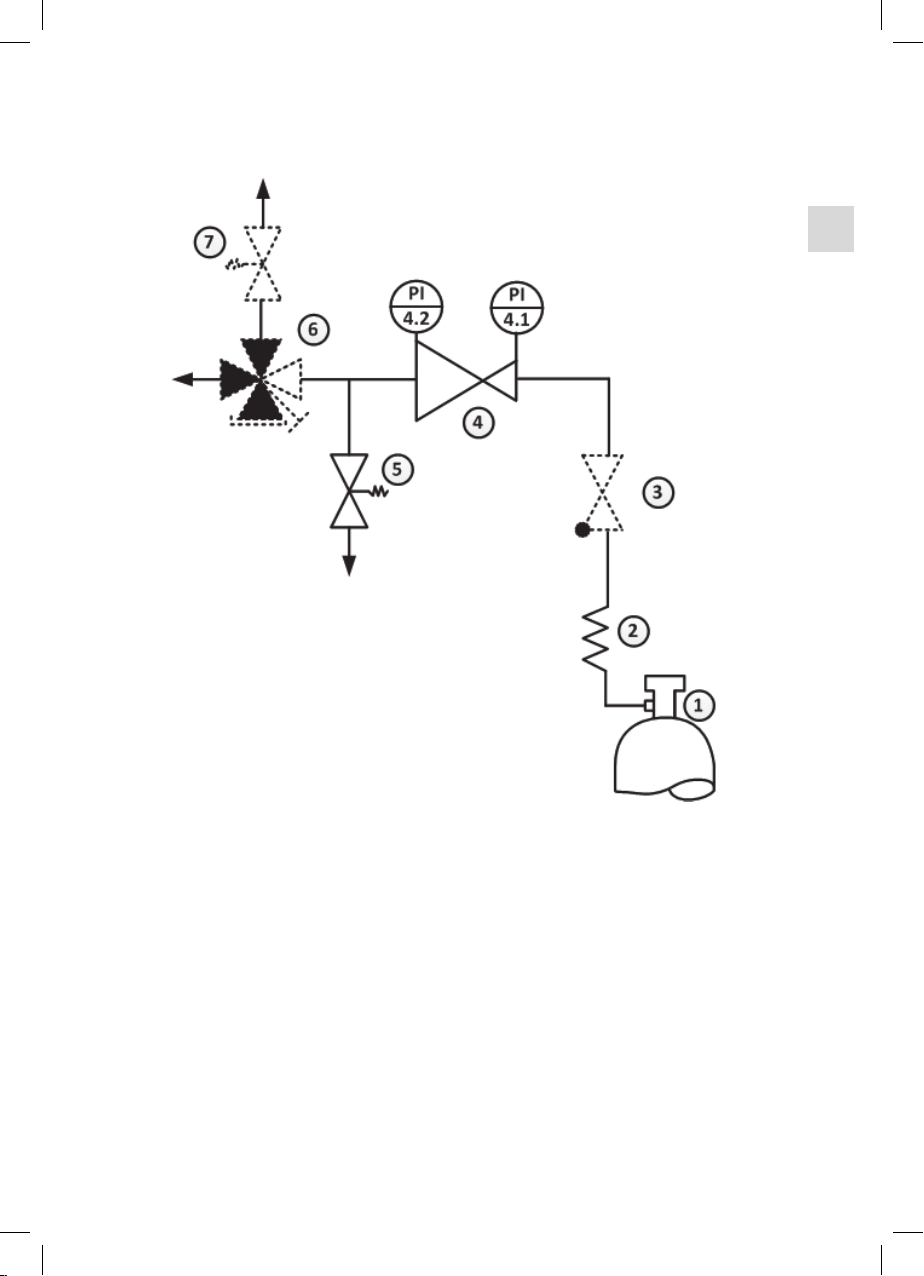

3.1 Flow Scheme – MPLH0XS0 / MSLH0XS0, MPLHEXS0 / MSLHEXS0 ....................................................................13

