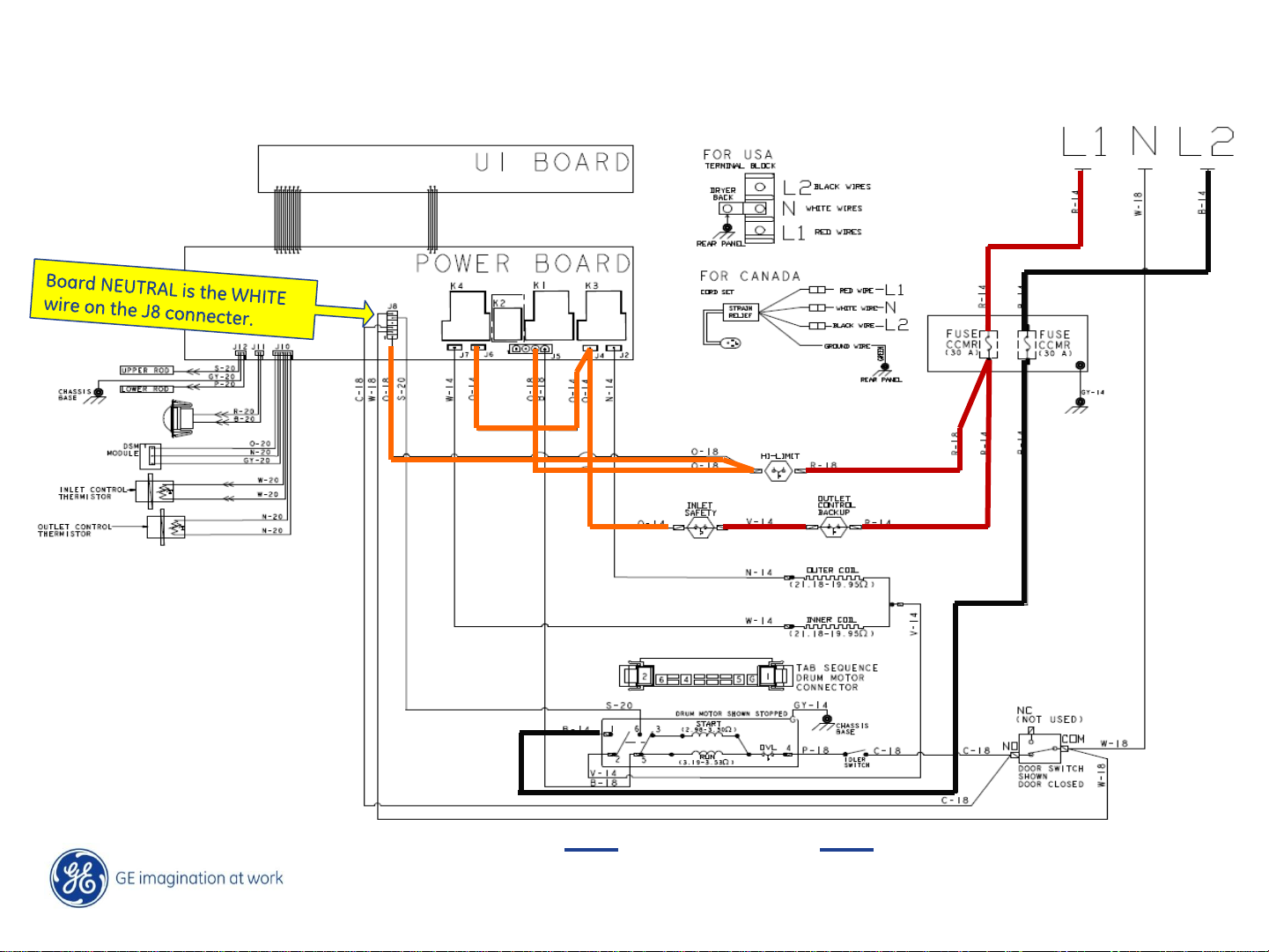

GE GTDP740EDWW User manual

Other GE Dryer manuals

GE

GE 364B7130P001 User manual

GE

GE DDE7100R User manual

GE

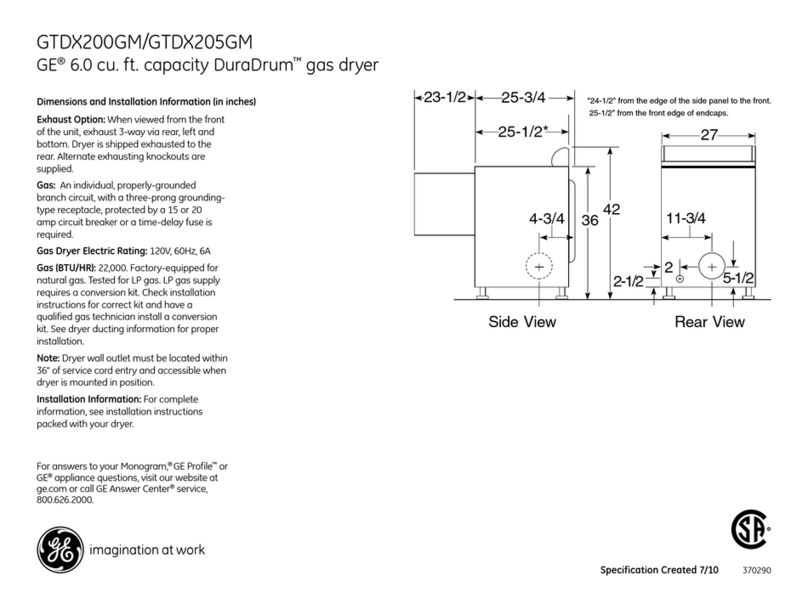

GE DuraDrum GTDX200GM Manual

GE

GE GTDS855ED0MC User manual

GE

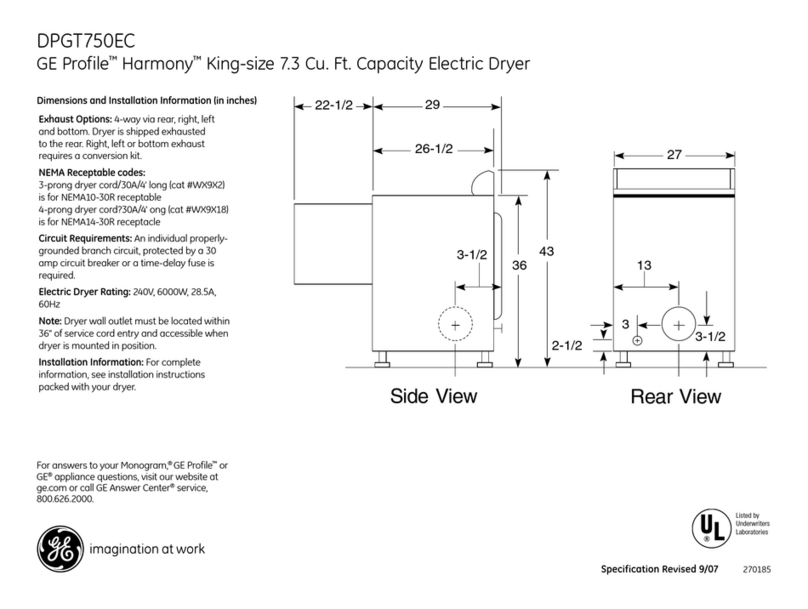

GE Profile Harmony DPGT750EC Manual

GE

GE DMCD330EJ3WC User manual

GE

GE Spacemaker DSXH43 User manual

GE

GE PCVH485EK Original instructions

GE

GE GTD75ECSL1WS User manual

GE

GE DDE5211 Installation instructions

Popular Dryer manuals by other brands

Alliance Laundry Systems

Alliance Laundry Systems TMB795C Installation

Asko

Asko T793C operating instructions

Kenmore

Kenmore 8041 - 5.8 cu. Ft. Capacity Electric Dryer installation instructions

Frigidaire

Frigidaire CAQE7077KW0 use & care

Bosch

Bosch WTX8HKM9SN User manual and installation instructions

Sharp

Sharp KD-NHH9S7GW2-PL user manual