– 3 –

Air Duct Assembly ............................................................................................................................................................34

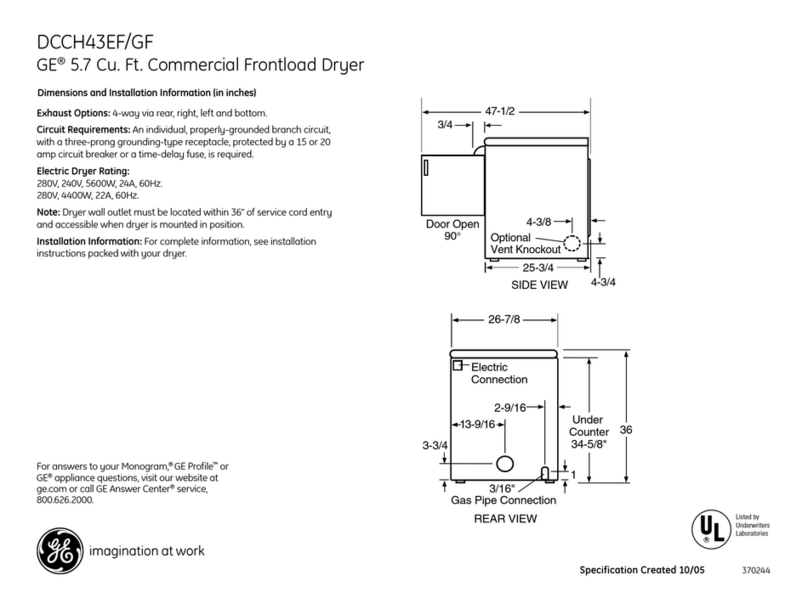

Airflow ....................................................................................................................................................................................27

Belt Switch............................................................................................................................................................................39

Blower Motor ......................................................................................................................................................................40

Blower Wheel......................................................................................................................................................................42

Burner Assembly and LP Conversion......................................................................................................................46

Component Locator Views...........................................................................................................................................28

Control Board Assembly ...............................................................................................................................................54