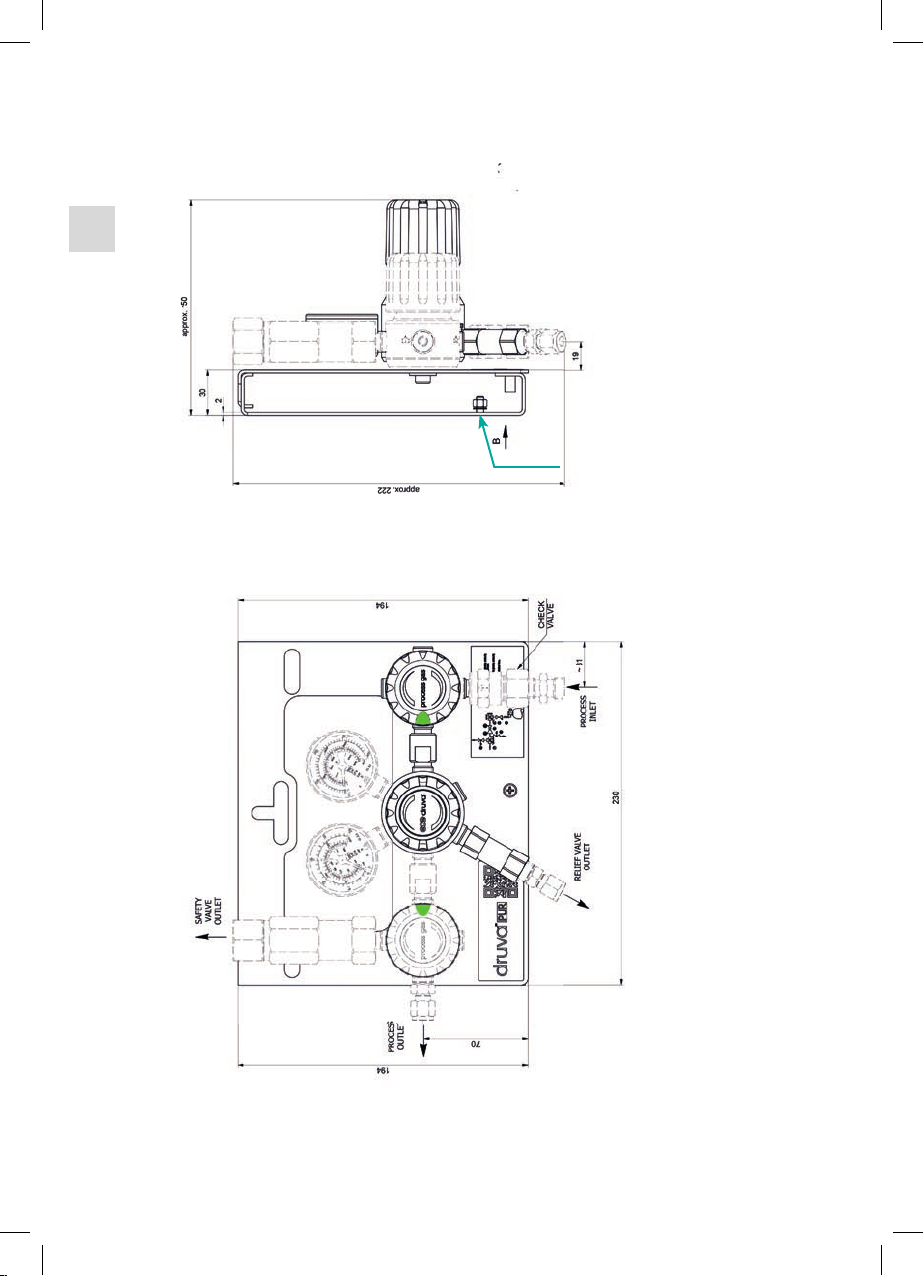

3.2 Dimension sheet – MPLH0XS0 / MSLH0XS0, MPLHEXS0 / MSLHEXS0 ...........................................................14

3.3 Flow Scheme – MPLH0XSS / MSLH0XSS, MPLHEXSS / MSLHEXSS ...................................................................15

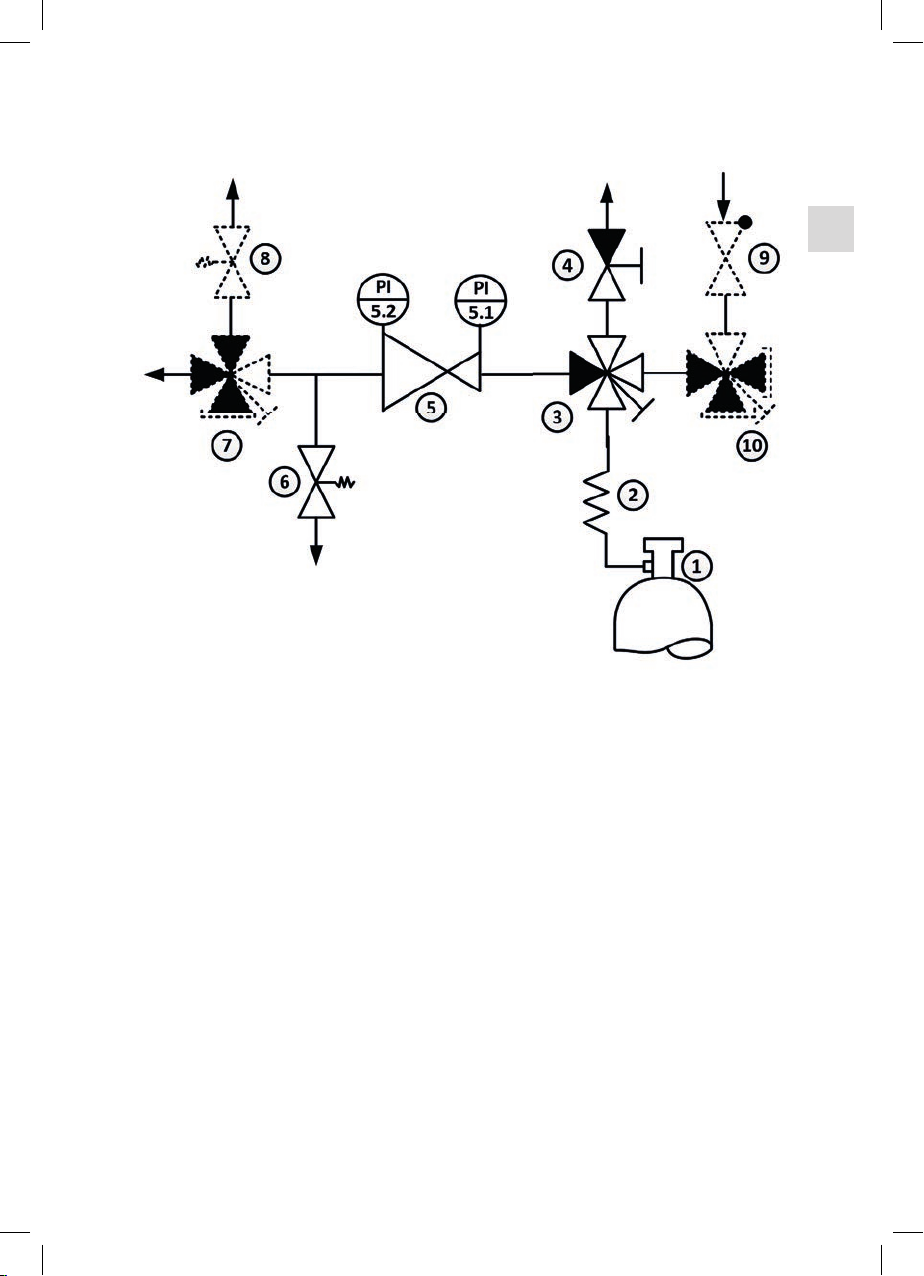

3.4 Dimension sheet – MPLH0XSS / MSLH0XSS, MPLHEXSS / MSLHEXSS .............................................................16

3.5 Flow Scheme – MPLH0XSP / MSLH0XSP, MPLHEXSP / MSLHEXSP ................................................................... 17

3.6 Dimension sheet – MPLH0XSP / MSLH0XSP, MPLHEXSP / MSLHEXSP .............................................................18

3.7 Flow Scheme – MSLH0XSE, MSLHEXSE.......................................................................................................................19

3.8 Dimension sheet – MSLH0XSE, MSLHEXSE ...............................................................................................................20

3.9 General information ............................................................................................................................................................21

3.10 Connection values ..............................................................................................................................................................21

3.11 Performance value ..............................................................................................................................................................21

3.12 Operating conditions . . .......................................................................................................................................................21

4 Set-up and function .........................................................................................................................................................22

4.1 Overview – MPLH0XS0SU, MPLHEXS0SU– Full version .........................................................................................22

4.2 Overview – MSLH0XS0SU, MSLHEXS0SU – Full version.......................................................................................22

4.3 Overview – MPLH0XSSSU, MPLHEXSSSU – Full Version ......................................................................................23

4.4 Overview – MSLH0XSSSU, MSLHEXSSSU – Full version .......................................................................................23

4.5 Overview – MPLH0XSPSU, MPLHEXSPSU – Full version ......................................................................................23

