Technical data

and startup

6.1 Technical data..........................................................................................................................24

6.2 Type plate................................................................................................................................26

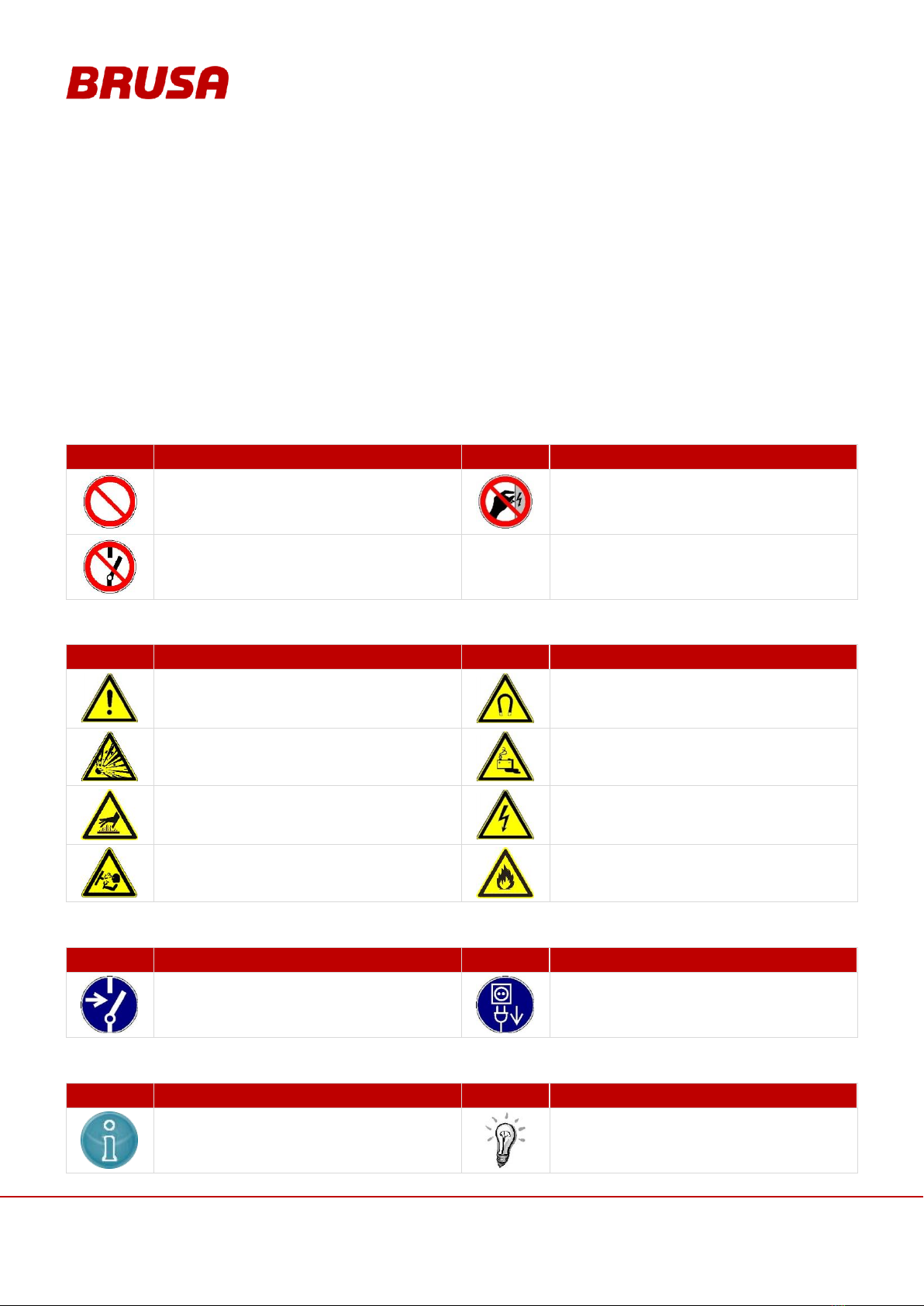

6.3 Device warnings.......................................................................................................................27

6.4 Basic function...........................................................................................................................27

6.5 Covers......................................................................................................................................28

6.6 Assembly information...............................................................................................................29

6.6.1 Installation position............................................................................................................29

6.6.2 Fixing (as in example DMC524) ........................................................................................29

6.7 Example of use ........................................................................................................................30

6.8 Input and output values............................................................................................................31

6.9 Block diagram output stage / power print..................................................................................32

6.10 Operating modes of the inverter...............................................................................................33

6.11 Regulatory approach and limitations ........................................................................................34

6.12 Error and warning messages....................................................................................................34

6.12.1 Error definition...................................................................................................................35

6.12.2 Warning message definition..............................................................................................35

7Level of inverter efficiency...............................................................................................36

7.1 DMC514 measured with HSM1-10.18.04 at 400V (first quadrant)............................................36

7.2 DMC524 measured with HSM1-6.17.12 at 400V (first quadrant)..............................................36

7.3 DMC534 measured with HSM1-10.18.13 at 400V (first quadrant)............................................37

7.4 DMC544 measured with HSM1-10.18.13-W7 at 400V (first quadrant)......................................37

8Connections.......................................................................................................................38

8.1 Circuit connections...................................................................................................................38

8.2 Pin assignment motor sensor connection (device side)............................................................39

8.3 Pin assignment of control connector (device side)....................................................................40

8.3.1 Pin 1 GND (ground terminal 31)........................................................................................41

8.3.2 Pin 2 AUX (Wiring system terminal 30)..............................................................................41

8.3.3 Pin 3 EN (Enable, Power ON) ...........................................................................................42

8.3.4 Pin 8 PG1, 14 PG2, 15 PG3 (Reserve ground, RS232 ground).........................................42

8.3.5 Pin 11 TXD, Pin 12 RXD (RS232 interface).......................................................................43

8.3.6 Pin 13 PRO (Enable firmware programming).....................................................................44

8.3.7 Pin 17 EXT AW1, Pin 18 EXT AW2 (External shut down path 1 + 2).................................45

8.3.8 Pin 19 IL1, Pin 20 IL2 (Interlock 1 + 2) ..............................................................................46