4

parking brake, turn engine off and remove key

before dismounting.

•DisengagethePTO,stoptheengineandwaituntil

the tiller comes to a complete stop before making

any repairs, adjustments, or removing any rocks or

debris.

•Useextracautionwhenloadingorunloadingthe

machine into a trailer or truck. A tractor with a tiller

attachment should not be driven up or down a ramp

onto a trailer or truck under power, the unit could tip

over causing serious personal injury. The unit must

be pushed manually to load or unload properly.

• Follow all manufacturer’s recommendations for use

of counterweights to improve machine stability.

•Ifsituationsoccurwhicharenotcoveredinthis

manual, use care and good judgment. Contact your

dealer for assistance. Telephone 1-800-528-1009

for the name of your nearest dealer.

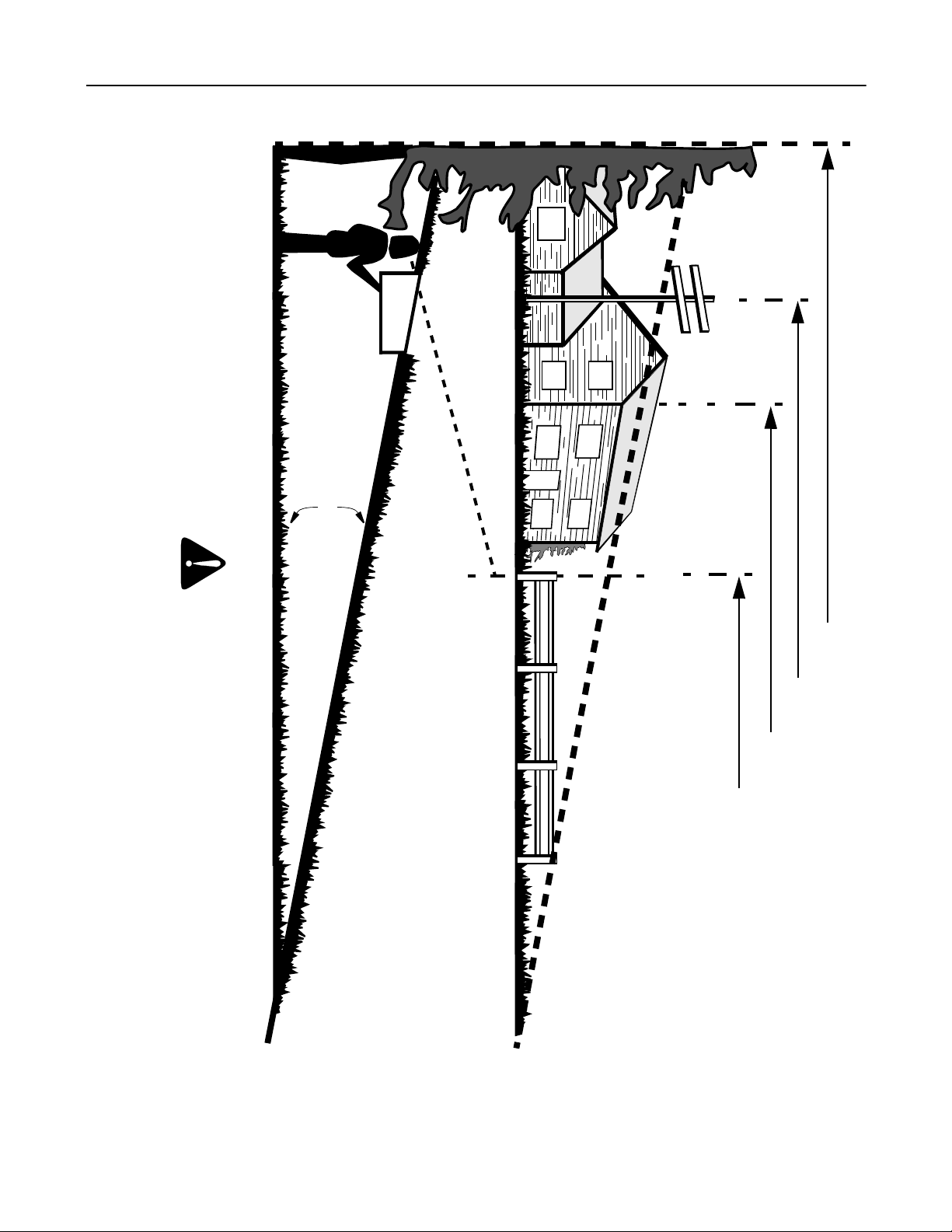

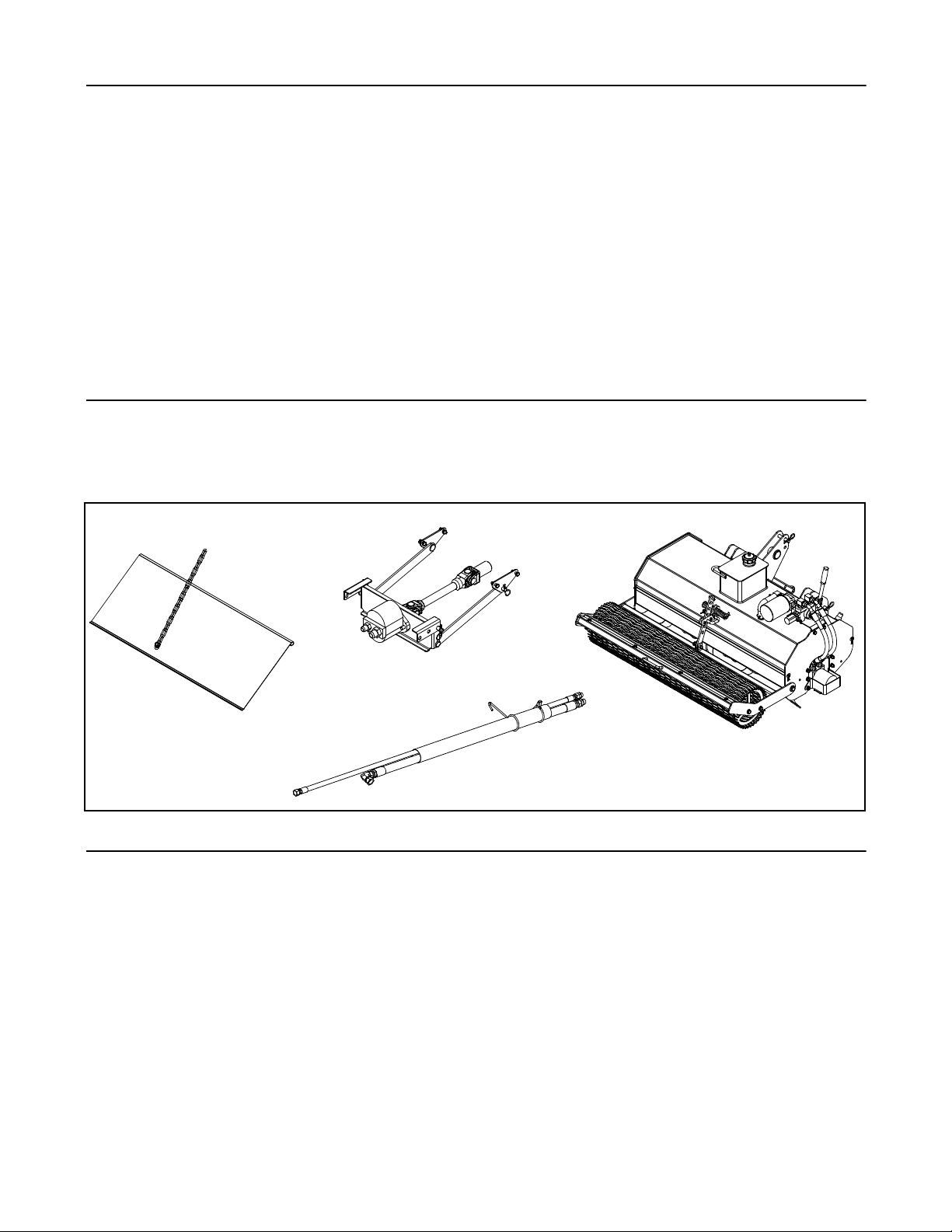

Slope Operation

Slopes are a major factor related to loss of control and

tip-over accidents which can result in severe injury or

death. Operation on slopes requires extra caution. If

you cannot back up the slope or if you feel uneasy on it,

do not till it. For your safety, use the slope gauge

included as part of this manual to measure slopes

before operating this unit on a sloped or hilly area. If the

slope is greater than 10 degrees as shown on the slope

gauge, do not operate this unit on that area or serious

injury could result.

Do:

•Tillupanddownslopes,notacross.Exercise

extreme caution when changing direction on slopes.

• Watch for holes, ruts, bumps, and hidden objects

(e.g. rocks etc.) which can be under the soil.

Uneven terrain could overturn the machine which

may cause personal injury.

•Useslowspeed.Choosealowenoughspeed

setting so that you will not have to stop or shift while

on the slope. Always keep the machine in gear

when going down slopes to take advantage of the

engine braking action.

•Keepallmovementsonslopesslowandgradual.

Do not make sudden changes in speed or direction.

Rapid engagement or braking could cause the front

of the machine to lift and rapidly flip over backwards

which could cause serious personal injury.

•Avoidstartingandstoppingonaslope.Iftireslose

traction, Disengage the PTO and proceed slowly

