GCL GCL-P6/60GD Series User manual

Version: GCL/XXJC/2-RD-357_B2

Bifacial Module Installation Manual for

GCL System Integration Technology Co., Ltd.

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

01

CONTENTS

Purpose of this Manual...........................................................................................................2

Disclaimer .............................................................................................................................2

Safety & Transport.................................................................................................................3

Mechanical Installation..........................................................................................................7

Electrical Installation ...........................................................................................................20

Grounding............................................................................................................................22

Bypass Diodes and Block Diodes.........................................................................................23

Maintenance ........................................................................................................................24

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

02

PURPOSE OF THIS MANUAL

This manual applies exclusively to the bifacial module (here in after referred to as

Module) of GCL System Integration Technology Co., Ltd. (here in after referred to as

GCLSI). The contents of this manual involve the installation methods, operation safety

and maintenance information of GCLSI’s Modules.

Modules must be installed by professionals. Please read this manual carefully before

installation. The installers must follow all the rules in this manual strictly as well as local

requirements and regulations by law or authorized organizations.

Before installing, the installer must be familiar with their mechanical and electrical

requirements. Please keep this manual in a safe place for future reference (care and

maintenance) and in case of sale or disposal of the Modules.

DISCLAIMER

GCLSI shall not be responsible for any loss arising from the installation, operation, use or

maintenance of the Modules which is not complying with the guidance of this manual,

including breakdown or damage of the Modules or any other expenses incurred.

Any customer shall not get any patent or authorization of the patent when using the

Modules, expressed or implied. Any infringement of patents or other rights of the third

party, which may result from the use of the Module, is not within the responsibility scope

of GCLSI. The information in this manual is based on GCLSI’s knowledge and

experience and is believed to be reliable, but such information including product

specification (without limitation) and relevant suggestions do not constitute a warranty,

expressed or implied.

GCLSI reserves the rights to change the manual, the Modules, the specifications or any

other information of the Modules without prior notice.

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

03

SAFETY & TRANSPORT

General Detailed Rules

Keep all the Modules and electrical connectors clean and dry before installation.

Use both hands to carry Modules. Do not overlap Modules.

Be cautious when carrying Modules. Slip-proof gloves are necessary.

Use supportive disassembling tools when unpacking.

The application level of GCLSI module is Class A, which can be used in systems operating at

greater than 50 V DC or 240W, where general contact access is anticipated;

Do not stamp on Modules or put weight on Modules.

Do not disassemble or drop Modules. Do not remove any nameplate or component

of the module.

Do not use mirrors or magnifiers to concentrate sunlight onto Modules.

Do not lift the module by grasping the junction box or cable wire.

Do not use any sharp object with Modules.

Do not directly apply pressure on the glass surface or backsheet of Modules.

Do not touch the surface of the coated glass with bare hands.

Ensure all contacts and the operating environment are clean and dry.

Module Carry and Installation Instruction

Both hands when handling Modules

Ensure Modules are fixed properly

Do not use sharp objects with Modules

Do not pull the wiring cables or junction

box

Do not stamp on Modules

Do not touch Modules with bare or dirty

hands

Do not pile up Modules on uneven ground

Do not drop or throw Modules

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

04

SAFETY & TRANSPORT

Description of Package Signs

Before the operation, it is necessary to read carefully the unpacking instruction and outer

packing box instruction, and carry out the operation as instructed.

1. DO NOT expose the module to rain or

moisture.

2. The Modules in the carton box are fragile.

Handle with care.

3. The package shall never be upside down

during the transportation.

4. It is prohibited to tramp on the packing

box and module.

5. During the stacking of the Modules, the

outer packing box can be stacked not

exceed the maximum layer allowed .(n=2

means it is allowed to stack for at most

two layers.)

6. One module shall be handled by two

people together.

n

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

05

SAFETY & TRANSPORT

Unloading, Transportation and Storage

When the Modules are delivered to the project site, the freight car shall be ready in the

flat, even and open area for parking and unloading.

Forklift unloading: Choose the appropriate carrying forklift according to the commodity

weight, unload the Modules from the freight car and place them on flat ground.

Unloading with a crane: Affix the lifting belt in the wood supporting frame buckle (Fig. 1,

2). It is allowed only to lift one pallet at a time. Before lifting, it is necessary to confirm

whether the pallet and paper box are damaged and ensure that the lifting rope is robust

and firm. When being lifted close to the ground, the paper box will be gently placed in a

relatively flat position on the project site by two people, one on each side.

