– 3 –

Table of Contents

(Continued next page)

Safety Requirements.....................................................................................................................................................................5

Introduction.......................................................................................................................................................................................6

Nomenclature...................................................................................................................................................................................7

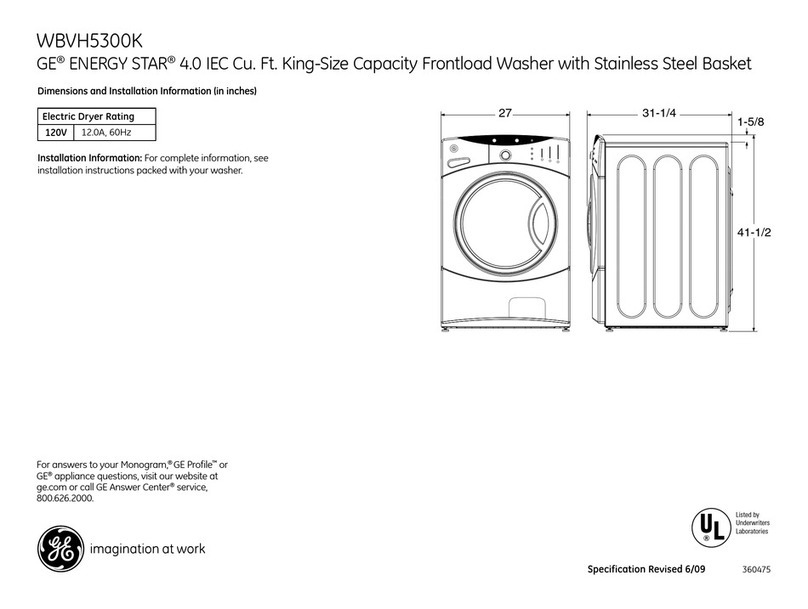

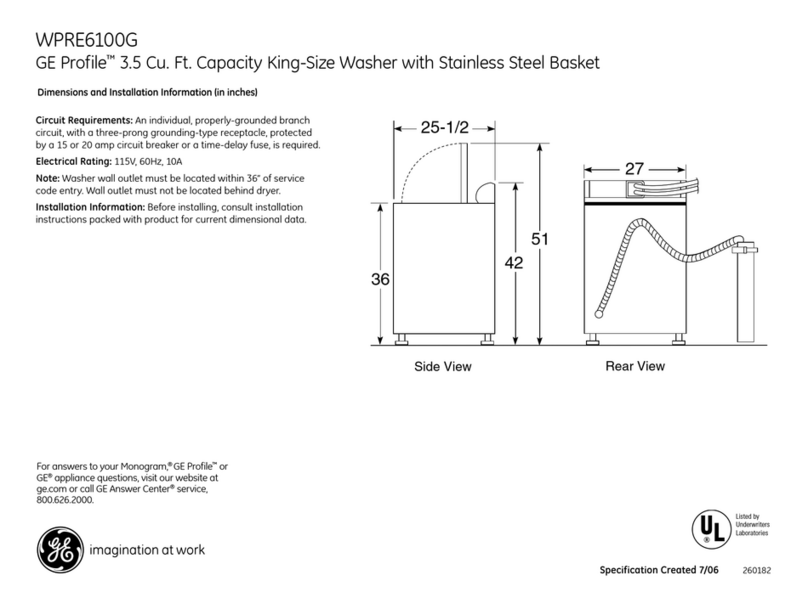

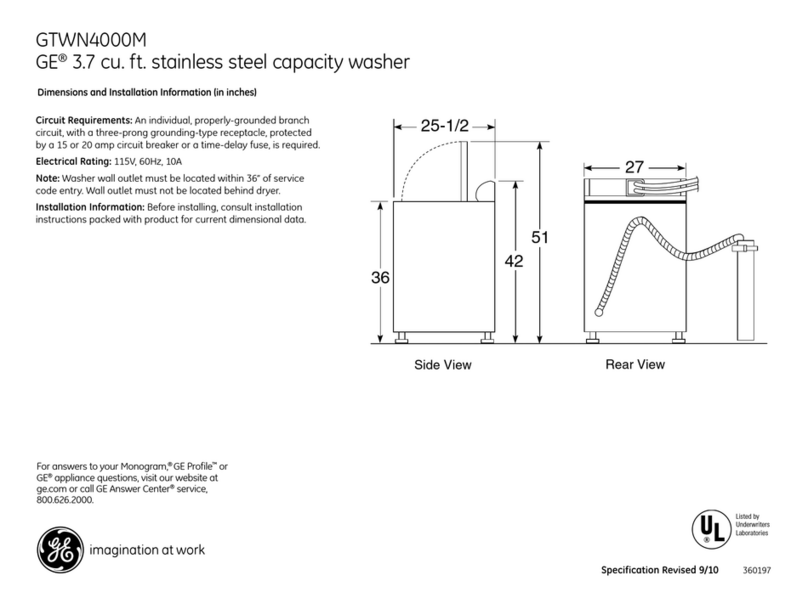

