– 3 –

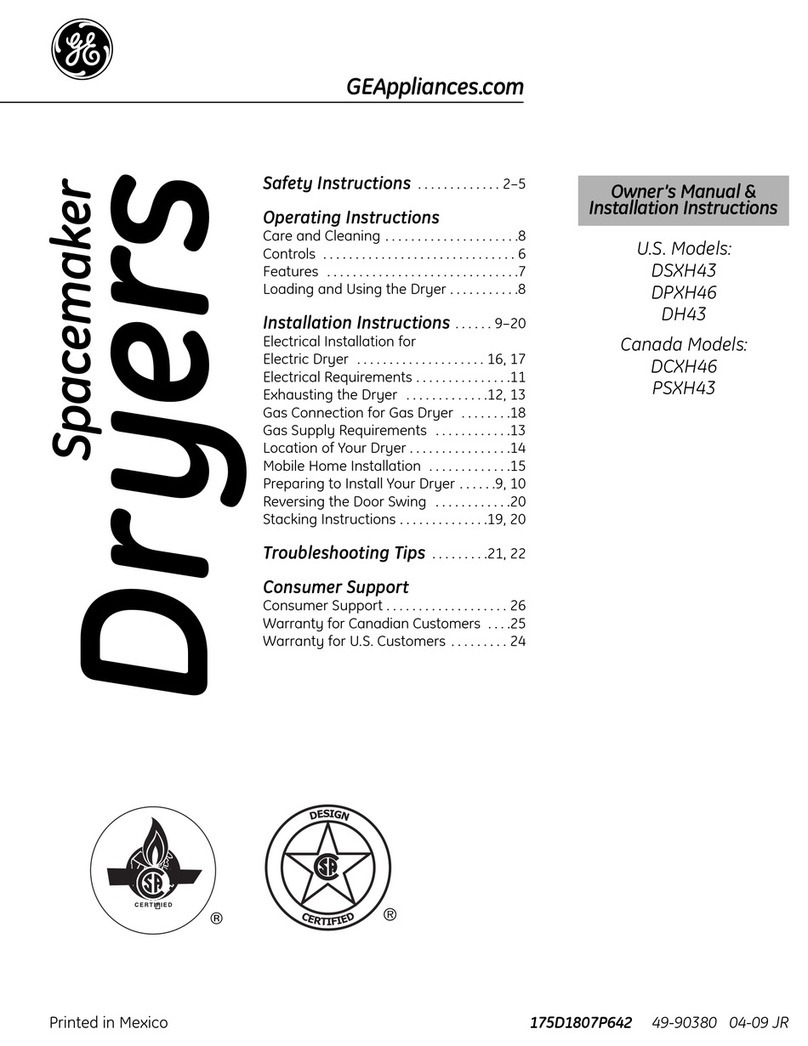

Table of Contents

Airflow ...............................................................................................................................................................................20

Auto Reset Thermostat .............................................................................................................................................37

Back Cover......................................................................................................................................................................34

Base ...................................................................................................................................................................................44

Belt Switch.......................................................................................................................................................................42

