–3 –

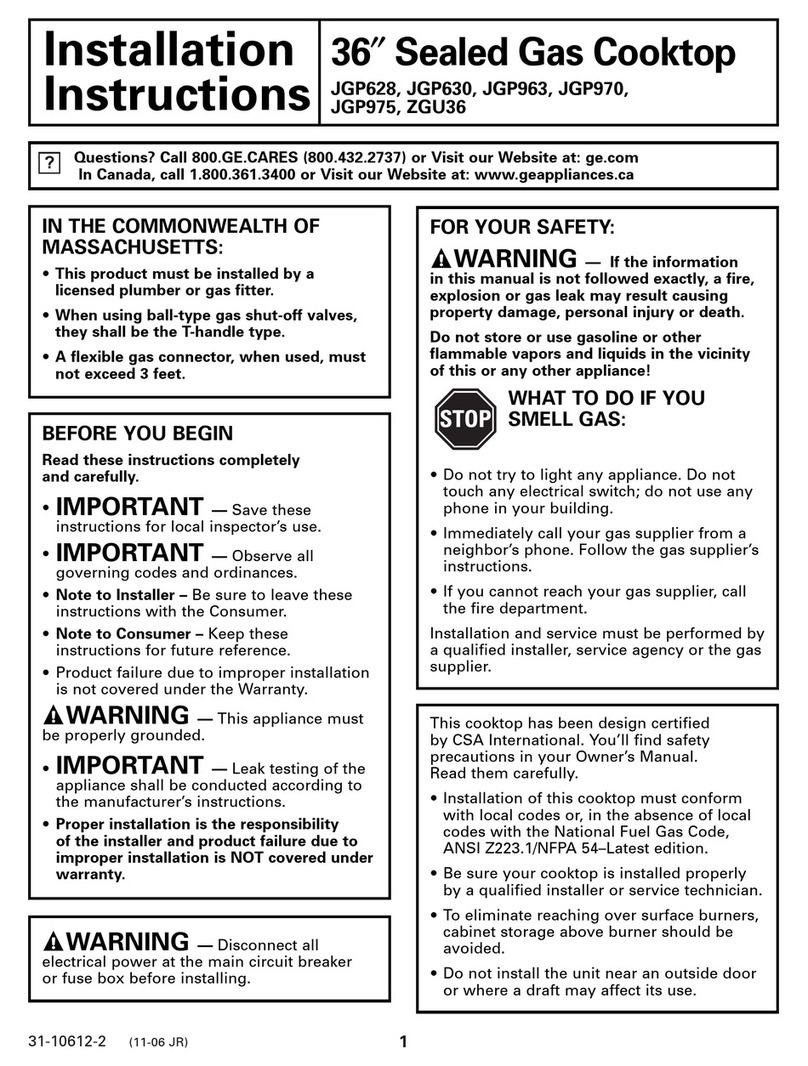

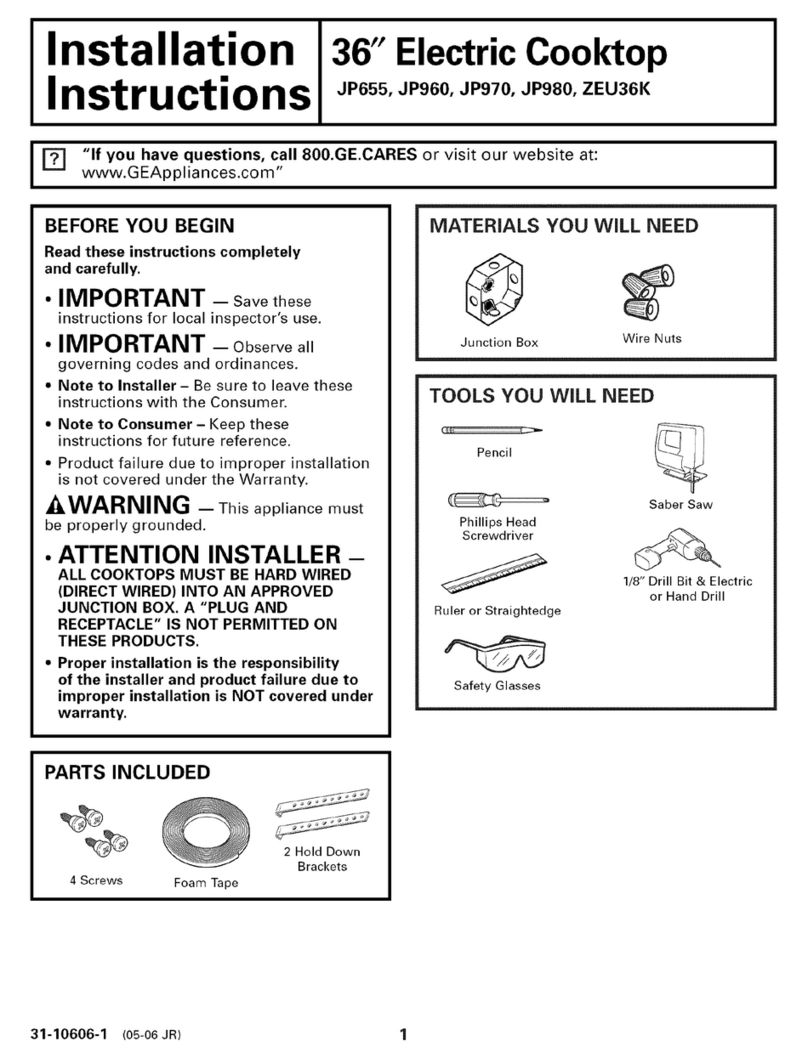

Installation

WARNING: Before beginning the installation,

switch power off at the service panel and lock the

service disconnecting means. When the service

disconnecting means cannot be locked, securely

fasten a warning tag to the service panel.

Before You Begin...

Note: The complete installation instructions

are inclosed with the

Use and Care Manual

.

Carefully read and follow these instructions.

