6

9

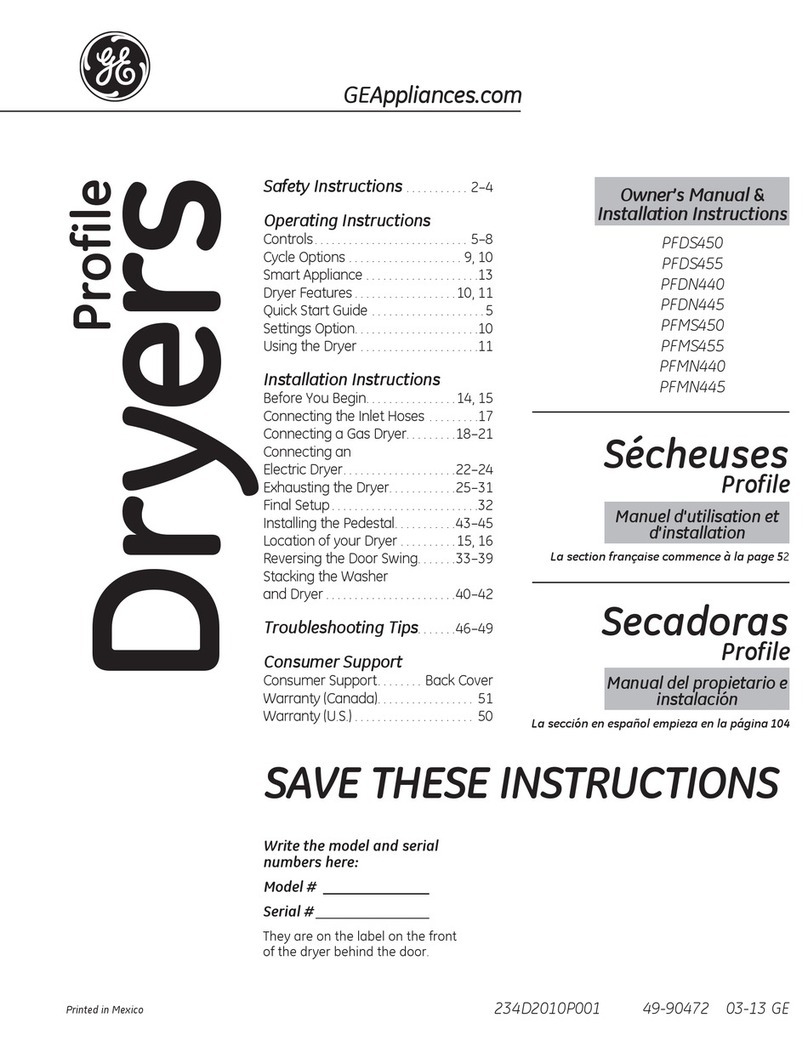

ALCOVE OR CLOSET INSTALLATION

10

BATHROOM OR BEDROOM

INSTALLATION

11

MOBILE OR MANUFACTURED

HOME INSTALLATION

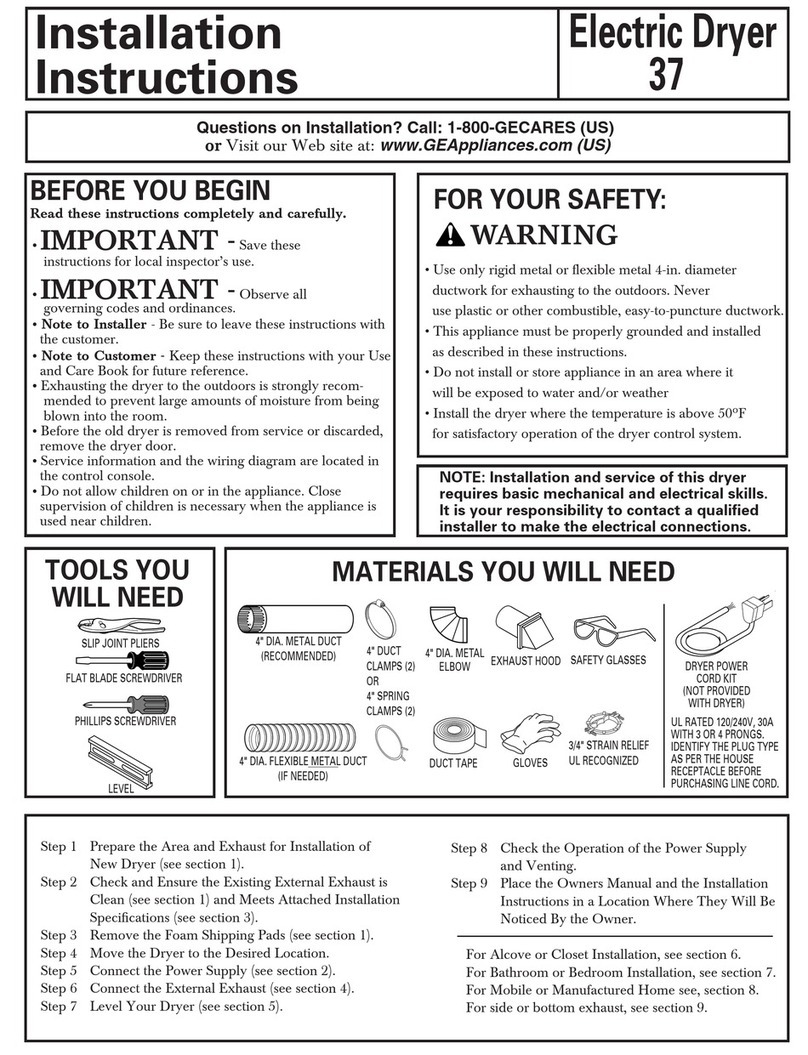

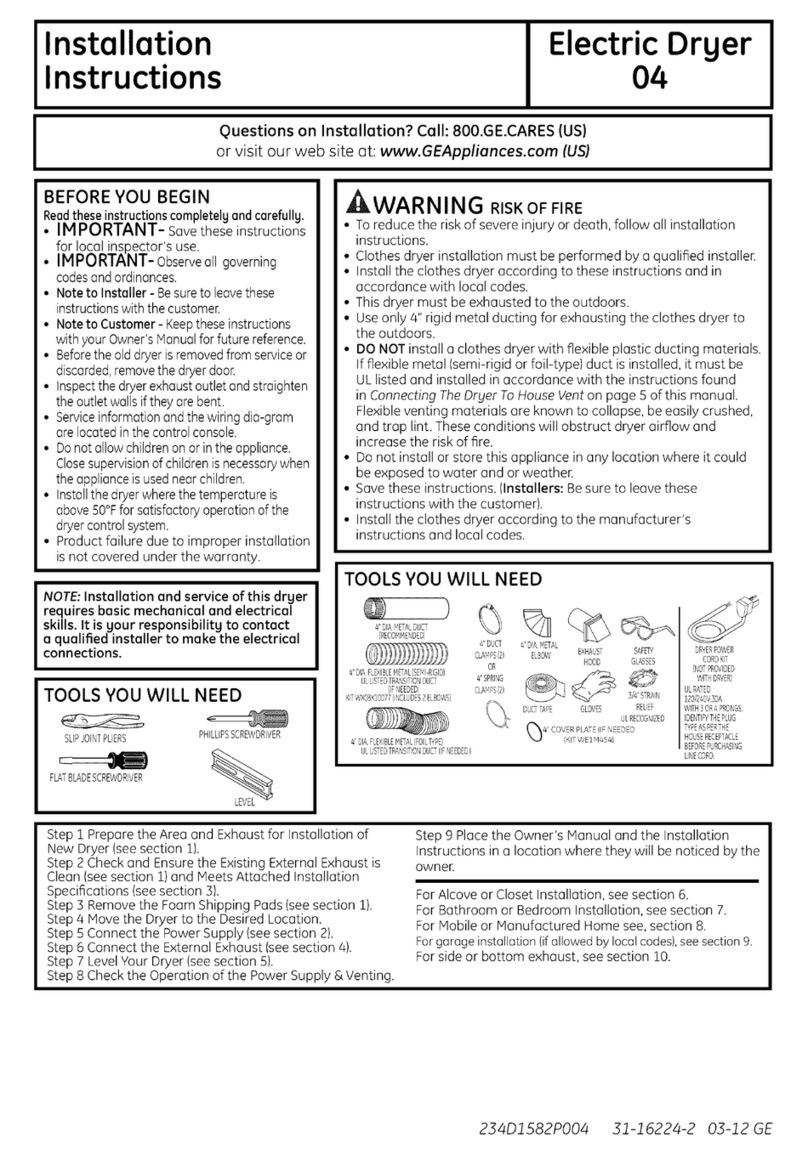

Installation Instructions

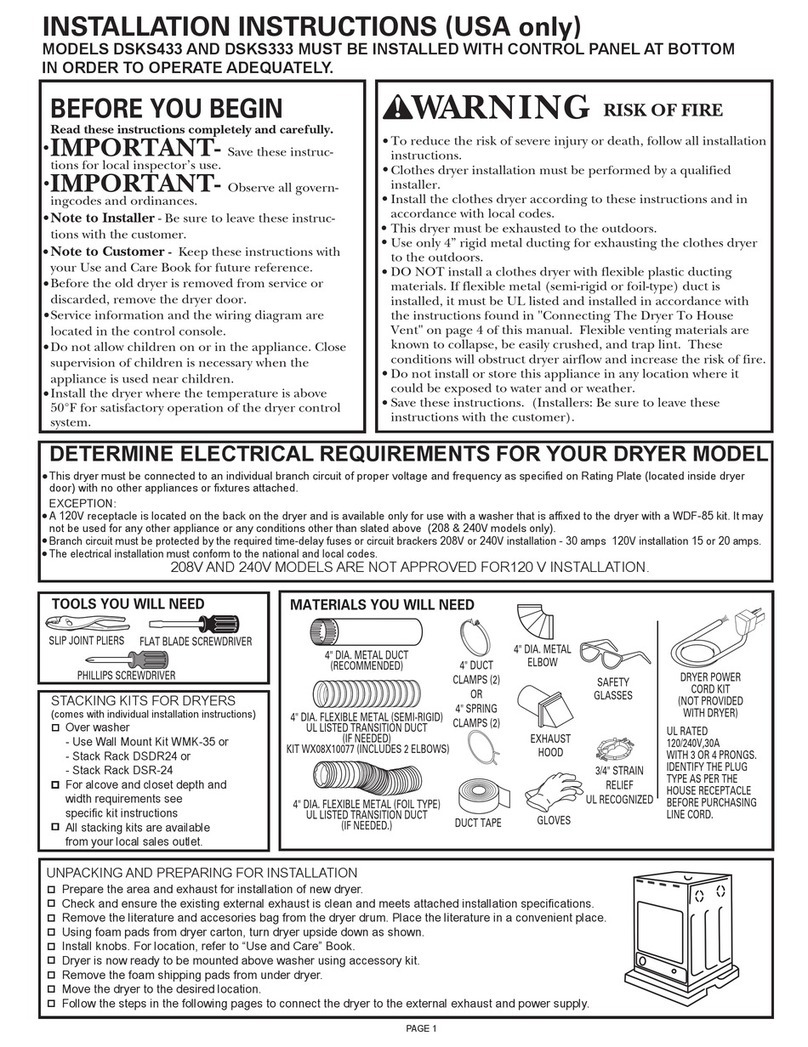

If rigid all-metal duct cannot be used, then flexible all-metal

venting can be used, but it will reduce the maximum

recommended duct length. In special installations when it is

impossible to make connection with the above recommendations,

then UL-listed clothes dryer transition duct may be used as

transition venting between the dryer and wall connection only. The

use of this ducting will affect dry time.

If flexible transition duct is necessary, the following directions must

be followed.

•Use the Shortest Length Possible.

•Stretch the Duct to Its Maximum Length.

•Do Not Crush or Collapse.

•Never Use Transition Duct Inside the Wall or

Inside the Dryer.

•Avoid Resting the Duct on Sharp Objects.

•Venting Must Conform to Local Building Codes.