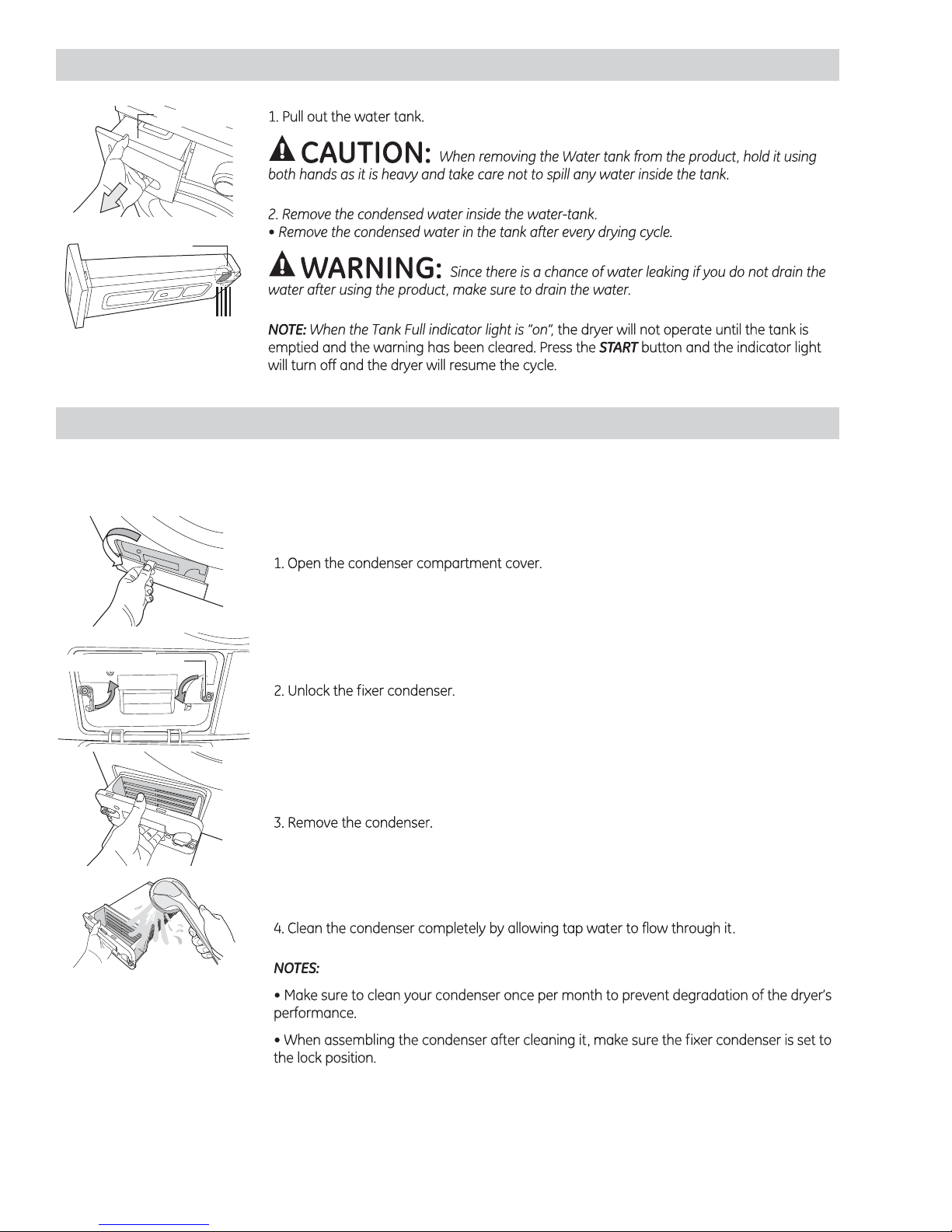

Cleaning the Condenser...........................................................................................................................................10

Component Locator Views......................................................................................................................................23

Condensate Pump.......................................................................................................................................................35

Condensation ................................................................................................................................................................22

Connecting the Drain Hose.....................................................................................................................................12

Control Board.................................................................................................................................................................29

Control Board Connections.....................................................................................................................................27