4.6 Overview – MSLH0XSPSU, MSLHEXSPSU – Full version .......................................................................................24

4.7 Overview – MSLH0XSESS, MSLHEXSESS – Full version ........................................................................................24

4.8 Brief description MPLH0XS / MSLH0XS, MPLHEXS / MSLHEXS ..........................................................................24

3/68

EN

5 Transport, packaging and storage .......................................................................................................................25

5.1 Safety information for transportation ..............................................................................................................................25

5.2 Transport inspection ..........................................................................................................................................................25

5.3 Packaging .............................................................................................................................................................................25

5.4 Storage ..................................................................................................................................................................................26

6 Installation and initial start-up ..................................................................................................................................26

6.1 Safety notes for installation and initial start-up ............................................................................................................26

6.2 Preparation ...........................................................................................................................................................................26

6.3 Installation .............................................................................................................................................................................26

6.4 Required qualifi cations for initial start-up and cylinder changing .......................................................................... 27

6.5 Initial Start Up.......................................................................................................................................................................27

6.5.1 Process gas purging (MPLH0XSP and MSLH0XSP, MPLHEXSP and MSLHEXSP) ....................................27

6.5.2 Inert gas purging (MSLH0XSE, MSLHEXSE) ....................................................................................................... 27

6.5.3 Fill the process gas tubing with process gas .....................................................................................................28

6.5.4 Change empty gas cylinder ...................................................................................................................................28

6.5.5 Taking manifold out of operation .........................................................................................................................28

6.6 Tests .......................................................................................................................................................................................28

7 Operation .................................................................................................................................................................................28

8 Maintenance .........................................................................................................................................................................29

8.1 Safety notes for maintenance ...........................................................................................................................................29

8.2 Maintenance plan ...............................................................................................................................................................29

8.3 Maintenance work ..............................................................................................................................................................29

8.3.1 Cleaning ........................................................................................................................................................................29

8.3.2 Requirements for maintenance .............................................................................................................................29

8.3.3 Necessary maintenance ..........................................................................................................................................29

8.4 Measures following maintenance ...................................................................................................................................30

9 Troubleshooting .................................................................................................................................................................30

9.1 Safety notes for troubleshooting .....................................................................................................................................30

10 Dismantling and disposal ..........................................................................................................................................32

10.1 Safety notes for dismantling and disposal ...................................................................................................................32

10.2 Dismantling . ........................................................................................................................................................................32

10.3 Disposal ............................................................................................................................................................................... 33

4/68

EN

1. GENERAL

1.1. INFORMATION ABOUT THIS INSTRUCTIONS MANUAL

This instruction is only intended for use with manifold product type:

• MPLH0XS, MPLHEXS – Single stage manifold for one cylinder

• MSLH0XS , MSLHEXS – Single stage manifold for one cylinder

Manifolds of this type are suitable to take gas out of gas cylinder or bundle and reduce the pressure. These

manifolds were installed as permanently wall assembly and are connected to gas cylinder or bundle with

coil or hose.

These instructions enable you to operate the system safely and e ciently. These instructions form an inte-

gral part of the system and must always be kept with the system and within easy reach of sta at all times.

Prior to commencing any work, the sta must read these instructions carefully and understand the contents.

Observance of all the safety information and instructions for operation that are contained in these instruc-

tions is essential to ensure work safety.

Local accident prevention regulations and general safety regulations governing the use of the system must

also be observed.

Illustrations in these instructions serve to ensure a basic understanding of the system and may di er from

the actual version.

1.2. INFORMATION ABOUT THIS MANIFOLD

Manifolds of this type are only suitable for gases defi ned as standard gas. The maximum working pressure

for these manifolds is 300 bar.

Single stage manifolds consists of valves and a pressure regulator with metal diaphragm, created and

approved as ISO7291/ISO10297 including oxygen shock test.

Product Line DruvaPUR Line

(purity 6.0 | brass chrome plated)

DruvaPUR Line

(purity 6.0 | stainless steel)

H0 - High Pressure Regulator

with FKM Relief Valve Seat

• Suitable Gases

(including their mixtures)

• High Purity

• Inert

• Flammable

• Oxidizing

• Use for O2

• Not Suitable Gases

(including their mixtures)

• Corrosive

• Toxic

• Not for CO2, N20

• Suitable Gases

(including their mixtures)

• High Purity

Inert

• Flammable

• Oxidizing

• Corrosive (in doubt ask)

• Toxic (in doubt ask)

• Not Suitable Gases

(including their mixtures)

• Not for O2

• Not for CO2, N20

• Not for NH3, SO2, H2S

LV - Low Pressure Regulator

with FKM Seat

• Suitable Gases

(including their mixtures)

• High Purity

• Inert

• Flammable

• Oxidizing

• Use for O2

• Not Suitable Gases

(including their mixtures)

• Corrosive

• Toxic

• Not for CO2, N20

• Suitable Gases

(including their mixtures)

• High Purity

• Inert

• Flammable

• Oxidizing

• Corrosive (in doubt ask)

• Toxic (in doubt ask)

• Not Suitable Gases

(including their mixtures)

• Not for O2

• Not for CO2, N20

• Not for NH3, SO2, H2S

ENGLISH

INSTRUCTION FOR USE: MANIFOLD

5/68

EN

AV - Absolute Pressure Regula-

tor with FKM Seat

• Suitable Gases

(including their mixtures)

• High Purity

• Inert

Flammable

• Oxidizing

• Use for O2

• Not Suitable Gases

(including their mixtures)

• Corrosive

• Toxic

• Not for CO2, N20

• Suitable Gases

(including their mixtures)

• High Purity

• Inert

• Flammable

• Oxidizing

• Corrosive (in doubt ask)

• Toxic (in doubt ask)

• Not Suitable Gases

(including their mixtures)

• Not for O2

• Not for CO2, N20

• Not for NH3, SO2, H2S

HE - High Pressure Regulator

with EPDM Relief Valve Seat

• Suitable Gases

(including their mixtures)

• High Purity

Inert

• Flammable

• Oxidizing

• Use for CO2, N20

• Not Suitable Gases

(including their mixtures)

• Corrosive

• Toxic

• Not for O2

• Suitable Gases

(including their mixtures)

• High Purity

• Inert

• Flammable

• Oxidizing

• Corrosive (in doubt ask)

• Toxic (in doubt ask)

• Use for CO2, N20

• Use for NH3, SO2, H2S

• Not Suitable Gases

(including their mixtures)

• Not for O2

LE - Low Pressure Regulator with

EPDM Seat

• Suitable Gases

(including their mixtures)

• High Purity

• Inert

• Flammable

• Oxidizing

• Use for CO2, N20

• Not Suitable Gases

(including their mixtures)