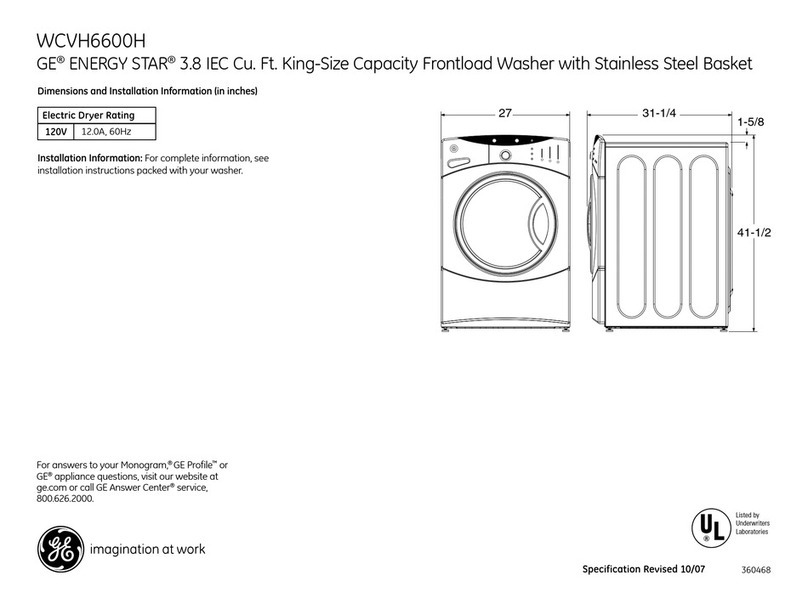

3URGXFW6SHFL¿FDWLRQV ..................................................................................................................................................................8

(OHFWULFDO6SHFL¿FDWLRQV .......................................................................................................................................................8

Tools Needed.............................................................................................................................................................................8

Installation Instructions................................................................................................................................................................9

