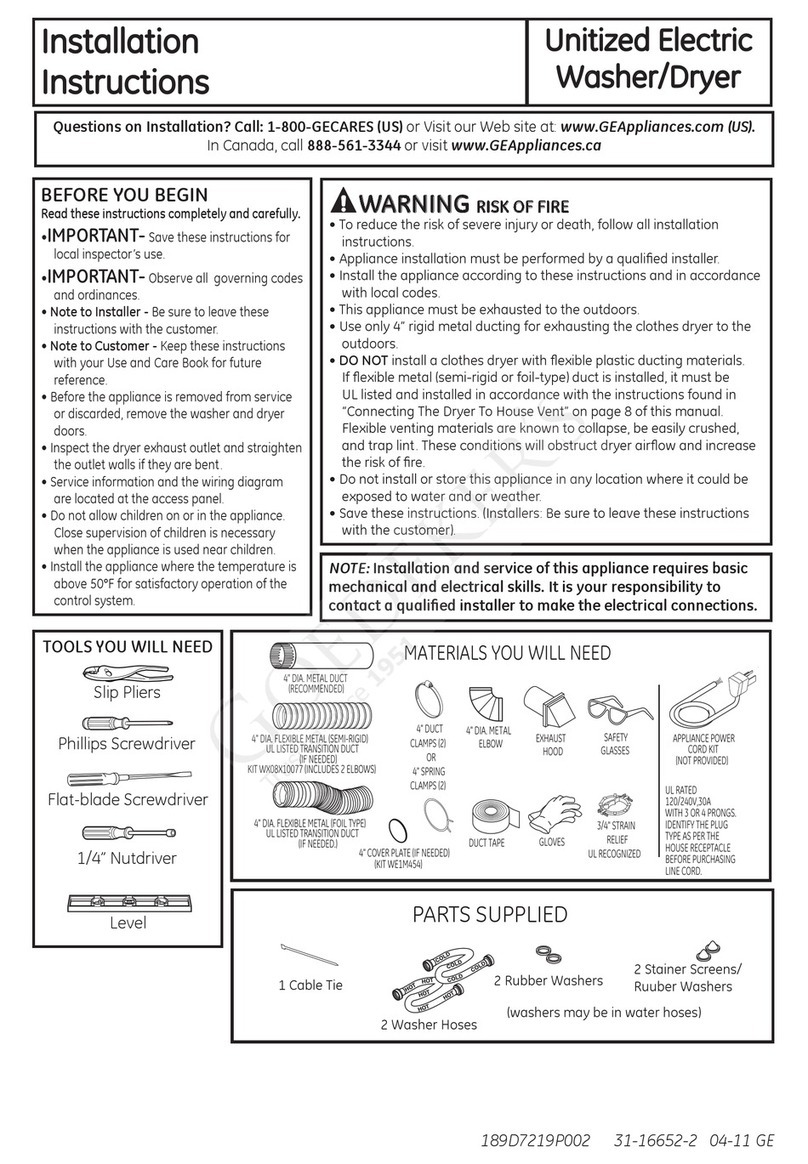

WASHER COMPONENTS AND PARTS

I

AGITATOR AND CAP

The polypropylene agitator and cap

are centered in the inner wash

basket. The cap is threaded into

the agitator drive block and can be

removed by turning counter

clockwise. The agitator can be

lifted off the drive blaock after

the cap is removed. The drive block

is splined and the agitator fits

tight to the block. Upward pressure

will be needed to free the agitator

from the drive block.

TO

REMOVE

OR

REPLACE AGITATOR AND

CAP

:

A. Raise washer lid.

B.

Remove agitator cap by turning

counter clockwise.

C.

Lift out agitator.

D. Install new agitator and/or cap.

E.

Reverse procedure to reassemble.

)

DRIVE BLOCK

The drive block is fastened to the

agitator drive shaft with a stud

bolt.

It

drives the agitator and

provides a means of adjusting the

clearance between the lower edge of

the agitator and tub. The drive

block height is adjusted with shims

3/16

"

minimum, 5/16

"

maximum. A

drive block puller is required to

remove the drive block.

TUB SPLASH COVER

The polypropylene tub splash cover,

which prevents water from splashing

over the top, has a molded rear 1ip

to prevent splash from the

fill

hose

and nozzle assembly. The splash

cover includes a bleach cup drain

area. A sealing gasket in a groove

around the circumference of the

s~lashcover snaps over the outer

tub assembly

-

AGITATOR CAP

TUB SPLASH

5

COVER

-

-

-

GASKET

-L

P,

AGITATOR

-

-

L-

GEAS 061162