• Corrosive

• Toxic

• Not for O2

• Suitable Gases

(including their mixtures)

• High Purity

• Inert

• Flammable

• Oxidizing

• Corrosive (in doubt ask)

• Toxic (in doubt ask)

• Use for CO2, N20

• Use for NH3, SO2, H2S

• Not Suitable Gases

(including their mixtures)

• Not for O2

AE - Absolute Pressure Regula-

tor with EPDM Seat

• Suitable Gases

(including their mixtures)

• High Purity

• Inert

• Flammable

• Oxidizing

• Use for CO2, N20

• Not Suitable Gases

(including their mixtures)

• Corrosive

• Toxic

• Not for O2

• Suitable Gases

(including their mixtures)

• High Purity

• Inert

• Flammable

• Oxidizing

• Corrosive (in doubt ask)

• Toxic (in doubt ask)

• Use for CO2, N20

• Use for NH3, SO2, H2S

• Not Suitable Gases

(including their mixtures)

• Not for O2

This table is not exhaustive. For questions and ambiguities please contact manufacturer. Contact details

section 1.8.

6/68

EN

1.2.1. MPLH0XS0 / MSLH0XS0, MPLHEXS0 / MSLHEXS0

This manifold is available in brass chrome plated (MPL…) and stainless steel (MSL…). It consists of the follow-

ing components:

• Pressure regulator with inlet pressure & outlet pressure gauge

• Option -0: 4-Port adapter to connect coil or hose

• Relief valve

• Front plate and ground plate

• Option –S: 4-Port Shut-o valve at outlet

SPECIALS

• S: safety valve at outlet

• C: check valves at inlets

• U: safety valve at outlet and check valves at inlets

1.2.2. MPLH0XSS / MSLH0XSS, MPLHEXSS / MSLHEXSS

This manifold is available in brass chrome plated (MPL…) and stainless steel (MSL…). It consists of the follow-

ing components:

• Pressure regulator with inlet pressure & outlet pressure gauge

• Option -S: 4-Port shut-o valve at inlet

• Relief valve

• Front plate and ground plate

• Option –S: 4-Port Shut-o valve at outlet

SPECIALS

• S: safety valve at outlet

• C: check valves at inlets

• U: safety valve at outlet and check valves at inlets

1.2.3. MPLH0XSP / MSLH0XSP, MPLHEXSP / MSLHEXSP

This manifold is available in brass chrome plated (MPL…) and stainless steel (MSL…). It consists of the follow-

ing components:

• Pressure regulator with inlet pressure & outlet pressure gauge

• Option -P: Purge valve for process gas purging and 4-Port shut-o valve at inlet

• Relief valve

• Front plate and ground plate

• Option –S: 4-Port Shut-o valve at outlet

SPECIALS

• S: safety valve at outlet

• C: check valves at inlets

• U: safety valve at outlet and check valves at inlets

1.2.4. MSLH0XSE, MSLHEXSE

This manifold is only available in stainless steel. It consists of the following components:

• Pressure regulator with inlet pressure & outlet pressure gauge

• Option -E: three 4-port purge valves for inert gas purging including 4-port shut-o valve at inlet

• Relief valve

• Front plate and ground plate

• Option –S: 4-Port Shut-o valve at outlet

SPECIALS

• S: safety valve at outlet

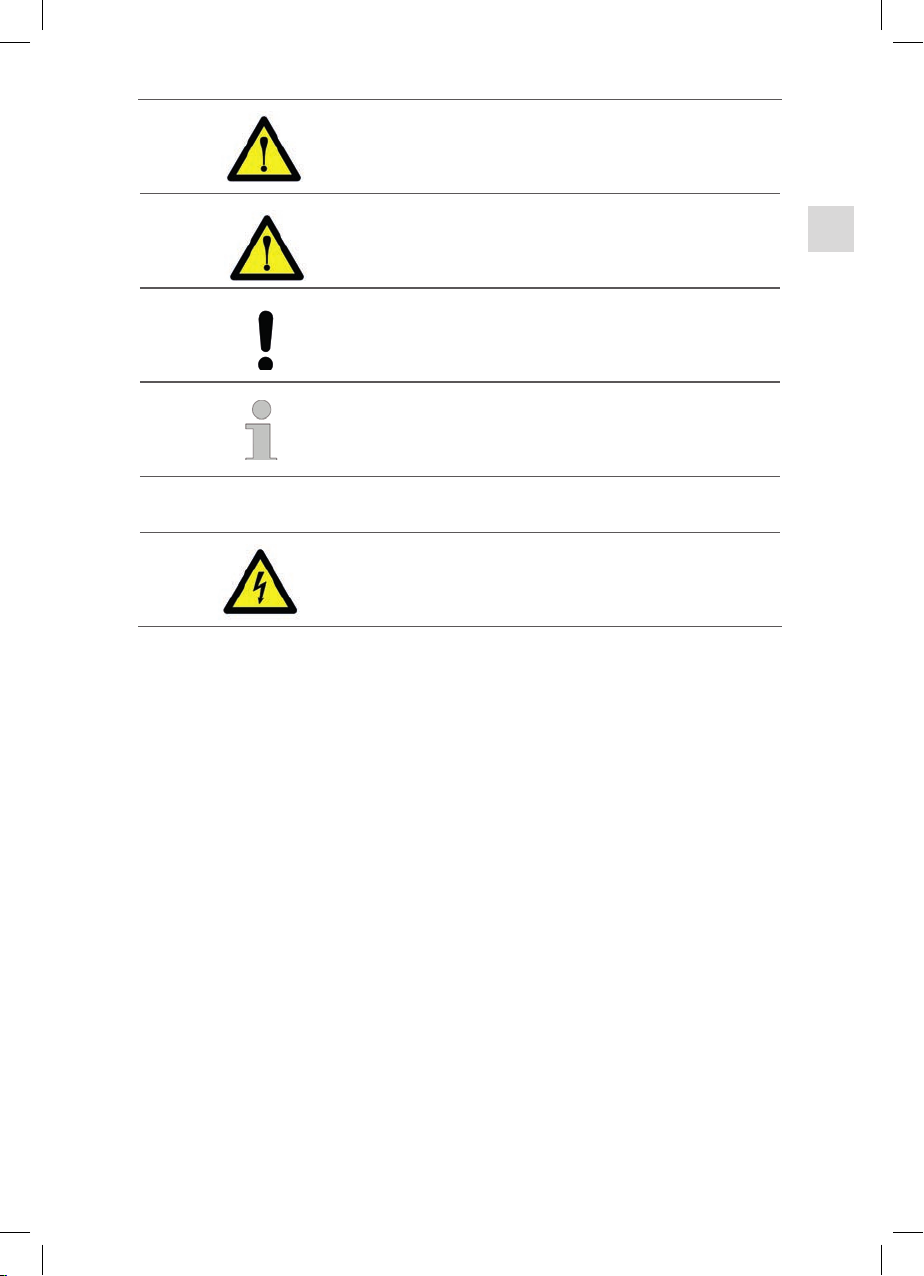

1.3. EXPLANATION OF SYMBOLS

SAFETY INFORMATION Safety information is highlighted by symbols in these instruc-

tions. This safety information is preceded by signal words that

defi ne the extent of risk.

