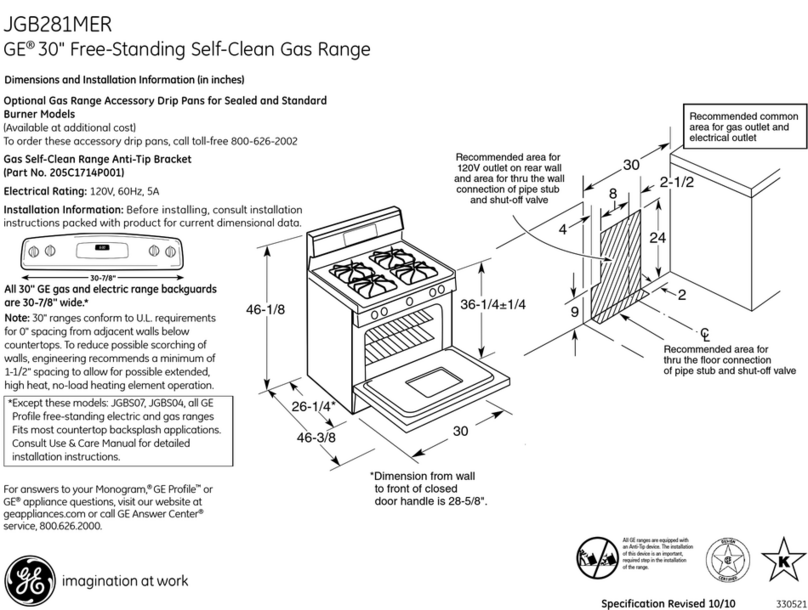

GE JGSP23 User manual

Other GE Range manuals

GE

GE JCP67FWW User manual

GE

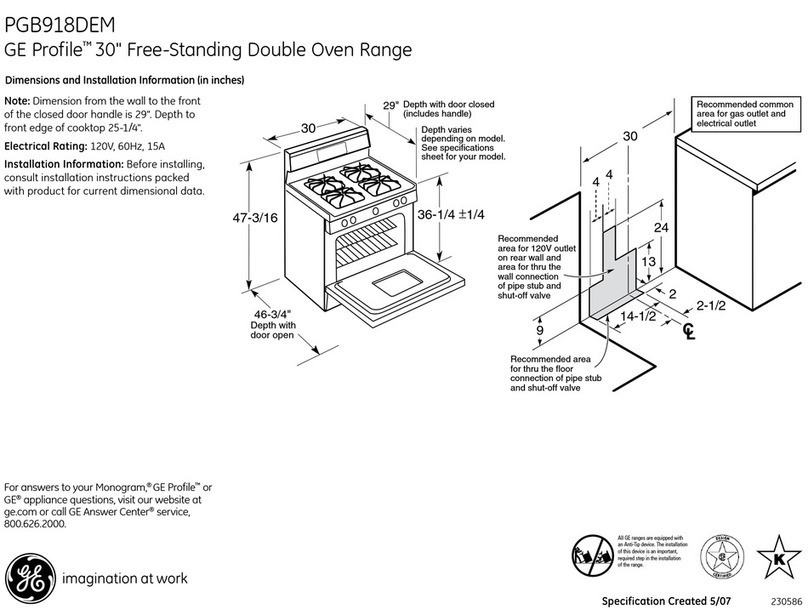

GE PGB918DEMBB - 30" Gas Ran DBLOVN Conv F/S... Manual

GE

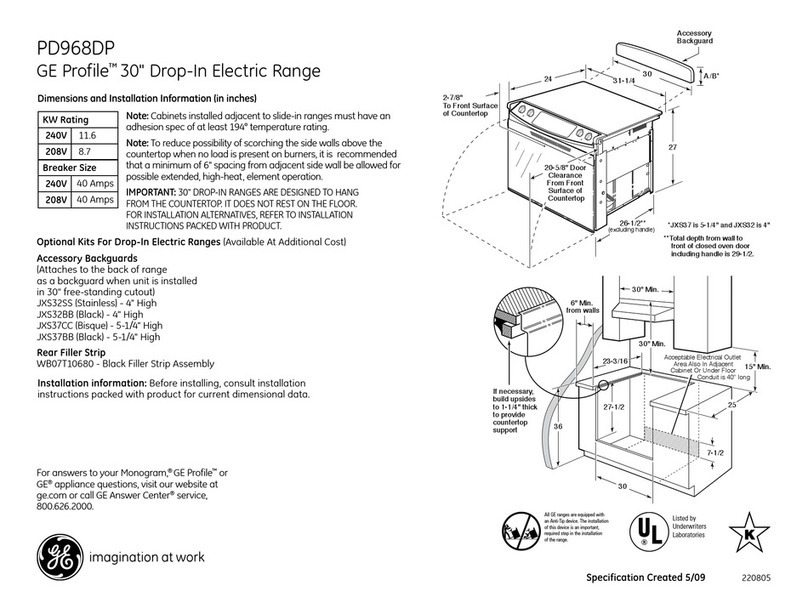

GE Profile PD968DP Manual

GE

