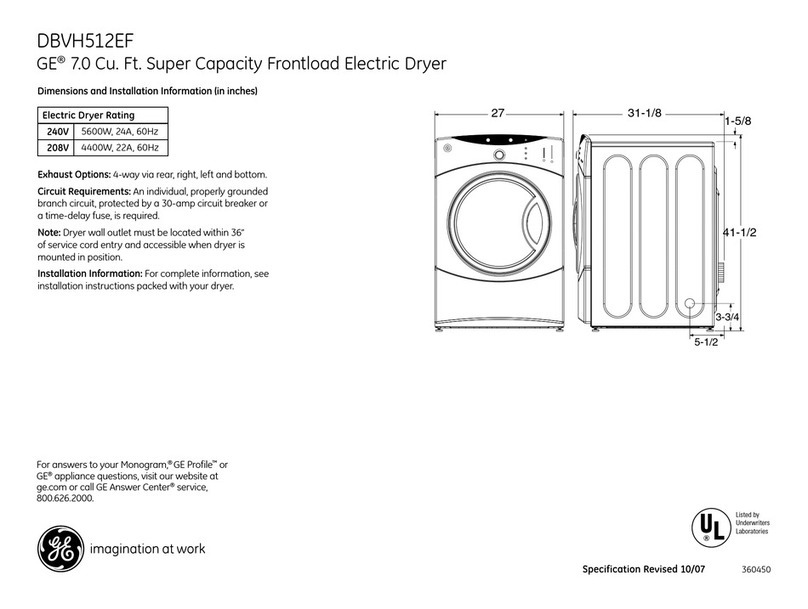

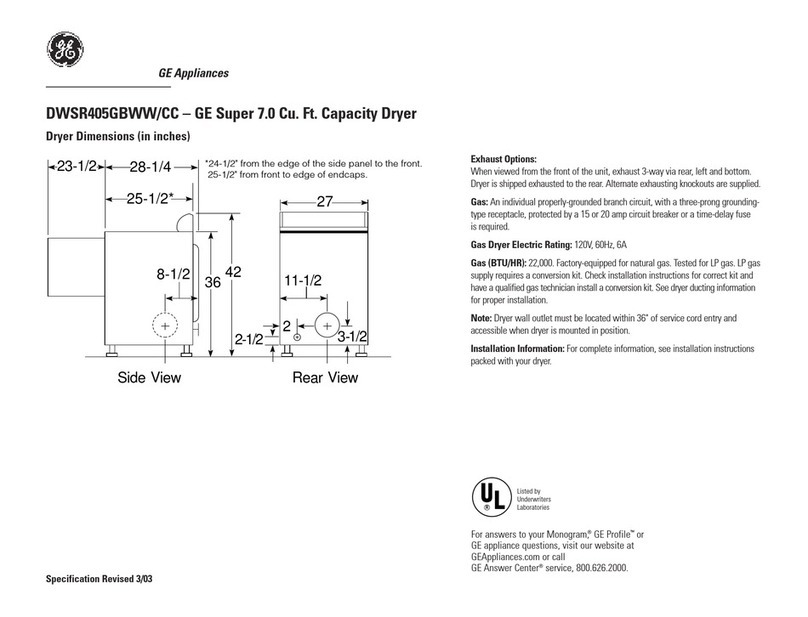

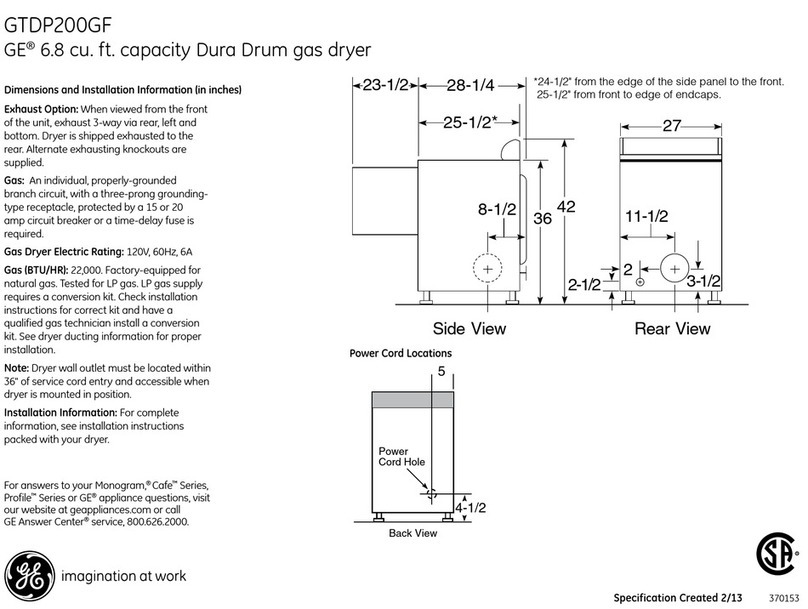

3 #10 AWG MINIMUM COPPER

CONDUCTORS OR 120/240V 30A POWER

SUPPLY CORD KIT MARKED FOR USE

WITH DRYERS & PROVIDED WITH CLOSED

LOOP OR SPADE TERMINALS WITH

UPTURNED ENDS (NOT SUPPLIED).

L1

L2

STRAIN RELIEF

BRACKET

3/4", UL

RECOGNIZED

STRAIN RELIEF

HOT

WIRE

HOT

WIRE

GROUND

STRAP

GREEN

GROUND

SCREW

NEUTRAL

(White)

SCREWS

(3)

If required, by local code,

install external ground

(not provided) to grounded

metal, cold water pipe, or

other established ground

determined by a qualified

electrician.

COVER

Installation Instructions