DANGER!

This combination of symbol and signal word indicates an im-

mediately dangerous situation that will cause death or severe

injury if not avoided.

7/68

EN

WARNING!

This combination of symbol and signal word indicates a pos-

sibly dangerous situation that can cause death or severe injury

if not avoided.

BEWARE!

This combination of symbol and signal word indicates a pos-

sibly dangerous situation that can cause minor injury if not

avoided.

NOTE!

This combination of symbol and signal word indicates a pos-

sibly dangerous situation that can cause property and environ-

mental damage if not avoided.

TIPS AND RECOMMENDATIONS

This symbol highlights useful tips and recommendations, to-

gether with help for ensuring e cient and trouble-free opera-

tion.

SPECIAL SAFETY

INFORMATION

The following symbols are used in the safety information to

draw your attention to particular risks.

DANGER!

This combination of symbol and signal word indicates an im-

mediately dangerous situation involving electrical current. Ig-

noring such a warning could result in severe or fatal injuries.

1.4. LIMITATIONS OF LIABILITY

All of the information and notes in these instructions have been compiled in accordance with applicable

standards and regulations. They refl ect best engineering practice and our years of experience.

The manufacturer accepts no liability for damages in the following instances:

• Failure to observe these instructions

• Utilization of the system for any other than the intended purpose

• Operation by untrained sta

• Unauthorized modifi cations

• Technical modifi cations

• Use of unlicensed spare parts

• Working with the gas supply panel when any safety device is broken or not functional mounted or safety

devices don’t work correctly

• Improper control of components, connections and gaskets, which are wearing parts.

• Incorrect reparations

• Violation of temperature limits, which are dedicated in the datasheet during operation or storage

• In case of disaster or force majeure

The actual scope of supply may di er from the explanations and illustrations in these instructions following

the incorporation of new technical changes.

The obligations stipulated in the supply agreement, our general terms and conditions of business, the manu-

facturer’s terms and conditions of supply and the statutory regulations in force at the time of contract conclu-

sion apply.

1.5. COPYRIGHT

The contents of these instructions are protected by copyright. They may be used in connection with the

operation of the system. Any other use above and beyond the aforementioned is only permitted with the

written consent of the manufacturer.

8/68

EN

1.6. SPARE PARTS

WARNING!

• Risk of injury from using incorrect spare parts!

• The use of incorrect or defective spare parts can result in risks for the operating sta and in damages,

malfunctions or total failure of the system.

• Only use original spare parts from the manufacturer or spare parts authorized by the manufacturer.

• Always consult the manufacturer if in doubt.

LOSS OF WARRANTY

• The manufacturer’s warranty lapses if unauthorized spare parts are used.

1.7. WARRANTY PROVISION

The warranty provisions are included in the manufacturer’s general terms and conditions of business. See

chapter VI. Warranty Claims.

1.8. CUSTOMER SERVICE

GCE GmbH

Weyherser Weg 8

DE-36043 Fulda

+49 (0) 661 8393 -0

www.gcegroup.com

Please do not hesitate to provide us with information and experiences gained through use; we welcome any

valuable input that will help to improve our products.

2. SAFETY

This section provides an overview of all the important safety aspects to ensure the protection of your sta

and the safe and trouble-free operation of the equipment. Further safety information relating to specifi c tasks

can be found in the sections on the individual life cycle phases.

2.1. INTENDED USE

The manifold is only usable for the defi ned standard gases and pressures observing the given temperature

range. The maximum fl ow is 20 m3/h.

Intended use also includes compliance with all the information in these instructions and compliance with

reparation, maintenance working, type label and data sheets.

Any use other than, or above and beyond, the intended use constitutes improper use.

WARNING!

• Danger from improper use!

• Improper use of the system can lead to dangerous situations.

• Never use the manifold with liquid fl uids.

2.1.1. STRUCTURAL CHANGES AT THE MANIFOLD

Without written approval of supplier no extensions, additions or alternations are allowed on the manifold.

Components which are not in perfect condition have to be changed immediately.

Cleaning of manifold and disposal of residues

Used components which are ready for reparation has to be purged with an inert gas before.

Noise Generation

In some cases when specifi c infl uence quantities collaborate together, e.g. fl ow and pressure range can

cause noise generation or the gas itself. If this happens please contact supplier.

9/68

EN

2.2. FUNDAMENTAL RISKS

The following section addresses the residual risks that may arise, even if the system is used properly.

Observance of the safety information included below and in other sections of these instructions is mandatory

in order to reduce the risk of injury and property damage and to avoid dangerous situations.

DANGER!

• Gases can be life threatening!

• Gases can supersede the oxygen in air. This can result in death by asphyxiation. Oxygen produces a

strongly oxidizing e ect.

THEREFORE:

• Su cient ventilation is absolutely essential.

• Installation only through certifi ed company.

• Observe ATEX directive

ATTENTION!

• Risk of injury from environment!

There can be malfunctions on component due to condensation and/ or icing.

THEREFORE:

• Observe suitable temperatures.

• Protect component from liquids from outside

• Protect component from dust from outside

• Protect component from weather conditions

• Grounding has to be mounted properly

WARNING!

• Risk of injury from using oil and grease!

Oil and grease must never be used in gas regulating systems. Oil and grease are highly infl ammatory and

can react violently to certain pressurized gases.

THEREFORE:

• Never use oil and grease

WARNING!

• Risk of injury from residual energy stored in the system!

If handled incorrectly, pressurized components can move uncontrollably and cause severe injury. If handled

incorrectly or defective, pressurized components can leak gas under high pressure and cause severe or

even fatal injuries.

BEFORE STARTING WORK WITH THESE COMPONENTS:

• Installation only through certifi ed company.

• Always wear protective goggles when working.

• Always wear ear protection.

• Make sure the equipment is depressurized. Also make sure the residual energy is discharged.

• Always ensure that gas cannot leak unintentionally.

• Make sure that defective components that are pressurized during operation are immediately replaced by

trained sta .

