D

GB

F

E

I

5

96389-08.2019-DGbFEIRu

1.3 Safety instructions

1|Safety

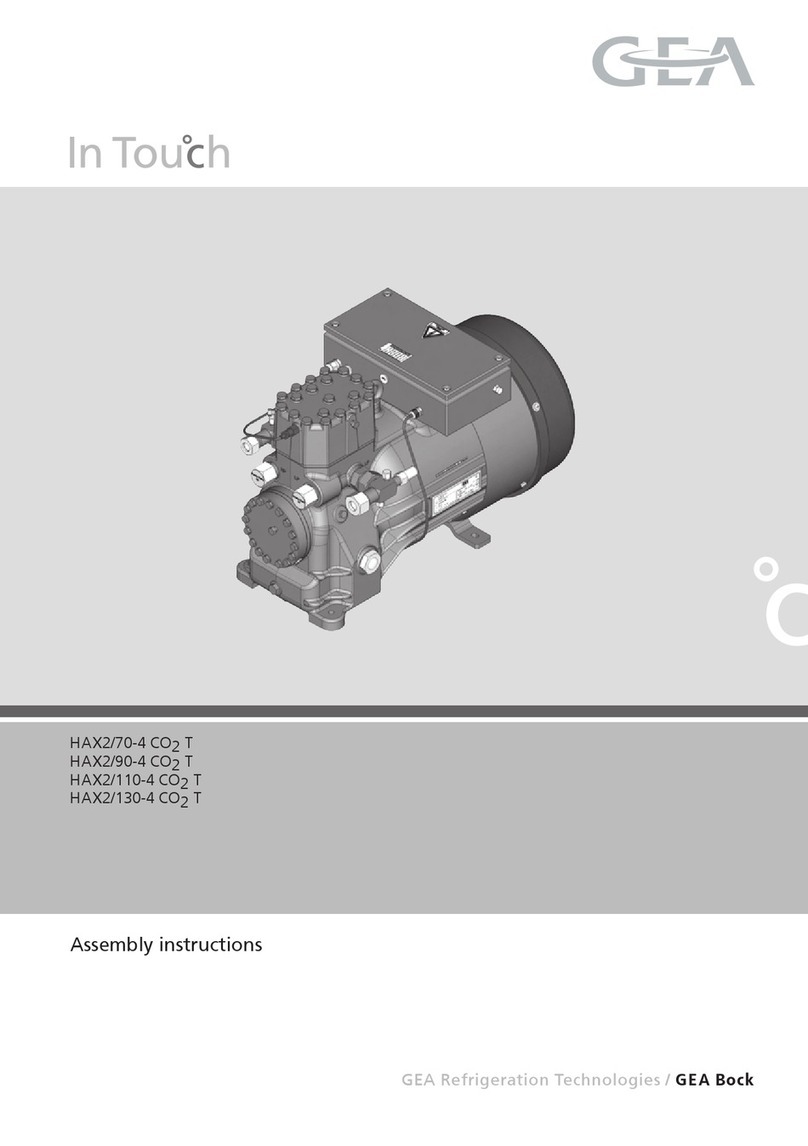

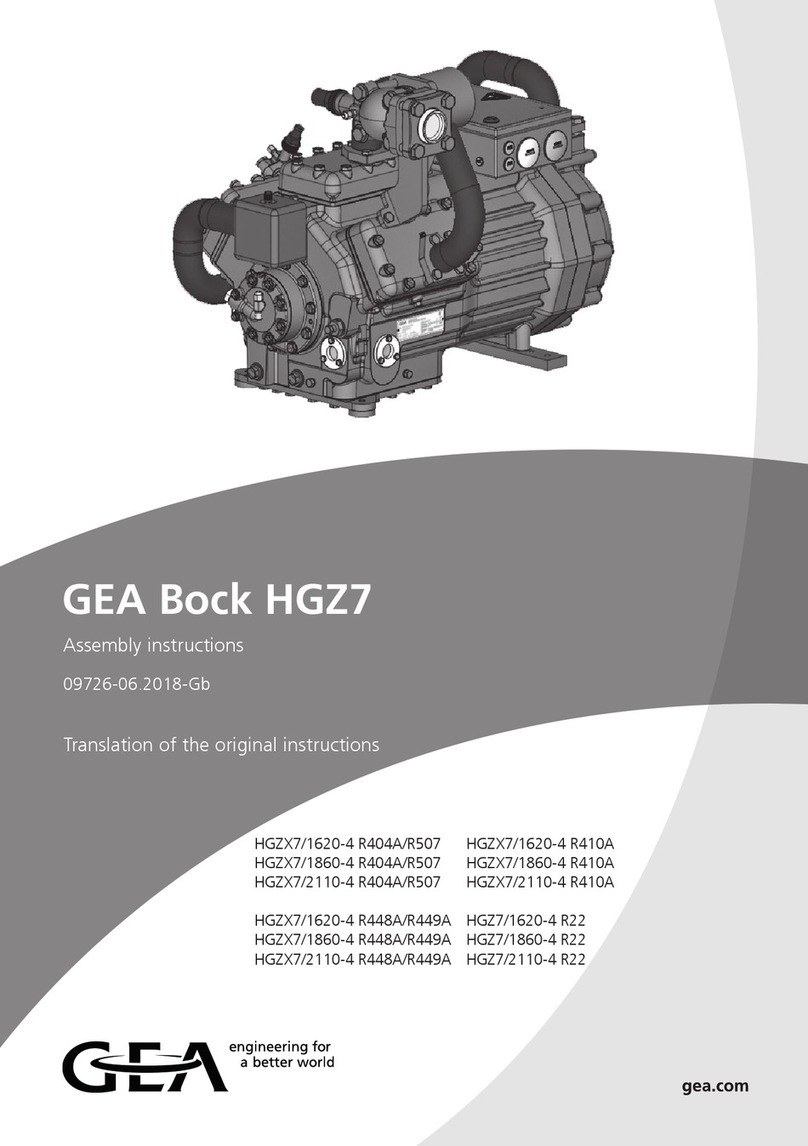

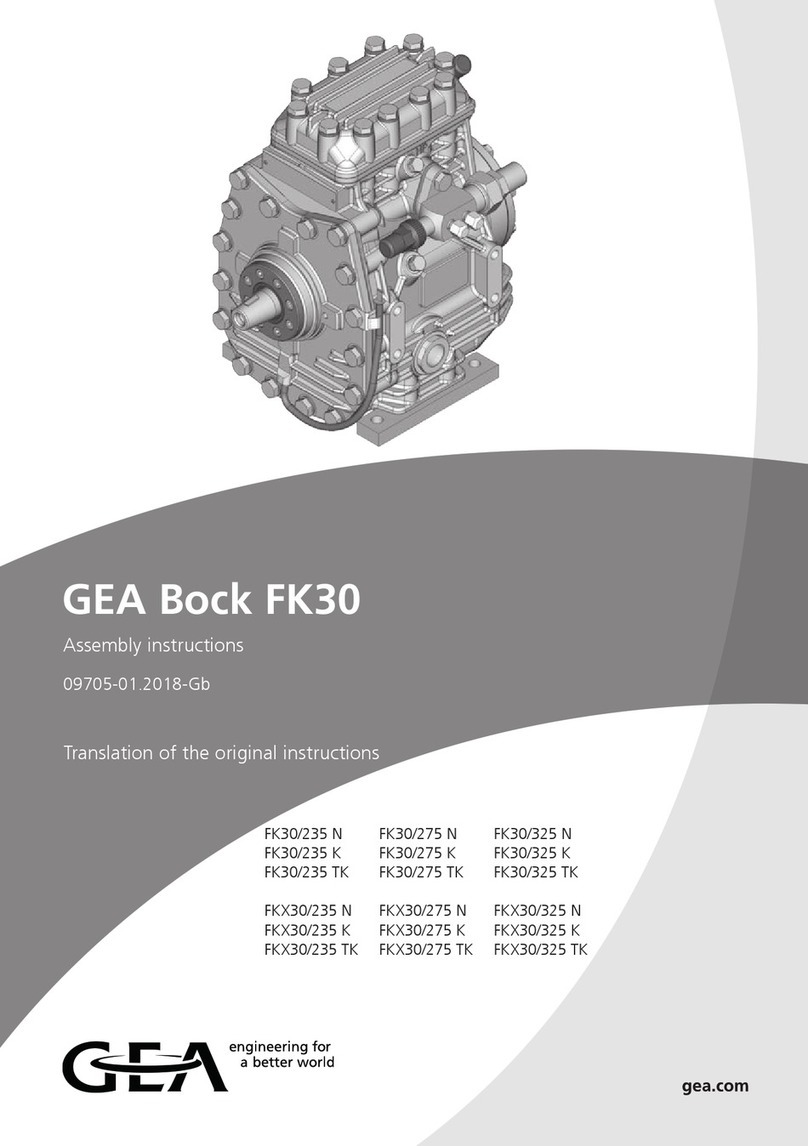

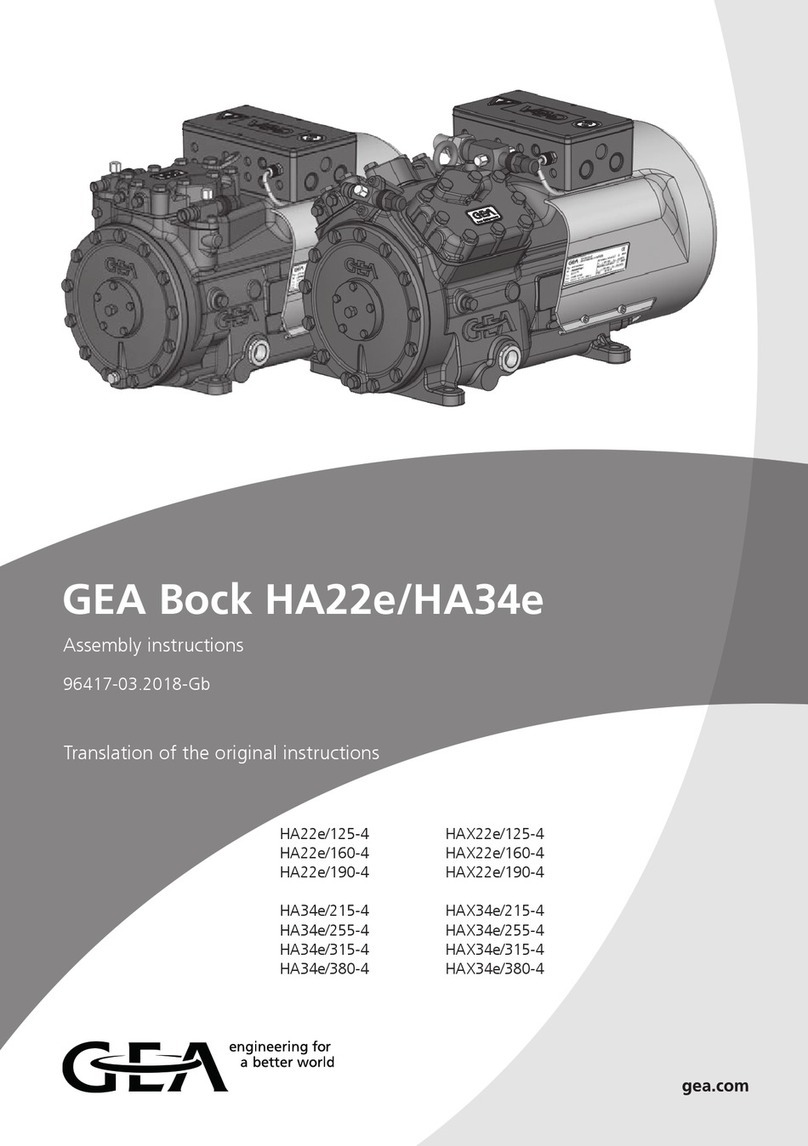

TheGEArefrigeratingcompressorsnamedinthetitleareintendedforinstallationinmachinesthat

weresetupinareasfallingundertheEUExplosionProtectionDirective1999/92/EC(operatordirec-

tive).IntheEuropeanUnion,electricalaswellasmechanicaldevicesoperatedinexplosiveatmos-

pheresmustfulfilwhatareknownasATEX (ATmospheresEXplosibles)conditions.

Thecompressorsarespeciallydesignedforthecategoryshownonthenameplateinaccordancewith

theATEXdirectiveandmayonlybeusedinconformitywiththeconditionsspecifiedanddocumented

intheset-uparea(explosionprotectiondocument).Usersafetyistakenintoaccountasaparticular