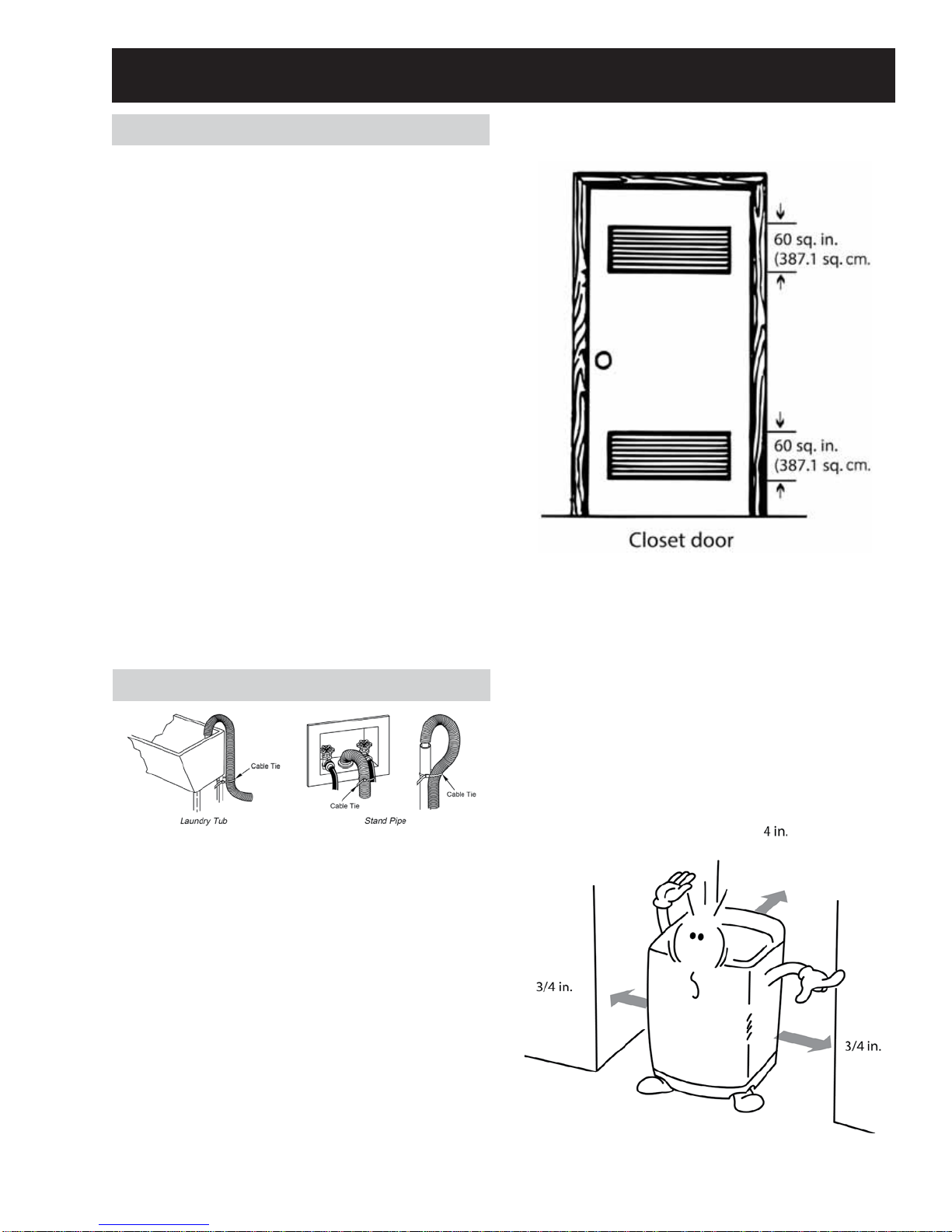

Location.......................................................................................................................................................................................9

Plumbing.....................................................................................................................................................................................9

Leveling the Washer..............................................................................................................................................................10

Electrical Wiring.......................................................................................................................................................................10

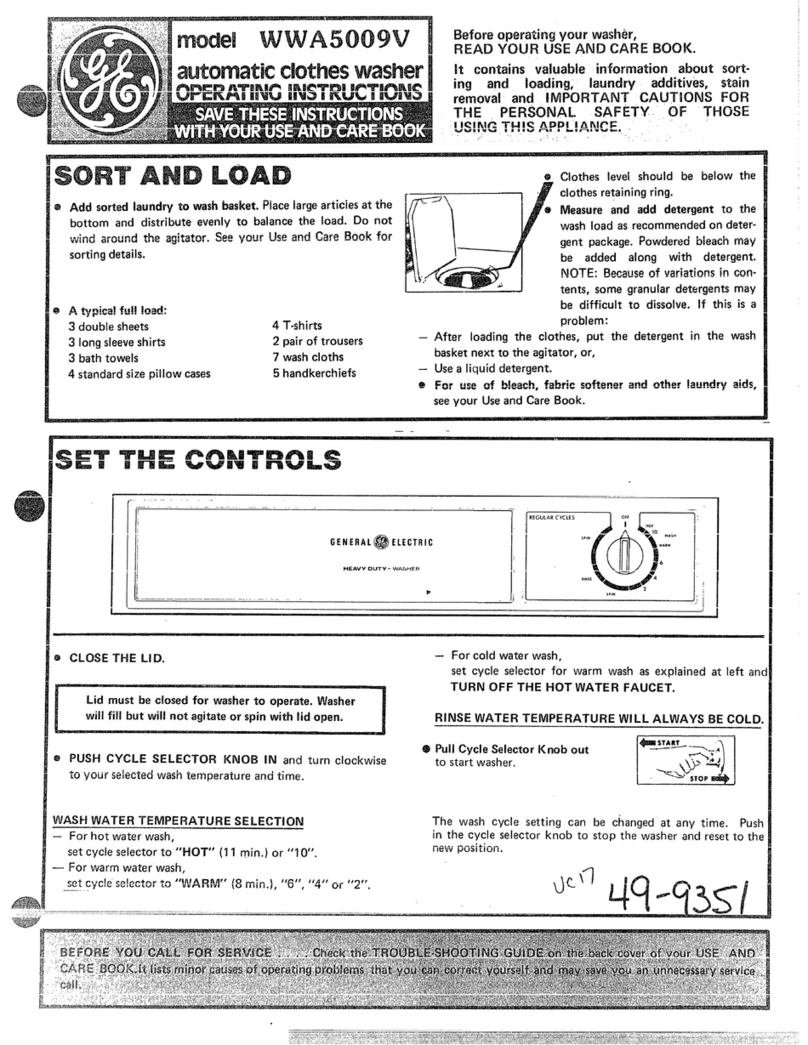

Operation............................................................................................................................................................................................11

