5

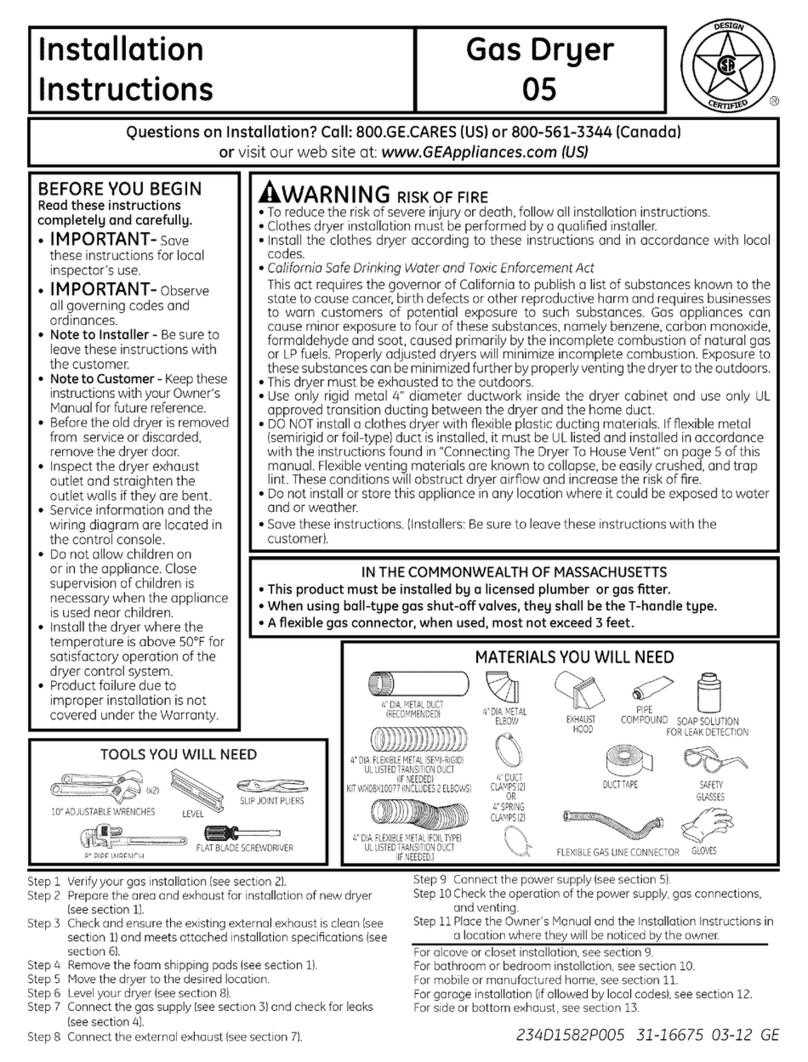

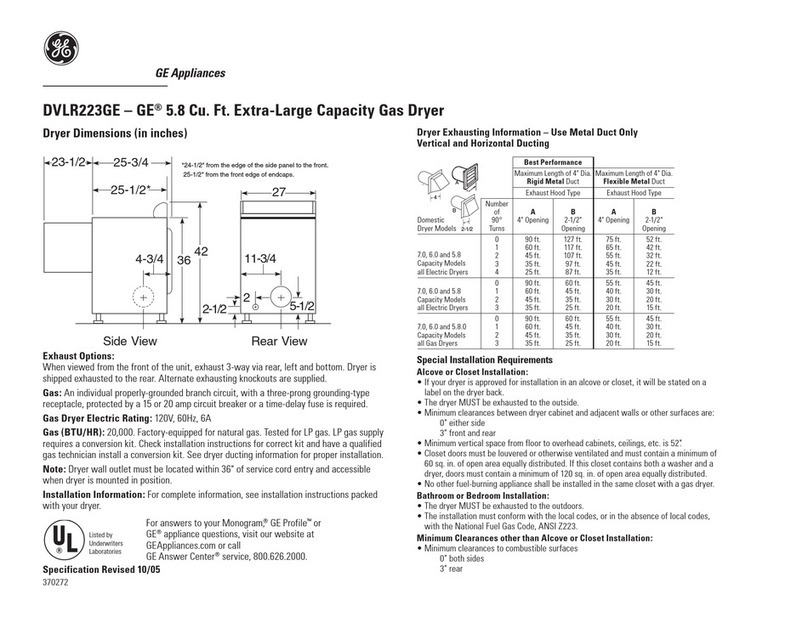

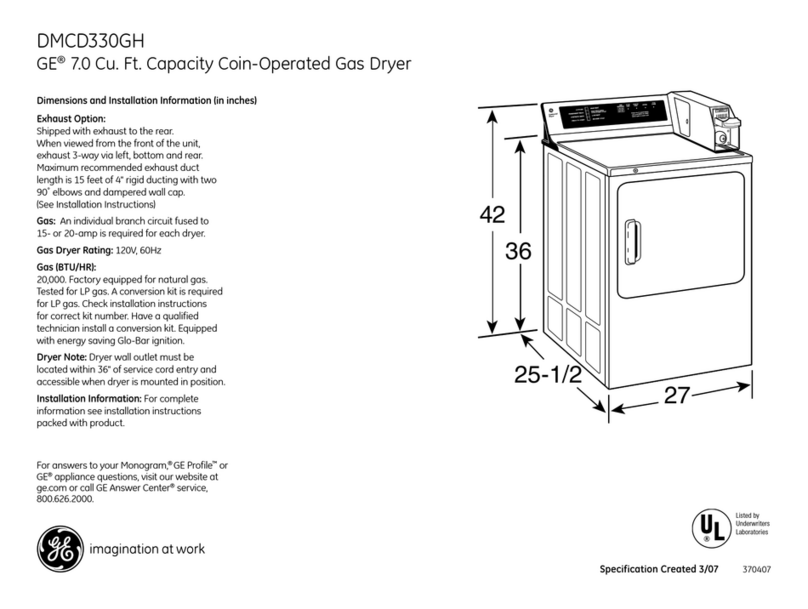

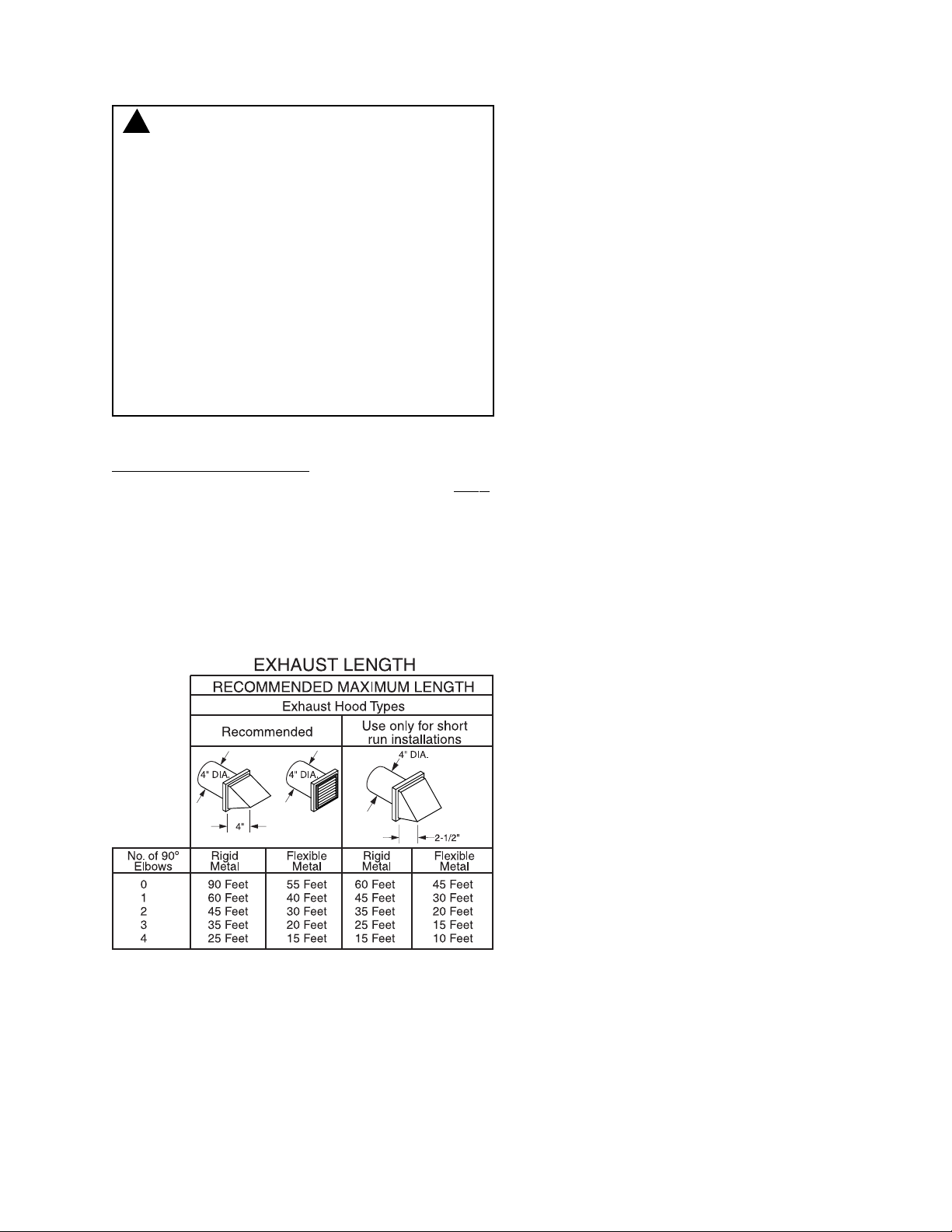

EXHAUSTING:

NOTE: The correct exhaust installation is

YOUR RESPONSIBILITY.

Problems due to incorrect installation are NOT

covered in the warranty.

The MAXIMUM ALLOWABLE length of the ex-

haust system depends upon the type of duct,

number of turns, the type of exhaust hood (wall

cap), and all conditions noted below. Both rigid

and flexible metal are shown in the chart below.

EXHAUST SYSTEM CHECK LIST

HOOD OR WALL CAP

-Terminate in a manner to prevent back drafts or

entry of birds or other wildlife.

-Termination should present minimal resistance to

the exhaust air flow and should require little or no

maintenance to prevent clogging.

-NEVER install a screen in or over the exhaust

duct. This could cause lint build up.

-Wall caps must be installed at least 12 in. above