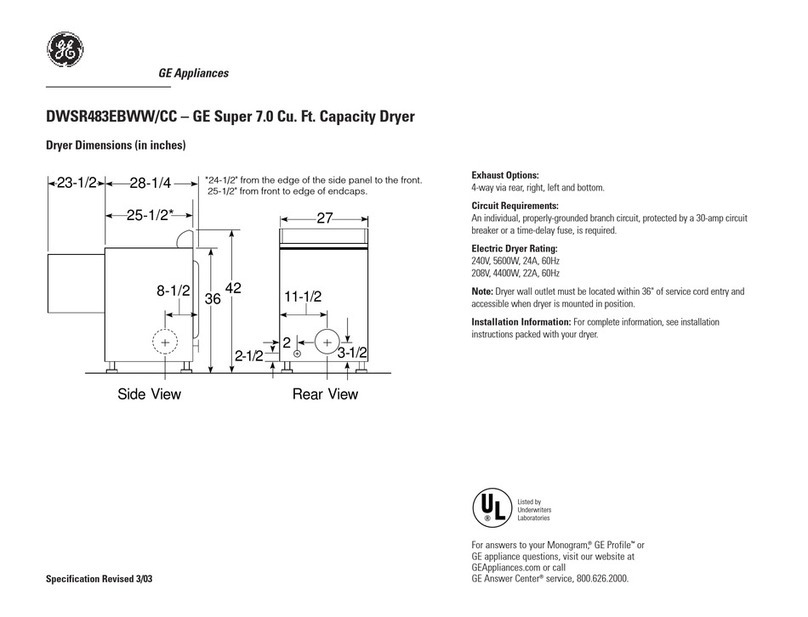

3EXHAUST INFORMATION

DO NOT USE DUCT LONGER THAN SPECIFIED IN THE

EXHAUST LENGTH TABLE.

Using exhaust longer than specified length will:

•Increase the drying times and the energy cost.

•Reduce the dryer life.

•Accumulate lint, creating a potential fire hazard.

The correct exhaust installation is YOUR RESPONSIBILITY.

Problems due to incorrect installation are not covered

by the warranty.

The MAXIMUM ALLOWABLE duct length and number of bends

of the exhaust system dependsupon the type of duct, number

of turns, the type of exhaust hood (wall cap), and all conditions

noted below. The maximum exhaust length for rigid metal duct

is shown in the table below.