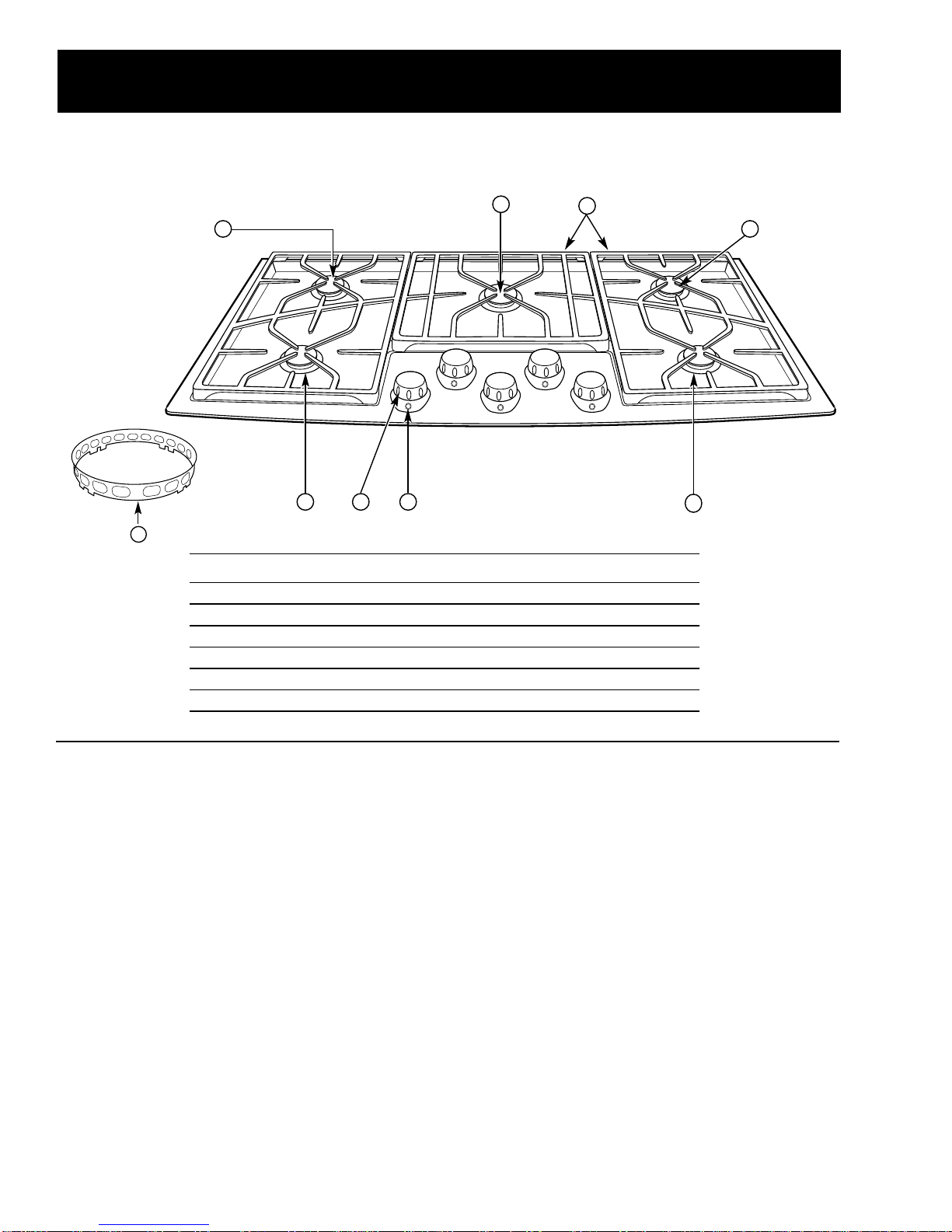

Gas Supply

WARNING: Cooktop model ZGU375NS isshipped

from the factory set to operate only with natural

gas. Do not use with LPG. If you wish to use

LPG, you must have cooktop model ZGU375LS.

These cooktops are designed to operate on natural

gas at 4 in. of water column pressure or on LP gas

at 10 in. of water column pressure, depending on

model. For proper operation, the maximum inlet

pressure to the regulator must be no more than

10 in. of water column pressure for natural gas

and 14 in. of water column pressure for LP gas.