focusofdesign.Butitispermissibletostartupthecompressoronlyifitwasinstalledinaccordance

withtheseinstructionsandtheentiresystemintowhichitisintegratedhasbeeninspectedinaccor-

dancewithlegalregulationsandapproved.

ThedeclarationsandremarksbyGEAcanonlyrefertotheproductitself.Weassumethattheappli-

cableregulations,standardsandtechnicalrulesarefollowedininstallationandduringoperation.The

plantconstructor/operatormustevaluatetheinteractionswithotherdevicesandcomponentsofthe

systemandwiththeenvironment,especiallyregardingpotentialignitionsources.

WARNING • Refrigerating compressors are pressurised machines and there-

fore require particular caution and care in handling.

• Risk of burns! Depending on the operating conditions, surface

temperatures of over 60 °C on the pressure side or below 0 °C on

the suction side can be reached.

• The maximum permissible overpressure must not be exceeded,

even for testing purposes.

• The compressor may be operated only if it is free of defects!

• No work may be performed when an explosive atmosphere is

present!

• Smoking, re and open ame are strictly prohibited! Mobile tele-

phones must be switched off!

• Strongly charge-generating processes must be excluded within

2 meters. The contact of rapidly moving particles with the sur-

face of the compressor must be avoided with certainty (e.g.

pneumatically moved dust, owing uids, direct ventilation, belt

drives, brushes, foils, etc.).

• Perform installation work only if no damage, leaks and/or

appearances of corrosion can be recognized.