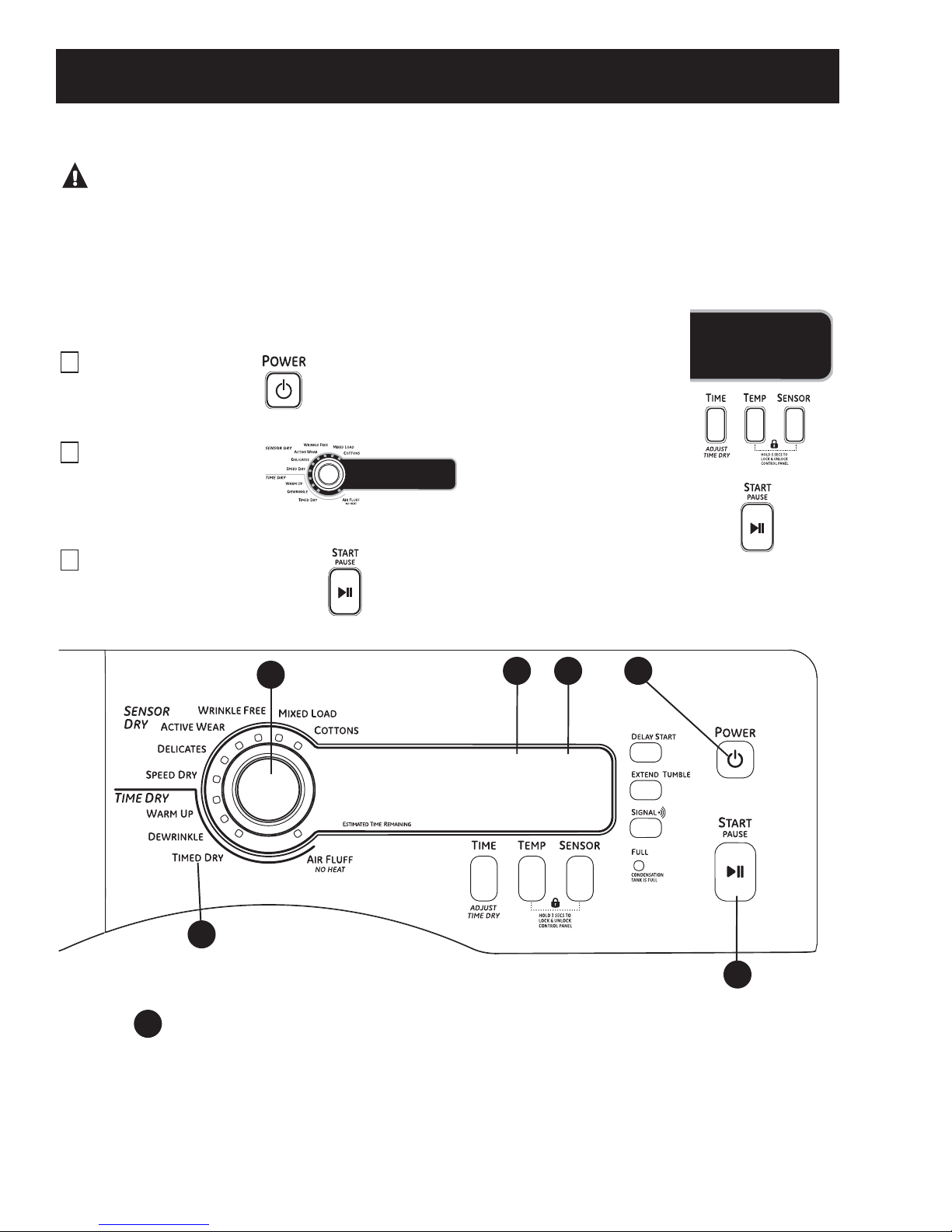

Control Features............................................................................................................................................................. 6

Control Panel ................................................................................................................................................................28

Cycle Options................................................................................................................................................................... 9

Door Switch ....................................................................................................................................................................31

Drum and Bearing.......................................................................................................................................................41

Drum Belt.........................................................................................................................................................................39

Drum Lamp Assembly...............................................................................................................................................31

Drum Rollers...................................................................................................................................................................34

Drum Support Assembly..........................................................................................................................................32

Dryer Components......................................................................................................................................................28

Emptying the Water Tank........................................................................................................................................10

Error Codes .....................................................................................................................................................................47

Float Switch....................................................................................................................................................................36

Front Panel......................................................................................................................................................................30

Heater Assembly..........................................................................................................................................................37

Inlet Thermistor.............................................................................................................................................................38

Introduction...................................................................................................................................................................... 4

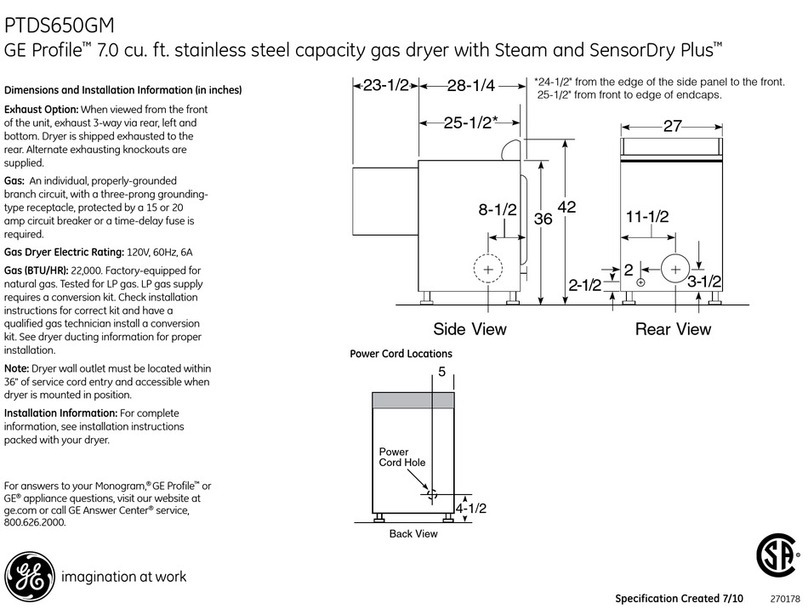

Location of the Dryer.................................................................................................................................................11

Manual Reset Thermostat .......................................................................................................................................38

Motor Assembly ...........................................................................................................................................................43

Nomenclature ................................................................................................................................................................. 5

Operation Overview....................................................................................................................................................19

Outlet Thermistor.........................................................................................................................................................32

Rear Blower Wheel......................................................................................................................................................39

Rear Drum Seal Assembly.......................................................................................................................................42

Reversing the Door Swing .......................................................................................................................................13

Schematics and Wiring Diagrams.......................................................................................................................48

Service Test Mode........................................................................................................................................................45

Stacking Instructions .................................................................................................................................................16

Top Cover.........................................................................................................................................................................28

Touch Sensors ..............................................................................................................................................................34

Troubleshooting ...........................................................................................................................................................45

Warranty .........................................................................................................................................................................49