Figure 1 Wood Supporting Frame Figure 2 Lifting Schematics

It is prohibited to stack the Modules in the project site.

During the transportation at the project site, the Modules shall not be stacked, but only

allowing for one layer in transportation.

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

06

SAFETY & TRANSPORT

Storage in the project site warehouse:

Storage environment requirements: Humidity<85%, temperature -20 ~+50℃; Modules

statically stacked for ≤2 layers.

Temporary storage at the project site: The Modules shall be stored in a dry,

well-ventilated place. They shall not be stacked but shall be covered with waterproof

cloth to prevent dampness in the Modules.

Unpacking description

1. In the outdoor unpacking process, it is prohibited to operate in rainy conditions;

2. If there is wind in the field, special attention shall be paid. Particularly in the event of

heavy wind, it is recommended not to handle the module, and it is necessary to properly

secure the unpacked Modules;

3. The working surface shall be such that the packing box can be placed in a stable, level

position, avoiding being overturned;

4. During the unpacking, it is necessary to wear protective gloves, and avoid scratching

the hands and leaving the fingerprints on the glass;

5. In the case of operation not according to the requirements or in the case of an

unskillful operation, it will result in the fall-off of the protective corner in small amounts,

which will be normal. The effect of the protective corner is to reduce damage due to external

force during transport, and the fall-off of the protective corner will not influence the reliability

of the Modules;

6. Before the unpacking, it is necessary to carefully check the product information on the

carton box, and carefully read the unpacking instruction;

7. Every module shall be carried by two people. When carrying the module by two

people, it is prohibited to pull the junction box.

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

07

MECHANICAL INSTALLATION

Location Selection

Select suitable places to install Modules. The module in the north latitude region shall

face south, and shall face north in the south latitude region.

Install Modules at the places with sufficient sunlight and without shade at any time. If a

module is shaded or even partially shaded, it will result in lower power output. A

permanent or regular shade will cause module damage, which will result in the invalidity

of product’s limited warranty.

Do not store, install or use Modules at the places where combustible gas is easily

generated or gathering.

The straight-line distance between the installation site and coastline shall not be shorter

than 1 km unless there is a writ ten approval from GCLSI or an engagement specified in

the contract.

Location Selection

Modules in the same string should be installed at the same angle. Modules installed in

different angles will receive different irradiation, which will cause current different. As a

result, it will decrease the operation efficiency of the system.

Please refer to Table 1 for the recommended mounting tilt angles of the Modules.

Local latitude

Mounting Tilt Angles

0°-15°

15°

15°-25°

Local latitude

25°-30°

Local latitude + 5°

30°-35°

Local latitude + 10°

35°- 40°

Local latitude + 15°

>40°

Local latitude + 20°

Table 1 Mounting Tilt Angle of Modules

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

08

MECHANICAL INSTALLATION

Installation requirements

The installation structure shall be made of the durable 、corrosion-resistant and

ultraviolet-resistant materials. It is necessary to ensure that the support and structure in

use have been tested, certified and approved.

No matter where the Modules are installed, it is necessary to ensure that the module is

firmly mounted on the support, and ensure that it can undertake the corresponding wind

loading and snow loading.

Choose proper installation height of the photovoltaic support system, the lower part of the

module should not be covered with snow for a long time in winter. Additionally, it is

necessary to ensure that the lowest part of the module is high enough, to avoid being

shaded by the plant or damaged by the flying sand.

For the photovoltaic system installed on the ground, GCLSI recommends that the

minimum distance from the module bottom to the ground surface shall be 24 inches

(60cm). The higher the lower point of the module from the ground, the higher the power

generation efficiency on the back of the module. When the module is installed on the roof,

it is necessary to ensure that the roof structure is suitable and the installed module shall

not be beyond the roof zone. Additionally, the roof shall be have water-proof treatment to

prevent the roof from water leakage.

If the module will be installed on the column, the chosen column and the module support

structure shall be able to undertake the locally expected loads of wind and snow. Ensure

that such loads are within the range of the respective maximums loading permitted by

GCLSI, meanwhile, the module will not be subjected to the thermal expansion force from

the support structure. The stacking of Modules shall be prohibited.

The back of the module shall be well ventilated to facilitate the cooling of the module.

GCLSI recommends that there shall be the gap of 30cm between the module and the

installation surface, if the surface is finished with the light-color and highly reflective

materials such as white paint and aluminum foil, the back of the module could contribute

5%-30% additional power output.

