Fig. 1

Fig. 2

4x 8

649

Y2

X

Y1

+2

968

679 +2

-

-

F

E

D

C

A

F

E

D

C

41

A

B

5

6

7

8

1

2

34

5

6

78

Zeichn.-Nr. / Drawing no. :

B

32

168195

Part-No. Maßstab /

±0.1

über / above

Freigabe / Approved

zy

Der Lieferant muss sicherstellen, dass die Ware

in einwandfreiem Zustand angeliefert wird

(Korrosionsschutz, Verpackung für sicheren

Layh

Allgemeintoleranzen / General tolerances

Drawing-No.

bis / up to

Dok-ID:

xw uts

-

Kunde / Customer:

packaging for safe transportation).

model or design.

-

in proper conditions (corrosion prevention,

DIN ISO 2768-mK

Ra Rz

18.05.16

Ersatz für / replacement for:

The supplier has to ensure the delivery of parts

Transport).

prohibited. Offenders will be held liable for the Dimension Passung / Clearance

Baumustergeprüft / Type examination:

--

K.-Auftrag / C.-Task:

Projektleiter / Project leader:

120

400

±0.5

0.5

6

GEA Bock GmbH - Benzstraße 7 - 72636 Frickenhausen - Germany - www.bock.de

-

-

-

Unbemaßte Radien / Undimensioned radii:

-

Bearb. / EditedDatum / Date

payment of damages. All rights reserved in the event Änd.-Nr. / Mod-No.

Werkstoff (Zeile 2+3 alternativ) /

Base part, Raw part:

-

-

Geprüft / Appr.

NameDatum / Date

18.05.16

Material (Line 2+3 alternative):

Ausgangsteil, Rohteil /

Workpiece edges

DIN ISO 13715

Erstellt / Drawn

Geprüft / Verified Zuder

Büttner

1/3

Oberflächenbehandlung, Härte / Treatment of surface, Hardness:

18.05.16

Werkstückkanten /

Page:

400 Benennung / Description:

±0.8

1000

306

206,0

±0.3

12030

-

Blatt /

±0.2

of the grant of a patent, utility /

DIN EN ISO 1302

Zust. / Rev.

Gußtoleranzen / General casting tolerances:

Gewicht / Weight: (kg)

Zeichnungs-Nr. /

Indication of surface texture

Scale:

%

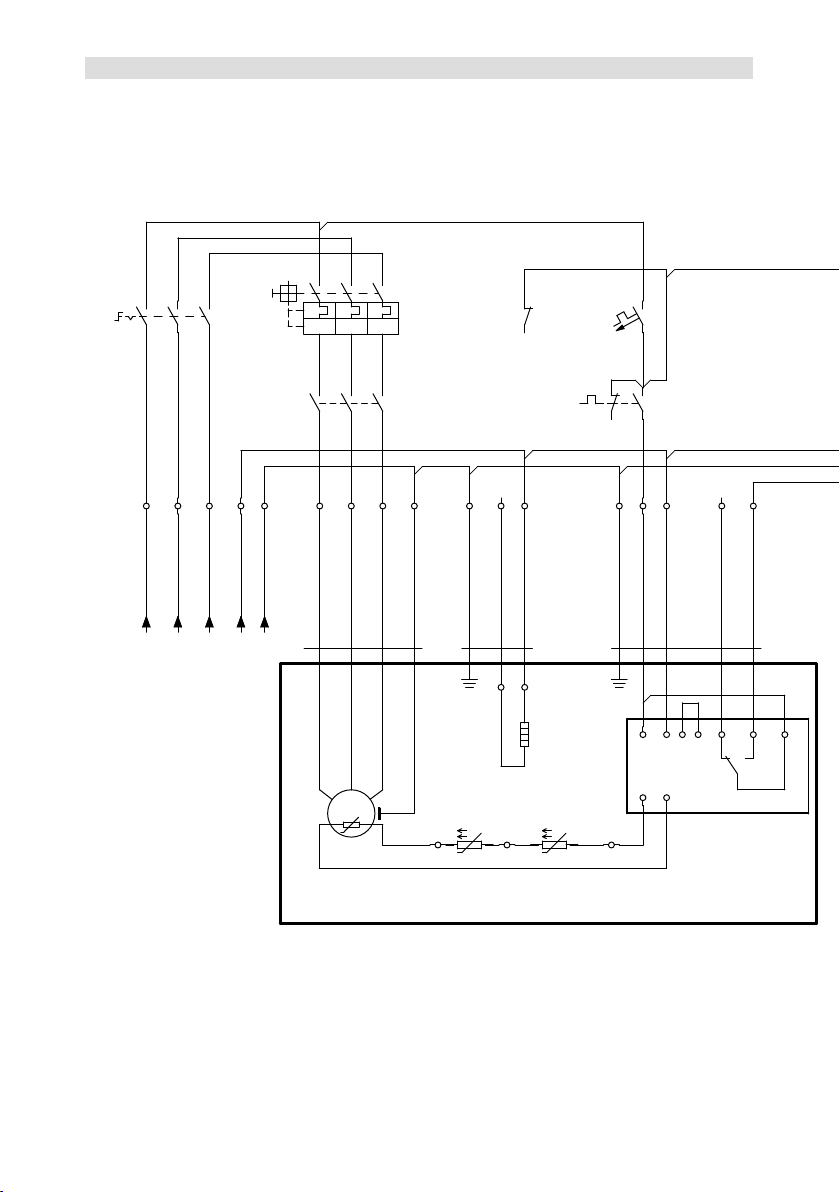

U - SHG34e/380-4 SPB

Rz 25

Rz 160

25 0,05 Rz 1,6

0,3

0,7

1,6

2Rz 16

6,3 Rz 63 Rz 6,3

Rz 12,5 Status:

-

-

in Bearbeitung (CAD)

Nein / No 16145 .2

A - SHG34e/380-4 SPB

-

10231.

Weitergabe sowie Vervielfältigung dieses Dokuments,

Verwertung und Mitteilung seines Inhalts sind ver-

boten, soweit nicht ausdrücklich gestattet. Zuwider-

handlungen verpflichten zu Schadenersatz. Alle

Rechte für den Fall der Patent-, Gebrauchsmuster-

oder Geschmacksmustereintragung vorbehalten.

The reproduction, distribution and utilization of this

document as well as the communication of its

contents to others without express authorization is

Maß

Oberflächenangaben /

Teile-Nr. /

Layh

Weitere Anschlüsse siehe Maßzeichnung Verdichter

For further connections see dimensional drawing of the compressor

Maße in mm

Dimensions in mm Änderungen vorbehalten

Subject to change without notice

Luftgekühlter Verflüssigungssatz / Air-cooled condensing unit

Aggregat

Bezeichnung /

unit description

Bestehend aus / composed of:

Verdichter

Teile Nr. /

compressor

part-no.

X-Verdichter

Teile Nr. /

X-compressor

part-no.

Sammler

Teile Nr. /

receiver

part-no.

Inhalt

(Ltr.) /

volume

(Ltr.)

SHG(X)34e/215-4 PB 16050 16058

60028 8

SHG(X)34e/215-4 SPB 16054 16062

SHG(X)34e/255-4 PB 16051 16059

SHG(X)34e/255-4 SPB 16055 16063

SHG(X)34e/315-4 PB 16052 16060

SHG(X)34e/315-4 SPB 16056 16064 60029 10SHG(X)34e/380-4 PB 16053 16061

SHG(X)34e/380-4 SPB 16057 16065

Anschlüsse /

Connections

SHG34/215 (S)PB

SHG34/255 (S)PB

SHG34/315 PB

SHG34/315 SPB

SHG34/380 (S)PB

SV Saugabsperrventil, Rohr (L)* mm / Zoll 28 - 1 1/8" 35 - 1 3/8"

Suction line valve, tube (L)* mm / inch

FLA Flüssigkeitsaustritt, Rohr (L)* mm / Zoll 12 - 1/2" 16 - 5/8"