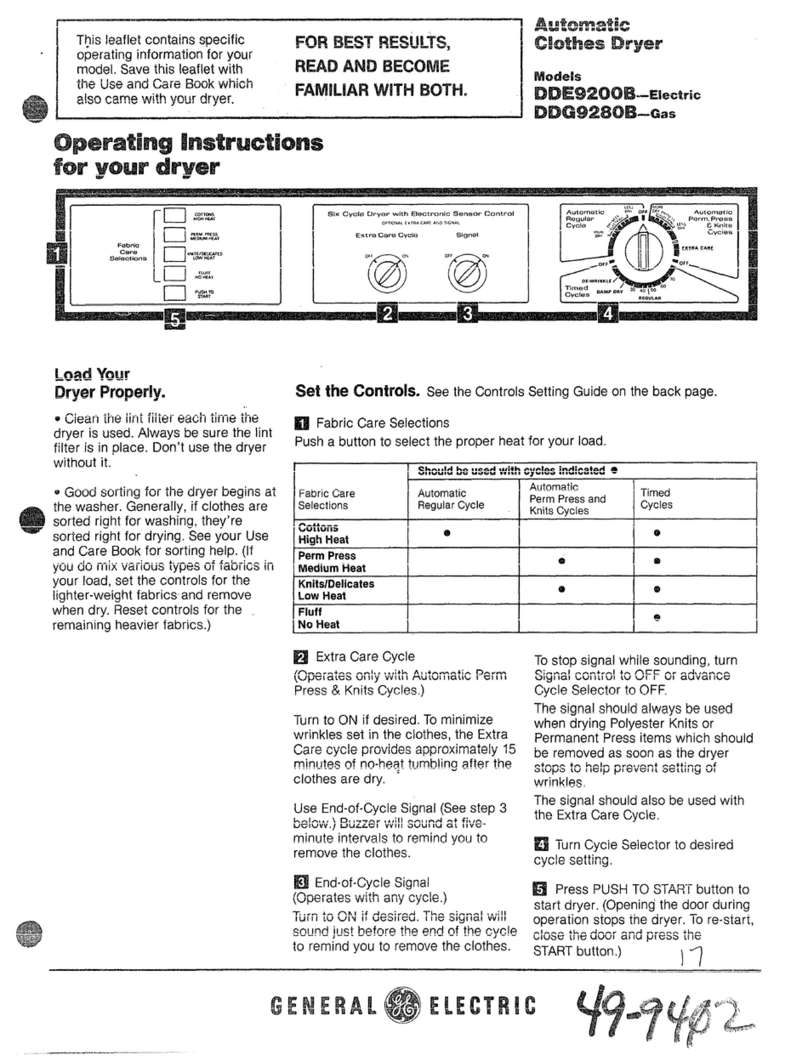

Control Features............................................................................................................................................................... 6

Control Panel.......................................................................................................................................................................32

Cycle Options......................................................................................................................................................................10

Display Board.....................................................................................................................................................................55

Door Switch ......................................................................................................................................................................... 35

Drive Belt...............................................................................................................................................................................36

Drum.......................................................................................................................................................................................37

Drum Motor.........................................................................................................................................................................39

Drum Shaft and Bearing................................................................................................................................................38

Drum Slide Assembly......................................................................................................................................................34