WARNING!

• Danger of accident!

Due to wrong installation there can be serious or even mortal injuries.

THEREFORE:

• During installation the component should be kept safe

• Never throw the component

Pressurised components are only for intended use.

If there are mechanical damages at tubing or components the whole system has to be put in a safe condi-

tion. A ected area has to be blocked. Troubles which could infl uence safety, have to be eliminated through

qualifi ed sta or supplier.

10/68

EN

Especially with gases failure in pressure regulator could happen. Indications for defective regulator is no fl ow

or immediately rising outlet pressure. In this case system has to be shut-o and the relevant department for

maintenance has to be informed. Never close exhaust piping.

2.3. OPERATOR’S RESPONSIBILITY

OPERATOR

The operator is the person who operates the system for commercial or business purposes or who provides

the system for use/application by a third party, and who bears legal product responsibility for protecting the

user, sta or third parties during operation.

OPERATOR’S DUTIES

The system is used for commercial purposes. The operator of the system is therefore subject to legal work

safety obligations.

Compliance with the safety, accident prevention and environmental protection regulations that apply for the

use of the system is mandatory, in addition to the safety information in these instructions.

THE FOLLOWING APPLIES IN PARTICULAR:

• The operator must be aware of the applicable work safety regulations and must perform a risk assessment

to identify risks that may occur as a result of the specifi c working conditions at the site where the system

is operated. The operator must use this assessment as the basis for compiling instructions for operating

the system.

• During the entire period in which the system is operated, the operator must ensure that these operating

instructions comply with the latest regulations, and must update the instructions if necessary.

• The operator must assign clear and specifi c responsibility for installation, operation, troubleshooting,

maintenance and cleaning.

• The operator must ensure that all members of sta who work with the system have read and understood

these instructions. The operator must also ensure that these members of sta are trained at regular inter-

vals and are aware of the risks.

• The operator must provide the sta with the requisite protective equipment and bindingly obligate the

sta to wear the necessary protective equipment.

In addition, the operator is responsible for ensuring full technical reliability of the system at all times.

AS SUCH, THE FOLLOWING APPLIES:

• The operator must ensure compliance with the maintenance intervals specifi ed in these instructions.

• The operator must ensure that all safety equipment is regularly inspected for functional reliability and

completeness.

2.4. PERSONNEL REQUIREMENTS

2.4.1. QUALIFICATIONS

The various tasks described in these instructions constitute di ering requirements in respect of the qualifi ca-

tions of the sta charged with performing these tasks.

WARNING!

• Danger if sta is insu ciently qualifi ed!

• Insu ciently qualifi ed sta is not able to assess the risks associated with the system and expose both

themselves and others to the risk of severe or fatal injury.

• Ensure that all works are only performed by sta qualifi ed for the specifi c task.

• Keep insu ciently qualifi ed people out of the work area.

The works must always be assigned only to individuals who can be trusted to perform the works reliably.

People with impaired reactions, e.g. as a result of drugs, alcohol or medication, must not be allowed to

perform works.

These instructions defi ne the qualifi cations below that are necessary for the respective tasks:

GAS ENGINEER:

Have a professional training, skills and experience and the knowledge of the pertinent standards and regula-

tions to perform works on gas systems and to identify potential hazards. Gas engineers are trained specifi -

cally for the site where they work and are familiar with all relevant standards and regulations.

TECHNICIAN

Have the professional training, skills and experience and the knowledge of the pertinent standards and regu-

lations to perform the assigned works and to identify and avoid potential hazards.

11/68

EN

2.4.2. UNAUTHORIZED PERSONNEL

WARNING!

• Risks associated with unauthorized personnel in the hazard and work areas can be life threatening!

• Unauthorized individuals without the qualifi cations described in this section are not familiar with the risks

in the work area. As such, they are in danger of severe or even fatal injury.

• Keep unauthorized personnel away from the hazard and work area.

• If in doubt, approach individuals and instruct them to leave the hazard and work area.

• Stop any work while unauthorized individuals are in the hazard and work area.

2.4.3. TRAINING

The operator must train the sta at regular intervals. A training log must be maintained for purposes of better

tracking and must contain the following information, at least:

• Date of training

• Names of trained sta

• Contents of the training session

• Name of trainer

• Signatures of the sta members in training and of the trainer

2.5. PERSONAL PROTECTIVE EQUIPMENT

Personal protective equipment protects sta from safety and health hazards while working.

Various tasks on and associated with, the system necessitate the use of personal protective equipment,

which is described in more detail in the individual sections of these instructions.

BREATHING APPARATUS

To protect against harmful gases, vapors, dust and similar materials and media.

Breathing apparatus (e.g. compressed air respirator) must be used when an oxy-

gen content of at least 17% in the ambient air is not guaranteed or when the limit of

a hazardous substance in the ambient air is exceeded more than 100-fold. Breath-

ing apparatus may only be worn by people who have been specially trained in

the use.

BREATHING APPARATUS, DEPENDENT ON AIR CIRCULATION

To protect against harmful gases, vapors, dust and similar materials and media.

Breathing apparatus must be worn if a permissible limit is exceeded 100-fold. The

breathing apparatus may only be used when the oxygen content in the ambient

air measures at least 17%.

PROTECTIVE GOGGLES

To protect the eyes against airborne parts and splashes of liquid.

CHEMICAL-RESISTANT GLOVES

To protect the hands from aggressive substances.

Make sure the protective gloves are leak-proof before wear, Before taking the

gloves o , clean them and then store them in a well ventilated location.

PROTECTIVE GLOVES

To protect the hands against abrasion, scrapes, pricks or deeper injuries and con-

tact with hot or cold surfaces.

WEAR HEARING PROTECTION

To protect the hands against abrasion, scrapes, pricks or deeper injuries and con-

tact with hot or cold surfaces.

12/68

EN

2.6. BEHAVIOR IN CASE OF FIRE OR ACCIDENT

PREVENTIVE MEASURE

• Always be prepared for fi res and accidents!

• Always keep fi rst aid equipment (kit, blankets, etc.) and fi re extinguishing equipment in working order and

close to hand.

• Familiarize the sta with accident reporting, fi rst aid and emergency procedures.

• Keep the access routes free for emergency service vehicles.

MEASURES IN THE EVENT OF FIRE OR ACCIDENT

• If there is no risk to your own safety, remove people from the danger zone.

• Administer fi rst aid if necessary.

• Notify the fi re brigade and/or emergency service.

• In the event of fi re: If there is no risk to your own safety, use fi re extinguishing equipment to fi ght the fi re

until the fi re brigade arrives.