Liquid outlet, tube (L)* mm / inch

SI Anschluss Sicherheitsventil Zoll 1/2" NPTF

Connection safety valve inch

Y1 Anschluss Flüssigkeitsseite, absperrbar Zoll 7/16" UNF

Connection liquid side, lockable inch

Y2 Anschluss Flüssigkeitsseite, nicht absperrbar Zoll 7/16" UNF

Connection liquid side, not lockable inch

Y3 Anschluss Drehzahlregler Zoll 7/16" UNF

Connection Speed Controller inch

(L)* = Lötanschluß

(L)* = Brazing connection

1.1023-16145.2

Typ /

type Teile-Nr./

part-no. Typ /

type Teile-Nr./

part-no. Typ /

type Teile-Nr./

part-no. Typ /

type Teile-Nr./

part-no.

SHG34e/215-4 PB 16138 SHGX34e/215-4 PB 16146 SHG34e/215-4 SPB 16142 SHGX34e/215-4 SPB 16150

SHG34e/255-4 PB 16139 SHGX34e/255-4 PB 16147 SHG34e/255-4 SPB 16143 SHGX34e/255-4 SPB 16151

SHG34e/315-4 PB 16140 SHGX34e/315-4 PB 16148 SHG34e/315-4 SPB 16144 SHGX34e/315-4 SPB 16152

SHG34e/380-4 PB 16141 SHGX34e/380-4 PB 16149 SHG34e/380-4 SPB 16145 SHGX34e/380-4 SPB 16153

4x 8

649

Y2

Y1

X

Weitere Anschlüsse siehe Maßzeichnung Verdichter

For further connections see dimensional drawing of the compressor

Maße in mm

Dimensions in mm Änderungen vorbehalten

Subject to change without notice

Luftgekühlter Verflüssigungssatz / Air-cooled condensing unit

Aggregat

Bezeichnung /

unit description

Bestehend aus / composed of:

Verdichter

Teile-Nr. /

compressor

part-no.

X-Verdichter

Teile-Nr. /

X-compressor

part-no.

Sammler

Teile-Nr. /

receiver

part-no.

Inhalt (Ltr.) /

volume (ltr.)

SHG(X)34e/215-4 P&P 16050 16058

60028 8

SHG(X)34e/215-4 SP&P 16054 16062

SHG(X)34e/255-4 P&P 16051 16059

SHG(X)34e/255-4 SP&P 16055 16063

SHG(X)34e/315-4 P&P 16052 16060

SHG(X)34e/315-4 SP&P 16056 16064 60029 10SHG(X)34e/380-4 P&P 16053 16061

SHG(X)34e/380-4 SP&P 16057 16065

1.1023-16129.2

Typ /

type Teile-Nr./

part-no. Typ /

type Teile-Nr./

part-no. Typ /

type Teile-Nr./

part-no. Typ /

type Teile-Nr./

part-no.

SHG34e/215-4 P&P 16122 SHGX34e/215-4 P&P 16130 SHG34e/215-4 SP&P 16126 SHGX34e/215-4 SP&P 16134

SHG34e/255-4 P&P 16123 SHGX34e/255-4 P&P 16131 SHG34e/255-4 SP&P 16127 SHGX34e/255-4 SP&P 16135

SHG34e/315-4 P&P 16124 SHGX34e/315-4 P&P 16132 SHG34e/315-4 SP&P 16128 SHGX34e/315-4 SP&P 16136

SHG34e/380-4 P&P 16125 SHGX34e/380-4 P&P 16133 SHG34e/380-4 SP&P 16129 SHGX34e/380-4 SP&P 16137

Anschlüsse /

Connections

SHG34/215 (S)P&P

SHG34/255 (S)P&P

SHG34/315 P&P

SHG34/315 SP&P

SHG34/380 (S)P&P

SV Saugabsperrventil, Rohr (L)* mm / Zoll

mm / inch 28 - 1 1/8" 35 - 1 3/8"

Suction line valve, tube (L)*

DV Druckabsperrventil, Rohr (L)* mm / Zoll

mm / inch 16 – 5/8" 16 – 5/8"