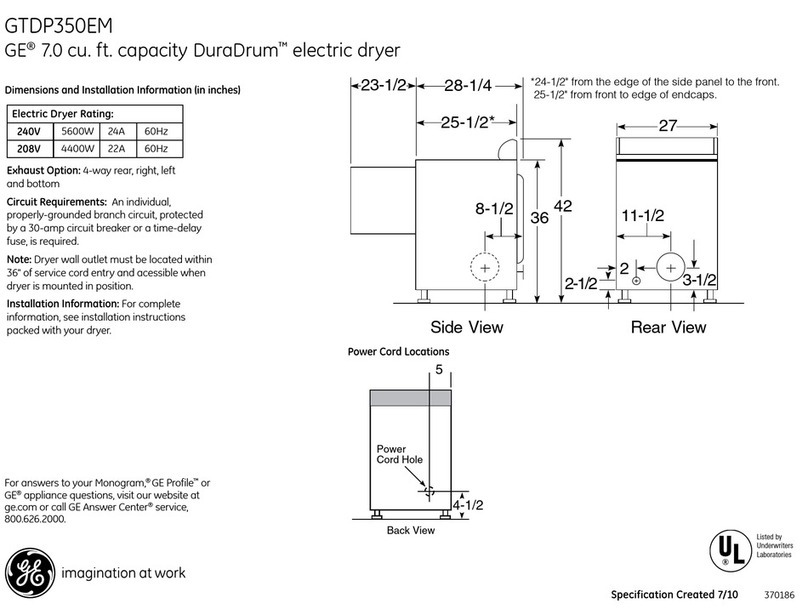

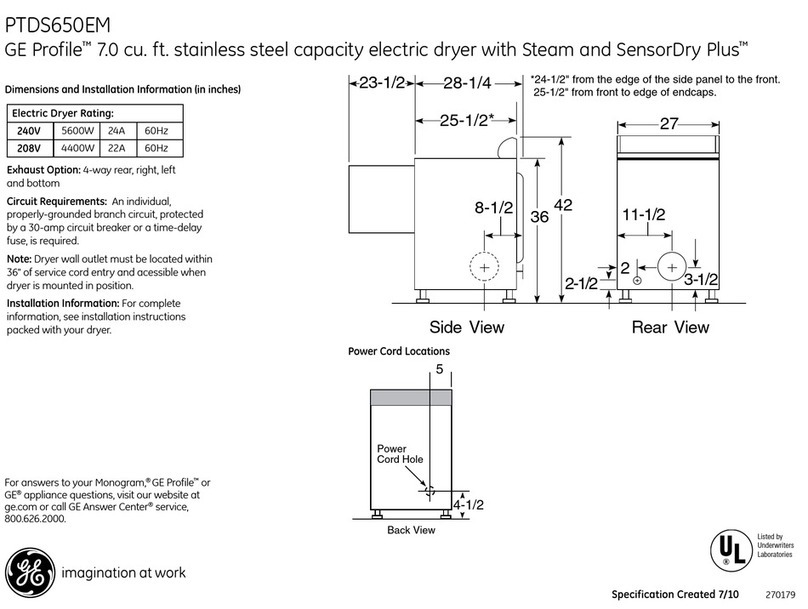

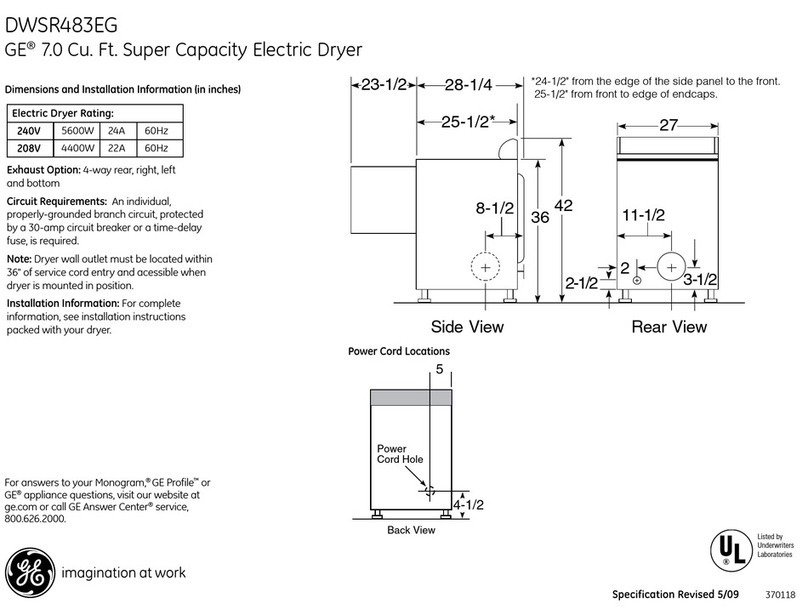

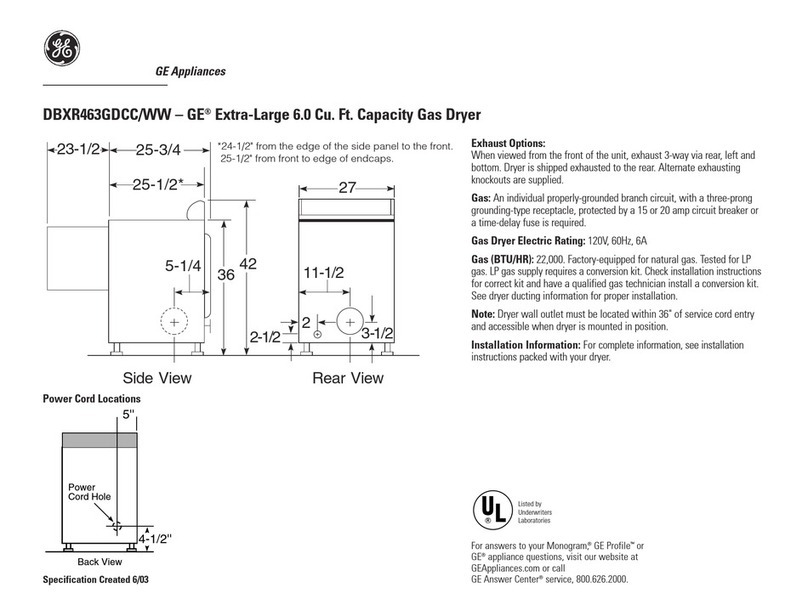

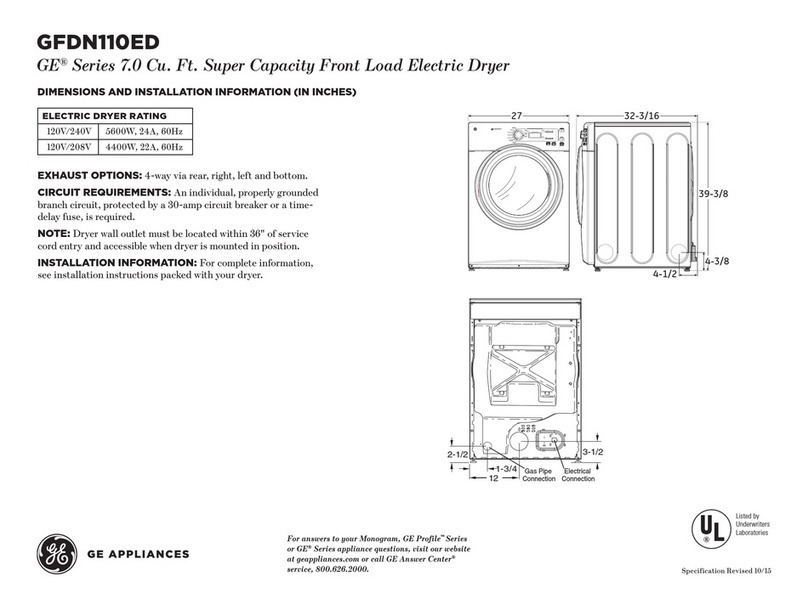

Dryer Components...........................................................................................................................................................32

Dryer Features...................................................................................................................................................................12

Dual Idler Assembly.........................................................................................................................................................38

Error Codes .......................................................................................................................................................................... 60

Flame Detector ..................................................................................................................................................................48

Front Panel...........................................................................................................................................................................33

Fuses.......................................................................................................................................................................................36

Gas Valve..............................................................................................................................................................................47

Gas Valve Coils...................................................................................................................................................................46

Heater Assembly...............................................................................................................................................................43

High Limit Thermostat....................................................................................................................................................52

Ignitor.....................................................................................................................................................................................48

Ignitor Circuit Operation................................................................................................................................................49

Inlet Control Thermistor.................................................................................................................................................51

Inlet Safety Thermostat.................................................................................................................................................51