• Inform the person responsible at the location.

• Make sure the access routes are free for emergency service vehicles.

• Direct the emergency service vehicles.

2.7. ENVIRONMENTAL PROTECTION

NOTE!

• Risk of environmental pollution from incorrect handling of environmentally hazardous substances!

• The environment can su er substantial damage if environmentally hazardous substances are handled,

and especially disposed of, incorrectly.

• Always observe the information below on handling environmentally hazardous substances and their dis-

posal.

• Take immediate measures if environmentally hazardous substances are accidentally released into the

environment. If in doubt, notify the responsible local authorities about the damage and enquire about the

suitable measures to be taken.

2.8. SIGNAGE

WARNING!

• Danger from illegible signs!

• Labels and signs can gather dirt or become otherwise illegible over time, thus preventing the recognition

of risks and compliance with the requisite operating information. This could result in injury.

• Make sure all safety, warning and operation information is legible at all times.

• Immediately replace any damaged signs or labels.

2.8.1. SIGNS THAT GIVE ORDERS

• No signs

2.8.2. SIGNS INDICATING BANS

• No signs

2.8.3. WARNING SIGNS

GAS BOTTLES HAZARD EXPLOSION HAZARDOUS

AREA

WARNING OF TOXIC AND/ OR

CORROSIVE SUBTANCES

13/68

EN

3. TECHNICAL SPECIFICATIONS

3.1. FLOW SCHEME MPLH0XS0/ MSLH0XS0, MPLHEXS0/ MSLHEXS0

1 – GAS CYLINDER

2 – COIL/HOSE

3 – CHECK VALVE

4 – PRESSURE REGULATOR WITH IN/OUT GAUGE

5 – RELIEF VALVE

6 – SHUT-OFF VALVE (1XIN, 3XOUT)

7 – SAFETY VALVE

Options are shown as dotted line

14/68

EN

3.2. DIMENSION SHEET MPLH0XS0/ MSLH0XS0,

MPLHEXS0/ MSLHEXS0

Grounding

15/68

EN

3.3. FLOW SCHEME MPLH0XSS/ MSLH0XSS, MPLHEXSS/ MSLHEXSS

1 – GAS CYLINDER

2 – COIL/HOSE

3 – CHECK VALVE

4 – SHUT-OFF VALVE (3XIN, 1XOUT)

5 – PRESSURE REGULATOR

6 – RELIEF VALVE

7 – SHUT-OFF VALVE (1XIN, 3XOUT)

8 – SAFETY VALVE

Options are shown as dotted line

16/68

EN

3.4. DIMENSION SHEET MPLH0XSS/ MSLH0XSS,

MPLHEXSS/ MSLHEXSS

Grounding

17/68

EN

3.5. FLOW SCHEME MPLH0XSP / MSLH0XSP, MPLHEXSP / MSLHEXSP

1 – GAS CYLINDER

2 – COIL/HOSE

3 – CHECK VALVE

4 – SHUT-OFF VALVE (3XIN, 1XOUT)

5 – PURGE OUTLET VALVE

6 – PRESSURE REGULATOR

7 – RELIEF VALVE

8 – SHUT-OFF VALVE (1XIN, 3XOUT)

9 – SAFETY VALVE

Options are shown as dotted line

18/68

EN

3.6. DIMENSION SHEET MPLH0XSP / MSLH0XSP,

MPLHEXSP / MSLHEXSP

Grounding

19/68

EN

3.7. FLOW SCHEME MSLH0XSE, MSLHEXSE

1 – GAS CYLINDER

2 – COIL/HOSE

3 – SHUT-OFF VALVE (3XIN, 1XOUT)

4 – PURGE OUTLET VALVE

5 – PRESSURE REGULATOR

6 – RELIEF VALVE

7 – SHUT-OFF VALVE (1XIN, 3XOUT)

8 – SAFETY VALVE

9 – CHECK VALVE

10 – PURGE INLET VALVE (1XIN, 3XOUT)

Options are shown as dotted line

20/68

EN

3.8. DIMENSION SHEET MSLH0XSE, MSLHEXSE

Grounding

This manual suits for next models

3

Table of contents

Languages:

Popular Control Unit manuals by other brands

Pepperl+Fuchs

Pepperl+Fuchs PS1000-D2-24.40.RM technical information

Hirschmann

Hirschmann PTN-4-DSL-LW user manual

Georg Fischer Piping Systems

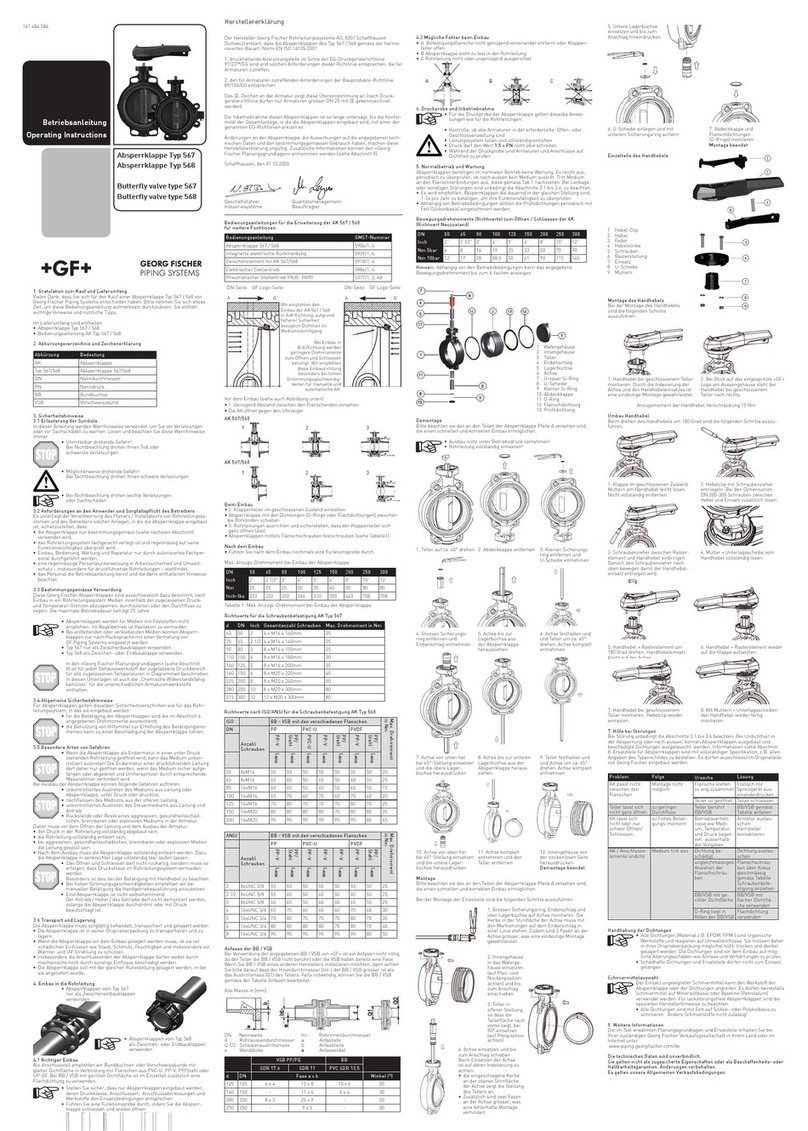

Georg Fischer Piping Systems 567 operating instructions

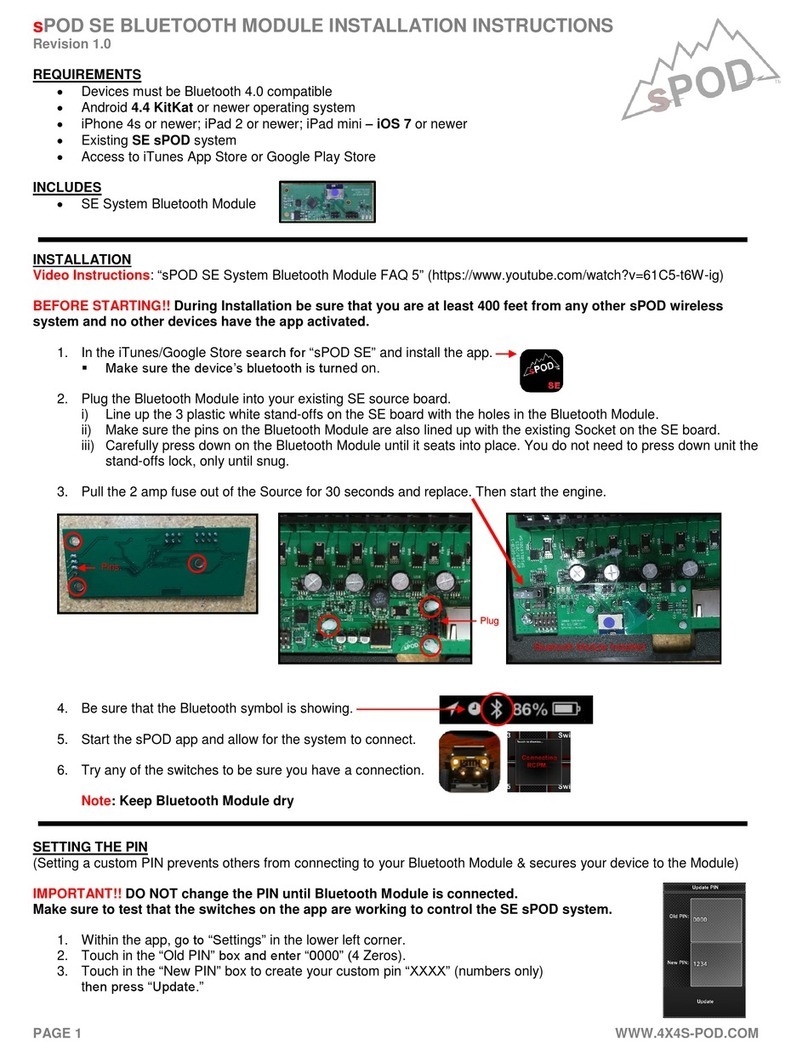

Spod

Spod SE Installation instructions manual

Bluewin

Bluewin ACB225 Installation

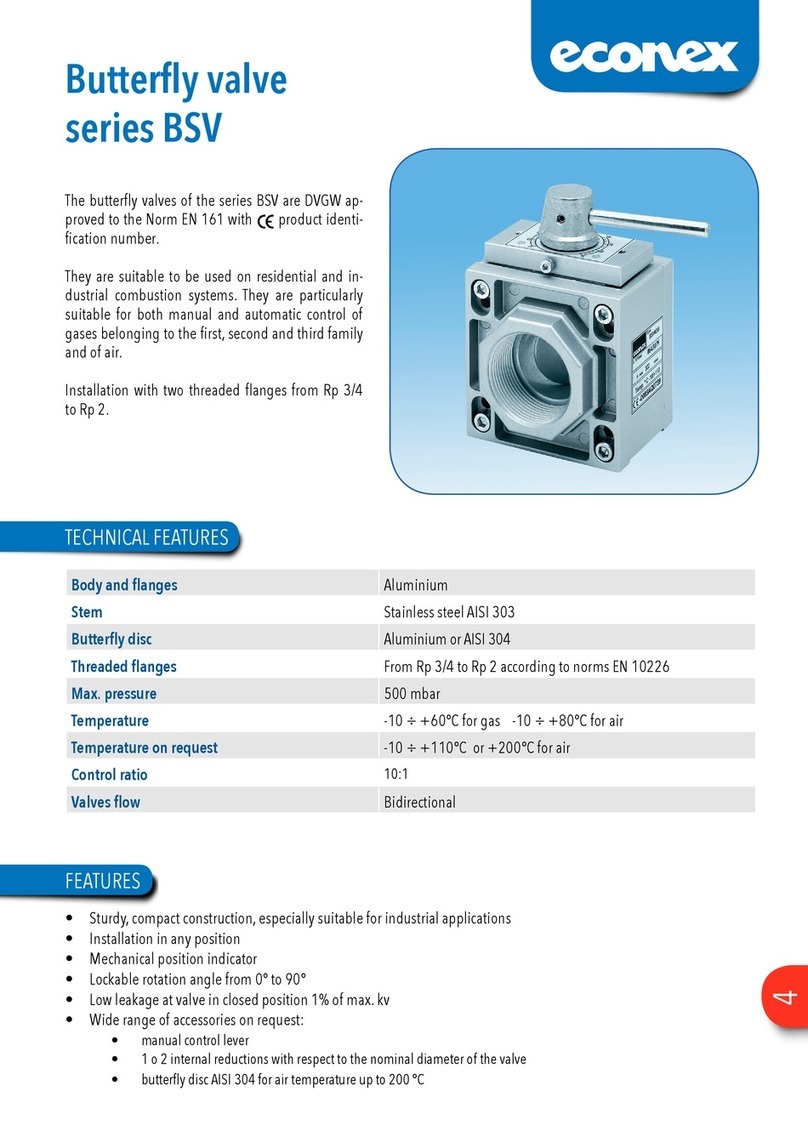

Econex

Econex BSV Series quick start guide