Preparingthe

backfofthe

cabinet

Read each stepthoroughly

beforeproceeding.

Took needed:

~Philiips-typescrewdriver

*Blade-typescrewdriver

*~/4°nutdriver

~Sharp knife

@Pliers

cation:

of electric SIMM

its electrical outlet. “

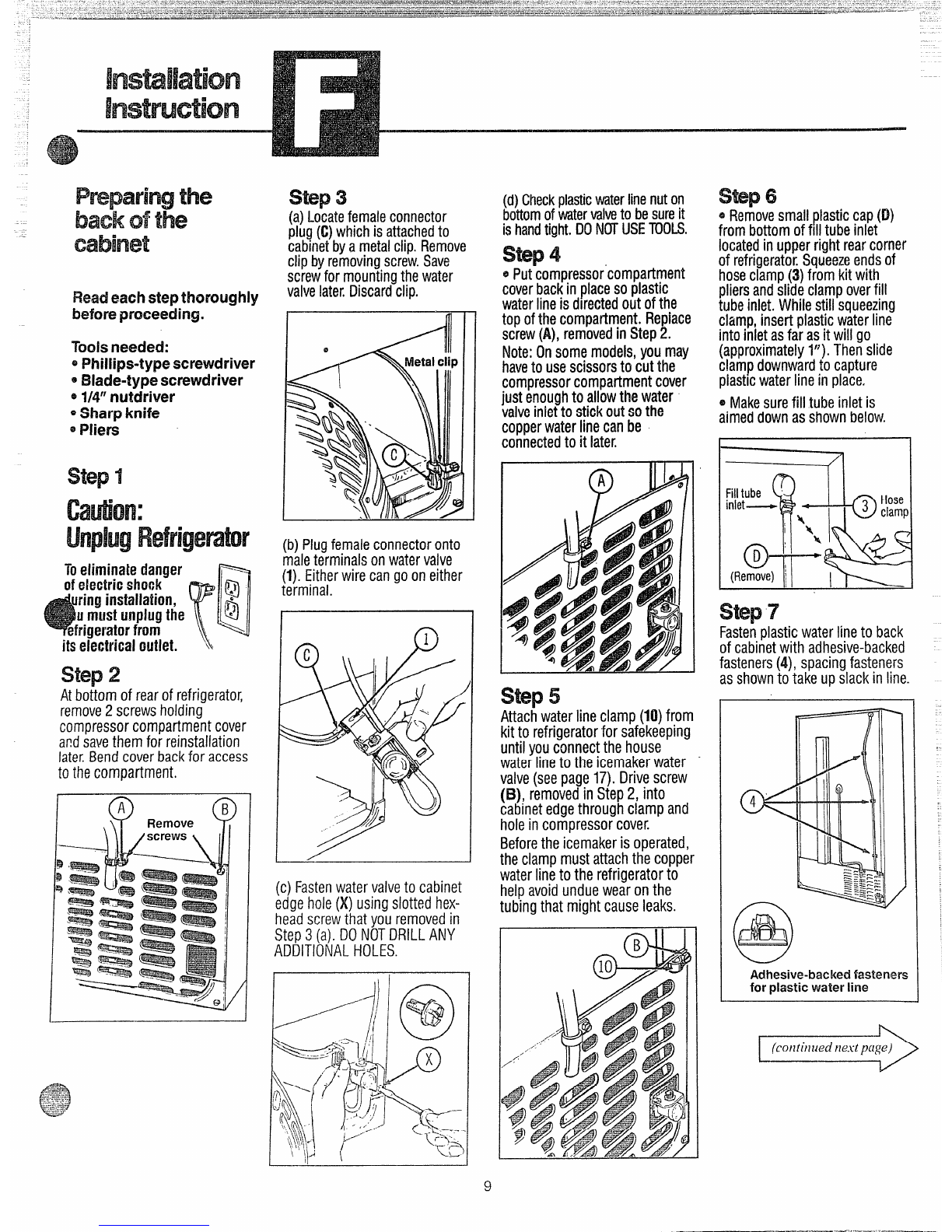

step2

At bottomof rearof refrigerator,

remove2screwsholding

compressorcompartmentcover

andsavethemfor reinstallation

late~Bend cover back for access

tothecompartment.

step3

(a)Locatefemaleconnector

plug(C)whichisattachedto

cabinetbyametalclip.Remove

clipbyremovingscrew.Save

screwfor mountingthewater

valvelate~Discardclip.

(b)Plugfemaleconnectoronto

maleterminalsonwatervalve

(l).Eitherwirecangoon either

terminal.

I

(c) Fastenwater valve to cabinet

edgehole(X)usingslott~dhex-

head screw that you removed in

Step3(a).DONOTDRILLANY

ADDITIONALHOLES.

,

(d)Checkplasticwaterlinenuton

bottomofwatervalveto besureit

ishandtight.DONOTUSETOOLS.

s~p 4

~Putcompressor’compartment

coverbackinplacesoplastic

waterlineisdirectedoutofthe

tonofthecom~artment.Re~lace

sc’rew(A),rembvedinStep2.

Note:I% somemodels,youmay

haveto usescissorsto cut the

compressorcompartmentcover

just enoughto allowthewater

valveinletto stick outsothe

copperwaterlinecanbe

connectedto it later.

o

A

step5

Attachwaterlineclamp(10)from

kitto refrigeratorfor safekeeping

untilyouconnectthe house

waterlineto theicemakerwater

valve(seepage17).Drivescrew

(B), removedinStep2, into

cabinetedgethroughclampand

holeincompressorcover

Beforethe icemakerisoperated,

theclampmustattachthecopper

waterlinetothe refrigeratorto

helpavoidunduewearonthe

tubingthat mightcauseleaks.

.. .

Swp6

~Removesmallplasticcap(D)

frombottomoffill tubeinlet

locatedinupperrightrearcorner

ofrefrigerator.Squeezeendsof

hoseclamp(3)from kit with

pliersandslideclampoverfill

tubeinlet.Whilestill squeezing

clamp,insertplasticwaterline

intoinletasfar asit will go

(approximatelyV). Thenslide

clampdownwardto capture

plastlcwaterline inplace.

~Makesurefill tubeinletis

aimeddownasshownbelow. I

step7

Fastefiplasticwaterline to back

ofcabinetwith adhesive-backed

fasteners(4), spacingfasteners

asshownto takeupslackinline.

Adhesive-backed fastemers

for plastic water line

(continued next p(ige)

9