8

D

GB

F

I

Tr

Ru

09705-01.2018-DGbFITrRu

3|Areas of application

The compressors are factory-lled with the following oil type:

- for R134a, R404A/R507, R407C FUCHS Reniso Triton SE 55

- for R22 FUCHS Reniso SP 46

Compressors with ester oil charge (FUCHS Reniso Triton SE 55) are marked with an X in the type

designation (e.g. FKX30/325 N).

3.1 Refrigerants

• HFKW / HFC: R134a, R404A/R507, R407C

• (H)FCKW / (H)CFC: R22

3.2 Oil charge

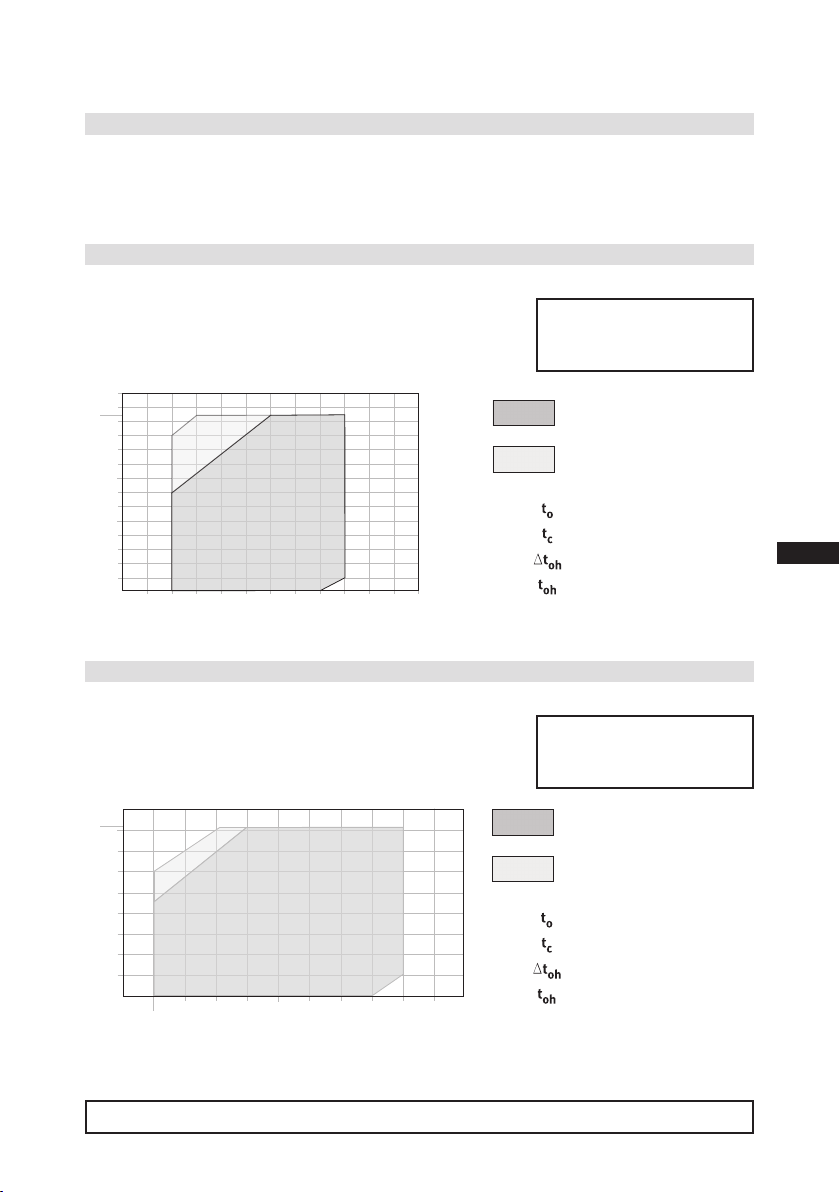

ATTENTION Compressor operation is possible within the limits of application

showninthediagrams.Pleasenotethesignicanceoftheshaded

areas. The limits of application must be observed. Thresholds

should not be selected as design or continuous operating points.

- Max. permissible discharge end temperature: 140°C

- Max. permissible ambient temperature: 100°C

-Max.permissibleswitchingfrequency:12x/h

-A minimum running time of 2 min. at equilibrium (continuous

operation) must be achieved.

Avoid continuous operation near the threshold. Should the com-

pressor happen to be used near the thresholds, we recommend the

useofathermalprotectionthermostat(Accessories,Chap.7).

When operating in the vacuum range, there is a danger of air en-

tering on the suction side. This can cause chemical reactions, a

pressure rise in the condenser and an elevated compressed-gas

temperature. Prevent the ingress of air at all costs!

3.3 Limits of application

INFO For recharging, we recommend the above oil types. Alternatives are:

see lubricants table, Chapter 6.6.