To prevent the influence of thermal expansion between the Modules upon the module,

GCLSI recommends that the minimum distance between two Modules shall not be less

than 10mm, which is the minimum linear distance between two Modules.

It is necessary to always observe the instruction guide and safety rules attached for

module installation.

It is prohibited to drill the holes in the glass surface. Otherwise, it will invalidate the

quality guarantee.

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

9

MECHANICAL INSTALLATION

Installation Method

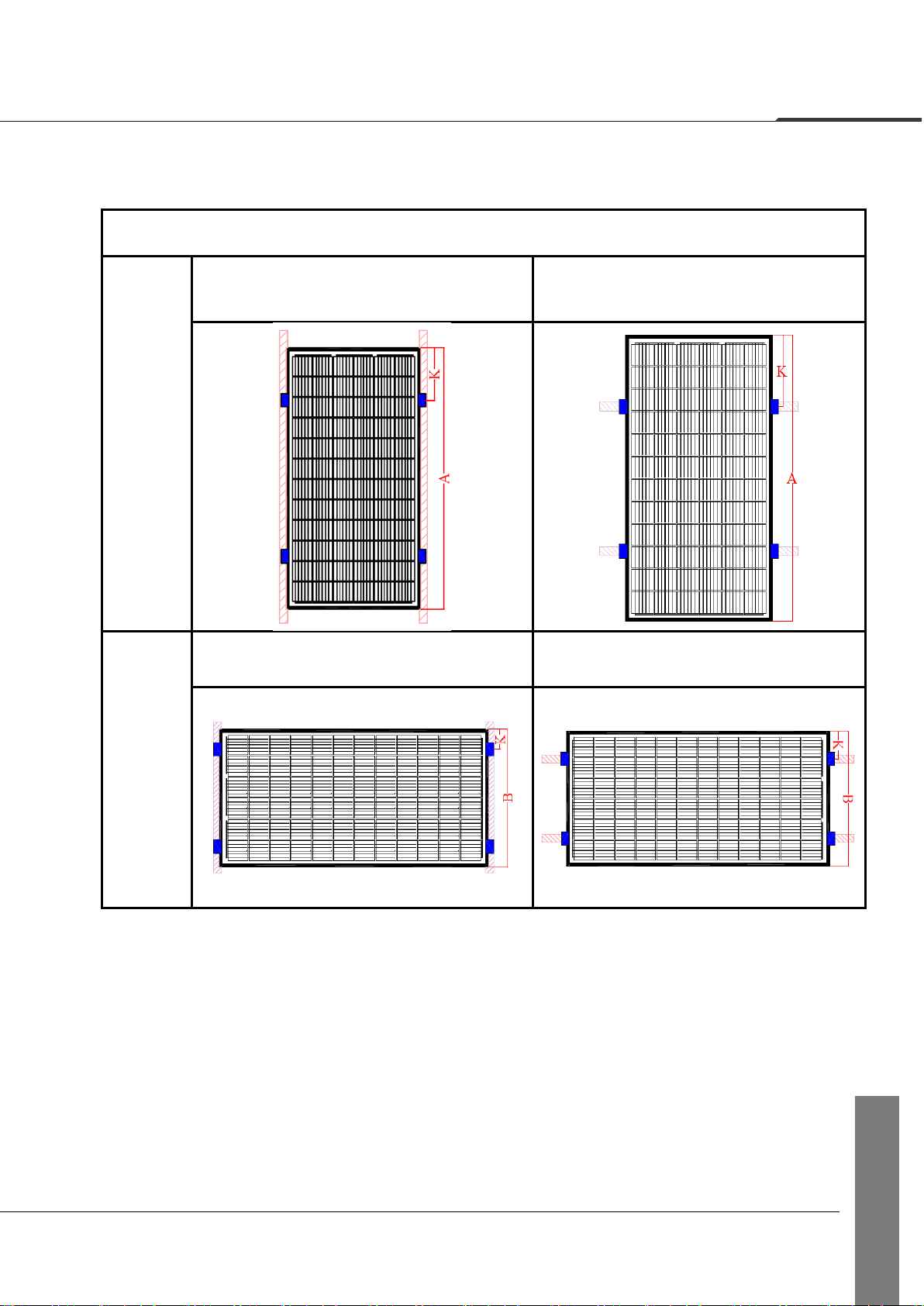

1、Modules without frames

Installation with the mounting clamp

Table 2 Installation Method

Clamping

on the

long side

Installation Method A

Installation Method B

Table 3 Installation method and load capacity

Module Type

Module

dimensions

(mm)