Redistribution Attempt.........................................................................................................................................................12

Drain and Spin Operation....................................................................................................................................................12

Program Time Chart.......................................................................................................................................................................13

Dispensers..........................................................................................................................................................................................14

Detergent Dispenser..............................................................................................................................................................14

Bleach Dispenser.....................................................................................................................................................................14

Fabric Softener Dispenser...................................................................................................................................................14

Special Features...............................................................................................................................................................................15

Easy to Clean Lint Filter........................................................................................................................................................15

Non-Powered Water Recirculation.................................................................................................................................15

Component Locator Views..........................................................................................................................................................16

Control Board and Wire Connection Locator.............................................................................................................18

UI Board.......................................................................................................................................................................................18

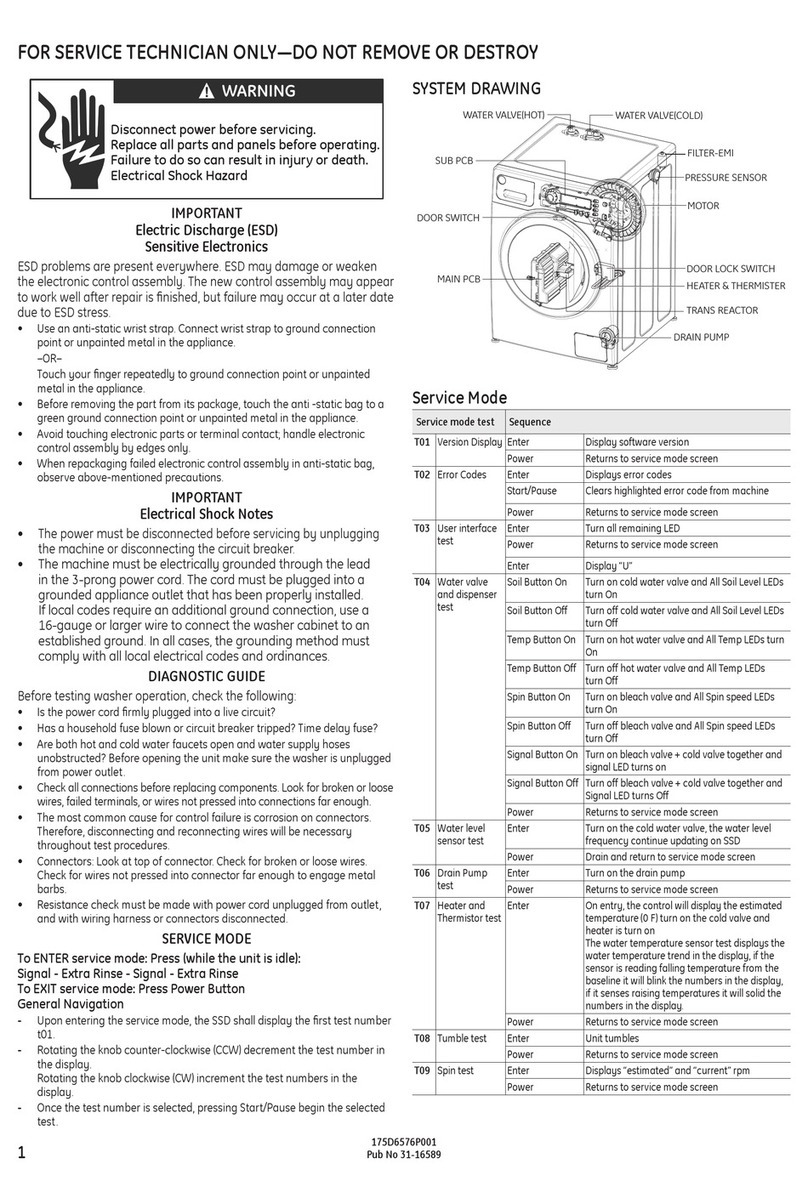

Diagnostics.........................................................................................................................................................................................19

Service Mode.............................................................................................................................................................................19

Fault Codes.........................................................................................................................................................................................20

Cabinet and Structure...................................................................................................................................................................21

Front Control Panel.................................................................................................................................................................21

Control Panel Removal.........................................................................................................................................................21