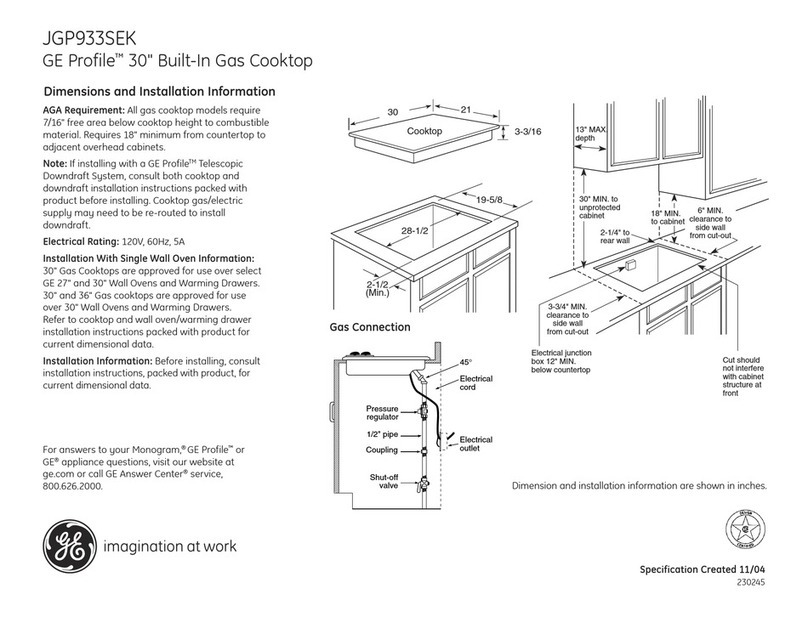

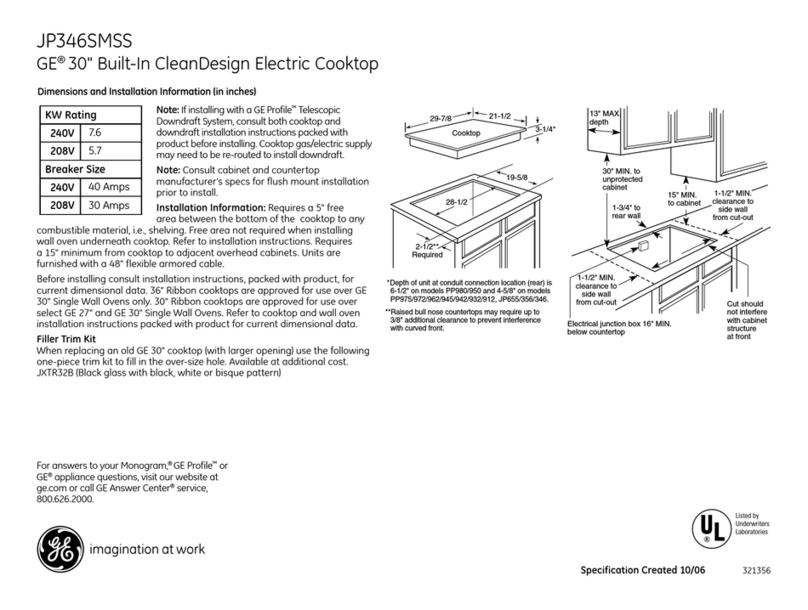

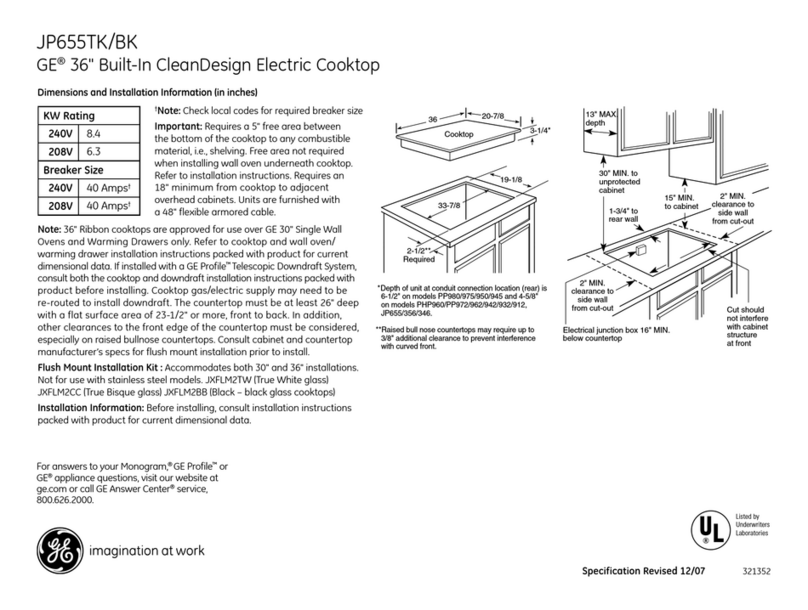

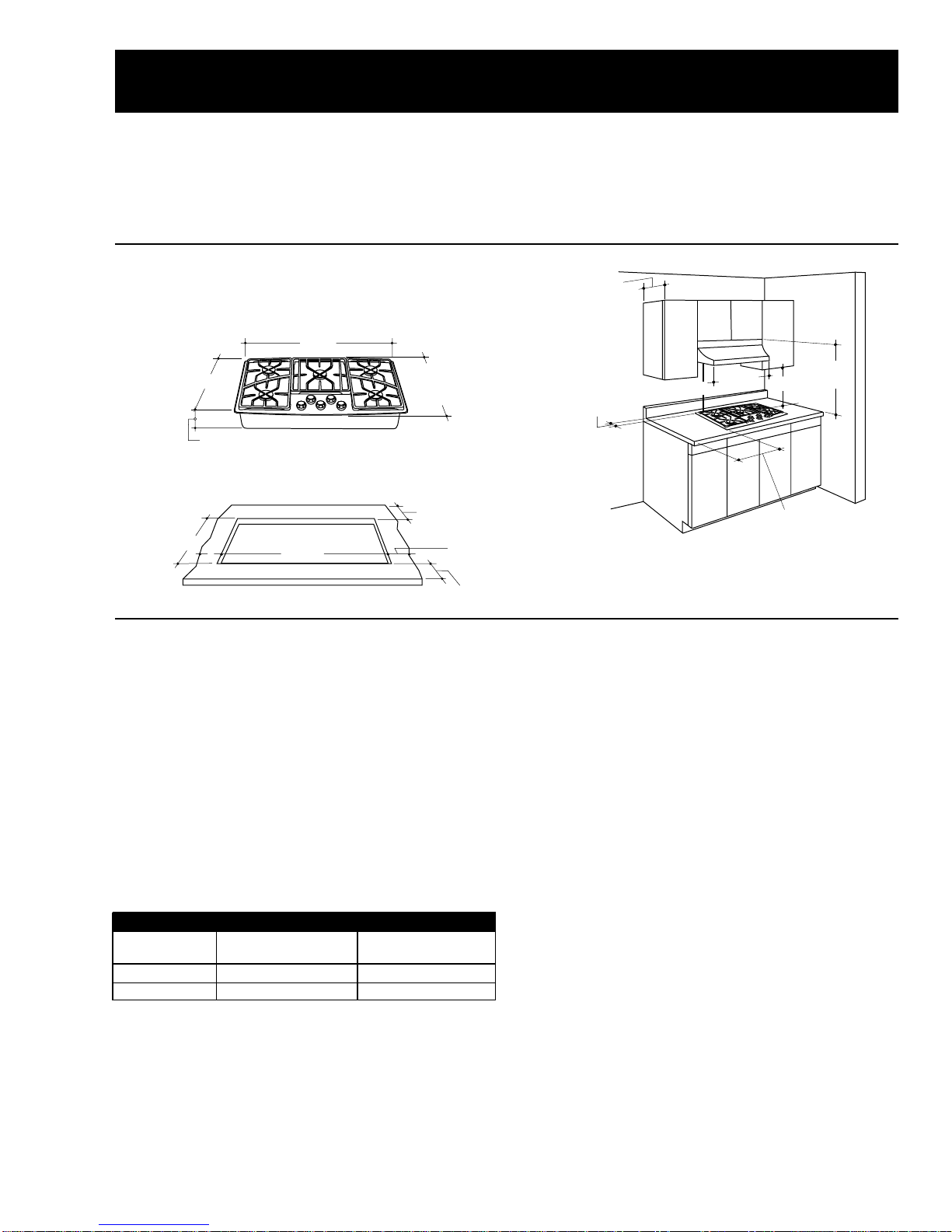

20-5/8"

Deep

at Center

19-3/4"

36-1/2"

5-1/2"

18-7/8"

3-3/8" Min. From Cutout

to Vertica Combustib es

2-3/4" Min.

35-5/16" 7-9/16" Min. to

Wa From Cutout

2-3/

From

to V

Com

Surf

Insta

Monogram Cooktop Dimensions

Dimensionsforreferenceonly

Unitshown fully assembled

Gas Supply Shutoff Valve

The cooktop itself is not equipped with a gas shut-

off valve. If installed correctly, a shutoff valve will be

in the main gas supply line “upstream”of the

appliance pressure regulator.

Measuring the Gas Pressure

Supplied to the Burners

A pressure tap hole is located on the side of the

regulator to allow checking of the manifold pres-

sure. Remove the regulator plug and install a

WB02X10820 tap (or 1/8 in. NPT nipple) for test

with a manometer. Turn on the gas and light at least

one burner to serve as a load. Reinstall the regular

plug and check for leaks.