3

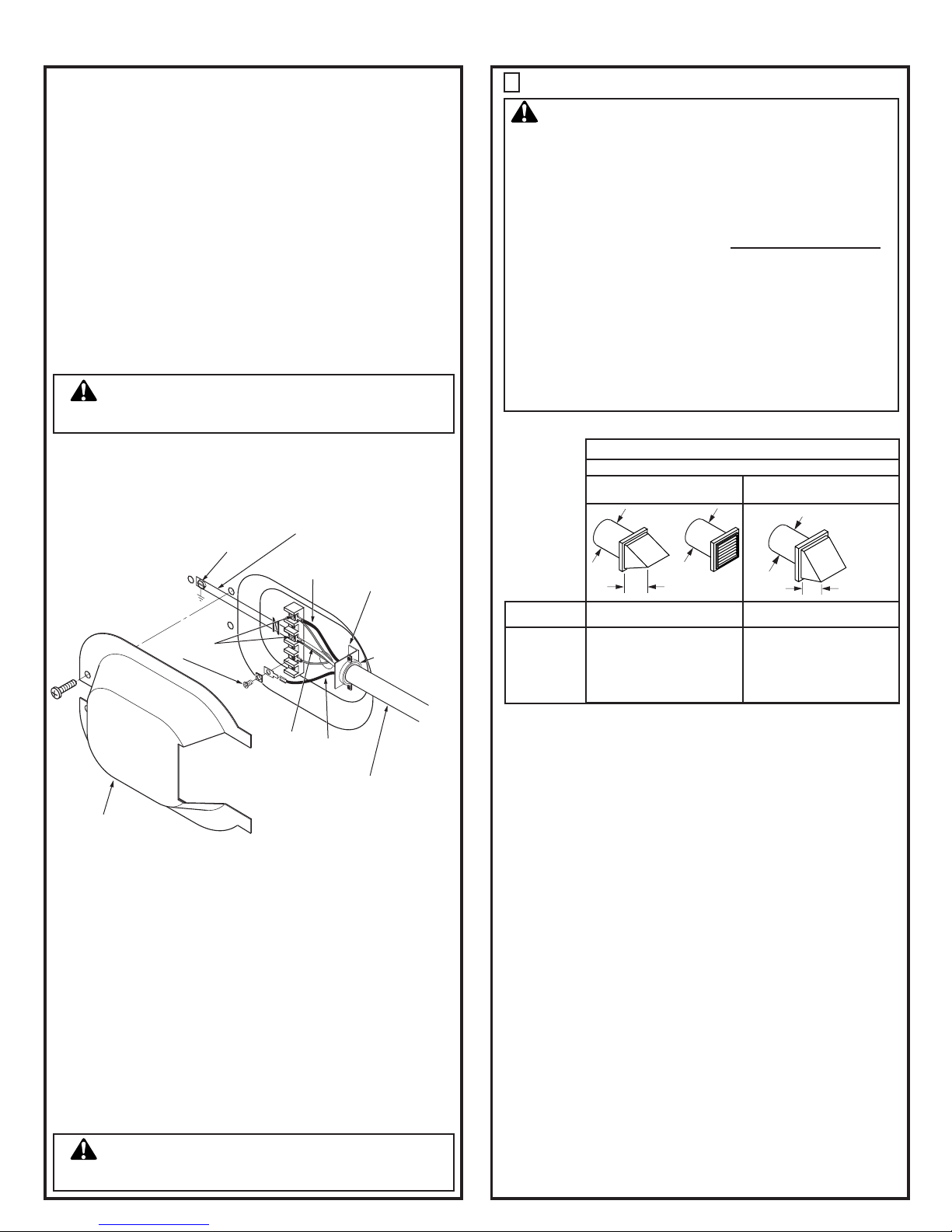

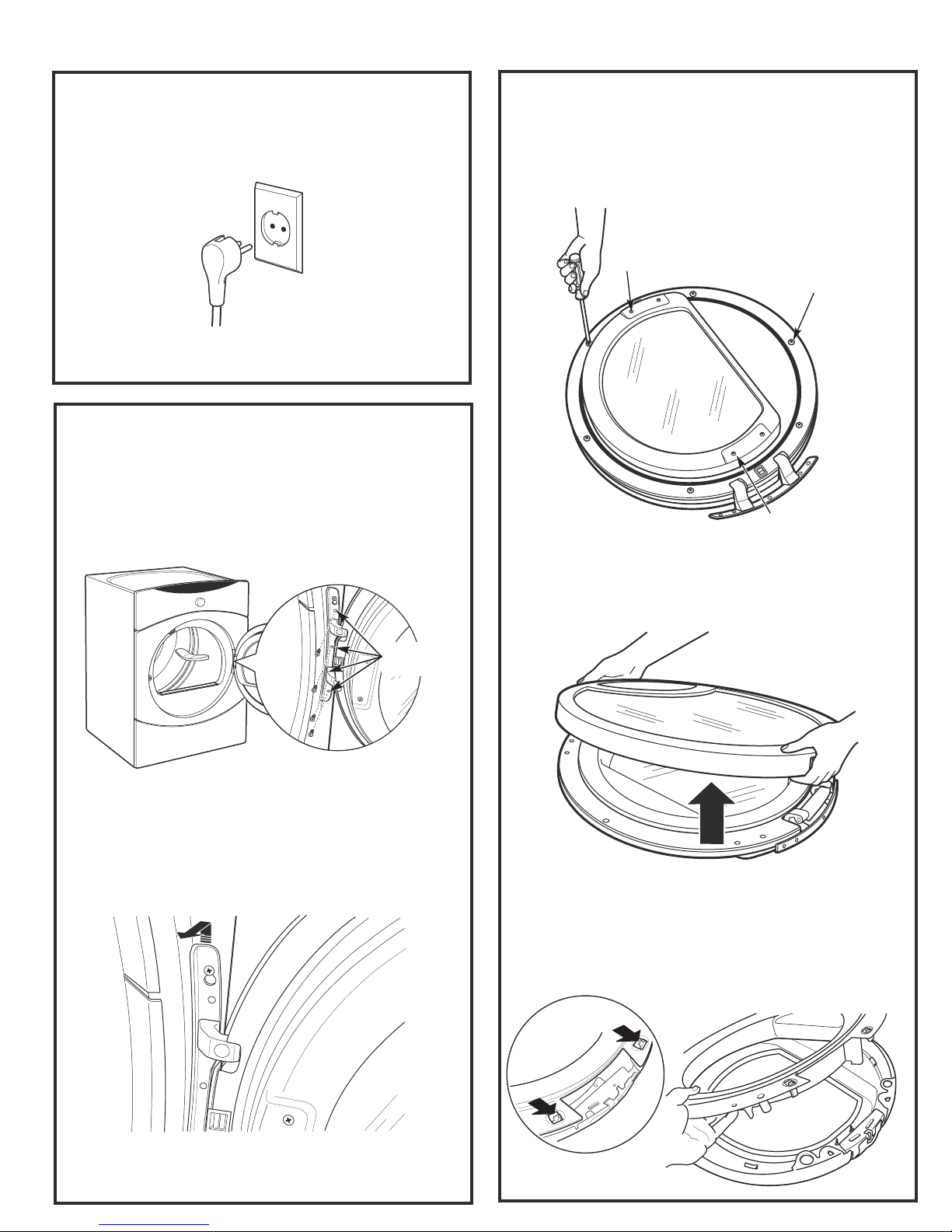

1. Turn off the circuit breaker(s) (30 amp) or remove the dryer’s

circuit fuse at the electrical box.

2. Be sure the dryer cord is unplugged from the wall receptacle.

3. Remove the power cord cover located at the lower back.

4. Remove and discard ground strap. Keep the green ground screw

for step 7.

5. Install 3/4 in. UL recognized strain relief to power cord entry hole.

Bring power cord through strain relief.

6. Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws of the terminal

block (marked L1 and L2).

B. Connect the neutral (white) line to the center of the terminal

block (marked N).

7. Attach ground wire of power cord with the green ground screw

(hole above strain relief bracket). Tighten all terminal block

screws (3) completely.

8. Properly secure power cord to strain relief.

9. Reinstall the cover.

WARNING - NEVER LEAVE THE

COVER OFF OF THE TERMINAL BLOCK.

CONNECTING DRYER USING 3-WIRE

CONNECTION

1. Turn off the circuit breaker(s) (30 amp) or remove the dryer’s

circuit fuse at the electrical box.

2. Be sure the dryer cord is unplugged from the wall.

3. Remove the power cord cover located at the lower back.

4. Install 3/4 in. UL recognized strain relief to power cord entry

hole. Bring power cord through strain relief.