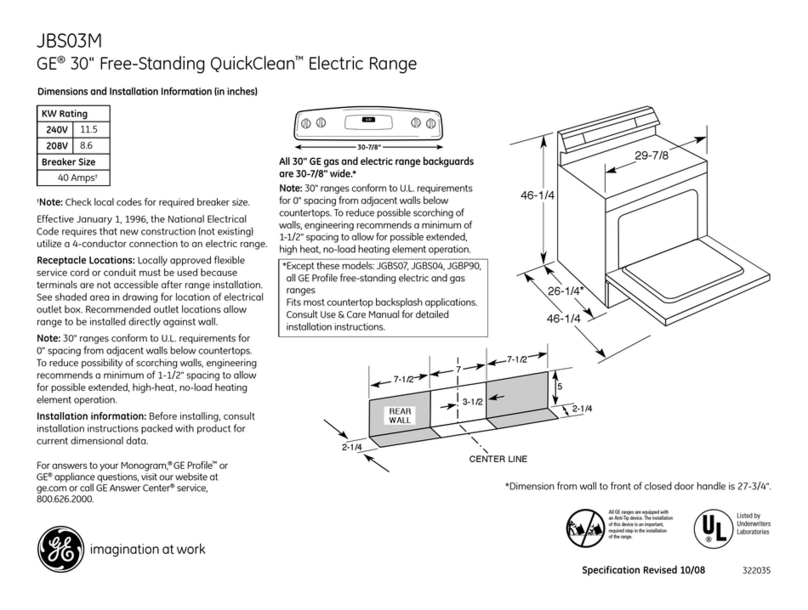

GE QuickClean JBS03MWH Manual

GE

GE JGBP33SEMSS Original instructions

GE

GE RGB530DEHBB User manual

GE

GE JCB560 User manual

GE

GE JXS76WW User manual

GE

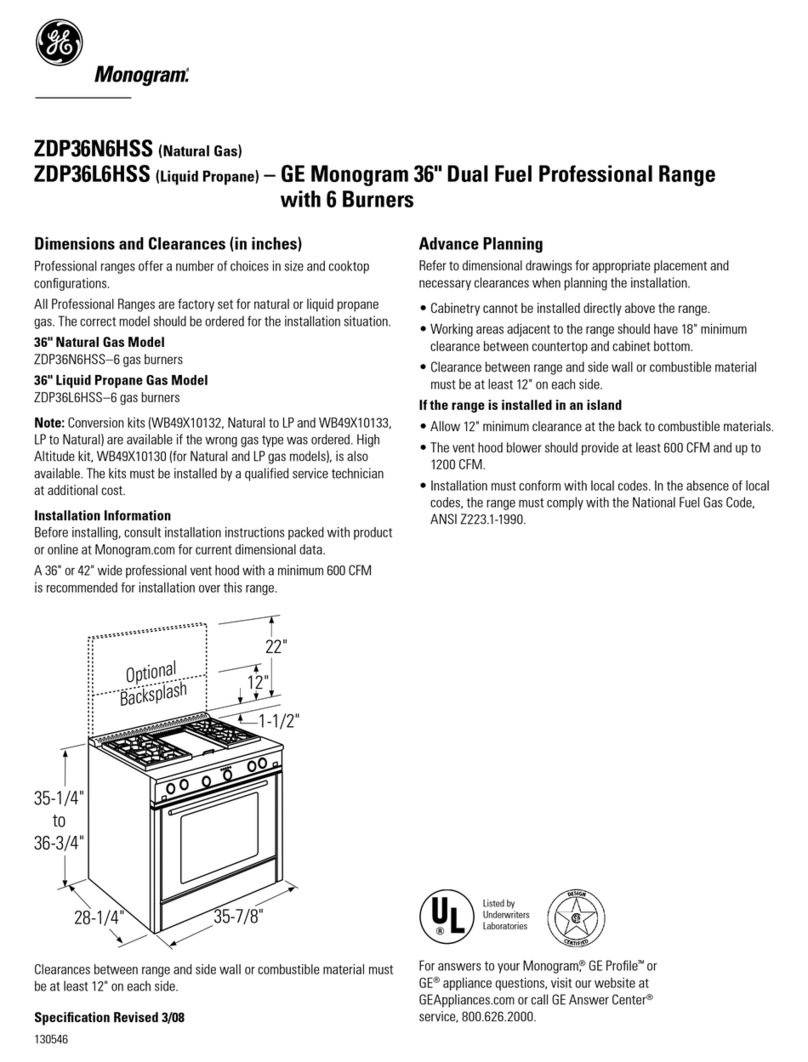

GE Monogram ZDP36L6HSS Manual

GE

GE JSS28 User manual