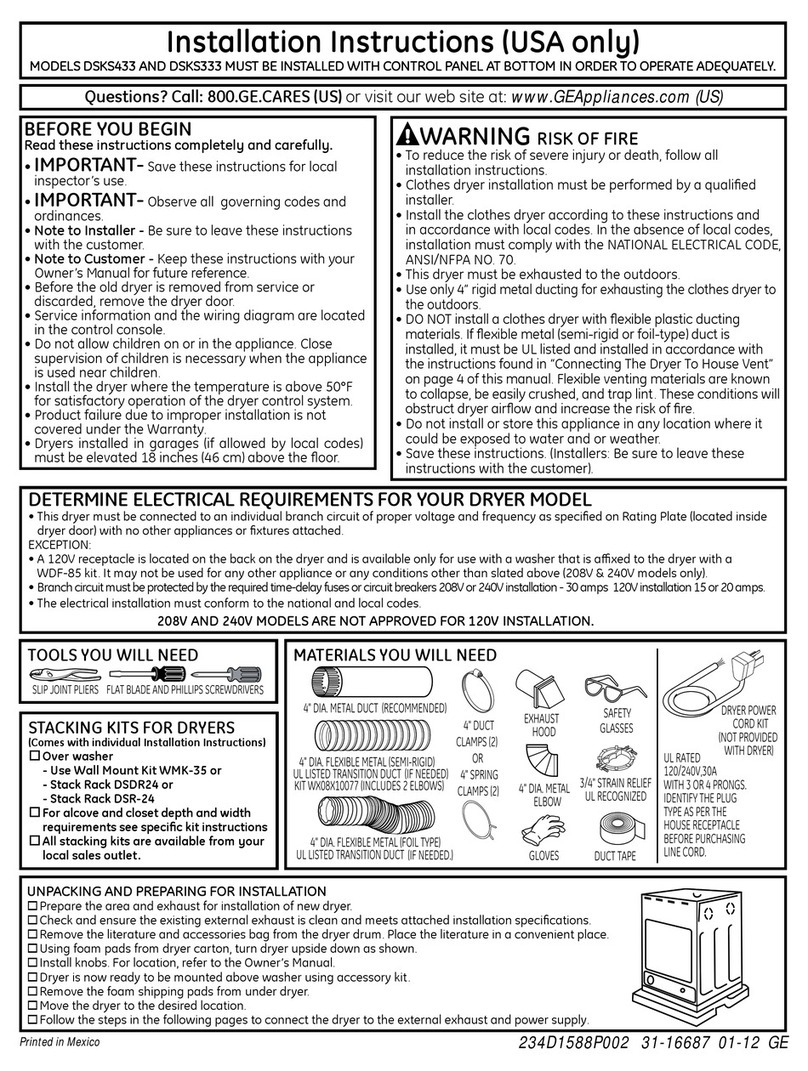

USING FLEXIBLE METAL DUCTS

ELBOWS HIGHLY

RECOMMENDED

ELBOW HIGHLY

RECOMMENDED

DO NOT

SIT DRYER

ON FLEXIBLE

EXHAUST.

DO NOT USE

EXCESSIVE

EXHAUST

LENGTH

DO NOT

CRUSH

FLEXIBLE

EXHAUST

AGAINST

WALL.

•If your dryer is approved for installation in an alcove or

closet, it will be stated on a label on the dryer back.

•The dryer MUST be vented to the outdoors. See the

EXHAUST INFORMATION section.

•Minimum clearance between dryer cabinet and adjacent

walls or other surfaces is:

0 in. either side

3 in. front and rear

•Minimum vertical space from floor to overhead cabinets,

ceiling, etc. is 52 in.

•Closet doors must be louvered or otherwise ventilated and

must contain a minimum of 60 sq. in. of open area equally

distributed. If the closet contains both a washer and a

dryer, doors must contain a minimum of 120 sq. in. of open

area equally distributed.

•The closet should be vented to the outdoors to prevent gas

pocketing in case of a gas leak in the supply line.

•No other fuel-burning appliance shall be installed in the

same closet with the dryer.

•The dryer MUST be vented to the outdoors. See

EXHAUST INFORMATION section 6.

•The installation must conform with local codes or, in the

absence of local codes, with the NATIONAL FUEL GAS

CODE, ANSI Z223.

•Installation must conform to the MANUFACTURED

HOME CONSTRUCTION & SAFETY STANDARD,

TITLE 24, PART 32-80 or, when such standard is not

applicable, with AMERICAN NATIONAL STANDARD

FOR MOBILE HOME, NO. 501B.

•The dryer MUST be vented to the outdoors with the

termination securely fastened to the mobile home

structure. (See EXHAUST INFORMATION section 6.)

•The vent MUST NOT be terminated beneath a mobile or

manufactured home.

•The vent duct material MUST BE METAL.

•KIT 14-D346-33 MUST be used to attach the dryer

securely to the structure.

•The vent MUST NOT be connected to any other duct,

vent, or chimney.

•Do not use sheet metal screws or other refastening

devices which extend into the interior of the exhaust vent.

•Provide an opening with a free area of at least 25 sq. in.

for introduction of outside air into the dryer room.

DO

DON’T