7159-9001-108

01. February 2020 3 / 92

6 commissioning 57..........................................................

6.1 Special Personnel Qualifications 57............................................................

6.2 Safety Instructions 57........................................................................

6.3 Particular hazards 57.........................................................................

6.4 Requirements for commissioning 58............................................................

6.5 Align light scanners 59.......................................................................

6.6 Antenna transformer settings 60...............................................................

6.7 Settings in DairyPlan 61......................................................................

6.7.1 Settings with DairyPlan (DPSetup) 61...........................................................

6.7.2 Setting selections flags (DPSingle) 64..........................................................

6.7.3 Settings with DairyPlan (DPService 1.xx) 65.....................................................

6.7.4 Responder settings 67.......................................................................

6.8 Settings on the transceiver 67.................................................................

6.9 Setting the segregation gate opening and closing speed 67........................................

6.10 Checks before initial commissioning 68.........................................................

6.11 First Start 68................................................................................

6.12 Checks after first start 68.....................................................................

6.13 Handing over to the owner 70.................................................................

7 Operation and control 71....................................................

7.1 Special Personnel Qualifications 71............................................................

7.2 Safety Instructions 71........................................................................

7.3 Particular hazards 72.........................................................................

7.4 Description of the control elements 72..........................................................

7.5 Operation / Control 72........................................................................

7.6 Attaching the leg responders in ”stand-alone” operating mode (AutoSelect 3000) 76...................

8 maintenance 77............................................................

8.1 Special Personnel Qualifications 77............................................................

8.2 Safety Instructions 77........................................................................

8.3 Particular hazards 78.........................................................................

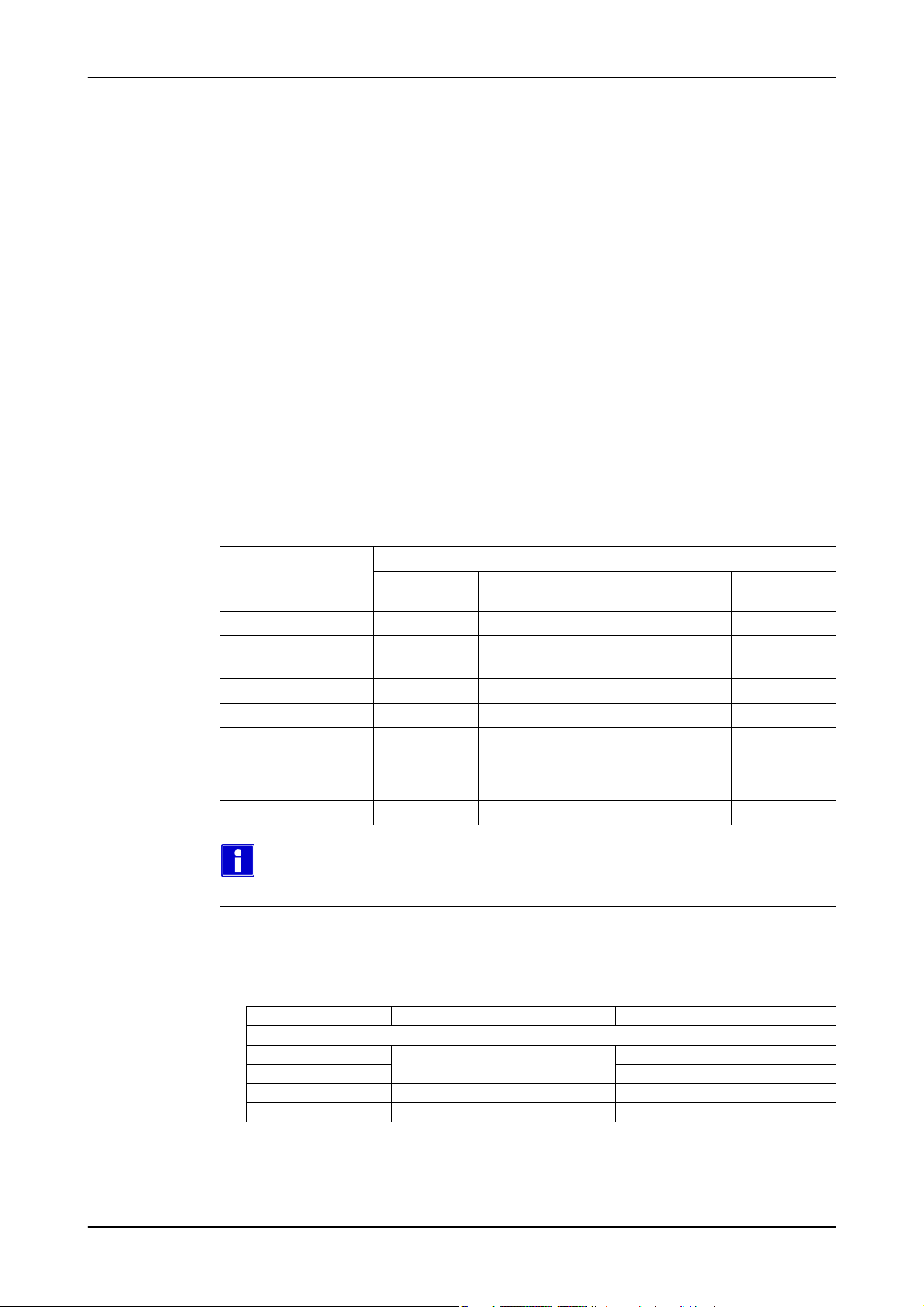

8.4 Inspections and preventive maintenance 78.....................................................

9 Operation Faults 80.........................................................

9.1 Special Personnel Qualifications 80............................................................

9.2 Safety Instructions 80........................................................................

9.3 Particular hazards 80.........................................................................

9.4 Transceiver faults 80.........................................................................

9.5 Faults and troubleshooting help 81.............................................................

10 Decommissioning 82.......................................................

10.1 Special Personnel Qualifications 82............................................................

10.2 Safety Instructions 82........................................................................

10.3 Particular hazards 82.........................................................................

10.4 Temporary decommissioning 82...............................................................

10.5 Final Decommissioning / Disposal 82...........................................................

11 Spare Parts 83.............................................................

11.1 Animal segregation 83........................................................................

11.1.1 control panel 87.............................................................................

11.1.2 Gate locking system 88.......................................................................

11.2 animal identification 89.......................................................................

11.3 Accessories for animal identification - AutoSelect 3000 SA 89......................................

12 Appendix 90...............................................................

12.1 Directories 90...............................................................................