5. Connect power cord as follows:

A. Connect the 2 hot lines to the outer screws of the terminal

block (marked L1 and L2).

B. Connect the neutral (white) line to the center of the terminal

block (marked N).

6. Be sure ground strap is connected to neutral (center) terminal of

block and to green ground screw on cabinet rear. Tighten all

terminal block screws (3) completely.

7. Properly secure power cord to strain relief.

8. Reinstall the cover.

WARNING - NEVER LEAVE THE

COVER OFF OF THE TERMINAL BLOCK.

EXHAUST SYSTEM CHECKLIST

HOOD OR WALLCAP

•Terminate in a manner to prevent back drafts or entry of birds or

other wildlife.

•Termination should present minimal resistance to the exhaust air flow

and should require little or no maintenance to prevent clogging.

•Never install a screen in or over the exhaust duct. This could cause lint

build up.

•Wall caps must be installed at least 12 in. above ground level or any

other obstruction with the opening pointed down.

SEPARATION OF TURNS

For best performance, separate all turns by at least 4 ft. of straight duct,

including distance between last turn and exhaust hood.

TURNS OTHER THAN 90¼

•One turn of 45¼ or less may be ignored.

•Two 45¼ turns should be treated as one 90¼ turn.

•Each turn over 45¼ should be treated as one 90¼ turn.

SEALING OF JOINTS

•All joints should be tight to avoid leaks. The male end of each section of

duct must point away from the dryer.

•The duct shall not be assembled with screws or other fastening means

that extend into the duct and catch lint.

•Duct joints can be made air and moisture-tight by wrapping the

overlapped joints with duct tape.

•Horizontal runs should slope down toward the outdoors 1/2 inch per foot.

INSULATION

Duct work that runs through an unheated area or is near air conditioning

should be insulated to reduce condensation and lint build-up.

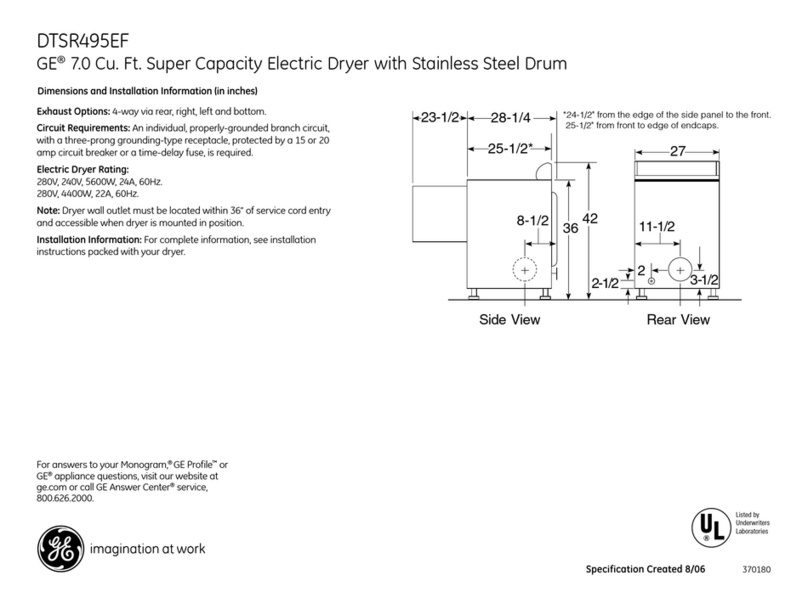

4" DIA.

4"

4" DIA.

4" DIA.

2-1/2"

RECOMMENDED MAXIMUM LENGTH

Exhaust Hood Types

Recommended

No. of 90°

Elbows Rigid

Metal Rigid

Metal

90 Feet

60 Feet

45 Feet

35 Feet

25 Feet

60 Feet

45 Feet

35 Feet

25 Feet

15 Feet

0

1

2

3

4

Use only for short

run installations

EXHAUST LENGTH

WARNING - IN CANADA AND IN THE UNITED STATES,

THE REQUIRED EXHAUSTDUCT DIAMETER IS 4 IN (102mm).

Remove and discard existing plastic or metal foil transition duct

and replace with UL listed transition duct.