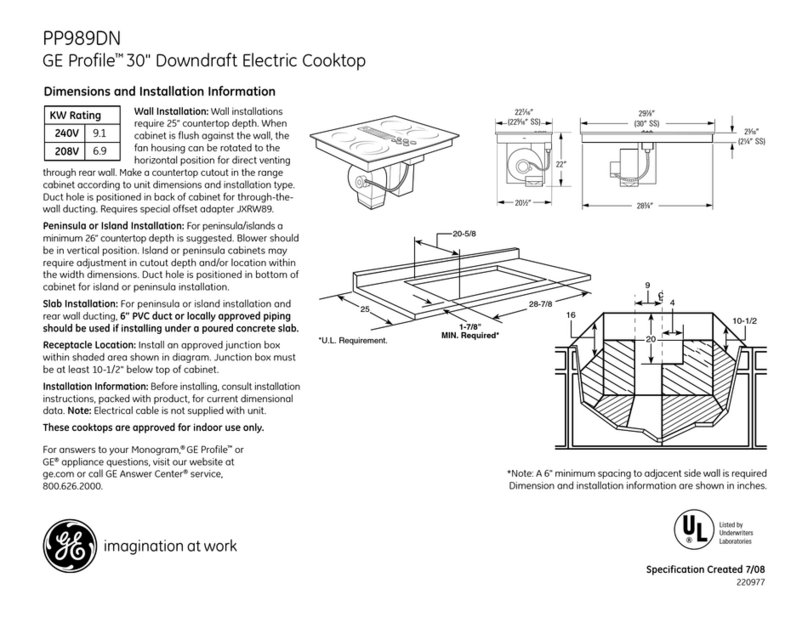

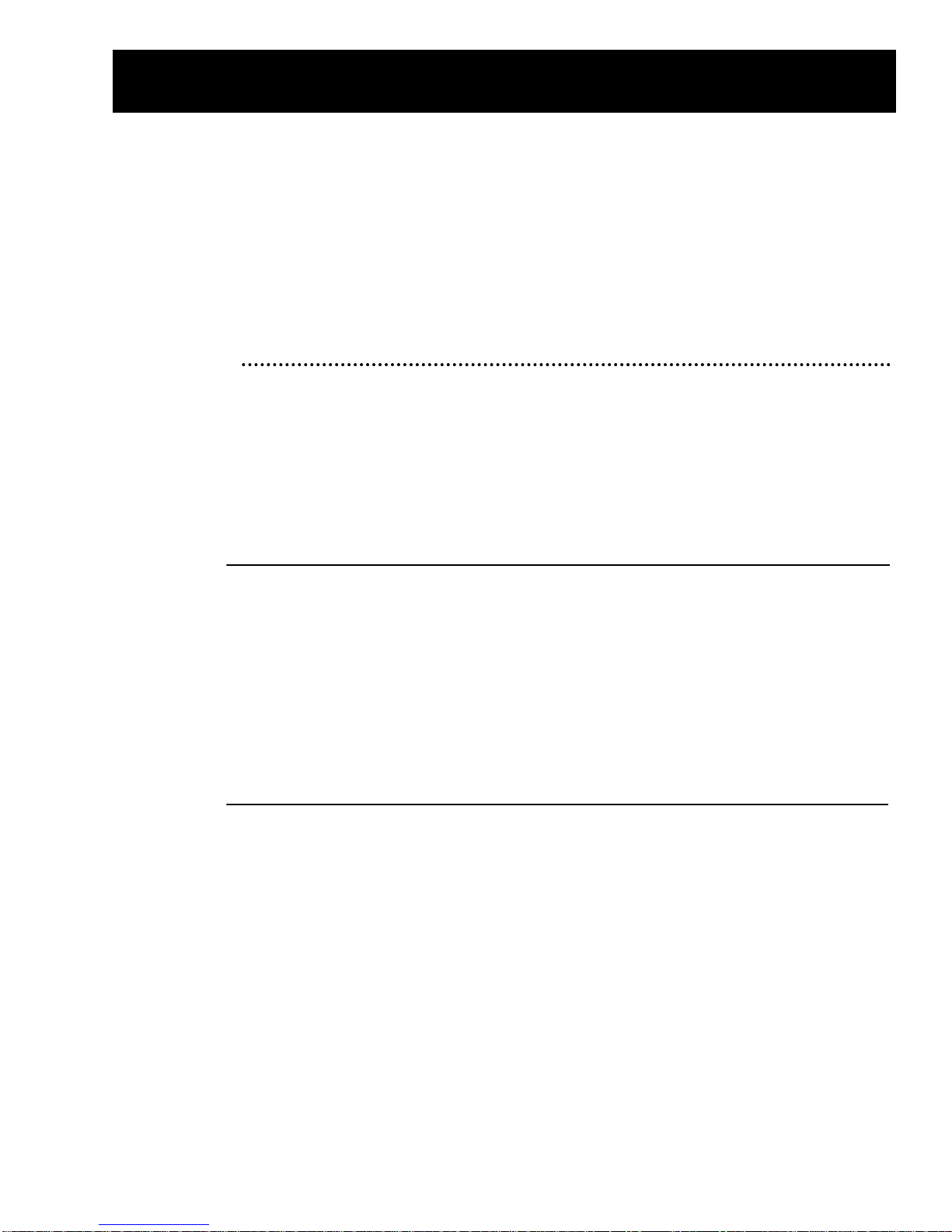

Optional Combination Installations

This cooktop may be installed in combination with a

ZVB36 Monogram downdraft vent, with a ZTD30

warming drawer, or with a ZET837 single convec-

tion oven. The gas and electrical supply must be

located where it will not interfere with the vent