Length of

the clamp

(mm)

Installation Method A

Installation Method B

Position of

clamp K

(mm)

Design load :

downward/

upward,

γm=1.5

(Pa)

Position of

clamp K

(mm)

Design load :

downward/

upward,

γm=1.5

(Pa)

GCL-P6/60GDXXX

GCL-M6/60GDXXX

1658*992*6

150

300-400

2400

1600

300-400

3600

1600

1680*1000*6

GCL-N6/60GXXX

1658*992*6

150

300-400

2400

1600

300-400

3600

1600

GCL-P6/72GDXXX

GCL-M6/72GDXXX

1968*992*6

200

400-500

2400

1600

400-500

3600

1600

2000*1000*6

GCL-N6/72GXXX

1968*992*6

200

400-500

2400

1600

400-500

3600

1600

GCL-P3/60GDXXX

GCL-M3/60GDXXX

1700*1000*6

150

300-400

2400

1600

300-400

3600

1600

GCL-P3/72GDXXX

GCL-M3/72GDXXX

2030*1000*6

200

400-500

2400

1600

400-500

3600

1600

GCL-M/P3/60GTXXX

1700*1034*6

150

300-400

2400

1600

300-400

3600

1600

GCL-M10/60GTXXX

1980*1166*6

200

400-500

2400

1600

400-500

3600

1600

Note: Test load = γm(safety factors) ×design load

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

10

MECHANICAL INSTALLATION

The installation of the double-glass bifacial module shall match the photovoltaic support

design and the customized accessories, and comply with the system design requirements.

It is necessary to use the specified clamp for the module installation, and the torque force

shall meet the requirements.

Horizontal installation: the first module and the last module of every row shall be fixed

with the side-clamp, and the Modules in the middle should be fixed by middle-clamp.

Vertical installation: the first module and the last module of every line shall be fixed with

the side-clamp, and the Modules in the middle should be fixed by middle-clamp.

To avoid the clamp producing the shade on the front or back of the module.

side-clamp

middle-clamp

Figure 3 Structural breakdown schematics of

side-clamp

Figure 4 Structural breakdown schematics

of middle-clamp

Installation tool: 13mm socket wrenches (electric wrenches optional), torque wrenches

10-100 N.M; Tightening torque of the clamp: 16 N.M~20N.M.

Side clamp, middle clamp: including lower and upper EPDM blocks, fastener

combination (M8 bolt, washer, spring washer, nut).

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

11

MECHANICAL INSTALLATION

Read the following installation procedure contents and be familiar with full procedure

before installation. Additionally, get the field preparation works ready prior to installation

starts. The module may be installed horizontally and vertically.

Installation steps

Step 1: install the

support.

Install the track

support.

Step 2: Install the

clamp.

Fix the clamp on the

support with the nut

not tightened.

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

12

MECHANICAL INSTALLATION

Step 3: Install the

module.

Install the module

into the clamp as

required , and tighten

the nut with the

torque of the clamp:

16 N.M~20 N.M.

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

13

MECHANICAL INSTALLATION

2、Framed Modules

Installation with the mounting clamp

Table 4 Installation Method

Clamping

on the

long side

Installation Method C

Installation Method D

Clamping

on the

short side

Installation Method E

Installation Method F

Note: The length of the clamp≥50mm.

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

14

MECHANICAL INSTALLATION

Table 5 Installation method and load capacity

Installation Method

Installation Method C

Installation Method D

Installation Method E

Installation Method F

Module Type

Module

dimensions

(mm)

Position

of

clamp

K

(mm)

Design

load :

downward/

upward,

γm=1.5

(Pa)

Position

of

clamp

K

(mm)

Design

load :

downward/

upward,

γm=1.5

(Pa)

Position

of

clamp

K

(mm)

Design

load :

downward/

upward,

γm=1.5

(Pa)

Position

of

clamp

K

(mm)

Design

load :

downward/

upward,

γm=1.5

(Pa)