ground level or any other obstructions with the

opening pointing down.

-If roof vents or louvered plenums are used, they

must be equivalent to a 4-in. dampened wall cap

in regard to resistance to air flow, prevention of

back drafts, and maintenance requied to prevent

clogging.

SEPARATION OF TURNS:

-For best performance, separate all turns with at

least 4 ft. of straight duct., including distance

between last turn and exhaust hood.

TURNS OTHER THAN 900

-One turn of 450or less may be ignored

-Two 450 turns should be treated as one 900 turn.

-Each turn over 450 shold be treated as one 900

turn.

SEALING OF JOINTS

-All joints should be tight to avoid leaks. The male

lend of each section of duct must point away from

dryer.

-Do not assemble the ductwork with fasterners

that extend into the duct. They will serve to collect

lint.

-Duct joints can be made air tight by wrapping the

overlapped joints with duct tape.

-Horizontal runs should slope down toward the

outdoors 1/2 in. per foot.

INSULATION:

Duct work that runs through an unheated area or

is near air conditioning, should be insulated to

reduce condensation and lint build-up.

WARNING! - TO REDUCE THE RISK

OF FIRE OR PERSONAL INJURY:

-Exhausting the dryer to the outdoors is strongly

recommended to prevent large amounts of moisture

from being blown into the room.

-Use only metal duct.

-Do not terminate exhaust in a chimney, any gas vent,

under an enclosed door (crawl space), or into an

attic. The accumulated lint could create a fire

hazard.

-Provide an access for inspection and cleaning of the

exhaust system, especially at turns. Inspect and

clean at least once a year.

-Never terminate the exhaust into a common duct with

kitchen exhaust. A combination of lint and grease

could create a fire hazard.

-Do not obstruct incoming or exhausted air.

!