housing, the oven, or the warming drawer.

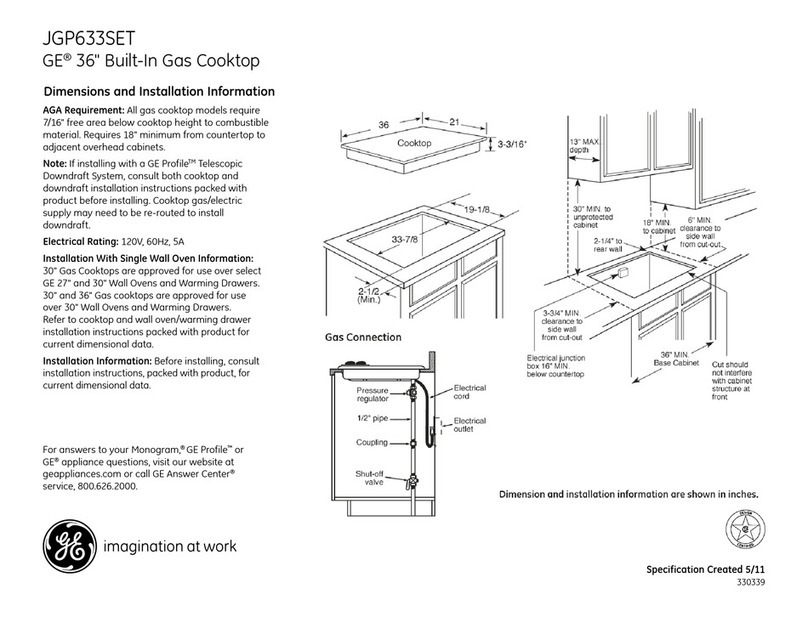

GAS SUPPLY REQUIREMENTS

Gas Type Incoming Pressure Pressure Regulator

to Regulator Output Supplies

Natural 6.0" to 9.0" W.C.P. 4.0" W.C.P.

LP 11" to 14" W.C.P. 10.0" W.C.P.

Recommended minimum regulator input pressure

to maximize performance:

Natural Gas –7.0-in. W.C.P.

LP Gas –12.0-in. W.C.P.

