8

Step-by-step installation instructions.

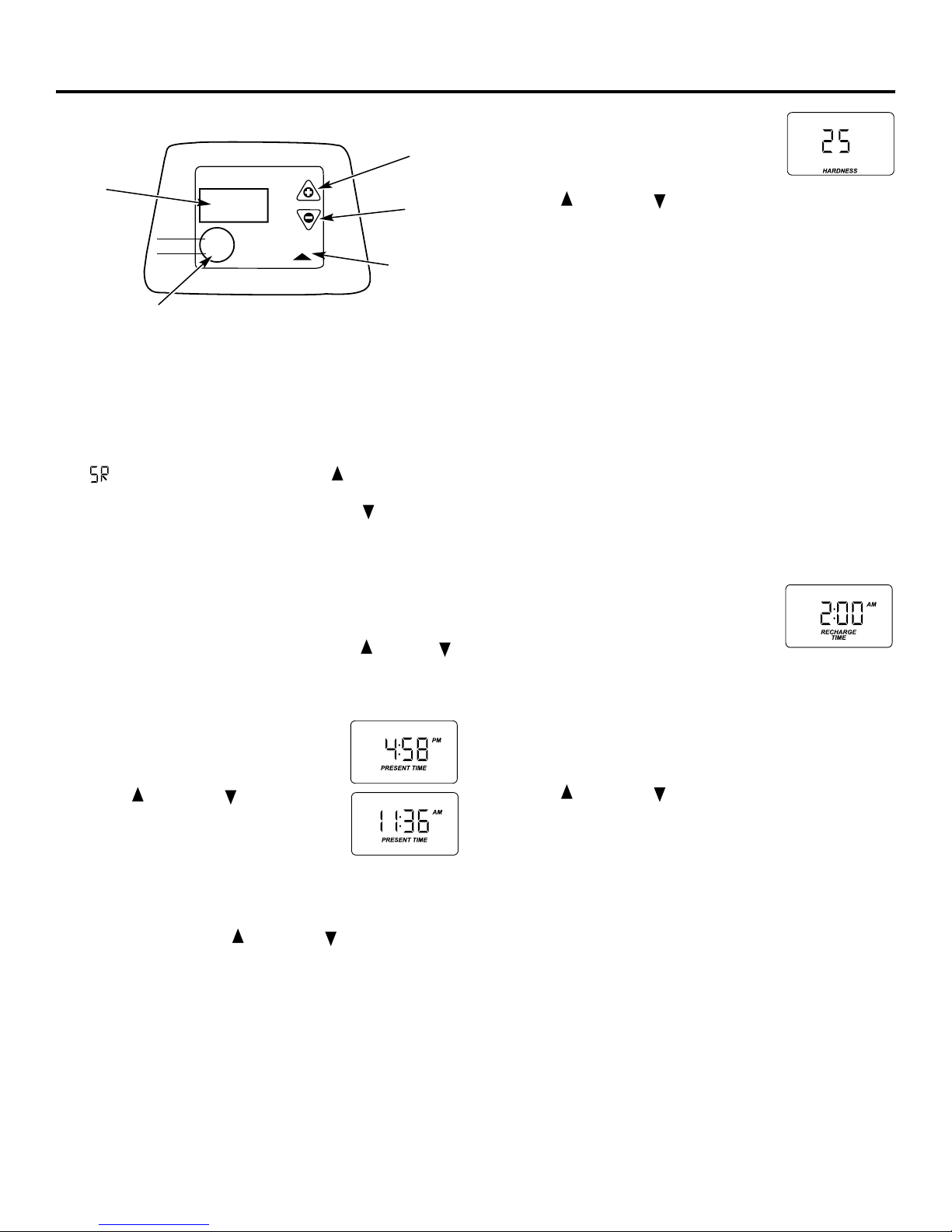

Programming the Control

CONTROL SETTINGS REQUIRED upon installation and

after an extended power outage.

NOTES:

■WHEN THE TRANSFORMER IS PLUGGED INTO THE

ELECTRICAL OUTLET, 12:00 PM (flashing), and PRESENT

TIME is displayed. Program the control as instructed below.

■If - - - or - - - - is flashing, use the UP button to set the

correct model code as follows: F35 for GNSF35. If you pass

by the correct code number, use the DOWN button.

Then press the SELECT button to accept the correct model.

■A “beep” sounds while pressing buttons for control

programming. One beep signals a change in the control

display. Repeated beeps mean the control will not accept

a change from the button you have pressed, and you should

select another button.

■To program the control, you will use the UP , DOWN

and SELECT buttons.

■Use the SELECT button to select the desired control function.

SET PRESENT TIME OF DAY

1. Press the SELECT button until PRESENT

TIME appears in the display.

2. Press UP or DOWN button to set.

The UP button advances the time; the

DOWN button moves the time in reverse.

2. If the present time is between noon and midnight, be sure

PM shows in the display. If the present time is between

midnight and noon, be sure AM shows in the display.

NOTE: Each press of an UP or DOWN button changes

the time by one minute. Holding the button changes the time

at a rapid rate.

3. When the present time is correct, press SELECT to accept.

SET WATER HARDNESS NUMBER

1. Press the SELECT button until

HARDNESS appears in the display.

2. Press UP or DOWN button to set your water hardness

number in the display. DOWN decreases the hardness value.

UP increases the hardness value.

NOTE: Each press of a button changes the display by 1, between

1 and 25. Above 25, the display changes 5 at a time (25, 30, 35,

etc.). Holding a button in changes the numbers at a rapid rate.

3. When the display shows your water hardness (in grains per

gallon), press SELECT to accept.

NOTE: If there is clear water iron in your water supply, you will

need to increase the hardness setting by 5 for each 1 ppm of

clear water iron in your water supply.

You can get the grains per gallon (gpg) hardness of your water

supply from a water analysis laboratory. If you are on a

municipal supply, call your local water department. Or call

Legend Technical Services, an independent laboratory, to

request a water hardness test kit at 1.800.826.8553, extension

47. If your report shows hardness in parts per million (ppm)

or milligrams per liter (mg/l), simply divide by 17.1 to get the

equivalent number of grains per gallon.

SET RECHARGE (STARTING) TIME

1. Press the SELECT button until

RECHARGE TIME appears in the display.

NOTE: A flashing 2:00 AM (factory default)

should show in the display. This is a good time for recharge

to start (takes about 2 hours) in most households because water

is not in use. HARD WATER is bypassed to house faucets

during recharge.

If no change is needed, go to step 3. To change the recharge

starting time, follow step 2.

2. Press UP or DOWN button to set the desired recharge

start time. Be sure to observe the AM or PM as you did when

setting the time of day.

NOTE: Each press of a button changes the time by 1 hour.

Holding the buttons in changes the time at a rapid rate.

3. Press the SELECT button to accept.