GCL-P6/60GDFXXX

GCL-M6/60GDFXXX

1664*998*30

366-466

3600

1600

366-466

3600

1600

25~250

1600

1600

25~250

1600

1600

1686*1002*30

372-472

372-472

25~251

25~251

GCL-P6/72GDFXXX

GCL-M6/72GDFXXX

1974*998*30

444-544

3600

1600

444-544

3600

1600

25~250

1600

1600

25~250

1600

1600

2006*1002*30

452-552

452-552

25~251

25~251

GCL-P3/60GDFXXX

GCL-M3/60GDFXXX

1706*1002*30

377-477

3600

1600

377-477

3600

1600

25~251

1600

1600

25~251

1600

1600

1706*998*30

377-477

377-477

25~250

25~250

GCL-P3/72GDFXXX

GCL-M3/72GDFXXX

2036*1002*30

459-559

3600

1600

459-559

3600

1600

25~251

1600

1600

25~251

1600

1600

2026*998*30

457-557

457-557

25~250

25~250

GCL-P6/60DHXXX

GCL-M6/60DHXXX

1686*1000*35

372-472

3600

1600

372-472

3600

1600

25~250

1600

1600

25~250

1600

1600

1666*1000*35

367-467

367-467

25~250

25~250

GCL-P6/72DHXXX

GCL-M6/72DHXXX

2010*1000*35

453-553

3600

1600

453-553

3600

1600

25~250

1600

1600

25~250

1600

1600

1980*1000*35

445-545

445-545

25~250

25~250

GCL-P3/60DHXXX

GCL-M3/60DHXXX

1706*1000*35

377-477

3600

1600

377-477

3600

1600

25~250

1600

1600

25~250

1600

1600

1686*1000*35

372-472

372-472

25~250

25~250

GCL-P3/72DHXXX

GCL-M3/72DHXXX

2036*1000*35

459-559

3600

1600

459-559

3600

1600

25~250

1600

1600

25~250

1600

1600

2010*1000*35

453-553

453-553

25~250

25~250

GCL-M8/72GDFXXX

GCL-P8/72GDFXXX

2130*1048*30

483-583

3600

1600

483-583

3600

1600

25-262

1600/1600

25-262

1600/1600

2094*1038*35

473-573

3600

1600

473-573

3600

1600

25-260

1600/1600

25-260

1600/1600

GCL-M8/72DHXXX

2130*1048*35

483-583

3600

1600

483-583

3600

1600

-

-

-

-

GCL-M10/72GDFXXX

2256*1133*35

-

-

514-614

3600

1600

-

-

-

-

2278*1134*35

2279*1134*35

2278*1134*30

-

-

520-620

-

-

GCL-M10/60GDFXXX

1890*1133*35

-

-

422-522

3600

1600

-

-

-

-

1908*1134*30

-

-

427~572

3600

1600

-

-

-

-

GCL-M12/60GDFXXX

2172*1303*35

-

-

493-593

3600

1600

-

-

-

-

GCL-M12/66GDFXXX

2384*1303*35

-

-

546-646

3600

1600

275-375

-

275-375

1600/1600

Note: Test load = γm(safety factors) ×design load

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

15

MECHANICAL INSTALLATION

Installation with the mounting hole

Table 6 Installation Method

Mounting

on the

long side

Installation Method G

Installation Method H

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

16

MECHANICAL INSTALLATION

Table 7 Mounting dimension and load capacity

Module Type

Module dimensions

(mm)

Mounting

distance M

(mm)

Mounting

distance N

(mm)

Installation

Method G

Installation

Method H

Design load :

downward/

upward, γm=1.5

(Pa)

Design load :

downward/

upward, γm=1.5

(Pa)