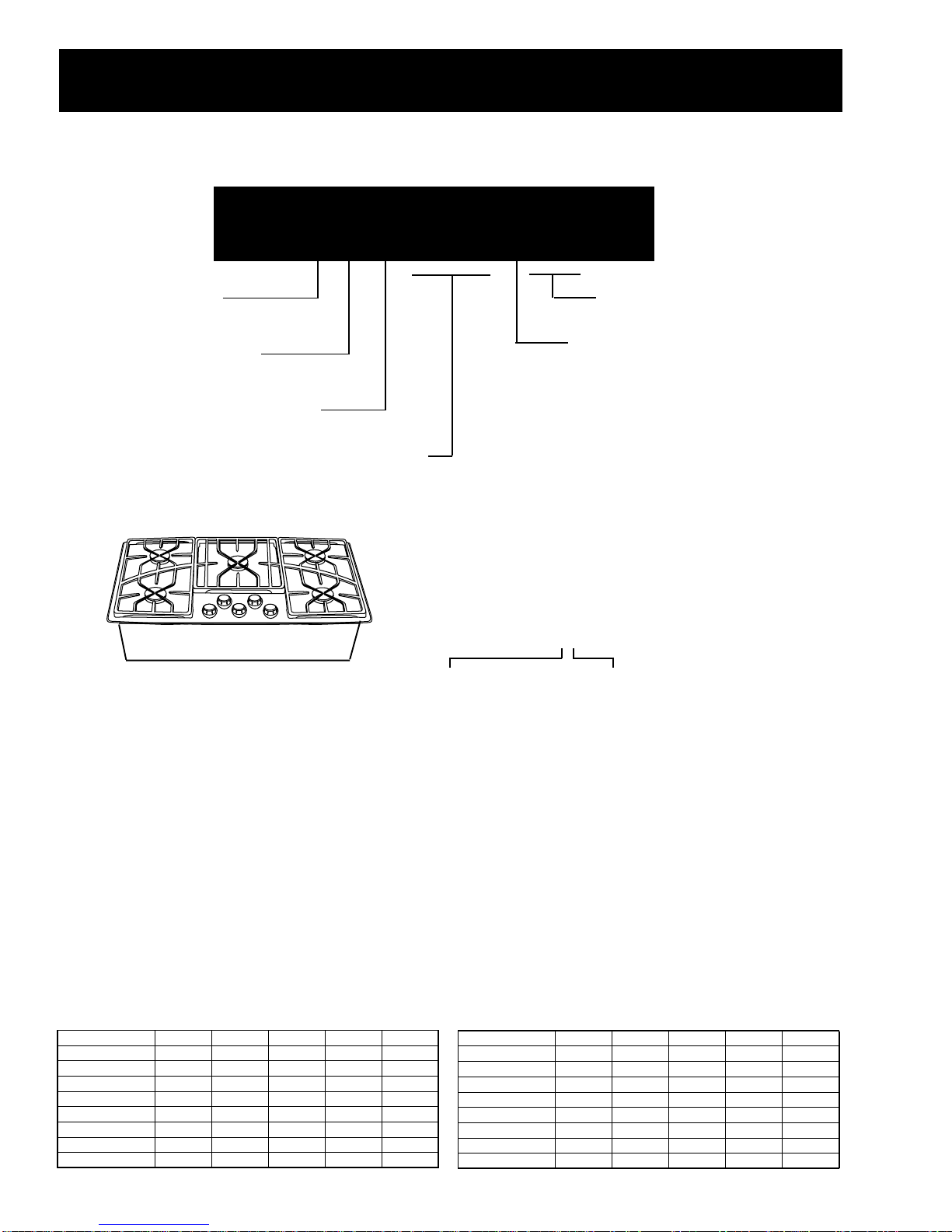

18" Min.

13"

Max.

36" Min.

2-3/4" Min.

From Cooktop

to Vertica

Combustib e

Surface When

Insta ed

7" Min. to Wa

From Cooktop Edge

When Insta ed Both Sides

30"

Min.

See Note

Note: Refer to hood installation instructions for dimension.