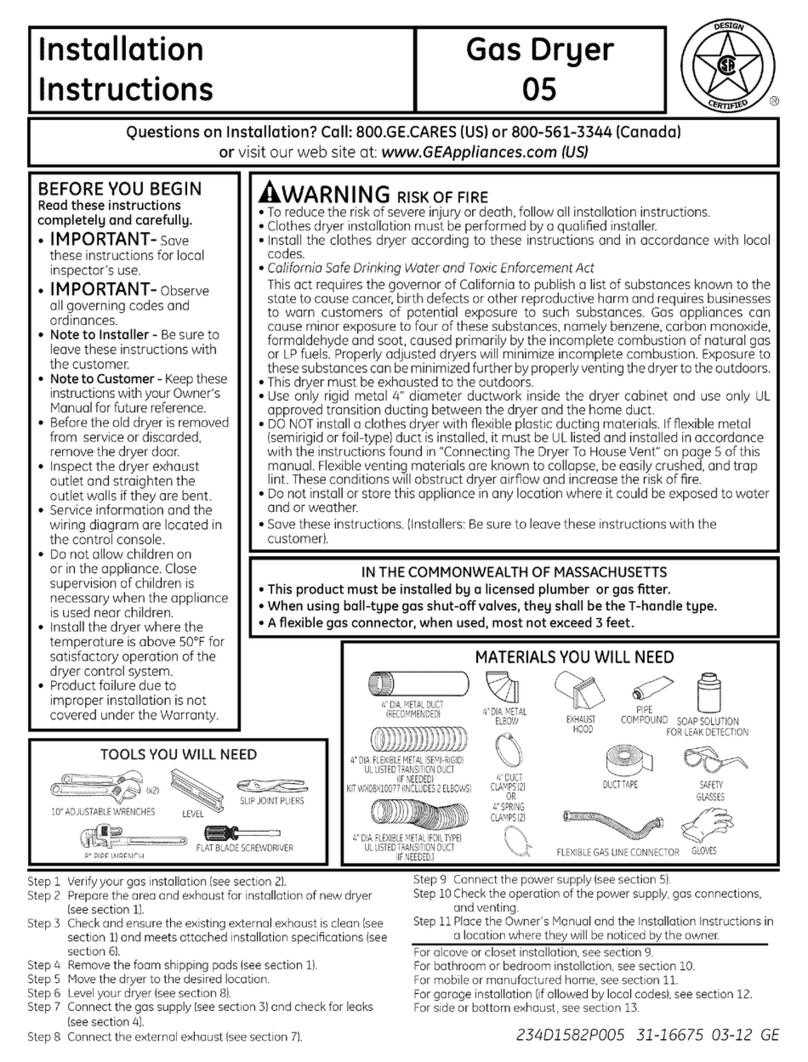

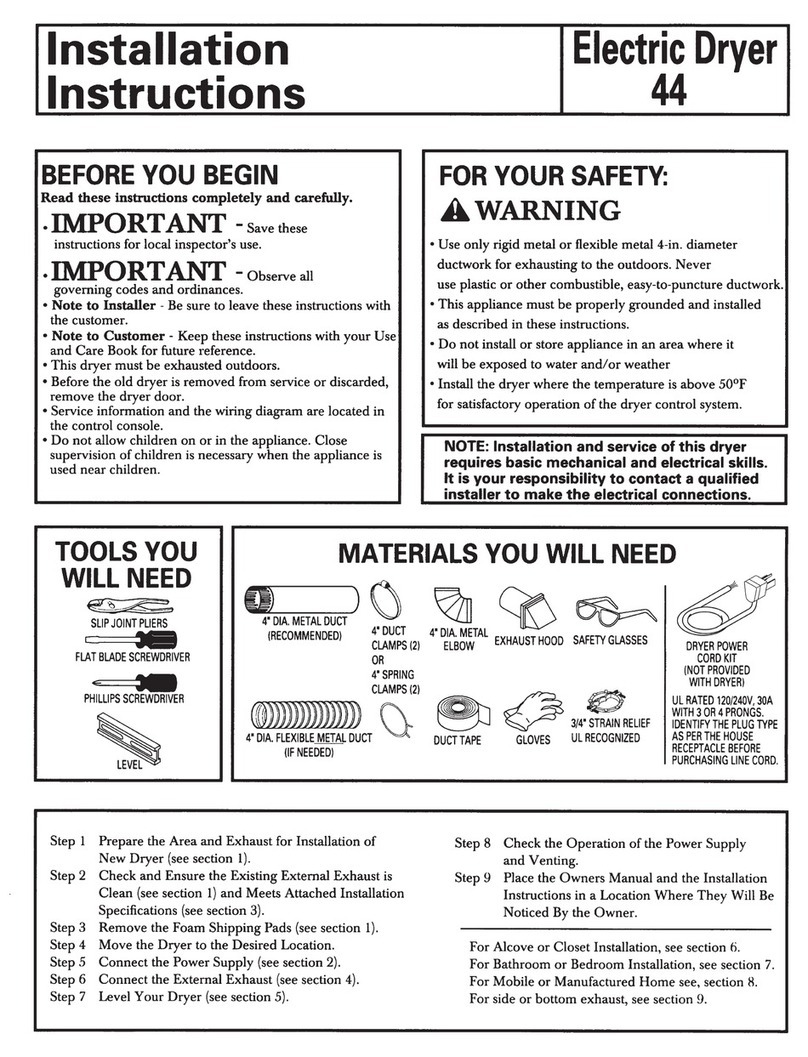

Introduction......................................................................................................................................................................... 5

Moisture Sensor ................................................................................................................................................................35

Nomenclature .................................................................................................................................................................... 4

Operation Overview.........................................................................................................................................................26

Outlet Control Backup Thermostat...........................................................................................................................53

Outlet Control Thermistor .............................................................................................................................................52

Pedestal Installation (Washer and Dryer)..............................................................................................................20

Power Board........................................................................................................................................................................54

Power Board Connector Locator View....................................................................................................................30

Rack Dry Calrod®Element ...........................................................................................................................................50

Rack Dry Thermostat......................................................................................................................................................53

Reversing the Door Swing ............................................................................................................................................14

Sales Demo Mode.............................................................................................................................................................11

Schematics and Wiring Diagrams............................................................................................................................63

Service Test Mode.............................................................................................................................................................56

Stacking Instructions ......................................................................................................................................................23

Top Panel ..............................................................................................................................................................................33

Triac.........................................................................................................................................................................................43

Troubleshooting ................................................................................................................................................................56

Warranty ..............................................................................................................................................................................68

Table of Contents