4

Installation

The unit should be mounted in a position which is accessible and in the field of vision. Mains should

be from a fused supply (2A) and connected to the mains input terminals of the power supply unit.

The vent port should be piped to atmosphere without reduction. This will prevent possible back

pressure affecting the sensor reading.

A minimum of two intake modules should be located within the target area, their position will

be depedant upon the type of gas to be monitored and its density with respect to air.

Heavy gases (LPG, Propane, Butane, Refrigerant Gases) – locate at 15 to 20 cm from the floor.

Lighter gases (Methane, Natural Gas, Town Gas) – locate at 5 to 10 cm from the ceiling.

Carbon Monoxide – locate at 1.5 to 2 metres from floor level.

The control panel should be mounted away from direct heat.

Operation

On power up the green power indicator will flash for 60 seconds indicating that the system is

stabilising. During this period all alarms are held in the off position.

After the stabilisation period any gas detected by the sensor will be indicated on the display, with

any alarm level being exceeded resulting in the sounder and appropriate red alarm LED and relay

activating.

Pressing the reset pad will result in the sounder being silenced. Alarm indicators and relays may

only be reset when the indicated gas level has reduced to below that of the alarm trip points.

A reduced power mode feature is activated one hour after any operator activity. This state is

indicated by a screen power reduction of approximately 50%. Pressing any button will return the

screen to full display.

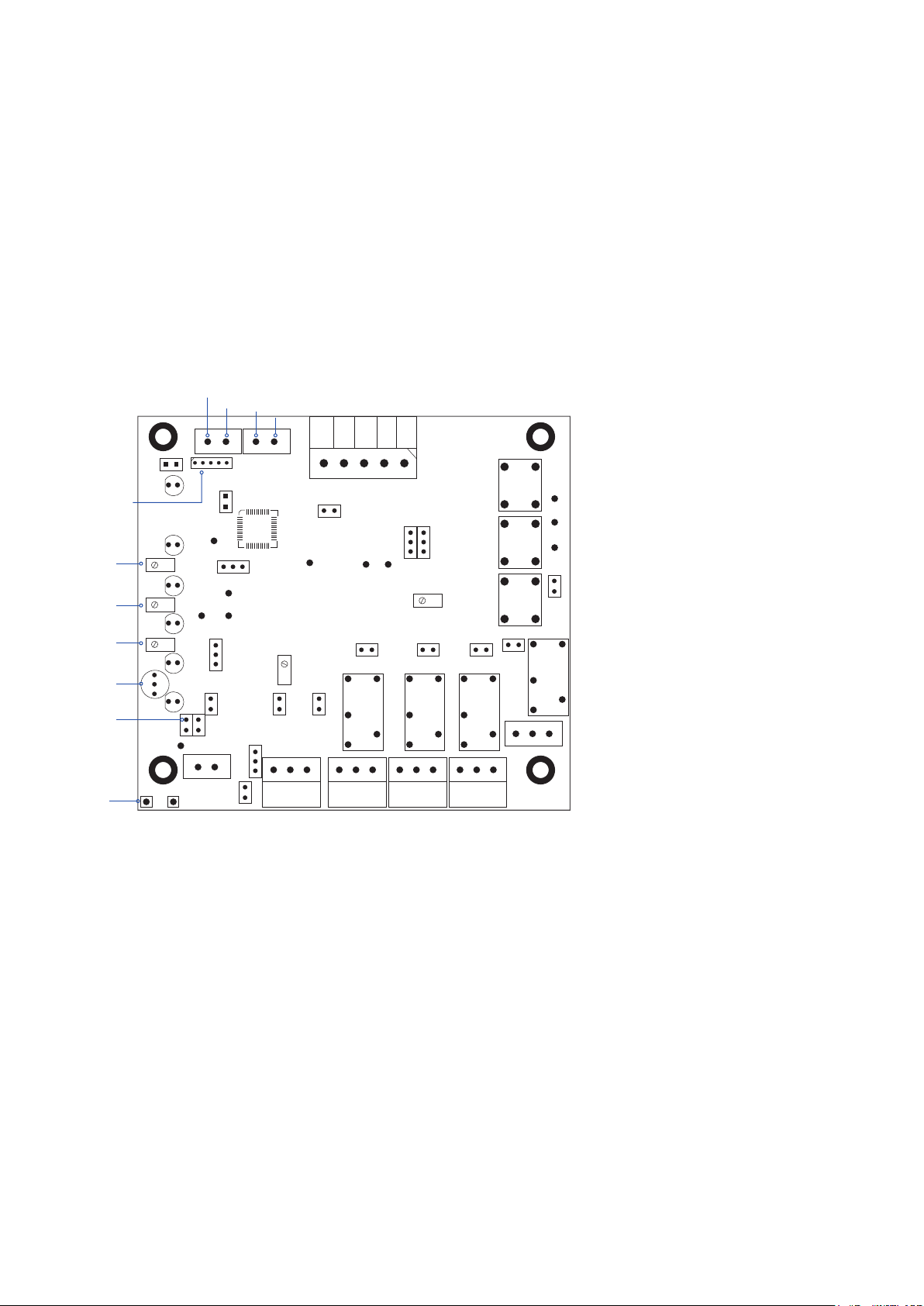

4-20

OV

Lo

Hi

24V

NO C

AL3

NC NO C

NCNO C

AL2

NCNO C

AL1

NC

W

+

Y

sig

P

-

SENSOR FAULT

+ -

4-20mA

Output

PC comms via

hyperterminal

Sensor

Voltage

test pins

Zero LED

4mA

J28

20mA

Zero

Gain

J3

J29

J11

J18 J17 J16

J15

J19

J1

TP3

A B

A

B

A

B

TP11

TP12

TP6TP7

TP13

TP8 TP9 TP2

TP4

TP1

Contrast

J6

J20

J5

J4 J7

J12

J13 J14

J8

J8

x fault

Inhibit Ov 24v J1 CANbus – EOL – see Combi

J4/7 For Semiconductor sensors

J5/11 Sensor (B-catalytic A-4~20mA)

J6/20 Sink/Source 4~20mA output

J8 Gain – factory set

J9 Normally fitted 4~20mA out

J12 Bridge fault enable fit for catalytic sensor

J13 See J8

J14 Sensor supply selector

A for catalytic sensor

B for 4~20mA sensor

J15 Sounder mute

J16 N/E - A1 relay link on

J17 N/E - A2 relay link on

J18 N/E - A3 relay link on

J19 N/E - fault relay link on

J28 Reset processor

J29 Address change enable – see Combi

A

B

4~20mA In

Sensor

supply

adjust

4~20mA

Output

Fig 2