GCL-P6/60GDFXXX

GCL-M6/60GDFXXX

1664*998*30

990

962

3600/1600

3600/1600

1300

962

1600/1600

1600/1600

1686*1002*30

860

966

3600/1600

3600/1600

1360

966

1600/1600

1600/1600

GCL-P6/72GDFXXX

GCL-M6/72GDFXXX

1974*998*30

400

962

1600/1600

1600/1600

990

962

3600/1600

3600/1600

1300

962

1600/1600

1600/1600

2006*1002*30

400

962

1600/1600

1600/1600

860

966

3600/1600

3600/1600

1360

966

1600/1600

1600/1600

GCL-P3/60GDFXXX

GCL-M3/60GDFXXX

1706*1002*30

860

966

3600/1600

3600/1600

1360

966

1600/1600

1600/1600

1706*998*30

860

962

3600/1600

3600/1600

1360

962

1600/1600

1600/1600

GCL-P3/72GDFXXX

GCL-M3/72GDFXXX

2036*1002*30

400

962

1600/1600

1600/1600

860

966

3600/1600

3600/1600

1360

966

1600/1600

1600/1600

2026*998*30

400

958

1600/1600

1600/1600

860

962

3600/1600

3600/1600

1360

962

1600/1600

1600/1600

GCL-P6/60DHXXX

GCL-M6/60DHXXX

1686*1000*35

1666*1000*35

860

951

3600/1600

3600/1600

1360

951

1600/1600

1600/1600

GCL-P6/72DHXXX

GCL-M6/72DHXXX

2010*1000*35

1980*1000*35

400

954

1600/1600

1600/1600

860

951

3600/1600

3600/1600

1360

951

1600/1600

1600/1600

GCL-P3/60DHXXX

GCL-M3/60DHXXX

1706*1000*35

1686*1000*35

860

951

3600/1600

3600/1600

1360

951

1600/1600

1600/1600

GCL-P3/72DHXXX

GCL-M3/72DHXXX

2036*1000*35

2010*1000*35

400

954

1600/1600

1600/1600

860

951

3600/1600

3600/1600

1360

951

1600/1600

1600/1600

GCL-M8/72GDFXXX

GCL-P8/72GDFXXX

2130*1048*30

400

1008

1600/1600

1600/1600

990

1012

3600/1600

3600/1600

1300

1012

3600/1600

3600/1600

2094*1038*35

400

989

1600/1600

1600/1600

990

989

3600/1600

3600/1600

1300

989

3600/1600

3600/1600

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

17

MECHANICAL INSTALLATION

Note: Test load = γm(safety factors) ×design load

Module Type

Module dimensions

(mm)

Mounting

distance M

(mm)

Mounting

distance N

(mm)

Installation

Method G

Installation

Method H

Design load :

downward/

upward, γm=1.5

(Pa)

Design load :

downward/

upward, γm=1.5

(Pa)

GCL-M8/72DHXXX

2130*1048*35

400

1002

1600/1600

1600/1600

990

999

1600/1600

1600/1600

1300

999

3600/1600

3600/1600

GCL-M10/72GDFXXX

2256*1133*35

-

-

-

-

990

1084

-

3600/1600

1400

1084

-

3600/1600

2278*1134*35

2279*1134*35

-

-

-

-

990

1085

-

3600/1600

1400

1085

-

3600/1600

GCL-M10/60GDFXXX

1890*1133*35

-

-

-

-

990

1084

-

3600/1600

1400

1084

-

3600/1600

1908*1134*30

990

1085

-

3600/1600

1400

1085

-

3600/1600

GCL-M12/60GDFXXX

2172*1303*35

——

——

——

——

1400

1254

-

3600/1600

GCL-M12/66GDFXXX

2384*1303*35

——

——

——

——

1400

1254

-

3600/1600

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

18

MECHANICAL INSTALLATION

The Modules may be installed and fixed with the following methods:

Mounting hole system: Use the corrosion-resistant M8 bolt, for fixing with the

installation support through the installation hole in the side frame of the module, as

shown in Fig. 5.

Clamping system: use proper clamp, and fix the module with the installation support, as

shown in Fig. 6.

Figure 5 Mounting holes

Figure 6 Mounting clamps

The mounting accessories recommended are listed below:

Bolt

Flat washer

Spring washer

Nut

Material: stainless

Steel material: stainless steel

Material: stainless steel

Material: stainless steel

Size: M8

Size: M8

Size: M8

Size: M8

The range of torque for screw tightening is 14N.m to 20N.m.

GCL System Integration Technology Co., Ltd.

Bring Green Power to Life

19

MECHANICAL INSTALLATION

Mounting with Single-axis Tracking System

1. This installation is only for 72 cells framed modules.

2. It is a Single-axis Tracking System; the module is fixed on the axis by bolting long

frame.

3. The frame of each module has 4-φ7*12mm mounting holes with specific location

shown in Figure 7.

4. Secure the module in each fixing location with an M6 bolt, two flat washers, a spring

washer and nut as shown in Figure 7, torque: 9~12 N.m.

Figure 7

This manual suits for next models

11

Table of contents

Popular Inverter manuals by other brands

Brusa

Brusa DMC514 Technical Data and Start-Up

LeadSolar

LeadSolar Energy Microinverter LS600 Installation & operation guide

Toshiba

Toshiba TOSVERT VF-AS3 instruction manual

Power One

Power One TRIO-20.0-TL instruction manual

SEW-Eurodrive

SEW-Eurodrive MOVITRAC LTP-B operating instructions

FRONIUS

FRONIUS IG Plus USA operating instructions