Discharge line valve, tube (L)*

FLA Flüssigkeitsaustritt, Rohr (L)* mm / Zoll

mm / inch 12 - 1/2" 16 - 5/8"

Liquid outlet, tube (L)*

FLE Flüssigkeitseintritt, Rohr (L)* mm / Zoll

mm / inch 12 - 1/2" 16 – 5/8"

Liquid inlet, tube (L)*

SI Anschluss Sicherheitsventil Zoll / inch 1/2" NPTF

Connection safety valve

Y1 Anschluss Flüssigkeitsseite, absperrbar Zoll / inch 7/16" UNF

Connection liquid side, lockable

Y2 Anschluss Flüssigkeitsseite, nicht absperrbar Zoll / inch 7/16" UNF

Connection liquid side, not lockable

Y3 Anschluss Drehzahlregler Zoll / inch 7/16" UNF

Connection Speed Controller

(L)* = Lötanschluss

(L)* = Brazing connection

-

-

F

E

D

C

A

F

E

D

C

41

A

B

5

6

7

8

1

2

34

5

6

78

Zeichn.-Nr. / Drawing no. :

B

32

166951

Part-No. Maßstab /

±0.1

über / above

Freigabe / Approved

zy

Der Lieferant muss sicherstellen, dass die Ware

in einwandfreiem Zustand angeliefert wird

(Korrosionsschutz, Verpackung für sicheren

Layh

Allgemeintoleranzen / General tolerances

Drawing-No.

bis / up to

Dok-ID:

xw uts

-

Kunde / Customer:

packaging for safe transportation).

model or design.

-

in proper conditions (corrosion prevention,

DIN ISO 2768-mK

Ra Rz

18.05.16

Ersatz für / replacement for:

The supplier has to ensure the delivery of parts

Transport).

prohibited. Offenders will be held liable for the Dimension Passung / Clearance

Baumustergeprüft / Type examination:

--

K.-Auftrag / C.-Task:

Projektleiter / Project leader:

120

400

±0.5

0.5

6

GEA Bock GmbH - Benzstraße 7 - 72636 Frickenhausen - Germany - www.bock.de

-

-

-

Unbemaßte Radien / Undimensioned radii:

-

Bearb. / EditedDatum / Date

payment of damages. All rights reserved in the event Änd.-Nr. / Mod-No.

Werkstoff (Zeile 2+3 alternativ) /

Base part, Raw part:

-

-

Geprüft / Appr.

NameDatum / Date

18.05.16

Material (Line 2+3 alternative):

Ausgangsteil, Rohteil /

Workpiece edges

DIN ISO 13715

Erstellt / Drawn

Geprüft / Verified Zuder

Büttner

1/3

Oberflächenbehandlung, Härte / Treatment of surface, Hardness:

18.05.16

Werkstückkanten /

Page:

400 Benennung / Description:

±0.8

1000

306

-

±0.3

12030

-

Blatt /

±0.2

of the grant of a patent, utility /

DIN EN ISO 1302

Zust. / Rev.

Gußtoleranzen / General casting tolerances:

Gewicht / Weight: (kg)

Zeichnungs-Nr. /

Indication of surface texture

Scale:

%

U - SHG34e/380-4 SP&P

Rz 25

Rz 160

25 0,05 Rz 1,6

0,3

0,7

1,6

2Rz 16

6,3 Rz 63 Rz 6,3

Rz 12,5 Status:

-

-

in Bearbeitung (CAD)

Nein / No 16129 .2

A - SHG34e/380-4 SP&P

-

10231.

Weitergabe sowie Vervielfältigung dieses Dokuments,

Verwertung und Mitteilung seines Inhalts sind ver-

boten, soweit nicht ausdrücklich gestattet. Zuwider-

handlungen verpflichten zu Schadenersatz. Alle

Rechte für den Fall der Patent-, Gebrauchsmuster-

oder Geschmacksmustereintragung vorbehalten.

The reproduction, distribution and utilization of this

document as well as the communication of its

contents to others without express authorization is

Maß

Oberflächenangaben /

Teile-Nr. /

Layh

+2

968

+2

679

60-80