4

Operating Instructions · Control Top T.VIS® M-15

Edition 2017-10-16

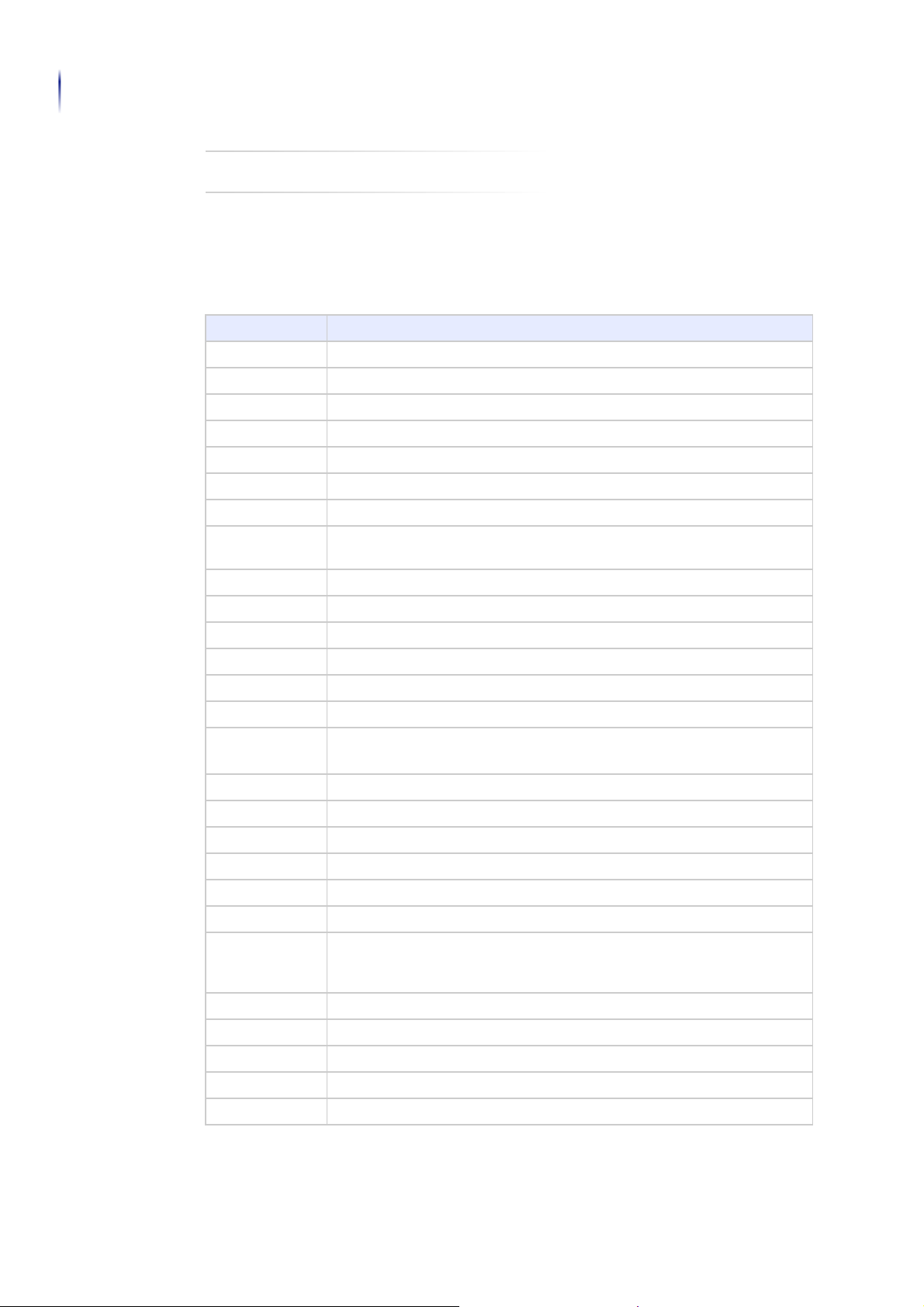

Connection .................................................................................................................................................... 29

Establishing Hose Connections ...................................................................................................................... 29

Pneumatic Connections .................................................................................................................................. 29

•Control Top without or with 1 Solenoid Valve ............................................................................................. 29

•Control Top with 2 Solenoid Valves ............................................................................................................ 30

•Control Top with 3 Solenoid Valves ............................................................................................................ 31

Electrical Connections..................................................................................................................................... 32

•Overview ..................................................................................................................................................... 32

•ASI Connections ......................................................................................................................................... 33

•External Proximity Switch (170) .................................................................................................................. 35

•Electrical 24 V DC Wiring ............................................................................................................................ 36

•Electrical Wiring of AS-Interface V.3.0 ........................................................................................................ 39

•Electrical Wiring of AC-Interface – AC Voltage ........................................................................................... 40

•Electrical DeviceNet Wiring ......................................................................................................................... 41

Wiring Diagram for 24 V DC Control Systems with P Logic ............................................................................ 43

Wiring Diagram for 24 V DC Control Systems with N Logic............................................................................ 45

Wiring Diagram for T.VIS M-15 with Adapter Module ..................................................................................... 47

Wiring Diagram for T.VIS M-15 24 V DC ........................................................................................................ 48

Visual Display.................................................................................................................................................. 49

Setting into Operation .................................................................................................................................. 50

Switching on the Control Air ............................................................................................................................ 50

Switching on the Operating Voltage ................................................................................................................ 50

Checking Valve Actuation ............................................................................................................................... 51

Service Function ............................................................................................................................................. 51

Adjusting the Sensor in the Control Top ......................................................................................................... 52

•Seat Valves – Position of Sensor S1 Down ................................................................................................ 52

•Seat Valves – Position of Sensor S1 Up ..................................................................................................... 56

•T-smart Butterfly Valves .............................................................................................................................. 59

Adjusting the Proximity Switch in the Lantern on Double-Disks Without Balancer ........................................ 62

Adjusting the Proximity Switch in the Lantern of PMO Valve Type M/2.0 ....................................................... 64

Test Procedure for

Tuchenhagen PMO Valves Type M/2.0 .......................................................................................................... 67

•Purpose ....................................................................................................................................................... 67

•Process Overview ....................................................................................................................................... 67

•Hardware Description ................................................................................................................................. 67

•Test Procedure 1 ........................................................................................................................................ 68

•Test Procedure 2 ........................................................................................................................................ 69

Mounting the Control Top to Different Valves............................................................................................ 70

Mounting to VARIVENT Valve or STERICOM Valve Types N_A/D, R ........................................................... 71

Mounting to a Butterfly Valve T-smart 8000 .................................................................................................... 72

Mounting to a Butterfly Valve T-smart 7 and a Mixproof Butterfly Valve T-smart 9 ........................................ 73

Mounting to ECOVENT Valves N_ECO and W_ECO ..................................................................................... 74

Mounting to VESTA Valve H_A/M................................................................................................................... 76

Mounting to VESTA Valve H_A....................................................................................................................... 78

Mounting to Valve N_/E or W_/E or STERICOM Valve .................................................................................. 80

Mounting to a T-smart Single-Seat and Double-Seal Valve ............................................................................ 81

Fitting to an ASEPTOMAG Valve.................................................................................................................... 83

Replacing Control Tops................................................................................................................................... 84