straight down the slope.

•Useextracarewiththetillerattachmentasitcan

change the stability of the machine.

• Follow all manufacturer’s recommendations for

wheel weights or counterweights to improve the

stability of the machine.

Do Not:

•Donotturnonslopesunlessnecessary;then,turn

slowly and gradually downhill, if possible.

• Do not till near drop-offs, ditches or embankments.

The machine could suddenly overturn if a wheel or

the attachment is over the edge, or if the edge

caves in.

• Do not operate machine on wet grass. Reduced

traction could cause sliding and loss of control of the

machine.

•Donottrytostabilizethemachinebyputtingyour

foot on the ground.

•Donottillslopesgreaterthan10degreesasshown

on the slope gauge.

Children

Tragic accidents can occur if the operator is not alert to

the presence of children. Children are often attracted to

the machine and the tilling activity. They do not

understand the dangers. Never assume that children

will remain where you last saw them.

•Keepchildrenoutofthetillingareaandunderthe

watchful care of a responsible adult other than the

operator.

•Bealertandturnthemachineoffifachildentersthe

area.

•Beforeandwhilemovingbackwards,lookbehind

and down for small children.

•Useextremecarewhenapproachingblindcorners,

doorways, shrubs, trees, or other objects that may

obscure your vision of a child who may run into the

machine.

•Nevercarrychildren,evenwiththeattachment

disengaged. They may fall off and be seriously

injured or interfere with safe machine operation.

• Keep children away from hot or running engines.

They can suffer burns from a hot muffler.

• Remove key when machine is unattended to

prevent unauthorized operation.

Never allow children under 14 years old to operate a

power mower. Children 14 years old and over should

read and understand the operation instructions and

safety rules in this manual and should be trained and

supervised by a parent.

Service

Safe Handling of Gasoline:

To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

• Use only an approved gasoline container.

•Extinguishallcigarettes,cigars,pipesandother

sources of ignition.

• Never fuel machine indoors because flammable

vapors will accumulate in the area.